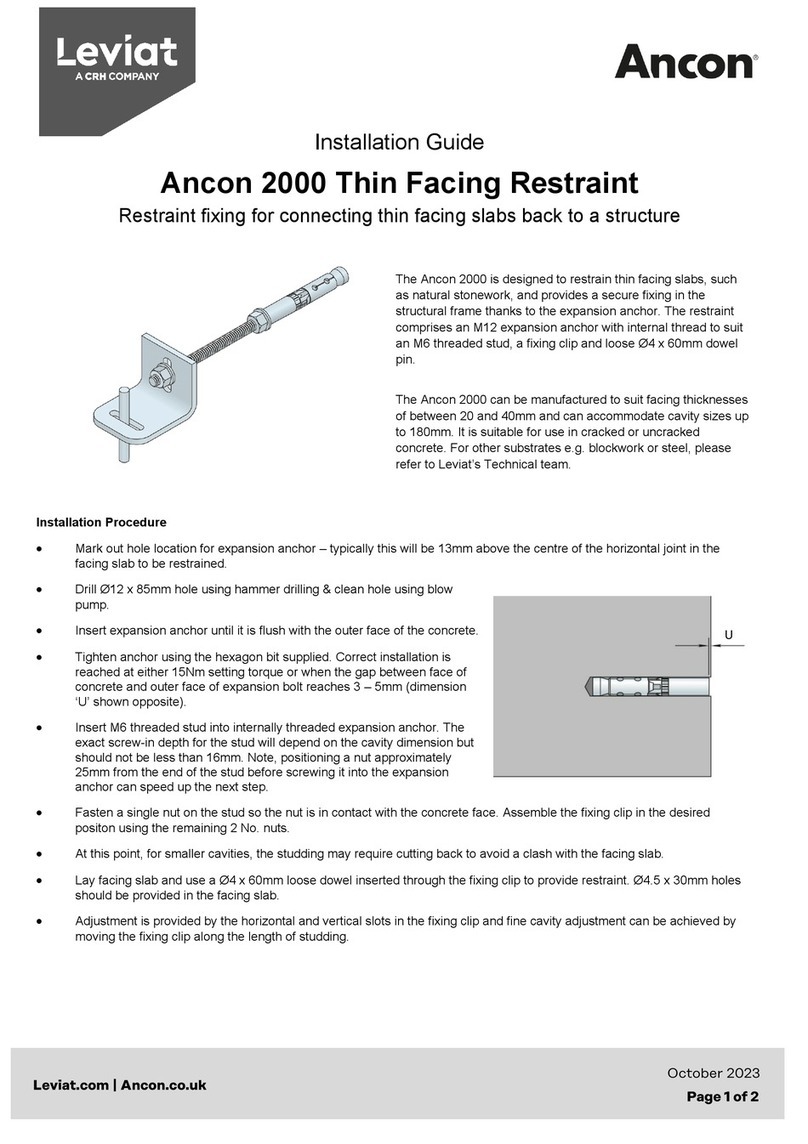

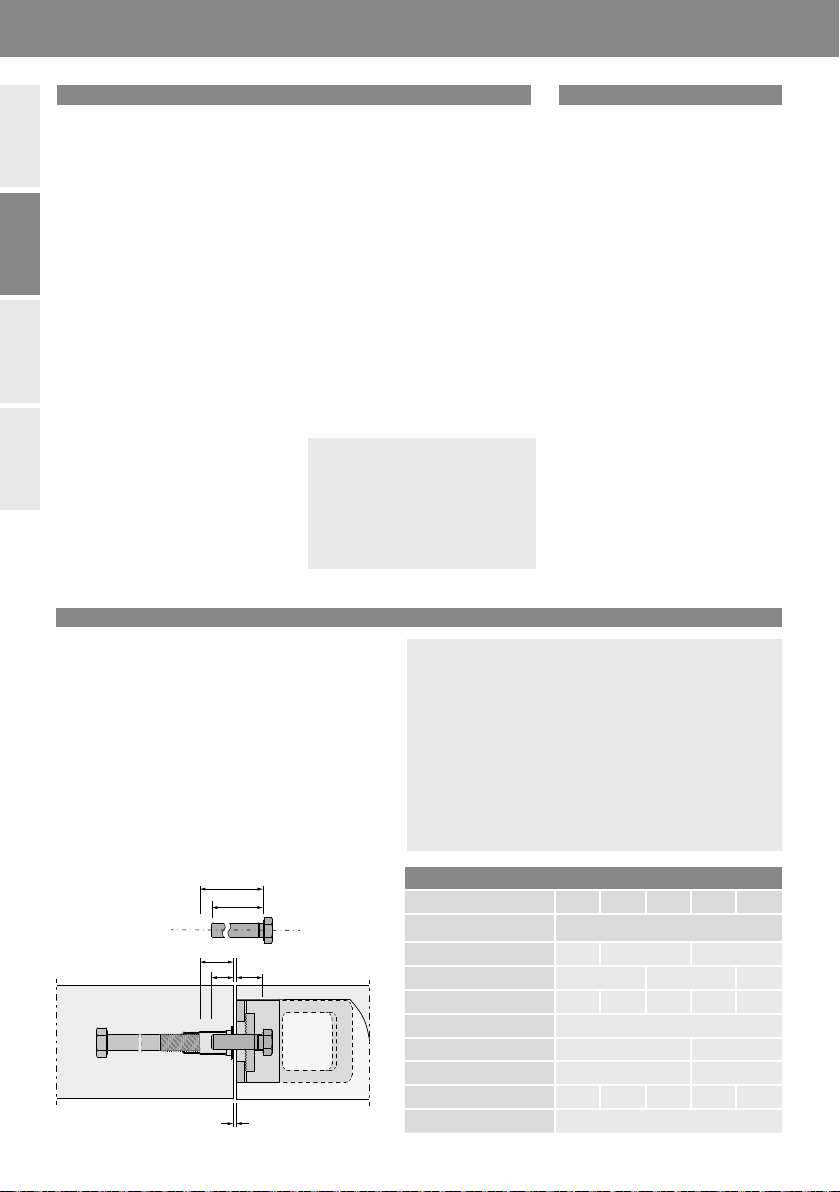

Ls,min

Ls,max

as

t1,fix

t2,fix

10 © 2023 · INST_HEK 04/23 · www.halfen.com

Deutsch EnglishNederlands

HALFEN HEK3 Montageanleitung

Polski

Ermittlung der erforderlichen Schraubenlänge

Allgemeine Einbauhinweise

Der Fertigteilverbinder wird bündig mit

einer Bauteiloberfläche eingebaut.

Abhängig vom Betonierverfahren/

Schalungsmaterial ist der entsprechende

HEK3-Aussparungskörper zu wählen.

Es wird empfohlen sowohl die Ra-

stungsfläche des HEK3 als auch den

HEK3- Aussparungskörper reichlich ein-

zufetten; dies erleichtert das Ausschalen

und erhöht die Lebensdauer des Aus-

sparungskörpers erheblich. Nach dem

Ausschalen verbleibt eine zu einer Bau-

teilseite offene Montageaussparung. Es

ist darauf zu achten, dass die Rastungs-

fläche des Fertigteilverbinders beim Be-

tonieren nicht verschmutzt wird.

Der Beton sollte sorgsam eingebracht

werden, der direkte Kontakt zwischen

Rüttler und Fertigteilverbinder ist zu

vermeiden. Die Belastung des Fertigteil-

verbinders darf erst nach Erreichen der

vorgesehenen Betonfestigkeit erfolgen.

Bei einer offenen Anschlussfuge oder

bei rückversetzter Lage des Hülsen-

ankers ist die Befestigung am Hülsen-

anker zu unterfüttern und die Schrau-

benbiegung nachzuweisen.

Bei der Montage der Schrauben sind

die erforderlichen Installationsanzieh-

drehmomente (Tinst) der HEK3 Fertig-

teilverbindung, siehe Tabelle, zu berück-

sichtigen. Die minimalen bzw. maxima-

len Einschraublängen der Schrauben in

den Hülsenankern sind einzuhalten.

Für die Fertigteilverbindung sind nur

Schrauben nach den Konstruktionsun-

terlagen des verantwortlichen Planers

zu verwenden.

Der HEK3 Fertigteilverbinder wird mit

der Schraube im Verankerungselement

des zweiten Betonfertigteils verankert.

Schraube und Verankerungselement

sind nach Vorgaben des verantwort-

lichen Planers zu verwenden.

Die erforderliche Schraubenlänge Lsist

nachzuweisen.

Schweißbarkeit

Alle im Katalog „HALFEN HEK3 Fertig-

teilverbindung“ aufgeführten Produkte

(aus Stahl) sind generell schweißbar. Al-

lerdings kann jede Form von Schweißen,

einschließlich Heftschweißen, die

mechanischen Eigenschaften der

Produkte beeinträchtigen. Sollte sich

Schweißen in speziellen Anwendungs-

fällen nicht vermeiden lassen, so ist

Folgendes unbedingt zu beachten:

• Aufgrund der Wärmeentwicklung

kann es zu verminderten Tragfähig-

keiten bis hin zu eingeschränkten

Funktionsfähigkeiten kommen.

• Evtl. vorhandene Überzüge oder Be-

schichtungen sind vor dem Schwei-

ßen zu entfernen; durch den Schweiß-

vorgang auftretende Dämpfe sind mit

geeigneten Hilfsmitteln abzusaugen.

• Es ist die vorgeschriebene Schutzaus-

rüstung zu tragen.

• Der Kunde ist verantwortlich für die

Einhaltung der geltenden Vorschriften

bzgl. des Schweißvorgangs.

• Wir übernehmen keine Haftung für

Schäden durch oder an HALFEN Pro-

dukten, die durch Schweißarbeiten

außerhalb unseres eigenen Produkti-

onsprozesses entstehen.

Für die Montage der HALFEN DEMU

Hülsenanker ist die mit dem Hülsen-

anker ausgelieferte Montageanleitung

INST_DEMU-FIX zu beachten.

Kostenloser Download unter

www.halfen.com

Erforderliche Schraubenlänge Ls[mm]

Fugenbreite [mm] 0 5 10 15 20

DEMU Hülsen- bzw.

Bolzenanker Schraubenlänge

1980-P FV M16 50 55 65

1988 FV M16 50 60 70

T-FIXX GV M16×60 50 55 60 65 70

T-FIXX GV M16×100/125 70

1980-P FV M20 60 70

1988 FV M20 60 70

T-FIXX GV M20×70 60 65 70 75 80

T-FIXX GV M20×100/145 80

Ls ≥Ls,min

Ls ≤Ls,max

mit

Ls,min = s + t1+ t2(minimale Schraubenlänge)

Ls,max = a + t1+ t2(maximale Schraubenlänge)

s = minimale Einschraublänge der Schraube in die

Gewindehülse nach Herstellerangabe

a = maximale Einschraublänge der Schraube in die

Gewindehülse nach Herstellerangabe

t1,fix = Klemmdicke der Anschlussfuge

t2,fix = 22mm (Klemmdicke von Fertigteilverbinder mit

Gegenplatte und Unterlegscheibe)