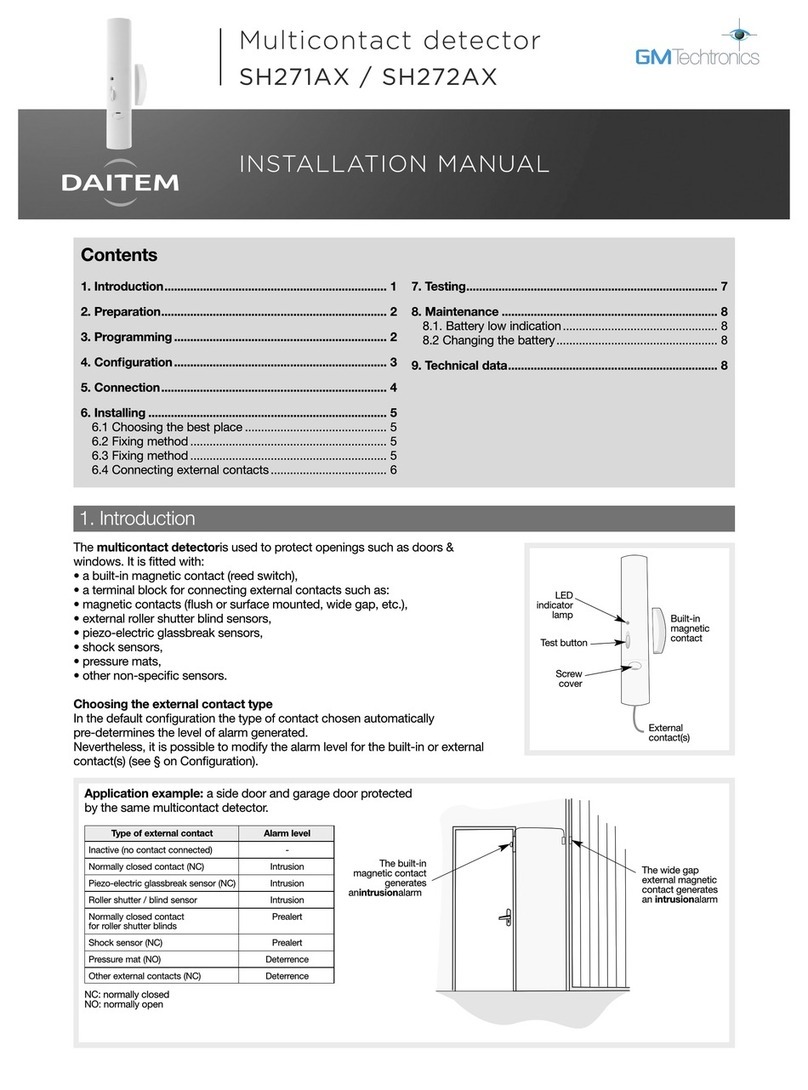

Cover

Magnet

Spacers

Base

Detector

Magnet holder

Spacers

Spacer

3. f necessary use the spacer

supplied for the magnet

holder or position a spacer

below the normally closed

detector.

Fix the magnet holder base,

place the magnet inside the

cover and clip it to the base.

4. Clip and then screw

the detector to its

base. Fit the screw

head plug (supplied

with the bunch of

plastic parts for the

magnet holder) to the

cover.

slot-arrow alignment

ax :

5 mm

35 mm

Overview of opening and closing distances between the

contact detector and the magnet used by the built-in

contact to analyse any change in entrance status.

15 mm

9 mm

12 mm

7 mm

15 mm

8 mm

12 mm

6 mm

Built-in contact opening and closing distances

ovement Contact

status

opening

closing

23 mm

11 mm

22 mm

11 mm

opening

closing

34 mm

20 mm

24 mm

9 mm

24 mm

15 mm

19 mm

8 mm

opening

closing

Spacing

Vertical

sliding

Horizontal

sliding

Wooden support Soft iron support

t

t

t

t

t

t

t

t

t

t

5. Testing

)))))

I PORTANT: the control panel must be in installation

mode for testing.

“beep, detecto X,

g oup Y immediate

(o delayed

o combined)”

The contact detector has a “test” mode for testing:

• the battery: the LED indicator lamp lights up when the test

button is pressed to indicate the battery is working

correctly,

• detection: the LED indicator lamp lights up when the

contact changes status,

• the radio link: see § on Checking the radio links described

in the control panel manual.

Screw cover

To unclip the magnet holder cover, insert a small flat-headed screwdriver into the slot provided

and turn.

about

5 sec. about 10 sec. about

2 sec.

about 10 sec. 2 1 or 2

Press 2 times

depending

on the equi ed

pa amete numbe .

Press the test 1 or 2 times to

select the equi ed pa amete .

• 1: inactive

• 2: active.

Finish the

p og amming by

p essing the test button

until the led is off.

LED lights

fo 2 seconds

to confi m valid

p og amming.

Press and hold and then

elease the test button as

soon as the LED lights fo

the 2nd time.

Commence

the sequence

by p essing the test button

until the LED is off.

I PORTANT: in accordance with the new functional requirements of EN50131-2-6, the LED is factory defaulted to be Inactive in

Test ode. To change this parameter, programme: