Currie Technologies Technical and Customer Service 1-800-377-4532 3

Pleaserecycle

packagingmaterials!

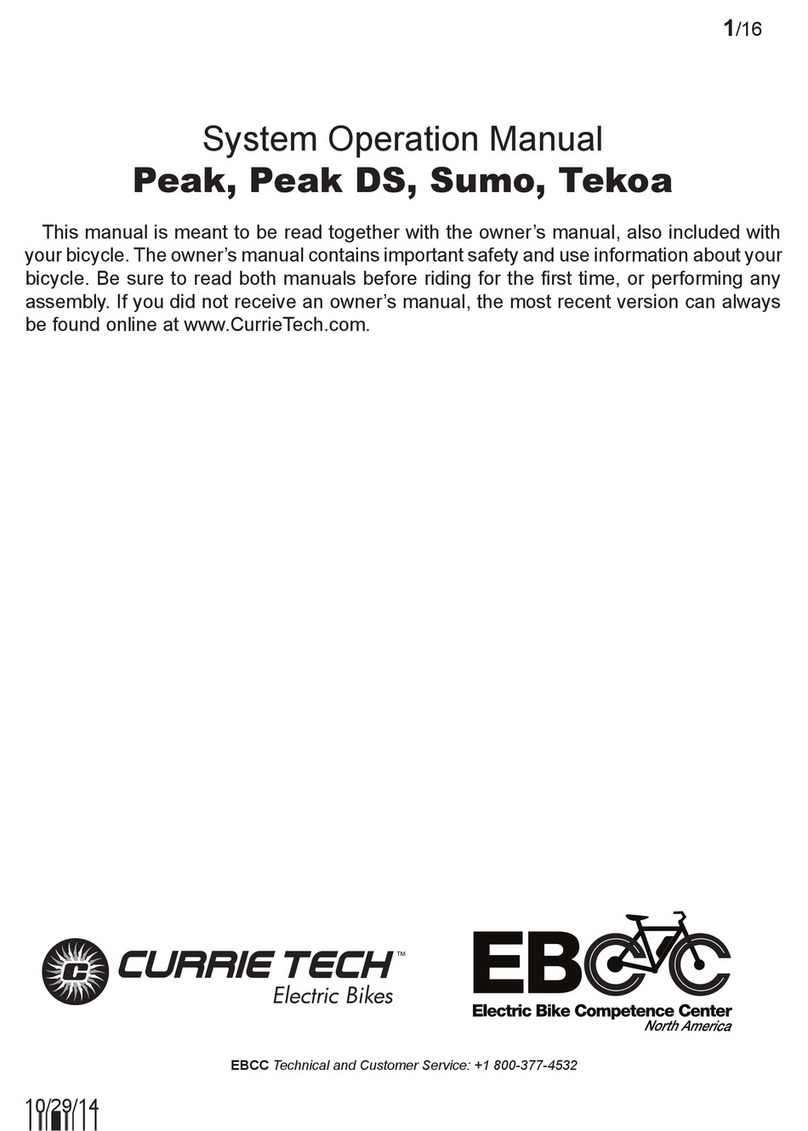

A

B

Unpacking and Preparation

Seatpost

1. Carefully remove the rear end sub-assembly and the main

frame sub-assembly from their boxes;youshouldhaveafriendhelp

youwiththis,asthesepartsareheavy.Findthepartsboxpackagedwiththe

mainframesub-assemblyandsetitasidefornow.

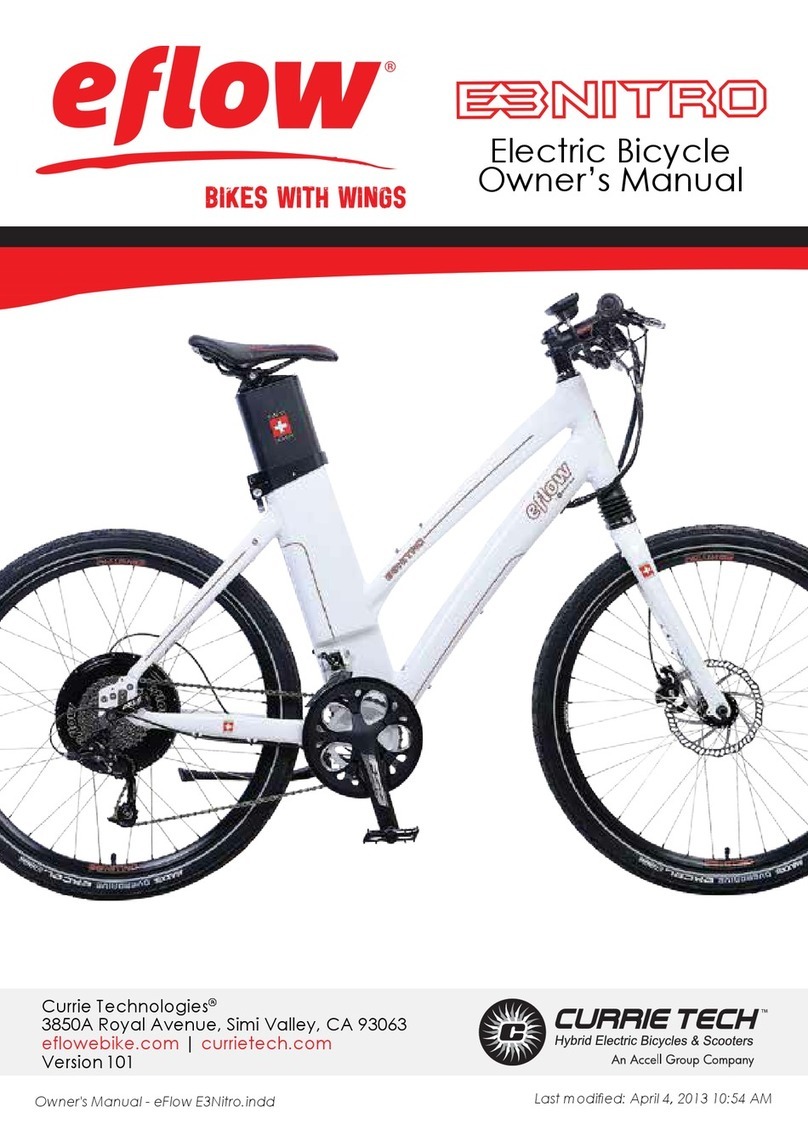

2. Remove the battery from the main frame sub-assembly (seethe

Batterysectiononpage14formoreinformation).

Begin charging the battery—thiswilltakeabout10hours.Thebattery

isinsidethemainframesub-assembly.Thechargerisinasmallwhitebox,

packagedwiththemainframesub-assembly.Asolidredorblinkinggreen

lightonthecharger(dependingonmodel)indicatesthebatteryischarging

properly.Asolidgreenlightindicatesthatthechargerhasenteredtrickle

chargemode,andyourbatteryisatleast80%full.Formaximumrange,

pleasechargeforthefullrecommendedtimeperiod(8-10hours).

3. Apply grease to the inside of the seat tube,theninsert the

seatpostandclose the quick release tightly (Photo B).Itwillhelp

duringthenextstepsifyoulowerthesaddleallthewaydown;itcanbe

adjustedtoacomfortableheightbeforeyourrstride.

Refertotheappendixtothisguideformoreinformationontheuseand

adjustmentofquickreleaselevers.It is vital to your safety that you

understand and properly secure this lever!

Battery plugged in to charger