TECHNICAL DATA

2-2 ©200338

Locking compounds and sealants

0

ΛΦ45/55 series

0

Applying the locking compound

1. Clean both the internal and external threads.

Degrease the thread with a suitable

degreasing agent which leaves no residue

that could affect proper functioning.

2. Apply one or more drops of locking

compound to the thread, depending on the

diameter. Never dip the bolt or stud fully into

the locking compound.

3. Apply a drop of oil under the bolt head.

Locking compounds also reduce the

frictional resistance, which means that

applying a drop of oil to the thread is not

required.

4. Tighten the connection to the specified

torque.

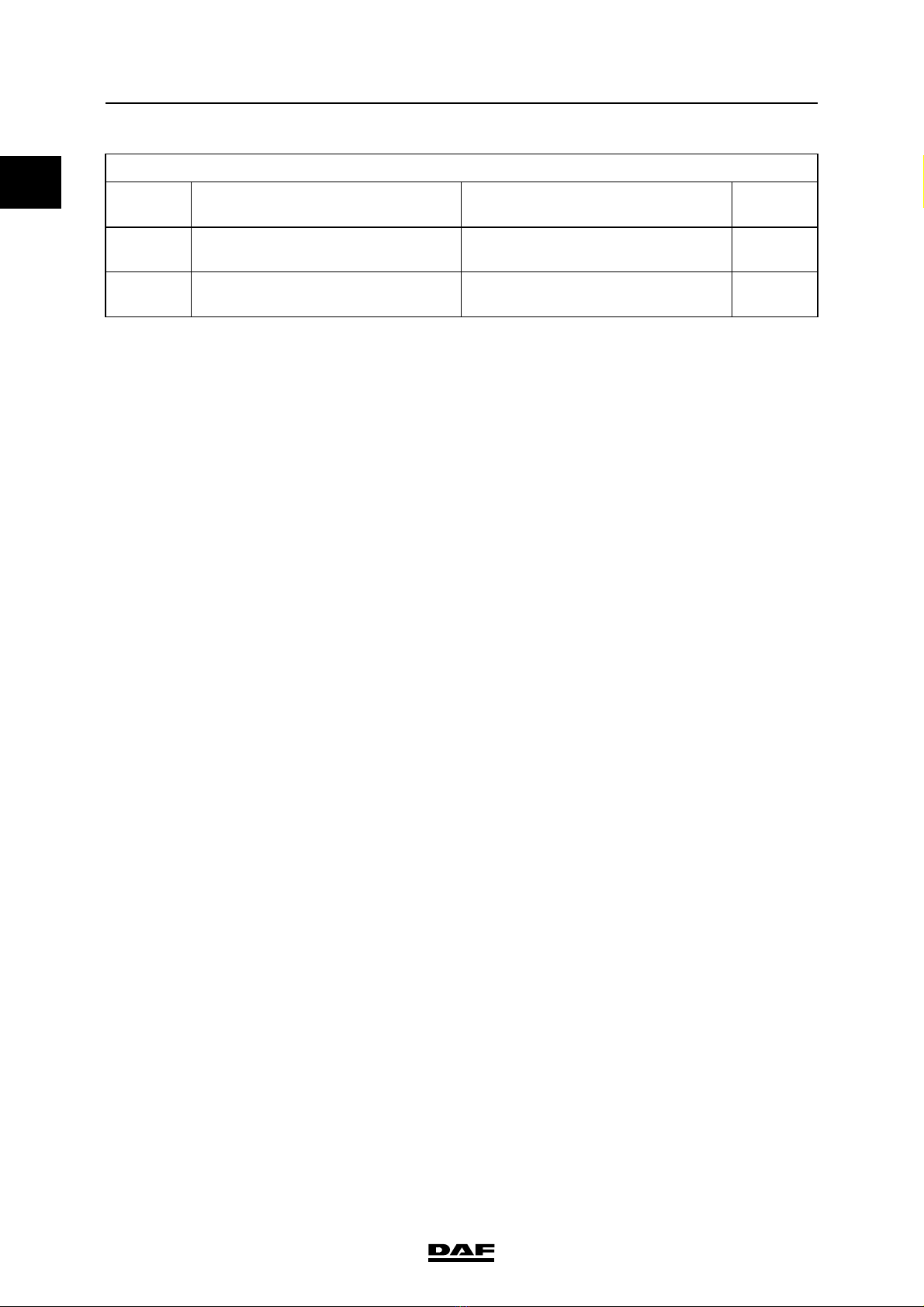

OVERVIEW OF SEALING COMPOUNDS

Product

name

Properties Applications DAF

number

Dirko D - Resistant to temperatures up to

180″C

- Resistant to oil, coolant

Sealing of surface connections 1345014

Loctite

510

- Resistant to temperatures up to

200″C

- Resistant to oil, brake fluid,

coolant

Sealing of surface (flange)

connections that are subjected to high

operating temperatures, such as the

flywheel housing

0697149

Loctite

574

- Resistant to high pressures (up to

350 bar)

- Resistant to oil, brake fluid,

coolant

Sealing of surface connections

against high pressures

1246867

Loctite

Blue

- Resistant to temperatures from

60″C to 260″C

- Resistant to oil

Sealing of flexible constructions such

as (valve) covers

1242895

Loctite

ultra grey

- Silicone sealant, good resistance

to coolant

- Resistant to temperatures up to

325″C

Sealing of (surface) connections in

the cooling system

1284123

Loctite

ultra

copper

- Silicone sealant, good resistance

to oil

- Resistant to temperatures of up

to 350″C

Sealing of surface connections such

as hub covers

1284122

Loctite

5910

- Silicone sealant, good resistance

to oil

- Resistant to temperatures up to

200″C

Sealing of surface connections, such

as front and rear covers of gearboxes,

differential housings, hub covers, stub

axle flanges and oil cooler

1360102

Loctite

572

- Seals against low pressure

immediately after fitting

Threaded connections 0292336