6

Troubleshooting

If the performanceof the shower deteriorates in service, follow the checksin the “self help” table

below beforecalling out the contractor.

Anyone of the simpleadjustmentscould restore the performance.

If thesefail torestorethe performance you should seek professional help.

The person who installedthe showeris probablythe best one to repair it and is certainlythe person

to contact if you have a problem in the guarantee period.

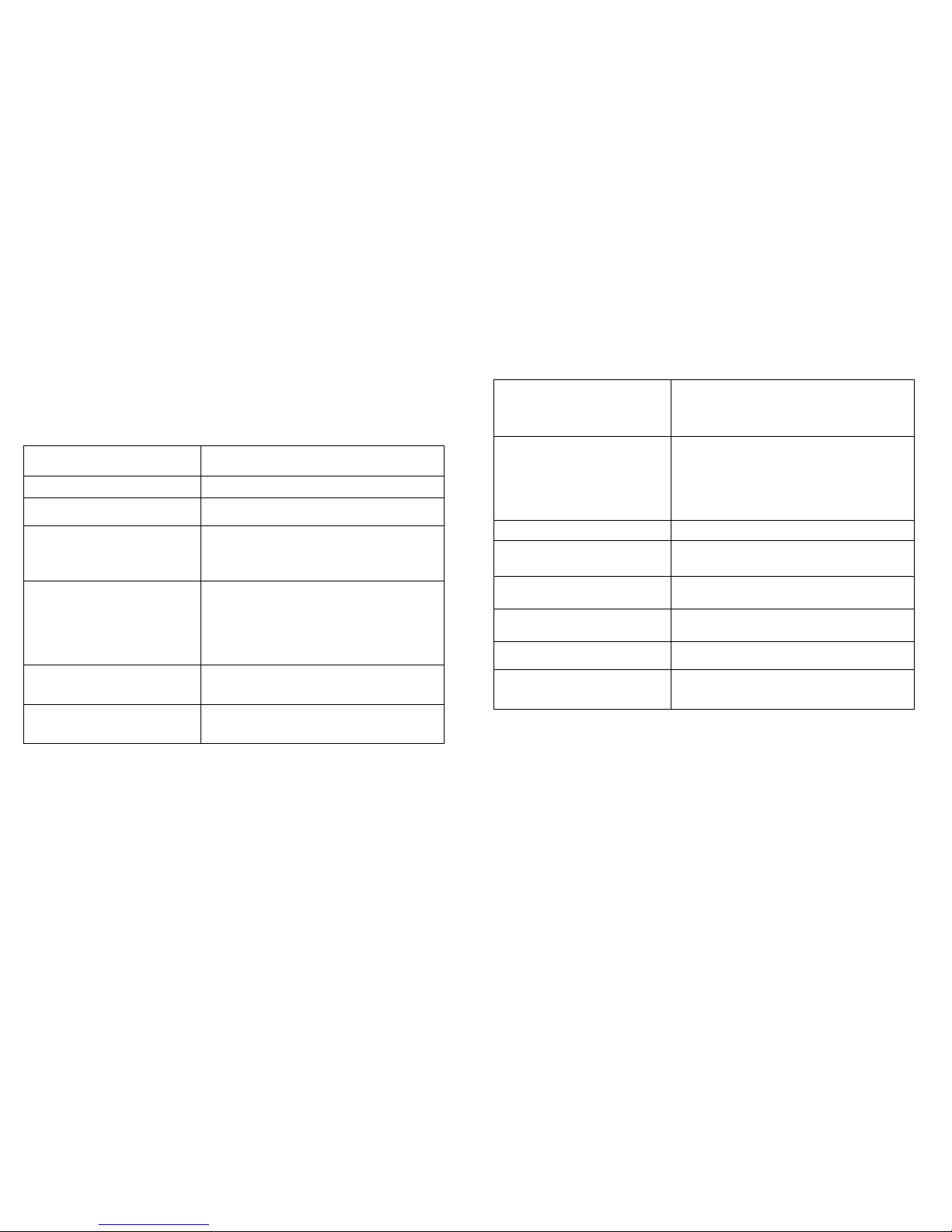

Self Help Check List

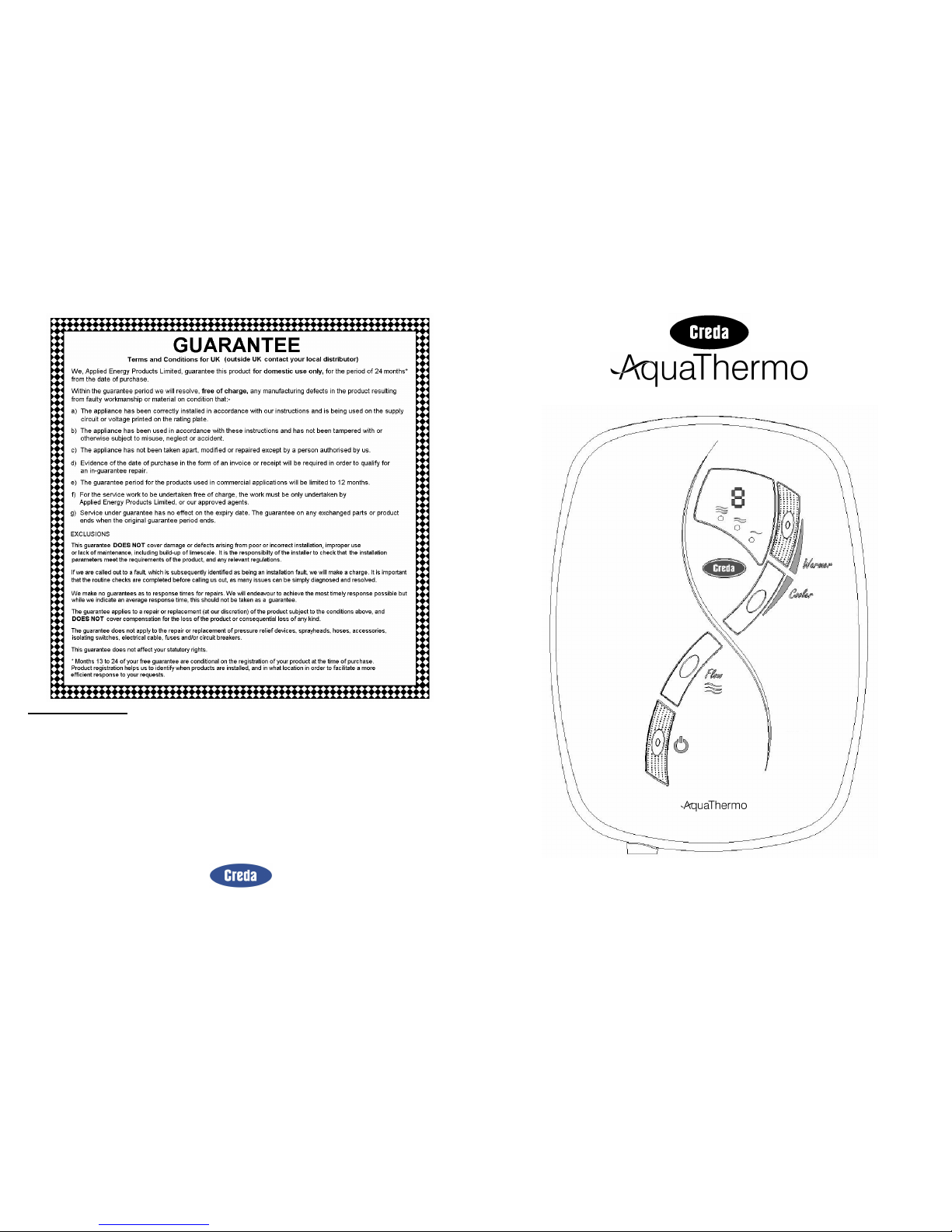

a)Watertoo HOT Pressthe coolerbutton.

Clean sprayplate holes.

b)Watertoo COLD Pressthe warmerbutton.

c)Spray pattern poor Clean sprayplate.

Select outer/ inneronly

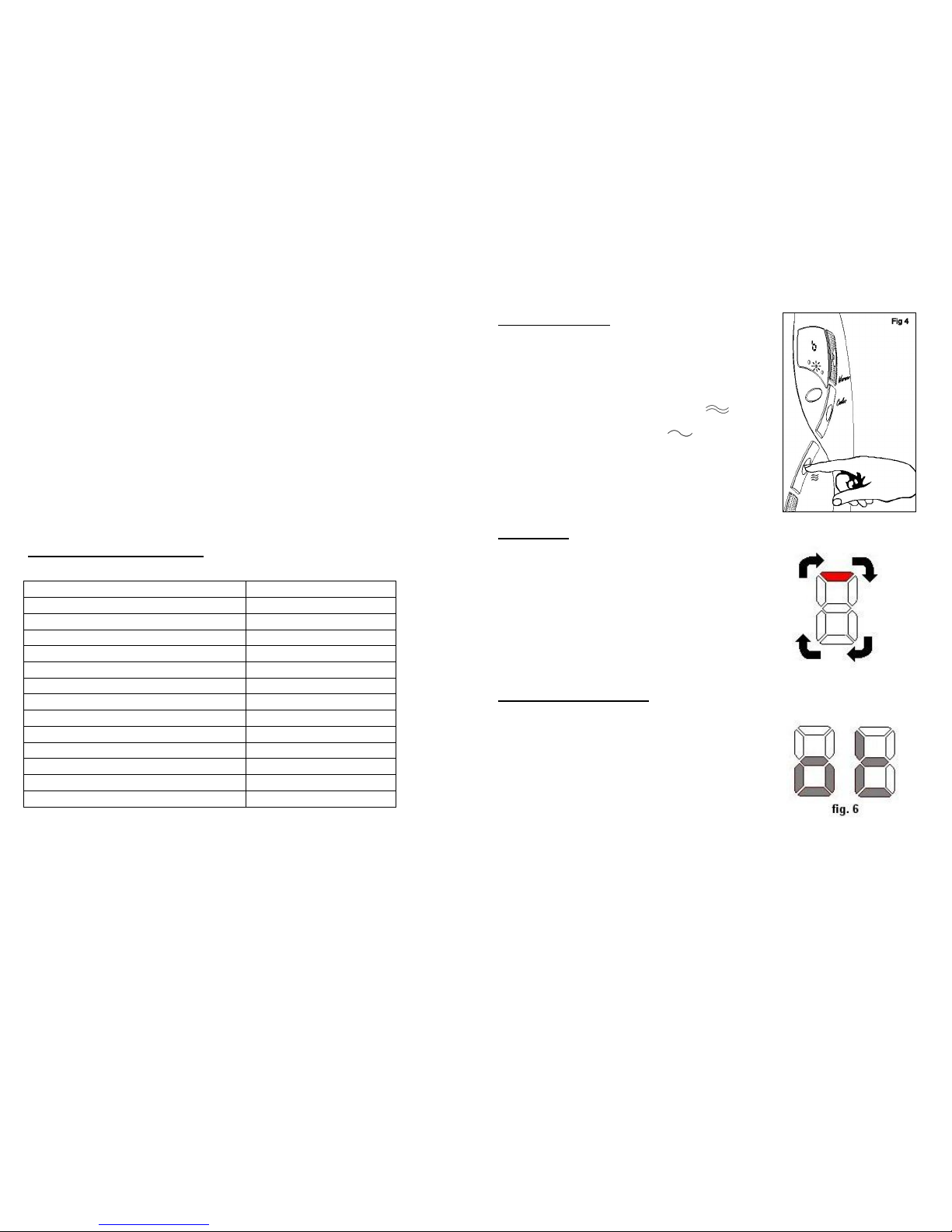

d)Display behaves erratically

Switch off electricityat ceiling / isolatingswitch,waita

few seconds,switch onagain.

(Note the shower should be switchedoff each timeafter

use attheceiling switch.)

e)Waterdoesnot flow when start/stop

buttonispressed

lights on

“o” and then “t” flashing in display

no lights

Note: If there isno waterflowing then theshowerwill

automaticallyswitch off afterabout5 seconds.

Check the watersupply isturned on.

Unit in over temperature mode see section on “purging”

Check ceiling switch ison. Check power ison.

f) Warmer/ cooler buttons only adjusts

between 2 and 5 See relevantsection inprofessional help

g)Unitmakes a whirring noise,

especially at the start of the shower

session.

Thisisnormal. There isa motor insidetheshower used

to adjust the flow and this alwaysoperatesat the start

of each shower.

7

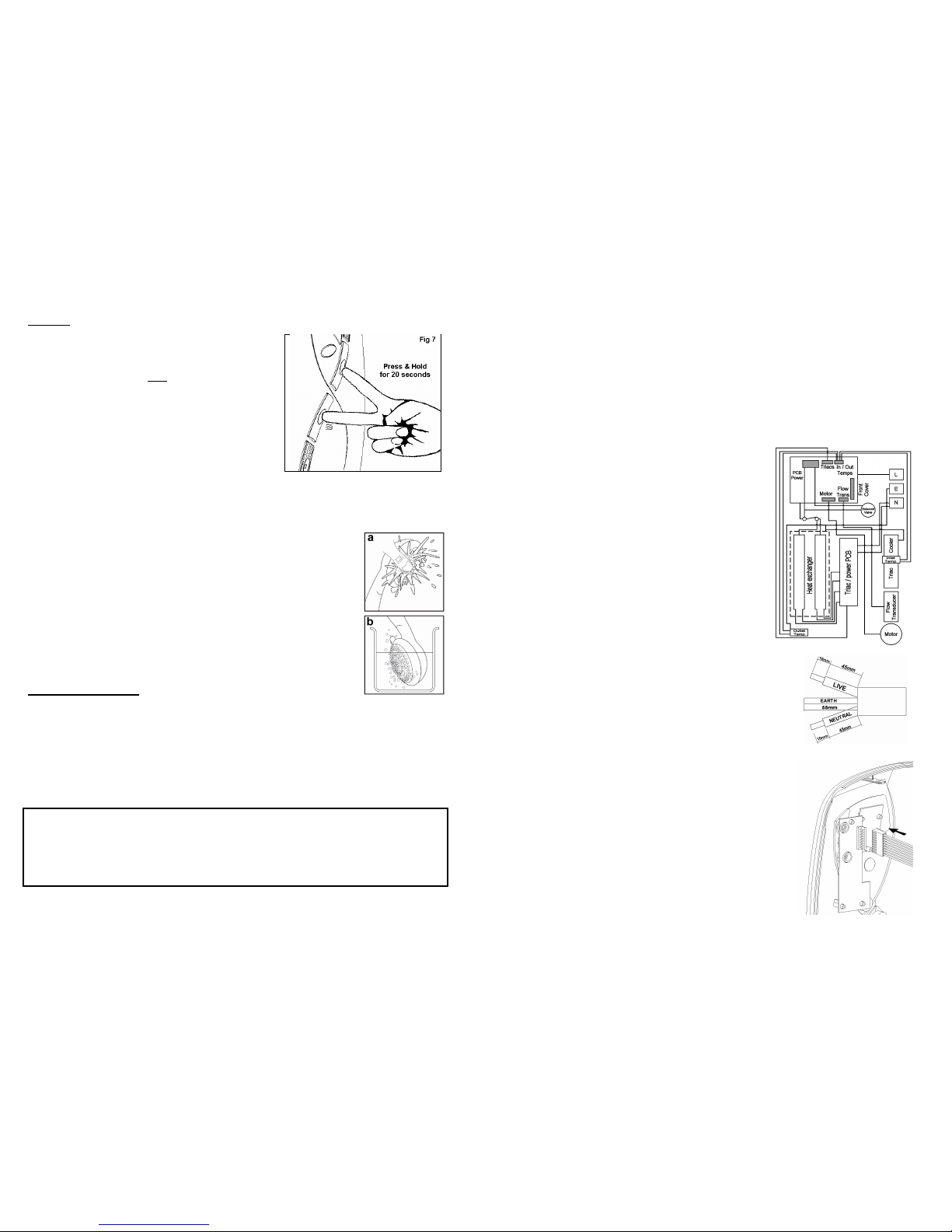

Professional Service Check List

Thisadditional checklist isprovided forthe benefitof the qualified service representative.

Warning. Switch Off The ElectricityAtThe Isolating Switch Before Removing

The Front Cover ToMake Checks.

a)Poortemperature control

Check inlet /outlet thermistors to see if theyarein

circuit.

Check forblockagein filter of solenoid valve

Check board configuration for correctpower rating

b)Watertoo COLD

Check circuitthrough thermal cut-out

Check circuitthrough all 4elements.

Test should be done using a low voltage resistance

meterwhilst the power isswitchedoff at theisolating

switch

Check circuitthrough triacs

Check working voltage

c)Poororno control over waterflow Replaceinletvalve assembly

d)No water when start button is

pressed.

Check watersupply.

Check circuitthrough solenoid coil.

Ifok replace logic PCB

e)Unithas been switched off using stop

button but canbe heard heatingthe

water Replacetriac PCB

f) Pressurerelief valve operated Check forcause of high pressure and remove it.

Replacepressurerelief valve (Not covered under

guarantee).

g)Temperature buttonsonlyadjust

between 2 and 5 ContactCustomer service

h)Shower runs for about 5secondsand

then switches off byitself

Flow transducer fault.

Check that internal blade “spins”when the water flows :

Ifnot, replacetransducer.