HOWTO MAINTAIN YOUR SPA100 SHOWER

5. Re-Fitthefrontcover (see Diagram 5) and replace the top and bottom fasteningscrews.

a. Ensure outer knob “A” is aligned fully anti-clockwise to the “ (stop)“position.

b. Ensure innerknob “B” is aligned to the “ (high)” position.

c. In the main body ofthe shower,turn the “Drive Spider” fully anti-clockwise until it stops.

d. In the main body ofthe shower,turn the “Drive Gite” anti-clockwise until it is at “12 o’clock”.

e. Fitthe front cover of the shower to the mainbody ensuring that the 3 x “Drive Spider Legs”

engage with theslotsin outer knob “A”.

f. Check that outer knob “A” has been correctly aligned by ensuring that all 3 power settings can

be selected, and returns to the “ (stop)“position.

g. Check that innerknob “B” has been correctlyalignedby turning clockwise and ensuring that

knob turns approximately 3/4 of a turn (270°) and when turned back fully anti-clockwise,

returns to the “ (high)” position.

6. Fit the shower hose, and operate the shower firstwithoutthe handsetto flushout particles,

fit thehandset and then operate the shower as on page 7 or 12 and check:

a. That the water getsto a satisfactorytemperature.

b. Waterflow can be adjustedbyinner control knob“B”.

c. Power selection operates in all 3 positions,giving a change in watertemperature and

that theneon lightfunctions correctly.

d. Check again for leaks and that the holes in the shower handsetare not blocked

8. DEMONSTRATE OPERATION TOUSERS

It isrecommended thatthe shower unit and hose etc.becleaned using a soft cloth and that theuse

ofabrasiveor solvent based cleaning fluid be avoided, especially on any plated finishes.

We recommend that before any cleaning,the isolating switch be turned off, thus avoiding

accidentallyswitchingon the shower.

WARNING:

YOU MUST REGULARLY INSPECTTHESHOWER HOSE FOR WEAR ANDDAMAGE.

REPLACEIF NECESSARY, OR EVERY TWO YEARS, WITH A CREDA APPROVED PART.

WARNING: IN ORDER TO MAINTAINTHE PERFORMANCEOFYOURSHOWER,

YOU MUST CLEANTHESHOWER HANDSETREGULARLY.

All water contains particles of lime, which build up in theshower handset and unit reducing the

performance. It is therefore important to clean the shower handset by simply rubbingthe rubber

nozzles, or soaking in aproprietary lime-scaleremover and rinsingthoroughly before use.

NOTE: After use itis normal for some water to drip fromthe shower handset for a few moments.

Thisinhibits scale build-upover prolongeduse.

7

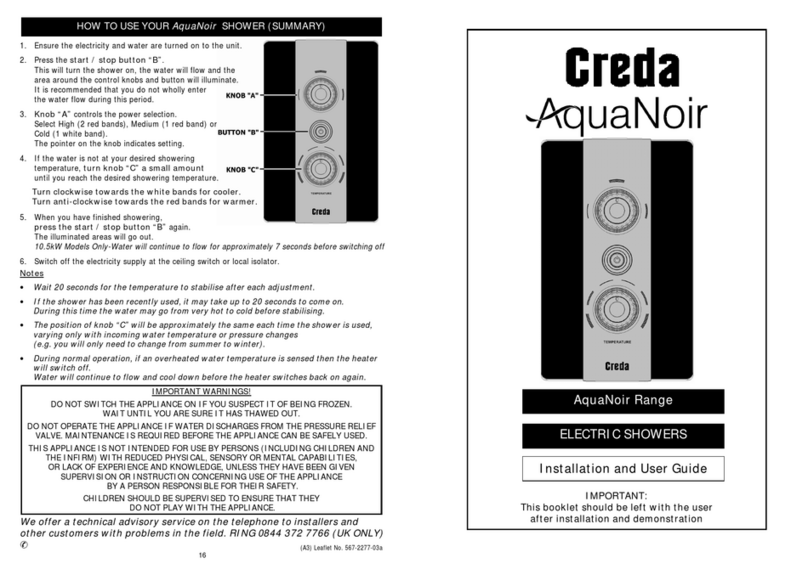

IF WATERIS TOO COLD

Turn innerknob“B” clockwise in the

direction of the “red arrows” to “1 o’clock”

and continue turning clockwise until you get

the water temperature of your liking.

Wait 20 seconds after each adjustment

forthe water temperature to stablise.

IF WATER IS TOO HOT

Turn inner knob “B” anti-clockwise in the

direction of the “blue arrows” to “11 o’clock”

and continue turning anti-clockwise until you

getthe water temperature of your liking.

Wait 20seconds after each adjustment for

the water temperature to stabilise.

Ifafter turning fully anti-clockwise,water is

still too hot,adjust outer knob “A” to

“(medium)” setting and re-adjust as above.

Water flow will be reduced on this setting.

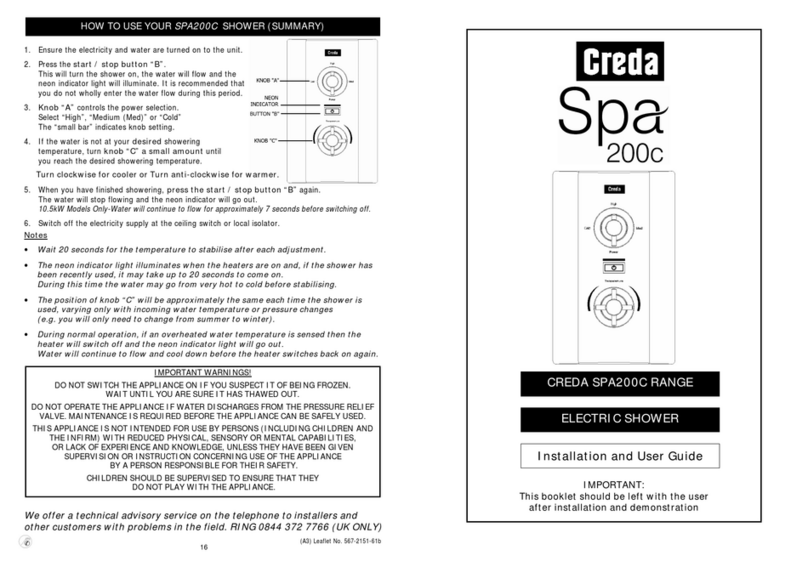

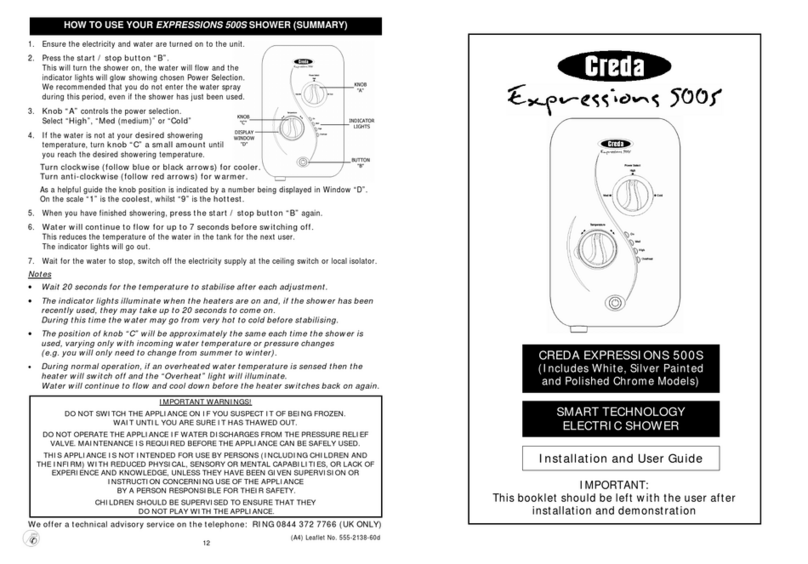

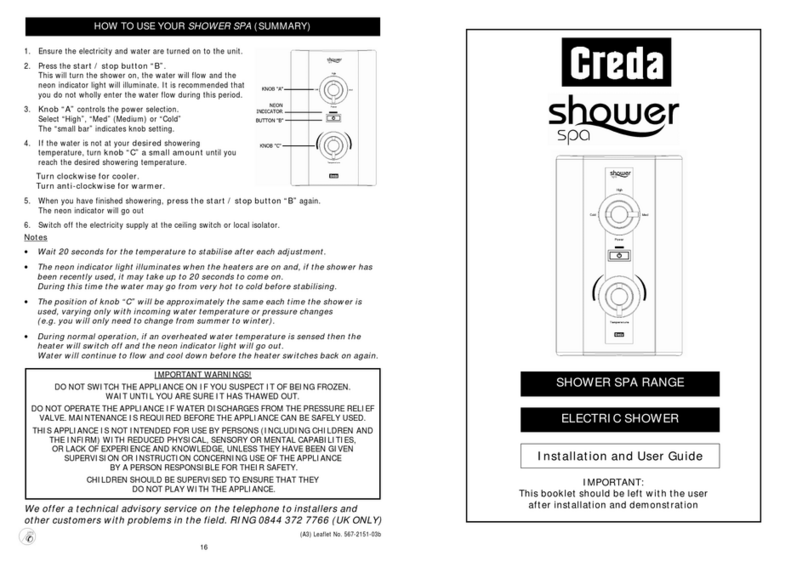

1. Ensurethe electricity and water are turned onto the unit.

2. Yourshower has 3 power settings selected by turning outer

knob “A” (see Diagram 6).

The most popular is“ (high)”.

There are also options for a “ (medium)”

or “ (cold)” shower (seenotes 8 and 9).

For this exampleturn outerknob “A” to “ (high) ”

andset inner knob “B” to “12 o’clock”.

3. The water will flow and the neon light will glow brightly.

4. Allow about 20 seconds forthe temperature of the water

to stabilise. Itis recommendedthat you do notwholly enter

the water spray during this period,even if the showerhas just been used.

5. Once a temperature setting to your liking

has been achieved,innerknob “B” will rarely

need adjusting.You musthowever take into

account required adjustments for variations

of incoming mains water temperature between summer and winter (see “Effect ofSeasonal

Incoming Water Temperature Changes” page 10).

6. When you have finished showering, turn outer knob “A” anti-clockwiseto the “ (stop)”

position. Water willcontinue to flowfor upto 3 seconds before switchingoff.

This reduces the temperature of the water in thetank for the next user.

Switch off the electricity at the ceiling switch or local isolator.

7. The “ (medium)” setting of outer knob “A” reduces the power used by the shower givinga

cooler shower or the option of reduced waterflow. This option is mainly used forsummer usage

and if this is used then innerknob “B” must be re-adjusted.

8. The “ (cold)” setting of outer knob “A”will supply water without any heating,and the neon

light will go out.

9. Yourshower is designed to stabilisetemperature changes caused bywater pressure

fluctuations (see “Effectof Other WaterDevices on Incoming Water Supply” page 10).

10. Note thatinner knob “B” IS NOT A TAP anddoes not turn thewateroff.

WARNING: DO NOT SWITCH THE SHOWER ON IFYOU SUSPECT ITOF BEINGFROZEN.

WAITUNTIL YOU ARESURE ITHAS THAWED OUT.

WARNING: DO NOT OPERATE THE SHOWER IFWATER IS DISCHARGED FROM THEPRESSURE

RELIEF VALVE. MAINTENANCE ISREQUIRED BEFORE THE SHOWER CAN BE USED.

WARNING: CONSIDERATION SHOULDBE GIVEN TOSUPERVISING THEYOUNG, ELDERLY AND

THE INFIRM WHILST THEY USE THIS SHOWER.

HOWTO USE YOUR SPA100 SHOWER (DETAILED)