8. Maintenance

8.1 Battery low indication

The control panel indicates when the multicontact detector’s

battery is low.

To check whether there is a problem with the detector

battery, press on the detector’s test button.

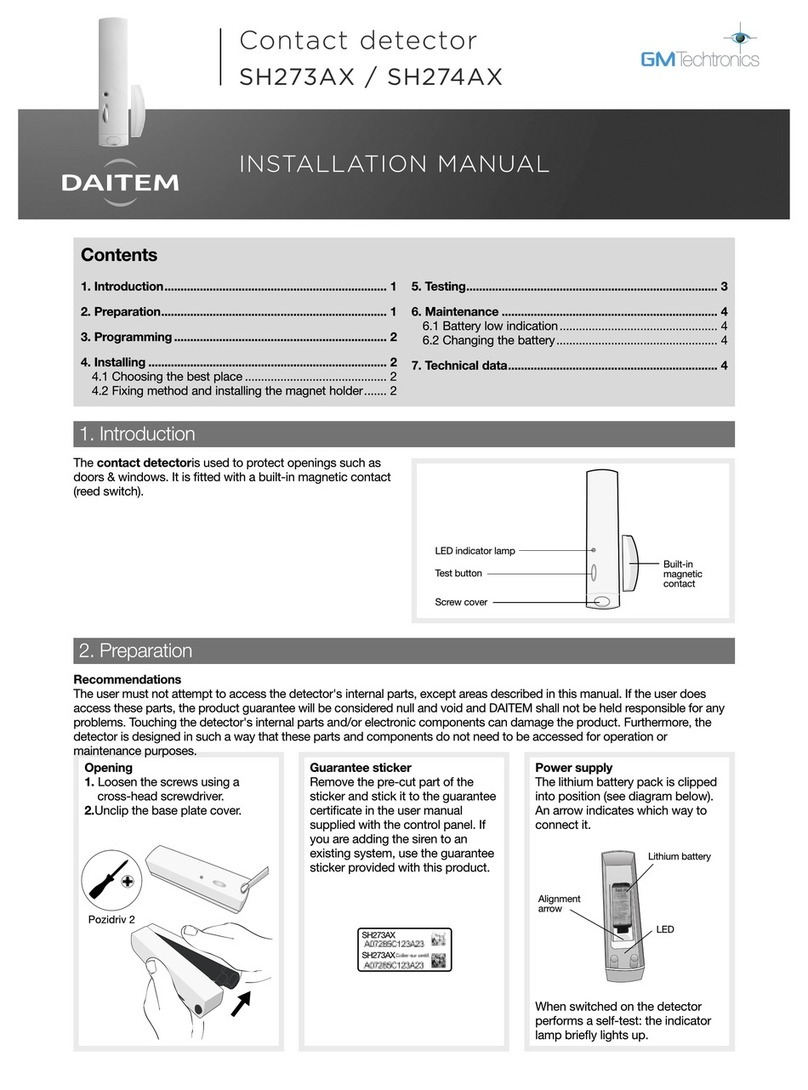

Recommendations

The user must not attempt to access the detector's internal

parts, except areas described in this manual. f the user does

access these parts, the product guarantee will be

considered null and void and DA TEM shall not be held

responsible for any problems. Touching the detector's

internal parts and/or electronic components can damage the

product. Furthermore, the detector is designed in such a

way that these parts and components do not need to be

accessed for operation or maintenance purposes.

I PORTANT: if the test LED indicator

lamp no longer lights up, the lithium

battery should be replaced.

9. Technical data

Specifications ulticontact detector

Built-in magnetic contact 1

Terminal block for external contact 1

Environment building interior

Power supply DA TEM 3.6 V lithium battery

Battery life 5 years in normal conditions of use

Average humidity rate 5% to 75% without condensation

at 25°C

Radio links TwinBand®400/800 MHz

Test button battery and detection

LED ndicator lamp 1

Operating temperature -10 °C to +55 °C

Anti-tamper & protection • against opening and removal

• against loop cutting

Degrees of mechanical protection P 31/ K 04

Dimensions L x W x H 138 x 26 x 30 mm

Weight (with battery) 70 g

DECLARATION OF CONFOR ITY

Manufacturer: Hager Security SAS

Address: F-38926 Crolles Cedex - France

Product type: ulticontact detector

Trade mark: Daitem

We declare under our sole responsibility that the product to which this

declaration relates is compliant with the essential requirements of the

following directives:

• R&TTE Directive: 99/5/EEC

• Low voltage directive: 2006/95/EC

• Directive ROHS: 2002/95/EC

in compliance with the following harmonised European standards:

This product can be used in all EU, EEA Countries

and Switzerland.

Crolles, 02.01.2013 Signature:

Patrick Bernard

Director of Research and Development

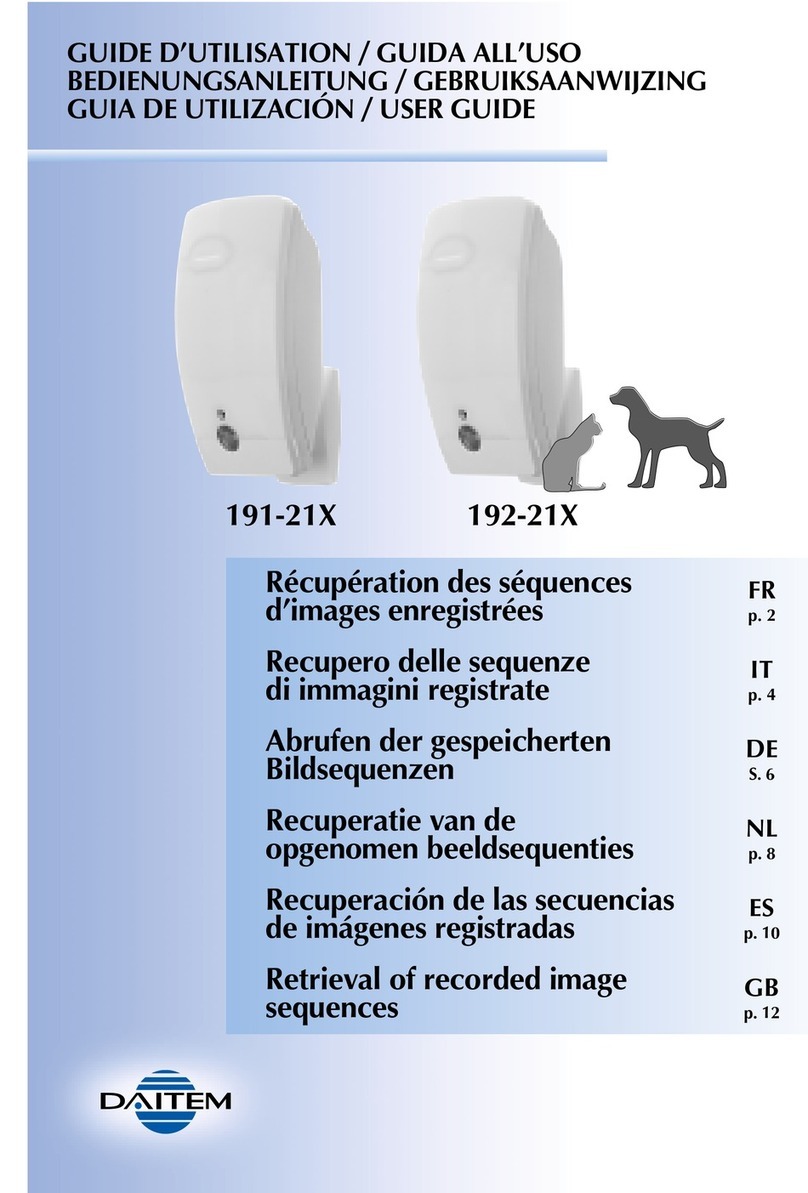

Products code SH271AX SH272AX

EN 300 220-2 V2.3.1 X X

EN 55022 & 55024 (2002) X X

EN 50130-4 (95) + A1 (98) + A2 (2002) X X

EN 60950 (2006) X X

EN 301 489-1 V1.8.1 X X

GB

13

Non-contractual document, may be modified without prior

notice.