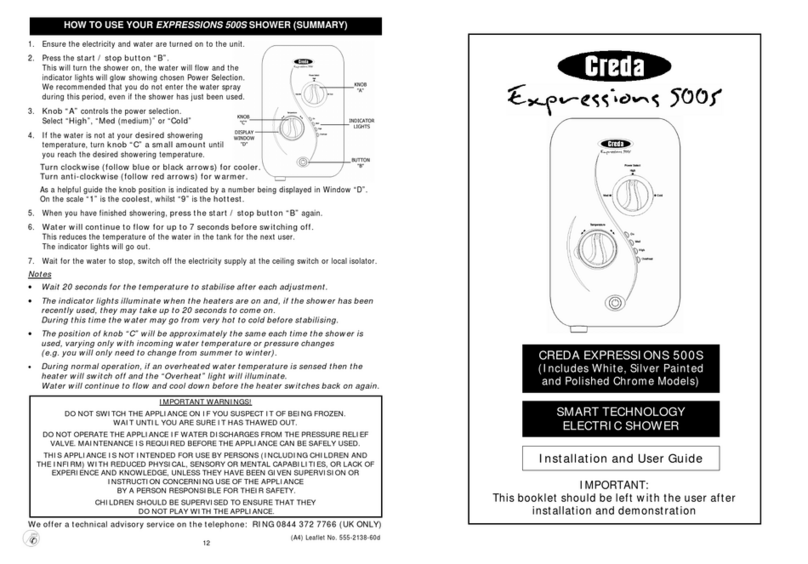

What to do if things go wrong

SELF HELP

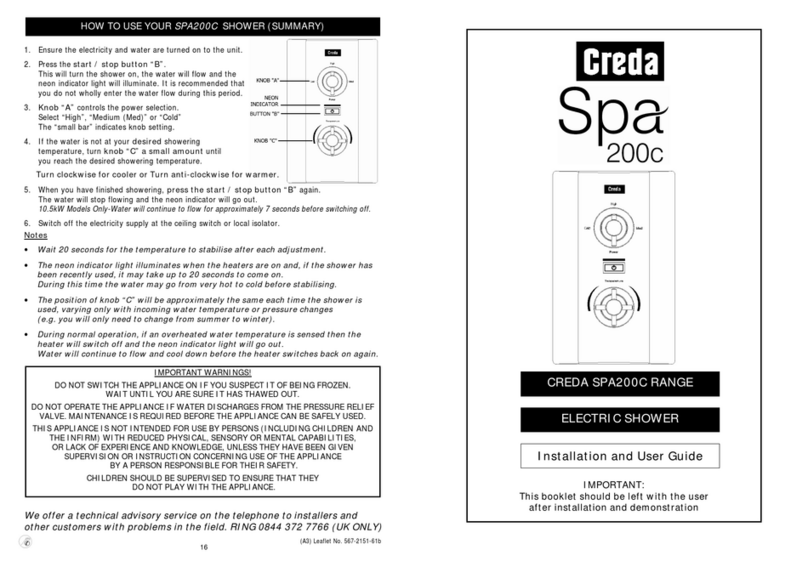

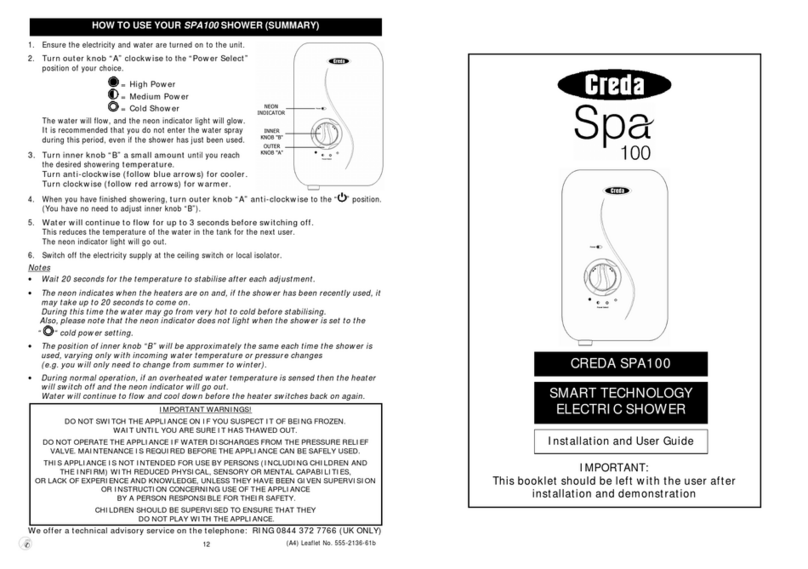

Ifthe shower is notworking satisfactorily, make the following checks before calling outthe contractor.

Any one ofthese adjustments could restore the performance.

a) The shower cycles

fromHOTtoCOLD The shower temperature is set too hot causing the thermalcut-out (safetydevice)to operate.

Turnknob “E”clockwise to increase water flow.

“MEDIUM” setting mayneed to be selected.

Slowly increase the watertemperature by turning knob “E”anti-clockwise until a comfortable

showering temperature has been reached.

You MUSTWAITapprox’ 20seconds foreach adjustment to affect the watertemperature.

b) Water too HOT Increase water flow by adjusting the temperature control clockwise.

Clean showerhead holes. Select outer orcombination spraypattern.

Switch power to “MEDIUM” setting. Increase pressure to water supplye.g. fully openservice

valve or stop cock. Checkhose is not kinked restricting the waterflow.

c)Water too COLD Decrease waterflowbyadjusting the temperature controlanti-clockwise.

Select inner orouterpattern only. Switch power to “HIGH” setting.

d) Spray pattern poor Clean showerhead and flush heater.Selectouter/inner only.

e) Water goes cold

while using

shower

Checkpowersetting lights are on.

Checkwater pressure has notfallen so faras tolet pressure switch cut out,

e.g. Another tap drawing wateroff, indicated by “low pressure” light on.

Raise position of handset.

f) Broken parts Please contact our spares department on0844 372 7750. Fitting instructions are provided

PROFESSIONALSERVICE

Ifthe above checks fail to restore the performance, you should seekprofessional help.

The person who installed the shower is probably the best one investigateand correct it, andis certainlythe person to

contact if youhave had a problemin the guarantee period.

The following additionalchecklist is provided forthe benefit of the qualified service person.

WARNING: SWITCH OFF THE ELECTRICITY ATTHEISOLATOR BEFOREREMOVING THECOVER TO MAKE CHECKS

a) Water too HOT Water flow restricted by blockage in filterof solenoid valve. Switch offwater, loosen inlet

connection to solenoid, remove filterin solenoidwith long nosed pliersand flush clean.

b) Water too COLD Checkcircuit through thermal cut-out.

Checkcircuit through microswitches on the pressure switch.

Checkeach element circuit.

Checktightness of electricalconnections.

c)Water discharges

frompressure

relief valve

Checkforcause of high pressure and remove it.

Blockage on outlet e.g. blocked showerhead.

Replace the pressure relief disc (not covered byguarantee).

d) Water does not flow

when button “A”,

“B”or “C” is

pressed.

Checkcircuit through solenoid coil. Ifdefective then replace.

Checkcircuit through microswitches. If defective then replace.

Possible PCBfault.If defective then replace.

Power supply not reaching shower.

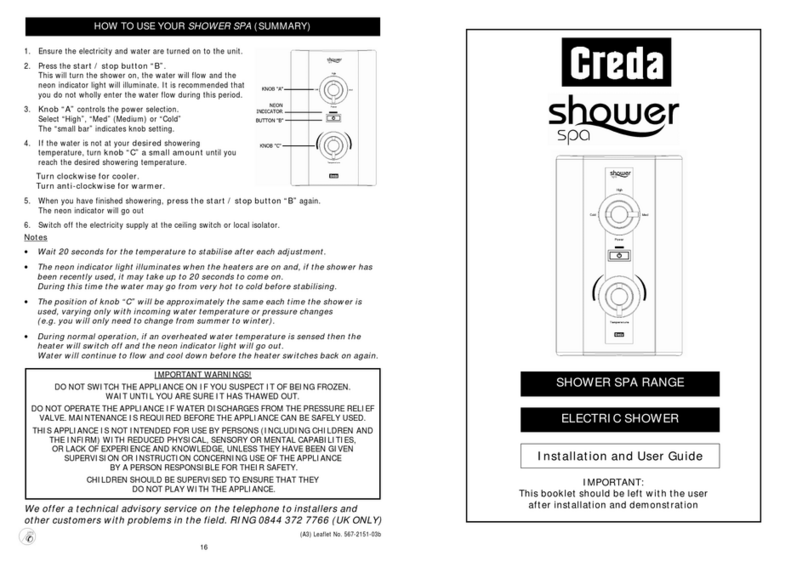

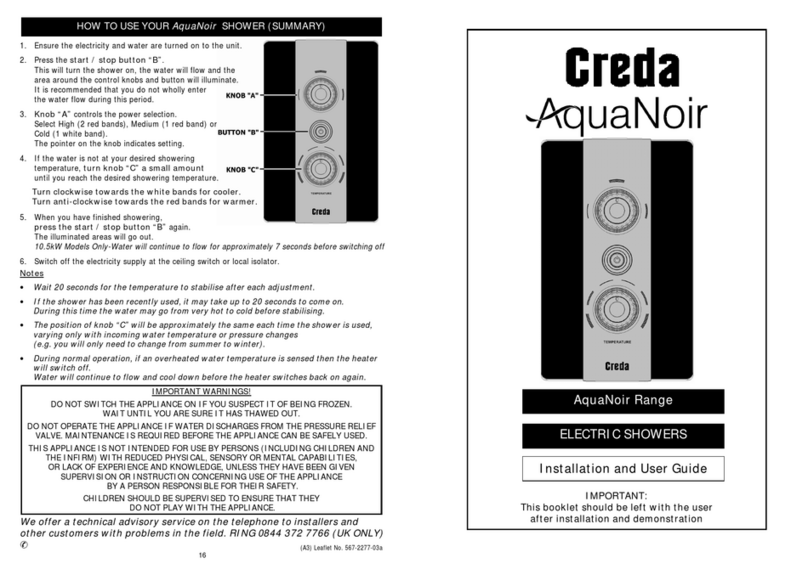

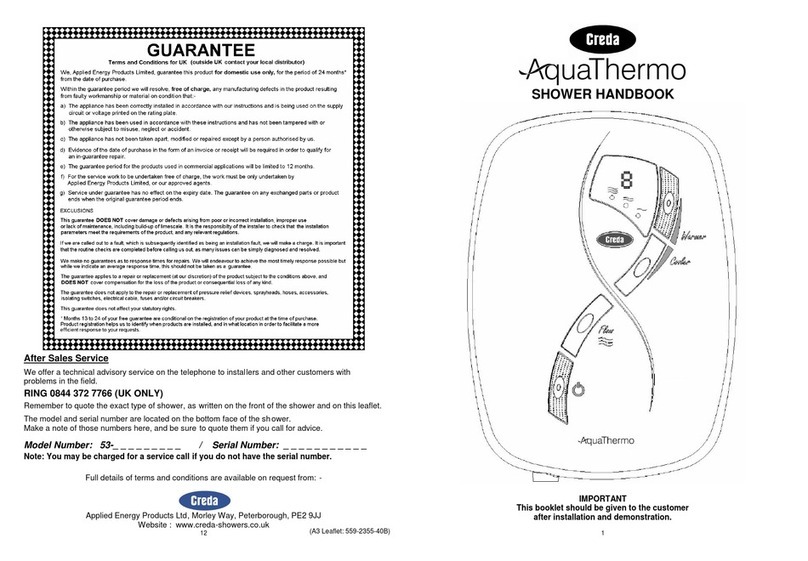

Creda After Sales Service

We offera technical advisoryservice on the telephoneto contractors

and other customers with problems in the field.RING 08443727766

Spare parts can be supplied against Credit or Debit cards. RING08443727750

Remember to quote the exact type of shower,as written on the frontface.

The model and serial number are located on the bottomface of the shower.

Make a note of those numbers, and quote themif you call for advice.

Model No: 53-………………….. / Serial No:………………………

Note: You may be charged for a service call ifyou do not havea serial number.

Howto maintain yourCreda Shower

It is recommend thatthe shower unit, riser rail,hose etc. be cleaned using

a soft cloth and thattheuse of abrasive or solvent based cleaning fluid be

avoided, especiallyon anyplated finishes.

We recommend that before anycleaning, the isolating switch be turned off,

thus avoiding accidentally switching on the shower.

The showerhead should beperiodically cleaned as detailed on page 3.

YOU MUST REGULARLYINSPECT THE SHOWER HOSEFOR WEAR AND DAMAGE.

REPLACE IF NECESSARY, OR EVERY TWO YEARS, WITH OURAPPROVED PART.

5

Installation Instructions

ALL WIRINGAND INSTALLATION MUST BE SUPERVISED BYAQUALIFIED ELECTRICIAN

WARNING:DO NOTINSTALL THIS SHOWERINAROOMWHEREIT MAY BESUBJECT TO FREEZING.

We recommend that theinstallation is done in the followingsequence.

a. Fixing the showerto the wall

b. Plumbing

c. Electrical connections

a. Fixing the shower to thewall

1. Position theriser rail at convenient height formajorityof users as recommended in diagram6 and markits position

2. Position the heaterso that the top oftheunit is horizontal and level with,

or up to 0.6 metres (2ft) maximum below the topof the riser rail. Choose a

flatpiece of wall to avoid the possibilityof distorting the backplate thus making

the front cover a poorfit.

3. Adjust the position to get the most convenient arrangement taking the following

into account.

•The possible need to use the handsetover the sink for hair washing etc.

•The heater must notbe mounted in the directspray from the handset.

•The handset must not be able to comeinto contact with used water in the

cubicle, bath orbasin. If it can, even afterthe hose has been retained by the

soap dish (see diagram11), then a vacuumbreaker must be fitted. Itshould

be noted that these devices are liable to minor leakage so they mustbe

positioned so that anydripsare not detrimental.

4. Fix the riser rail with screws provided. The fixing holes at thebase of the

brackets will be disclosed byremoving the plastic fronts. Assemble as shown in

diagram11. Additional “knock-out” slots are available if required to improve

security.

5. Decide the position of the electricalcable to the unit.If top or bottomentry

is chosen (according to diagram5), cut awaythe walls in the backplate as

shown in diagram7.

6. Decide the position of entry of the cold waterpipeinto the unit.

Iftop,cutaway the backplate.

Ifrear, please read thesection on plumbing.

If bottom,remove the frontcover (complete with knobs) and cut awaythe

detachable corner sectionas shown,

7. Ifyou have not yet done so, remove the front cover(complete with knobs)

of the unit by undoing the retaining screws at the top and bottomof the

unit and lifting the cover off.Your showerisprovided with 2 fixing

positions in the backplate (see diagram5).

The top-fixing hole is a “key-hole” slot (another key-hole is provided for

alternate fixing), and should be marked and drilled first.

Tighten top screw with head protruding about10mmfromthe wall and

hook the backplate over the screw head. Thisallows for correct and

accurate alignment of your showerbeforemarking andfixing the bottom

position.

You may not wish totighten up both screws at this stage as the holes are

elongated to allowfor adjustment after other connections have taken place.