ATTENTION:

Remove all chemicals before storing

the sprayer. Chemical products have

different reactions and can damage

the sprayer components as well as

cause personal injury.

Pump

the lever

until the

discharge

runs clear.

CLEANINGTHE SPRAYER

- After finishing the spray application, clean and wash all equipment in an approved

decontaminationarea.

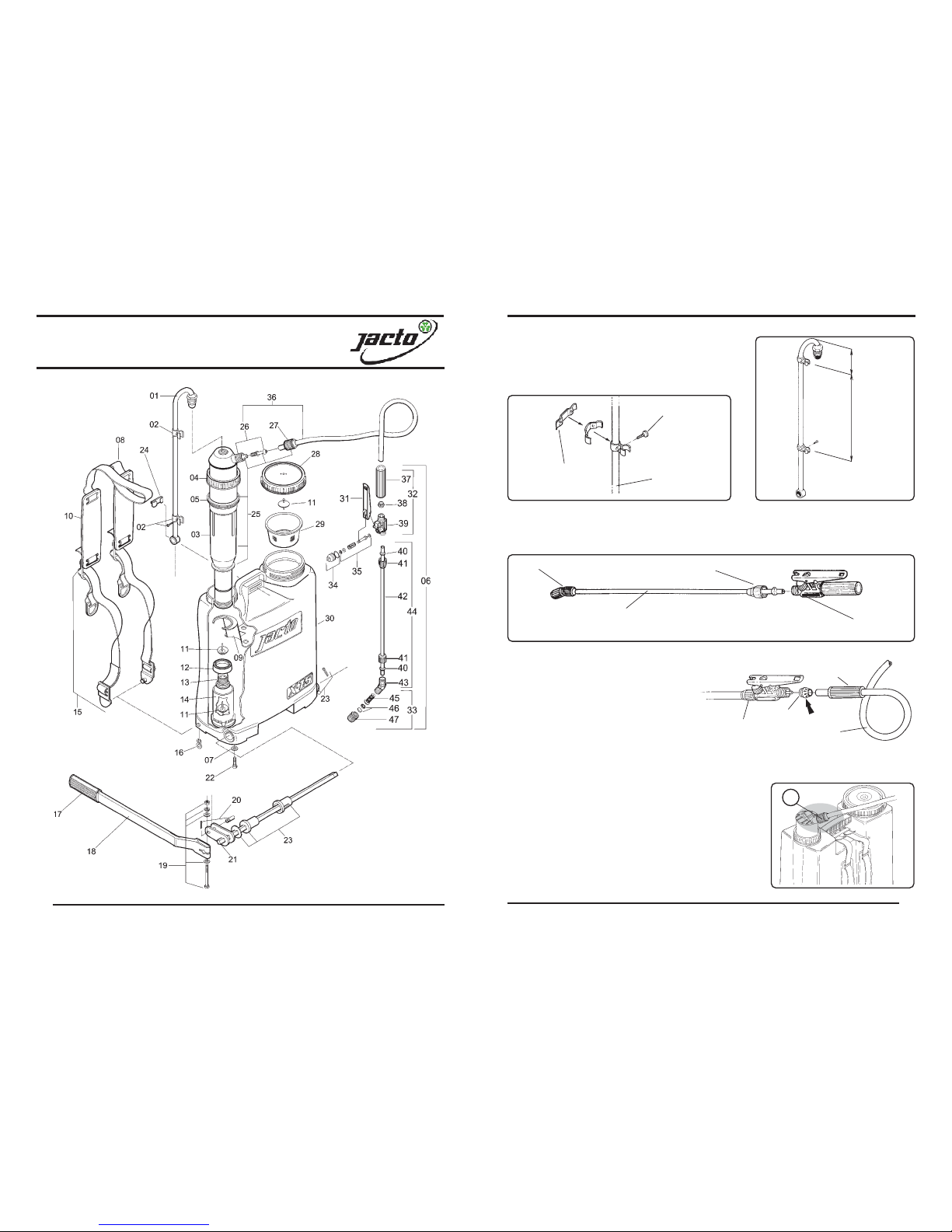

13-MAINTENANCE

LUBRICATION

Periodicallyremovethechamberandlubricatethepistons.In

sequence, clean and grease therod linkage, as described

:

- Pull up the protector (1).

- Loosen the fastener (2).

- Remove the rod (3) from the hole of ball compartment

. Clean and deposit the grease in this compartment (4).

- Proceed the assembling in reverse sequence of the

disassembling.

- Lubricate the others compomnents, as shown.

1

2

3

4

05

12

- Take the container cap off and carefully pour the rinse water into

the spray tank.

- Keep holding the container over the spray tank opening

for approximately 30 seconds to the last drop.

- REPEAT this operation twice more. This way, you complete the

TRIPLE WASH.

- Next, make the plastic and metallic containers

useless by piercing with a pointed instrument the

containers bottom. This way, their labels are not

damaged for identification purposes.

- The useless containers can be stocked temporarily in an appropriate place, until final

destination.

- In the case of mid and large size container (50, 100 and 200 liters), after washing with the

appropriate volume (1/4 of the total) and fitting the cap, roll it on the ground during approximately

30 seconds.

- Then in the upright position complete the agitation by moving back and forth for approximately

30 seconds.

- Then, empty the container by pouring the rinse water into the spray tank.

- REPEAT this operation twice more. In the last one, empty totally the container by pouring rinse

the water in the spray tank.

- The least the quantity of rinse water that remains in the container, from one wash to the next,

the most perfect and complete will be the decontamination.

- For the performance of the TRIPLE WASH, do not use a water volume either much lower or

much higher than 1/4 of the container capacity.

-The TRIPLE WASH must be done IMMEDIATELY AFTER emptying the container, during the

preparation of the solution

SOURCE - ANDEF (NATIONAL ASSOCIATION OF VEGETAL DEFENSE)

14-CYLINDERVALVEMAINTENANCE

ASSEMBLING

- Using a pen, install the diaphragm into the

cylinder as shown in the figure below.

- Replace the cylinder on the sprayer and

tighten the two bolts (1).

- Remount the chamber on the cylinder.

DISASSEMBLING

- Remove the chamber from the cylinder.

- Loosen both cylinder fastening bolts (1).

- Remove the cylinder (2).

- Removethe diaphragm (3).

- Wash or replace the diaphragm.

1

3

2