CTS IES-3006 Series User manual

IES-3006 SERIES

Industrial Ethernet Switch

IES-3006SFP-DR

4 Ports 10/100/1000Base-T plus 2 Ports 100/1000Base-X

Industrial Ethernet Switch

IES-3006SFP-F1-DR

5 Ports 10/100/1000Base-T plus 1 Port 100/1000Base-X

Industrial Ethernet Switch

IES-3006TP

6 Ports 10/100/1000Base-T Industrial Ethernet Switch

User’s Guide

Version 0.91

2

Revision History

Version

Date

Description

0.90

20141119

First release

0.91

20151104

Revise series wiring connection

illustration Section 2.5

3

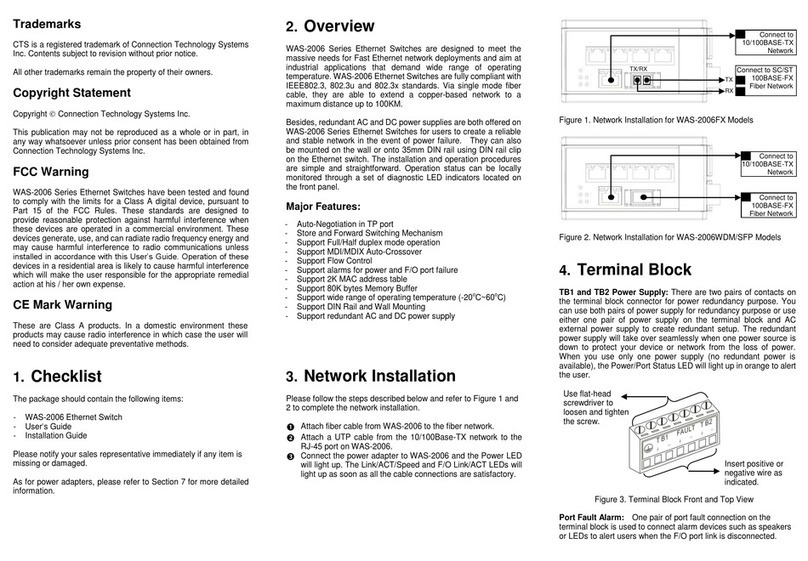

Trademarks

CTS is a registered trademark of Connection Technology Systems Inc.

Contents are subject to revision without prior notice.

All other trademarks remain the property of their respective owners.

Copyright Statement

Copyright 2014 Connection Technology Systems Inc.

This publication may not be reproduced as a whole or in part, in any way whatsoever unless

prior consent has been obtained from Connection Technology Systems Inc.

FCC Warning

This equipment has been tested and found to comply with the limits for a Class-Adigital device,

pursuant to Part 15 of the FCC Rules. These limitations are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if the equipment is not installed and used in

accordance with the instructions, it may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

Consult your local distributors or an experienced radio/TV technician for help.

Shielded interface cables must be used in order to comply with emission limits.

Changes or modifications to the equipment, which are not approved by the party responsible for

compliance, could affect the user’s authority to operate the equipment.

Copyright © 2014 All Rights Reserved.

Company has an on-going policy of upgrading its products and it may be possible that

information in this document is not up-to-date. Please check with your local distributors for the

latest information. No part of this document can be copied or reproduced in any form without

written consent from the company.

Trademarks:

All trade names and trademarks are the properties of their respective companies.

4

Table of Contents

1. OVERVIEW...................................................................................................5

1.1 Specification...............................................................................................5

1.2 Panel Layout...............................................................................................6

2. INSTALLATION ..........................................................................................10

2.1 Installation Requirements...........................................................................10

2.2 Checking the Package Contents...................................................................10

2.3 Installing the Industrial Ethernet Switch....................................................... 11

2.4 Wiring the Redundant Power Inputs ............................................................12

2.5 Wiring the Alarm Contact...........................................................................13

2.6 Connecting the switch to Network...............................................................14

3. OPERATION................................................................................................15

3.1 LED Definitions........................................................................................15

3.2 DIP Switch Definitions ..............................................................................15

4. MAINTENANCE..........................................................................................16

4.1 Fault Identification ....................................................................................16

4.2 Hardware Replacement Procedures .............................................................16

5

1. OVERVIEW

Thank you for choosing the IES-3006 series Industrial Ethernet Switches. IES-3006

series Industrial Ethernet Switches are designed to meet the massive needs for Gigabit

and Fast Ethernet network deployments and aim at industrial applications that demand

wide range of operating temperature. They are fully compliant with IEEE802.3, 802.3u,

802.3x, 802.3ab, 802.3z and 802.3x standards. Besides, redundant power supplies are

both offered on IES-3006 series Industrial Ethernet Switches for users to create a

reliable and stable network in the event of power failure. By employing

Store-and-Forward switching mechanism, the switch provides low latency and faster

data transmission.

1.1 Specification

Interface

1. IES-3006SFP-DR

LAN Ports: 10/100/1000BASE-T x 4

WAN Ports: 100/1000BASE-X x 2

2. IES-3006SFP-F1-DR

LAN Ports: 10/100/1000BASE-T x 4

WAN Ports: 100/1000BASE-X x 1 + 10/100/1000BASE-T x 1

3. IES-3006TP

LAN Ports: 10/100/1000BASE-T x 4

WAN Ports: 10/100/1000BASE-T x 2

Standards

Comply with IEEE 802.3, 802.3u, 802.3ab, 802.3z and 802.3x standards

Features

Switching:

Support Auto-Negotiation in TP ports

Support MDI/MDIX Auto-Crossover in TP ports

Full/Half Duplex Mode Operation

MAC Address Table: 2K

Store-and-Forward Switching Mechanism

Cable Specifications

The following table contains various cable specifications for the Industrial Ethernet

Switch. Please make sure that you use the proper cable when connecting the Industrial

Ethernet Switches.

6

Cable Type

Description

10BASE-T

UTP Category 3, 4, 5 (100 meters max.)

EIA/TIA- 568 150-ohm STP (100 meters max.)

100BASE-TX

UTP Cat. 5 (100 meters max.)

EIA/TIA-568 150-ohm STP (100 meters max.)

1000BASE-T

UTP Cat. 5e (100 meters max.)

UTP Cat. 5 (100 meters max.)

EIA/TIA-568B 150-ohm STP (100 meters max.)

100BASE-FX

Multi-mode fiber module(2km) / Single-mode fiber module

1000BASE-SX

Multi-mode fiber module (550m)

1000BASE-LX

Single-mode fiber module (10km)

1000BASE-LH

Single-mode fiber module (30km/50km)

1000BASE-ZX

Single-mode fiber module (80km)

Mini-GBIC

SFP Transceiver for 1000BASE-SX Multi-mode fiber module

(550m)

SFP Transceiver for 1000BASE-LX Single-mode fiber module

(10km)

SFP Transceiver for 1000BASE-LH Single-mode fiber module

(30km/50km)

SFP Transceiver for 1000BASE-ZX Single-mode fiber module

(80km)

1.2 Panel Layout

Front Panel

Figure 1. Front Panel for 4 Ports 10/100/1000Base-T + 2 ports 100/1000Base-X

➊

➋

➌

8

Rear Panel

Figure 4. Rear Panel

DIN-Rail metal spring (for more information, please see chapter 2.3)

Top Panel

Figure 5. Top Panel

➎Reset Button:

Insert a pin or paper clip to press the Reset Button for 5 seconds to

restart the system

Insert a pin or paper clip to press the Reset Button for 10 seconds to

reset the device back to factory defaults.

➏Terminal blocks (for more information, please see chapter 2.4)

➏

➐

➎

➑

10

2. INSTALLATION

To properly install the Industrial Ethernet Switch, please follow the procedures listed

below. Procedures covered in this chapter are described below in separate sections.

Installation Requirements

Unpacking the Industrial Ethernet Switch

Installing the Industrial Ethernet Switch

Powering on the Industrial Ethernet Switch

Connecting the Industrial Ethernet Switch to the Network

2.1 Installation Requirements

ATTENTION

Be sure to power off before installing or wiring your Industrial

Ethernet Switch.

Be sure to calculate the maximum possible current in each power

wire and common wire. If the current goes above the maximum

ratings, the wiring could overheat, causing serious damage to your

equipment.

Be sure to read and follow below important guidelines :

Do not run signal or communications wiring and power wiring through the

same wire conduit. Wires with different signal characteristics should be

routed separately to avoid interference.

It is recommended that wiring which shares similar electrical characteristics

can be bundled together.

Keep input wiring and output wiring separate and label the wiring to all

devices in the system if necessary.

2.2 Checking the Package Contents

Unpack the package carefully and check the package contents. The package should

contain the following items:

Items included in standard package:

1 Industrial Ethernet Switch

1 Documentation CD

11

If any of the above items is found missing or damaged, please contact your local sales

representative for support or replacement.

2.3 Installing the Industrial Ethernet Switch

ATTENTION

This product is intended to be mounted to a well-grounded mounting

surface, such as a metal panel.

DIN-Rail Mounting

STEP1 : Insert the top of the DIN-Rail

into the slot just below the metal spring

STEP2 : The DIN-Rail attachment unit

will be snapped into place as shown

Metal

Spring

DIN-Rail

DIN-Rail

Metal

Spring

12

Grounding the Industrial Ethernet Switch

Grounding helps to limit the effects of noise due to electromagnetic interference (EMI).

Be sure to install the ground connection from the ground screw to the grounding

surface before connecting devices.

Figure 6. Grounding wire

2.4 Wiring the Redundant Power Inputs

The Industrial Ethernet Switch can be used with DC power 48-54 VDC with 2 terminal

blocks. The terminal blocks are located on the upper panel of the Industrial Ethernet

Switch. Before powering the Industrial Ethernet Switch, please make sure that network

cables and power cables are securely connected.

ATTENTION

Before connecting the Industrial Ethernet Switch to the DC power

inputs, make sure the DC power source voltage is stable.

PWR1 and PWR2 power supply are two pairs of contacts on the terminal block

connectors for power redundancy purpose. The redundant power supply will take over

seamlessly when one power source is down to protect your device or network from the

loss of power. When you use only one power supply (no redundant power is available),

the LED Power/Port Status will flash in orange to alert the user.

13

STEP 1 :

Insert the negative/positive DC wires into the V-/V+

terminals.

STEP 2 :

Use a small flat-blade screwdriver to tighten the

wire-clamp screws on the front of the terminal block

connector.

STEP 3 :

Insert the plastic terminal block connector prongs into the

terminal block receptor, which is located on the IES’s top

panel.

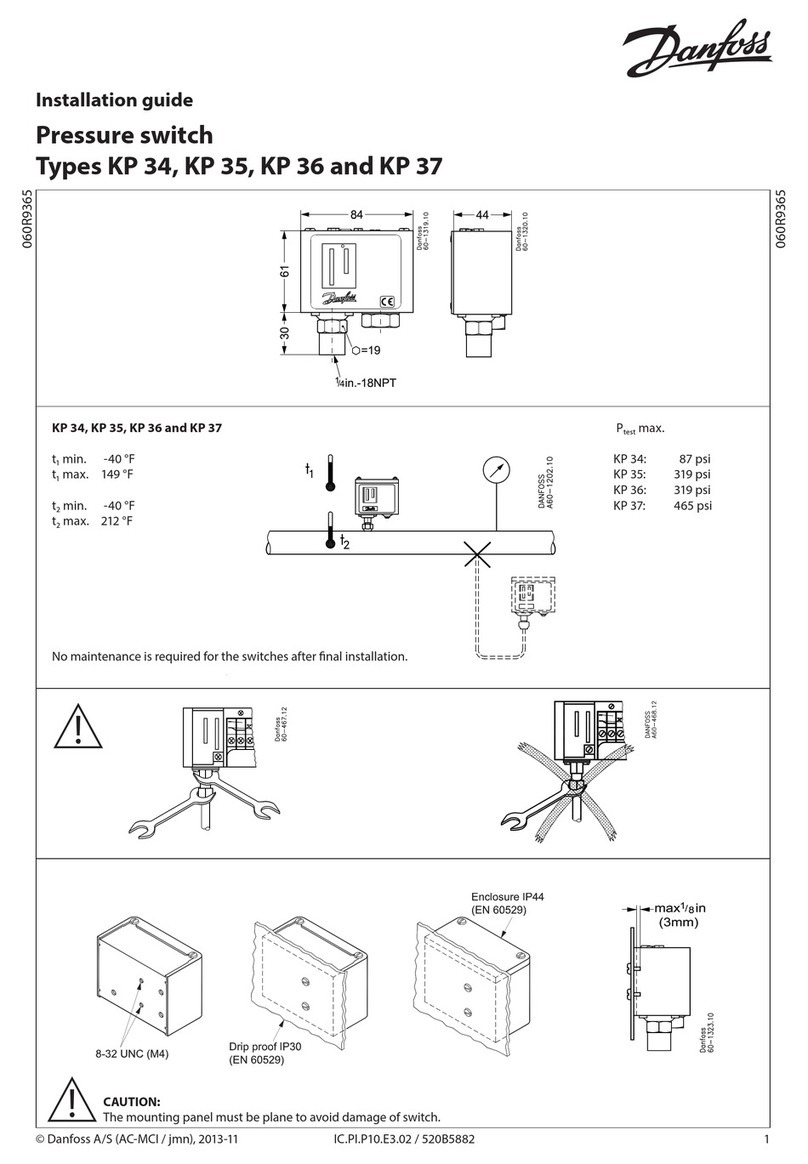

2.5 Wiring the Alarm Contact

The Industrial Ethernet Switch has two sets of Alarm Contacts which are used to detect

both power faults and port faults. We will explain the meaning of the two sets of

contacts used to connect the Alarm Contact below.

If you have two Alarm Systems:

ALM1:

The two wires attached to the Fault contacts form an

open circuit when the IES has lost power from one of the

DC power inputs.

ALM 2 :

The two wires attached to the Fault contacts form an

open circuit when one of the ports for which the

corresponding Port Alarm DIP Switch is set to ON be

not properly connected.

If you have only one Alarm System:

(series connection)

The two wires attached to the Fault contacts form an

open circuit when :

The IES has lost power from one of the DC power

inputs.

AND

One of the ports for which the corresponding Port Alarm

DIP Switch is set to ON be not properly connected.

14

(parallel connection)

The two wires attached to the Fault contacts form an

open circuit when :

The IES has lost power from one of the DC power

inputs.

OR

One of the ports for which the corresponding Port Alarm

DIP Switch is set to ON be not properly connected.

2.6 Connecting the switch to Network

Connect to Network

This Industrial Ethernet Switch has 2 uplink ports (RJ-45 or SFP, please refer to

ordering information) and 4 downlink 10/100/1000Mbps RJ-45 ports for you to

implement it in your industrial environment. All RJ-45 ports can be inserted by

10/100/1000Base-T cables, connecting to the end devices. The fiber port(s) can accept

any kind of connector with proper SFP transceiver (mini-GBIC).

Figure 7. Industrial Ethernet Switch general application

15

3. OPERATION

The Industrial Ethernet Switch is Plug & Play compliant. Real-time operational status

can be monitored through a set of LED indicators located on the front panel.

3.1 LED Definitions

LED

Definition

Color

Operation

PWR1

Power

Off

Device is powered down.

Green

Device is powered up.

PWR2

Power

Off

Device is powered down.

Green

Device is powered up.

STATUS

Ethernet Port

Link Down

Alarm Status

Orange

Alarm is currently present

Off

No alarm is currently present

LINK/ACT

1~6

Port Status

Off

Port link is down

Green

Link is up and works at 10 or 100Mbps.

Green

Blinking

Receiving and transmitting data.

Orange

Link is up and works at 1000Mbps.

Orange

Blinking

Receiving and transmitting data.

3.2 DIP Switch Definitions

Pin NO.

Function

OFF

ON

1

Port 1 Ethernet Port Link Down Alarm

Disable

Enable

2

Port 2 Ethernet Port Link Down Alarm

Disable

Enable

3

Port 3 Ethernet Port Link Down Alarm

Disable

Enable

4

Port 4 Ethernet Port Link Down Alarm

Disable

Enable

5

Port 5 Ethernet Port Link Down Alarm

Disable

Enable

6

Port 6 Ethernet Port Link Down Alarm

Disable

Enable

16

4. MAINTENANCE

It is easy to use and maintain this Industrial Ethernet Switch. The procedures are

suggested when you want to identify faults or perform hardware replacement.

4.1 Fault Identification

Identifying faults can greatly reduce the time required to find the problem and solution.

Users may perform local or remote checks to find the problems.

Local Check

Users can perform local checks by observing LED indicators status.

When the whole system fails to function,

Check Power LED status

Check Power connection

Reset power

When certain network link fails to function,

Locate the port of the switch

Check Port Link Status LED

Check cable connection between the port and the connected device

Reset power

4.2 Hardware Replacement Procedures

ATTENTION

The Industrial Ethernet Switch contains no user-serviceable parts.

DO NOT, UNDER ANY CIRCUMSTANCES, open and attempt to

repair it.

Failure to observe this warning could result in personal injury or

death from electrical shock.

Failure to observe the above warning will immediately void any

Warranty.

This manual suits for next models

3

Table of contents

Other CTS Switch manuals

CTS

CTS HES-3106SFP-F2 User manual

CTS

CTS SWH-3112 Series User manual

CTS

CTS ESW-3128 Series User manual

CTS

CTS FOS-5112 User manual

CTS

CTS FOS-3114 Series User manual

CTS

CTS IPS-3006 Series User manual

CTS

CTS SWH-2109FX User manual

CTS

CTS IES-3106 Series User manual

CTS

CTS FOS-3124 SERIES User manual

CTS

CTS EPS-3112 User manual

CTS

CTS SWH-2108 User manual

CTS

CTS HES-5106 Series User manual

CTS

CTS FOS-3128 Series User manual

CTS

CTS HES-3109 Series User manual

CTS

CTS FOS-5126 Series User manual

CTS

CTS FOS-3124-BAT-II Series User manual

CTS

CTS WAS-2006 Series User manual

CTS

CTS EPS-3128 Series User manual

CTS

CTS WPS-2006 Series User manual

CTS

CTS IPS-3120-PoE++ User manual