12

CREDA AFTER SALES SERVICE

SELFHELP

If the showeris not working satisfactorily,make the following checks before calling outthe installer

Any one oftheseadjustmentscould restore the performance.

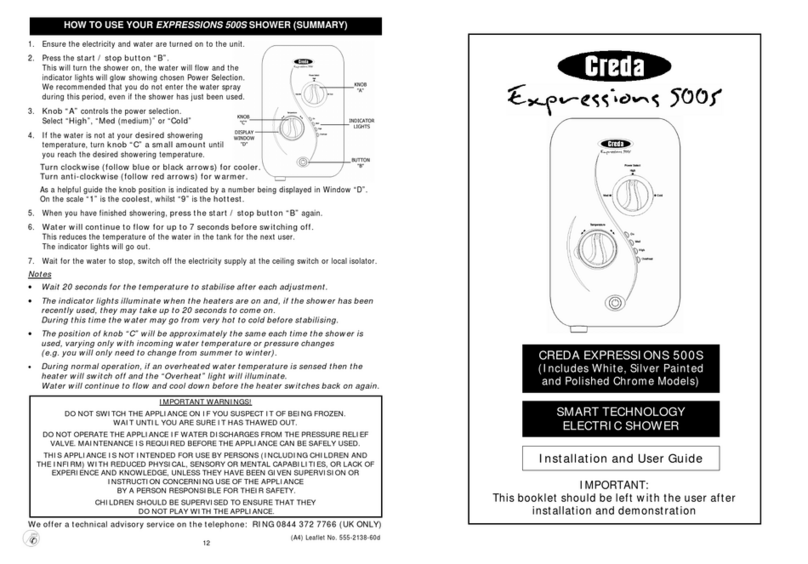

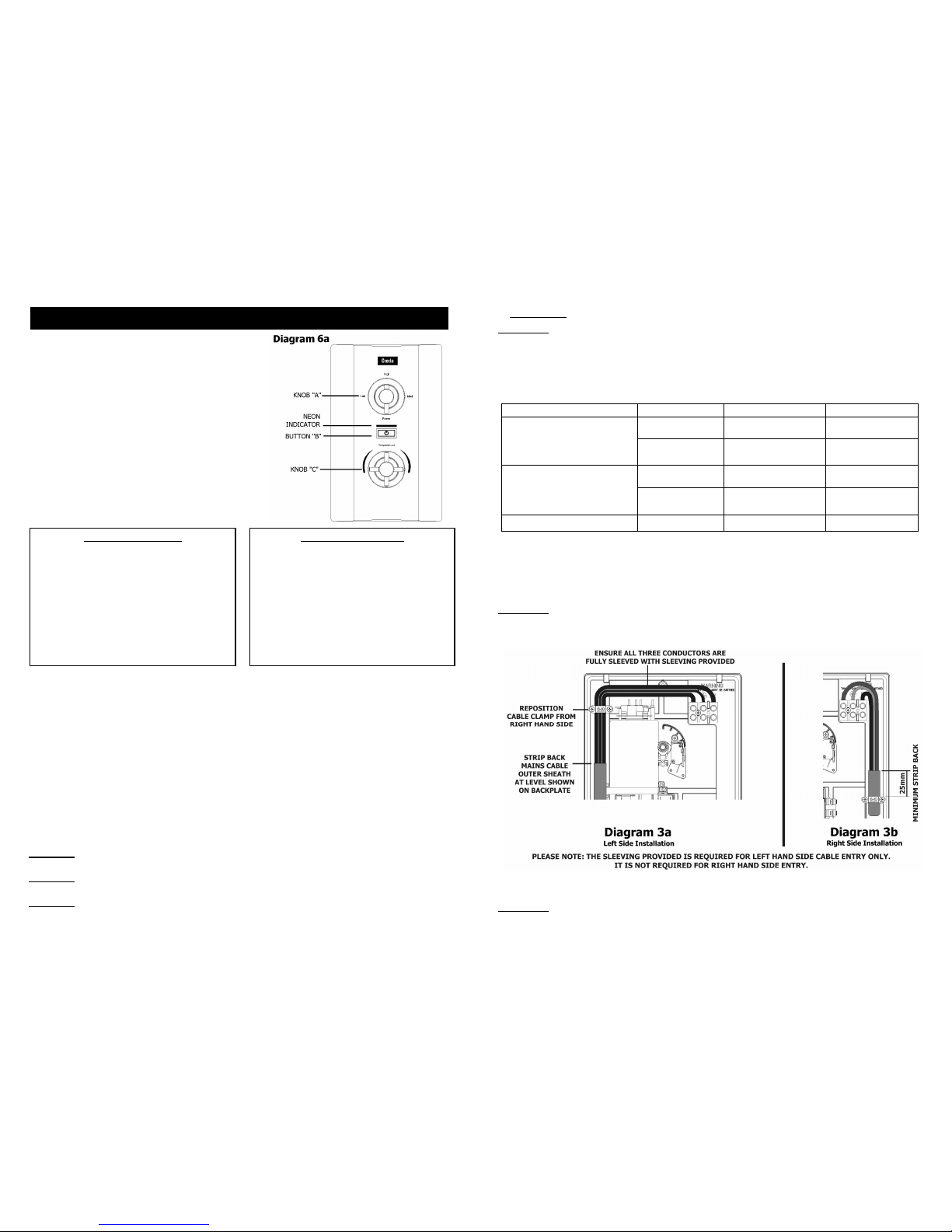

Theshower cycles

from HOTtoCOLD The shower temperature isset toohotcausingthe thermal cut-out (safety

device)tooperate.

Turn knob“C”clockwise

Slowlyincreasethe watertemperature by turning knob“C” anti-clockwise until a

comfortable showeringtemperature hasbeenreached.

You MUSTWAIT approximately20 secondsforeach adjustment toaffect the

watertemperature.

“Medium (Med)” settingmay needtobe selected.

WatertooHOT Increasewater flowbyadjustingknob “C” clockwise.

“Medium (Med)” settingmay needtobe selected.

Increasepressure towatersupplye.g.fullyopen service valve orstopcock.

Check hoseisnot kinked restrictingthe water flow andclean handset.

WatertooCOLD Check powerisonbyneonindicator beingilluminated.

Decrease waterflowbyadjustingknob“C” anti-clockwise.

“High” settingmayneed tobe selected.

Select inner orouter only handsetspray pattern.

Spray pattern poor Clean the showerhandset.

Watertakeslonger

toheat up Thermal cut-out hasoperatedafterprevious use andtheneon indicator has

gone out (automaticallyresetswhen unitcoolsdown)

“High” settingmayneed tobe selected.

Watergoescold

whileusing

shower

Check neon indicatorisilluminated.

Check waterpressure has notfallen sofarasto letpressure switch cut out,

e.g. Anothertapdrawing wateroff.

Raiseposition of shower handset.

Broken parts Please contactoursparesdepartmenton 0844 3727750 (UK only).

Fittinginstructionsare providedwith most spares

Watercontinues to

flow when button

“B” pressed tostop

Thisisnormal for 10.5kW modelsonly(Othermodelscontact “AfterSales”)

The shower includesa shutdown feature thatmeansthe water will continue to

flowfor upto7 seconds after“ (stop)”hasbeen selected.

We offer a technicaladvisory service on the telephone to installers and othercustomers with

problems inthe field.

RING 0844372 7766 (UKONLY)

Some spare parts (see Page 11) can be supplied againstCreditor Debit cards.

RING 0844372 7750 (UKONLY)

Remember to quote the exact type ofshower, as written on the front ofthe showerand on this

leaflet.

The modeland serial number arelocated on the bottom face ofthe shower.

Make a note of those numbershere, and be sure to quote them ifyou callfor advice.

Model Number: 53-67___ __ __/ Serial Number: __ __ ___ _ _ __

Note: You may be charged for aservice call if you do nothave the serialnumber.

WHAT TO DO IF THINGS GO WRONG (1)

5

8. Yourshowerisprovidedwith3 fixing

positionsin the backplate (seeDiagram 8).

The top-fixinghole is a “key-hole” slot,

andshouldbe markedand drilledfirst.

Tighten topscrew with headprotruding

about 10mm from thewall andhookthe

backplate overthe screw head.

Thisallowsforcorrectand accurate

alignment of yourshower before marking

andfixingthe bottompositions.

You maynot wish totighten upboth screws at this

stage asthe holesareelongatedtoallowfor adjustment after otherconnectionshave taken place.

b. PLUMBING (For yourconveniencea coldwater inletconfiguration diagramisshown on page 6)

WARNING: ENSURE THAT THE MAINS WATER SUPPLY MEETS THE REQUIREMENTS BELOW

BEFORE CONTINUINGWITH INSTALLATION.

The heater must be connectedtothe mains cold water supply.

Thismust have a minimumrunningpressure of69kPa (0.7bar, 10 psi)

anda maximum pressure of690kPa(7.0 bar, 100 psi).

WARNING: BEFORE CONNECTINGTHE PIPE WORK TO THESHOWER,

ENSURE THAT THE PIPE WORK IS FULLY FLUSHED OUT.

1. Unscrew the “RedCap”from the showeroutletpipe anddiscard it in a suitable manner.

It has been usedtoseal the showerduringtransit, and is nolongerrequired.

2. It is recommendedthat a WRAS (Water RegulationsAdvisory Scheme) listedisolatingvalveisfitted

tothe incomingmainscoldwaterbefore the shower unit. Thiswill allow the unit tobe serviced or

exchangedwithouthavingtoturn offthe mains water at the waterstop valve.

3. The heater can be fedfrom a header tankprovided thishasa minimum headof7 metres (23ft).

4.

The coldwaterinlet connectionsuppliedis a plain Ø15mm straightshank/shaft.

Thisconnectorwill accept eithera Ø15mmcompressionelbowor a Ø15mm“push-onelbow”.

Ø15mm copper, stainless steelor suitable plasticpipeshould beused.

Foryour convenience,acold waterinletconfiguration diagramisshownonpage 6

Ifrearentryisrequired, treatastopentrywithan additional “Yorkshire”elbow (solderedtype) for

fitting intotherearchannel.

Toaid installation, youmayfind itconvenienttomovetheflexiblepressurereliefvalveoutlet

assemblybyremoving thetwosecuring screws (SeeDiagram2b).

Inmultipleinstallations,correctpipeworksizes shouldbecalculatedtomaintain adequateflowto

eachshower.

5. It is permissible to use a WRAS (WaterRegulationsAdvisory Scheme)approved sealant sparingly

whilstavoidingexcess findingits way intothe showeroperatingparts.

6. With isolating valve connected, flush the pipework through to remove any particles etc,

before makingthe final connectiontothe shower.

Blockage in the waterways(particularly the handset andsolenoidvalve)will prevent the heater

workingproperly. Note: You maybe chargedfor a service call ifitisdue toincorrect installation.

7. The showerisdesignedtohavean open outletandshouldonly be used with “Creda” recommended

fittings.

Do not connect thehandset until afterthe front coveranddetachable bottom section are fitted.

WARNING: DO NOT FIT A TAP ON THE SHOWER OUTLET.

WARNING: TAKE CARE TO AVOID RESTRICTING THE OUTLET OF THE

PRESSURE RELIEF VALVE.