Appendix: Quick Release Levers

Many Izip and Ezip bicycle models use quick release (QR) levers to facilitate common tasks such as front wheel removal and seat height adjustment.

When properly adjusted, quick release levers are both safe and convenient, but you must understand and apply the correct technique to adjust them

properly before riding your bicycle to prevent serious injury or death from a fall.

Quick release levers use a cam action to clamp the wheel or other components in place. Because of their adjustable nature, it is critical that you

understand how they work, how to use them properly, and how much force you need to apply to secure them.

Warning: The full force of the cam action is needed to clamp the wheel securely. Holding the nut with one hand and turning the lever like a wing nut is

NOT a safe or effective way to close a quick release and will not clamp the wheel or other components safely.

QUICK RELEASE USAGE

Riding with an improperly adjusted wheel quick release can allow the wheel to wobble or fall off the bicycle, which can cause serious injury or death.

Therefore, it is essential that you:

1. Ask your dealer or a local bike shop to help you make sure you know how to install and remove your wheels safely.

2. Understand and apply the correct technique for clamping your wheel in place with a quick release.

3. Each time, before you ride the bike, check that the wheel is securely clamped.

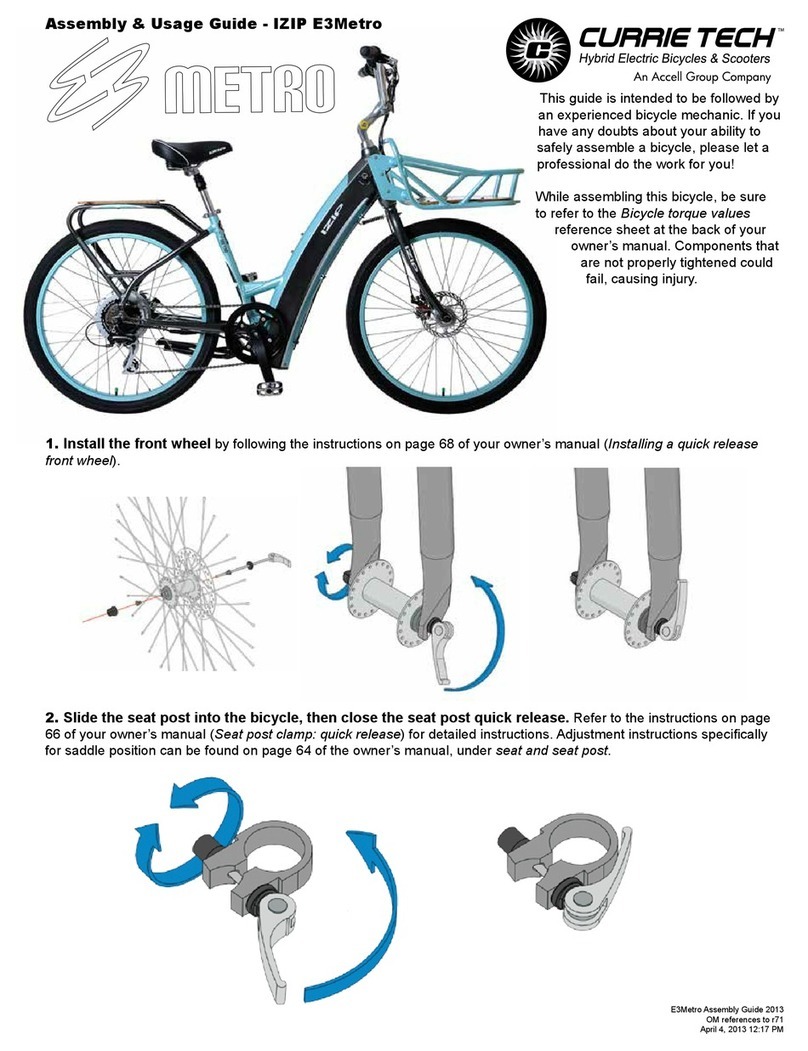

Installing a quick release front wheel

In a quick release system, the wheel hub is clamped in place by the force of the quick release cam pushing against one dropout and pulling the tension

adjusting nut, by way of the skewer, against the other dropout. The amount of clamping force is controlled by the tension adjusting nut. Turning the

tension adjusting nut clockwise while keeping the cam lever from rotating increases clamping force; turning it counterclockwise while keeping the cam

lever from rotating reduces clamping force. Less than half a turn of the tension adjusting nut can make the difference between safe clamping force and

unsafe clamping force.

Currie Technologies Technical and Customer Service 1-800-377-4532