2

THIS APPLIANCE CAN BE USED BY CHILDREN

AGED FROM 8 YEARS AND ABOVE AND PERSONS

WITH REDUCED PHYSICAL, SENSORY OR MENTAL

CAPABILITIES, OR LACK OF EXPERIENCE AND

KNOWLEDGE IF THEY HAVE BEEN GIVEN

SUPERVISION OR INSTRUCTION CONCERNING

USE OF THE APPLIANCE IN A SAFE WAY AND

UNDERSTAND THE HAZARDS INVOLVED.

CHILDREN SHALL NOT PLAY WITH THE

APPLIANCE.

CLEANING AND USER MAINTENANCE SHALL NOT

BE MADE BY CHILDREN.

•Your shower has been designed for

convenience, economy and safety of use,

provided that it is installed, used and

maintained in good working order and in

accordance with our instructions and

recommendations.

•All wiring and installation must be

supervised by a suitably qualified person

•THIS APPLIANCE MUST BE EARTHED.

•The installation must be in accordance with

the current edition of BS.7671 (

the ‘IEE Wiring

Regulations’)

and ‘Part P’ of the ‘

Building

Regulations’

in force at the time of installation.

Installations outside England and Wales must

also conform to any local regulations in effect

•This appliance is intended to be permanently

connected to the fixed electrical wiring of the

mains supply with its own dedicated supply.

•This appliance must NOT be fitted where it

may be subjected to freezing conditions

•DO NOT switch the appliance on if you

suspect it of being frozen.

Wait until you are sure it has thawed out.

•DO NOT fit any sort of tap or control on the

appliance outlet.

The appliance is designed to have an open

outlet and should only be used with

Manufacturer’s recommended fittings.

•THIS SHOWER IS DESIGNED AND

APPROVED TO EN-60335 WITH THE

HANDSET PROVIDED.

UNDER NO CIRCUMSTANCES MUST ANY

HANDSET THAT IS NOT APPROVED BY THE

MANUFACTURER BE USED WITH THIS

PRODUCT.

•Take care to avoid restricting the outlet of the

pressure relief device (fig.15).

If water is discharged from the pressure relief

device, maintenance will be required before

the appliance can be safely used.

•Isolate the mains electrical and water supply

before removing the appliance front cover.

•This appliance is not suitable for mounting

into steam rooms or steam cubicles.

•We DO NOT recommend this appliance be

used in heavy or unsupervised commercial

applications.

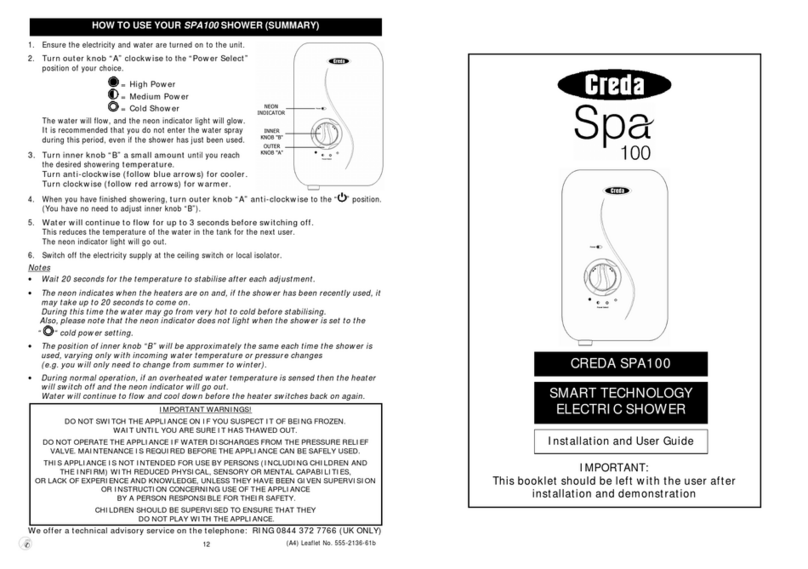

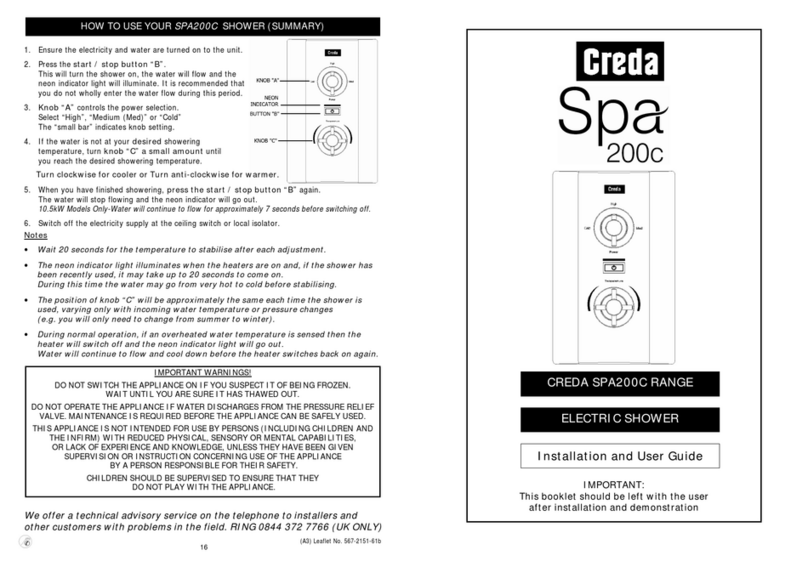

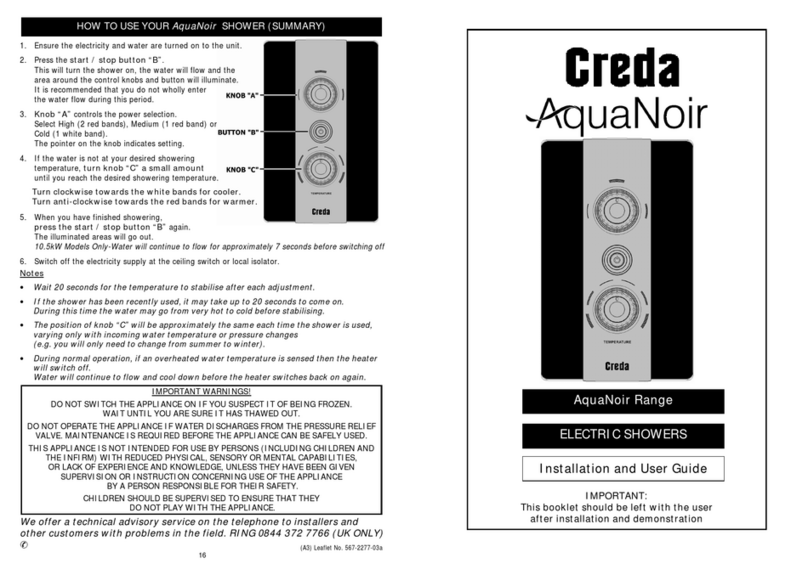

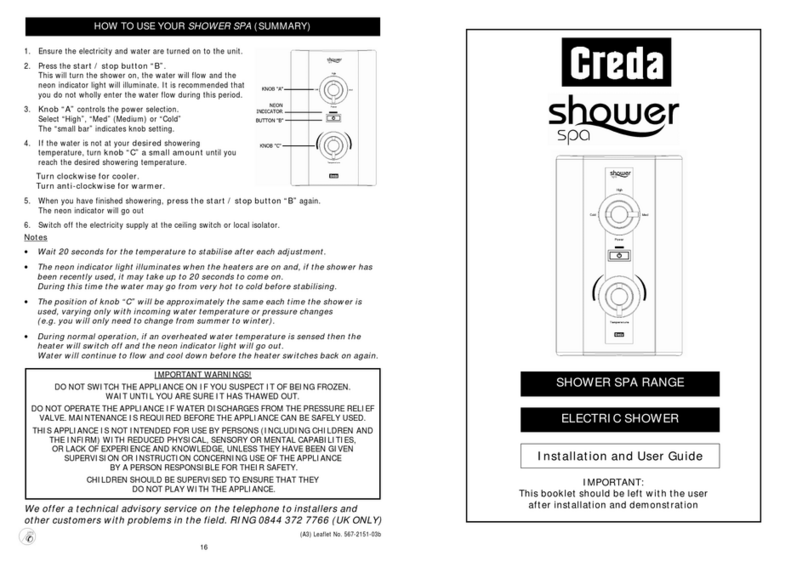

The following points will help you have a greater

understanding of how your shower works:

•The electric heating elements operate at a

constant rate, dependant on your chosen

power setting.

The required water temperature is achieved

by adjusting the rate of water flow.

The higher the water flow the lower the

temperature and vice versa.

The temperature of the water supplied from

the mains can vary considerably throughout

the year from 5 to 20°C.

This means that in the winter, flow rate will be

less than in the summer to achieve the same

outlet temperature.

In summer the ‘Economy’ (2 red bars) power

setting may give adequate hot water.

•Your shower is designed to stabilise

temperature changes caused by water

pressure fluctuations.

These can result from toilets being flushed or

taps being turned on and off.

When this happens your showering

temperature will be held within a controlled

band, provided that the minimum pressure

required by the shower is maintained (page.4)

If the water pressure falls below the minimum

pressure required, it is likely that the pressure

switch will turn off the power to the heating

elements, resulting in a cold shower.

•DO NOT place items such as soap, shampoo

or other such bottles on top of the unit.

Liquid could leak through the joint between

the cover and backplate, and possibly damage

the sealing rubber.

11

Effect of Seasonal Incoming Water

Temperature Changes

The required water temperature is achieved by

adjusting the rate of water flow.

The diagram shows the principle involved in

relating temperature rise to flow rate.

The higher the water rate

the lower the temperature

and vice versa.

The temperature of the

water supplied from the

mains can vary

considerably throughout

the year from 5 to 20°C.

This means that in the winter, flow rate will be

less than in the summer to achieve the same

outlet temperature.

In summer the ‘Economy’ (2 x red bars) power

setting may give adequate hot water.

Effect of Other Water Devices on Incoming

Water Supply

Your shower is designed to stabilise

temperature changes caused by water

pressure fluctuations.

These can result from toilets being flushed or

taps being turned on and off.

When this happens your showering temperature

will be held within a controlled band, provided

that the minimum pressure required by the

shower is maintained.

Your shower requires a minimum running

pressure of 100kPa (1.0 bar, 15 psi) at a

minimum flow rate of 8 litres/minute.

(

9 litres/minute for 9.5kW).

At pressures above 100kPa (1.0 bar, 15 psi) at a

minimum flow rate of 8 litres/minute.

(

9 litres/minute for 9.5kW),

it will minimise

temperature fluctuations as detailed above.

If the water pressure falls below 100kPa

(1.0 bar, 15 psi) at a minimum flow rate of

8 litres/minute, (

9 litres/minute for 9.5kW),

it is likely that the pressure switch will turn off

the power to the heating elements, resulting in a

cold shower.

Please Note:-

The fitting of Spare Parts must be supervised

by a suitably qualified person.

Front Cover c/w Display Cat No. 93672101

Front Cover Display PCB Cat No. 93672113

Front Cover Umbilical Cable Cat No. 93672116

Heat Exchanger (8.5kW) Cat No. 93672102

Heat Exchanger (9.5kW) Cat No. 93672103

Heat Exchanger Bottle Cat No. 93672114

Solenoid Valve Cat No. 93672104

Solenoid Securing Strap Cat No. 93672115

Flow Valve Top Assembly Cat No. 93672105

Tank Clip Cat No. 93672106

Pressure Relief Device Cat No. 93672107

Heat Exchanger ‘O’-Rings Cat No. 93672108

Thermal Cut-Out Cat No. 93672109

Pressure Switch Assembly Cat No. 93672110

Detachable Section Cat No. 93672111

Power PCB Cat No. 93672112

Terminal Block Cat No. 93590372

Single-Mode Handset Cat No. 93590738

Chrome Shower Hose Cat No. 93797641

Height Adjuster Cat No. 93590744

Ø18mm Riser Rail Tube Cat No. 93593533

Ø18mm Riser Rail Brackets Cat No. 93795877

Additional accessories and spare parts can be

supplied against any Credit or Debit cards

from the Creda Sales Hotline 0844 372 7750

WRAS Water Isolating Valve Cat No. 93792452

White 2m Shower Hose Cat No. 83792578

Chrome Accessories Cat No. 83595318

Chrome Premium Accs Cat No. 83595319

Chrome Curved Accs Cat No. 83595320

Curtain and Rail Pack Cat No. 83792812

Curtain and Rail Pack with

Non-Slip Mat Cat No. 83792811