CURTMFG.COM •PRODUCT SUPPORT: 877.287.8634 •16315-INS-RA •03/31/2021 •ECN8138 •PAGE 6

UNCOUPLING & RESETTING

Step 1

Park on a firm and level surface. Set automatic transmission vehicles to

park and activate emergency brake. Set standard transmission vehicles

to neutral and activate emergency brake.

Chock the trailer wheels. Multiple wheel

chocks should be used, both in front and

behind the tires. Do not substitute objects

such as stones, wood blocks, etc.

Disconnect all harnesses, lanyards, safety

devices, etc. as required to separate the

trailer from the tow vehicle. Lower or

remove truck tailgate as required.

Begin extending the front trailer lifting

jacks. The lifting jacks should be extended

just enough to remove the weight of the

trailer from the 5th wheel skid plate.

Note: Creating a gap between the trailer skid plate and the

5th wheel skid plate is not necessary or recommended. If a

gap is present, it should be minimal and no more than 1/16".

Excessive gap while coupled can damage internal components

of the 5th wheel hitch as well as components of your trailer.

Step 2

With the trailer jacks down and wheels chocked, reduce any remaining

load on the jaws and kingpin by backing the tow vehicle up slightly

and pushing the kingpin completely into the opening on the 5th wheel

head. Hold the position by applying your vehicle's parking brake

before putting the vehicle in park and releasing the standard brake.

Step 3

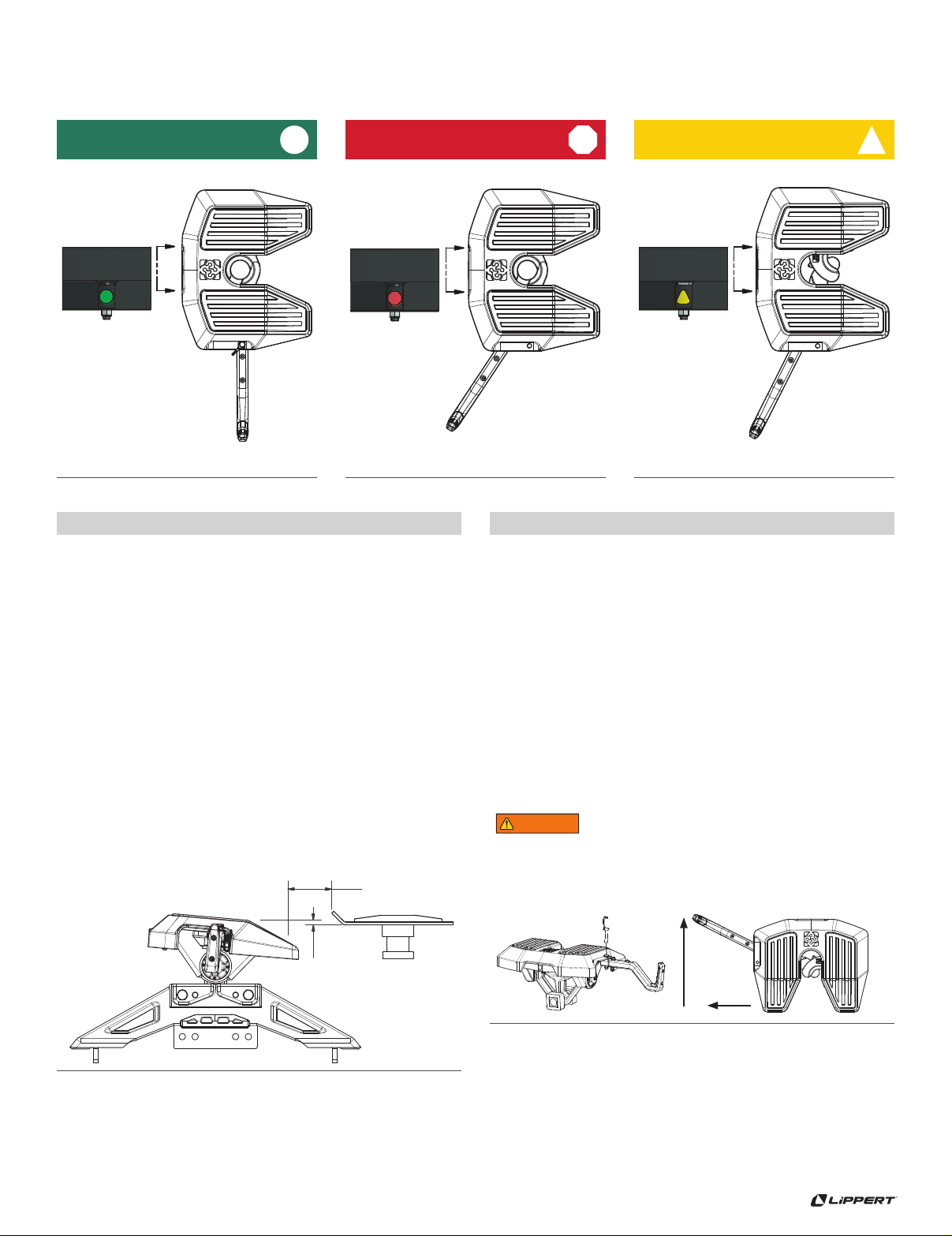

Remove the safety lynch pin from the handle of the 5th wheel.

Unlock the jaws by pulling the locking handle out about 1/2" and

then swinging it forward until it latches in the unlocked position.

The red unlocked indicator will be visible from the cab.

Note: If the operating handle fails to latch in the unlock position

while the kingpin is in the jaws, refer to steps 1 and 2 in the

'Preparation Troubleshooting' section on page 6. Never attempt

to uncouple without the handle being in the unlocked position.

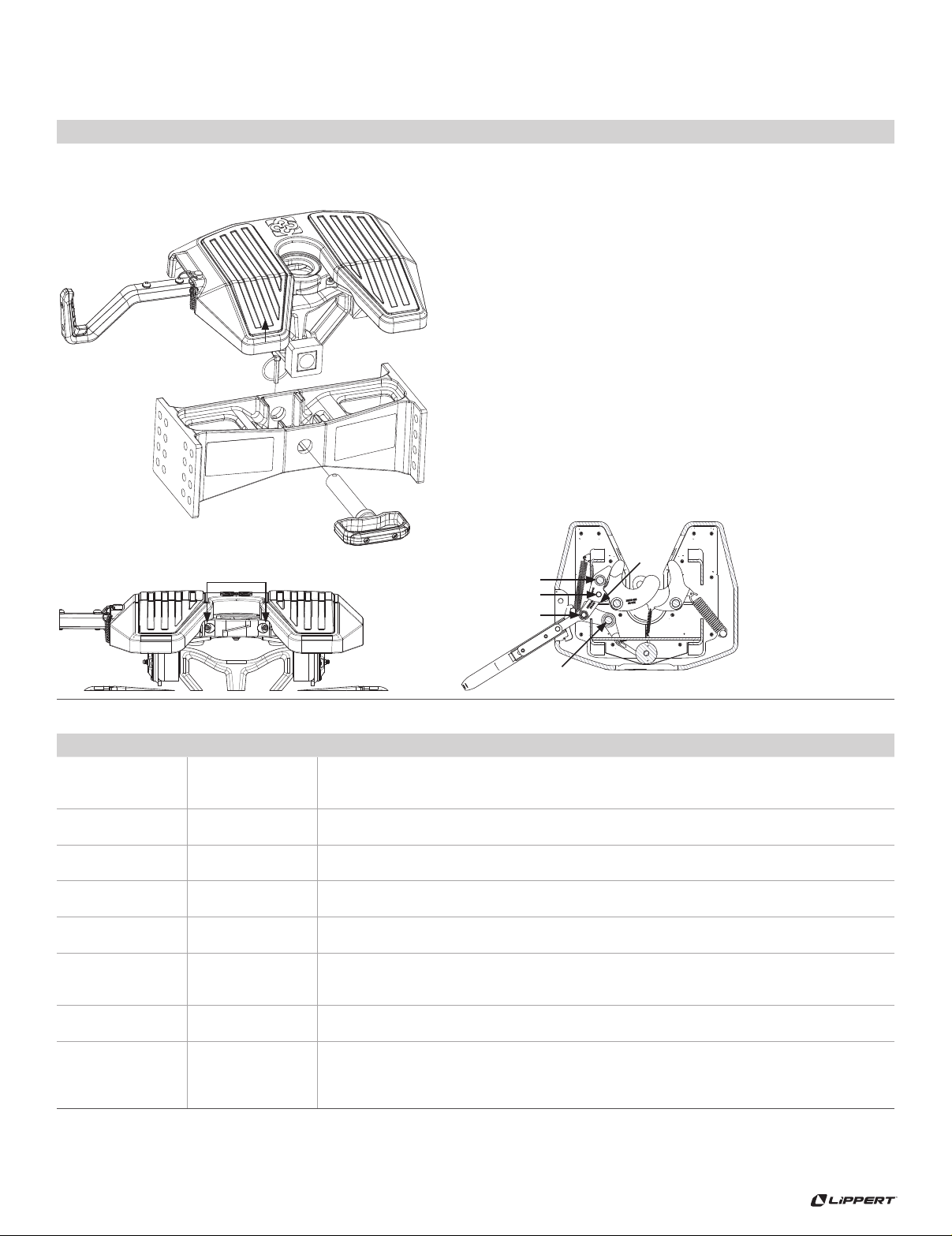

Step 4

Remove the safety lynch pin (#9) from the handle (#4) of the 5th wheel.

Remove the parking brake and slowly drive the tow vehicle out

from under the trailer. If resistance is encountered, determine the

corrective action and repeat uncoupling steps.

As the kingpin moves out of the 5th wheel jaws you will

see the handle drop back slightly to the couple position.

The indicator will also change from red to yellow.

Your 5th wheel hitch is now safely uncoupled and

is ready to be recoupled the next time you tow.

Preparing to tow

Confirm handle safety latch pin has been installed.

Attach electrical harnesses.

Attach lanyard and insert electric brake break-away

plunger. If hydraulic surge brakes are present, attach

lanyard from the surge brake assembly as required.

Fully retract front trailer lifting jacks.

Close truck tailgate or reinstall tailgate as required.

Remove tire chock blocks.

Check running lights, directional signals

and brake lights for proper operation.

Pull forward a few feet and apply brakes to check that trailer brakes

are activating. Adjust the electric brake controller if necessary.

Pull test

After coupling and prior to removing trailer wheel blocks

and / or raising front trailer jacks, you must do the following.

Set towing vehicle in a forward gear and lightly tug on the trailer

to ensure that 100% coupling has taken place. If resistance is felt,

release forward pressure, set vehicle to park (if equipped with an

automatic transmission) and activate the emergency brake. Place

in neutral if equipped with a standard transmission and activate

emergency brake.

If resistance is not felt, trailer may not be coupled correctly. Do

not continue applying forward pressure, immediately stop and back

towing vehicle into original position. Do not allow the truck and trailer

to separate. Separation can cause damage to the towing vehicle,

5th wheel hitch and / or trailer. Serious injury or death may result

if all warnings are not observed.

Review coupling instructions, apply

corrective action and repeat coupling steps.

COUPLING & LOCKING (CONT)

4

9