Page 2of 39

Contents

1. Introduction .................................................................3

1.1 Supported Lights........................................................3

1.2 Lighting Specification..................................................4

1.3 Pre-Installation Responsibilities and component packing list....4

1.4 Packing List .............................................................4

1.5 Essential adjustment information....................................6

2. Operation Guide Section ..................................................7

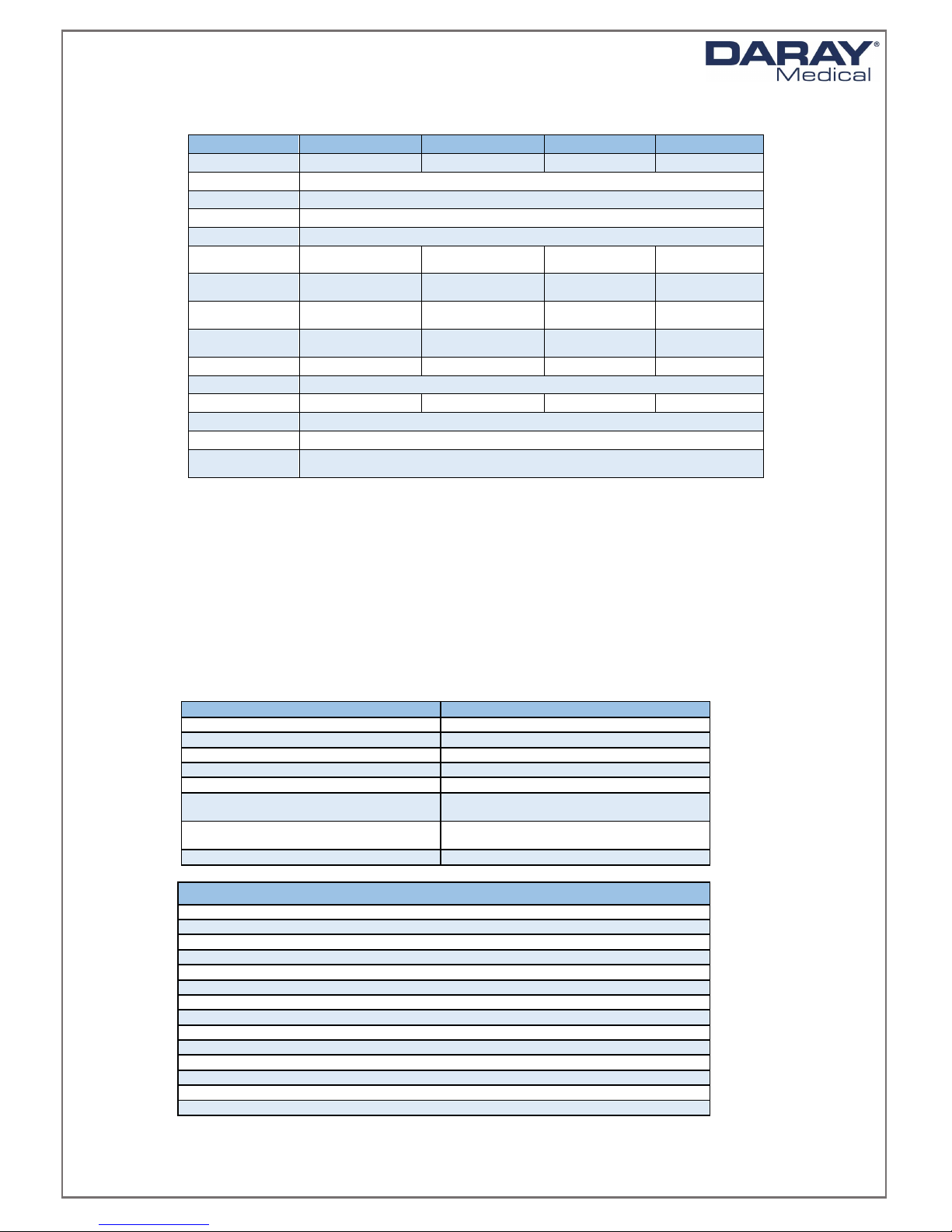

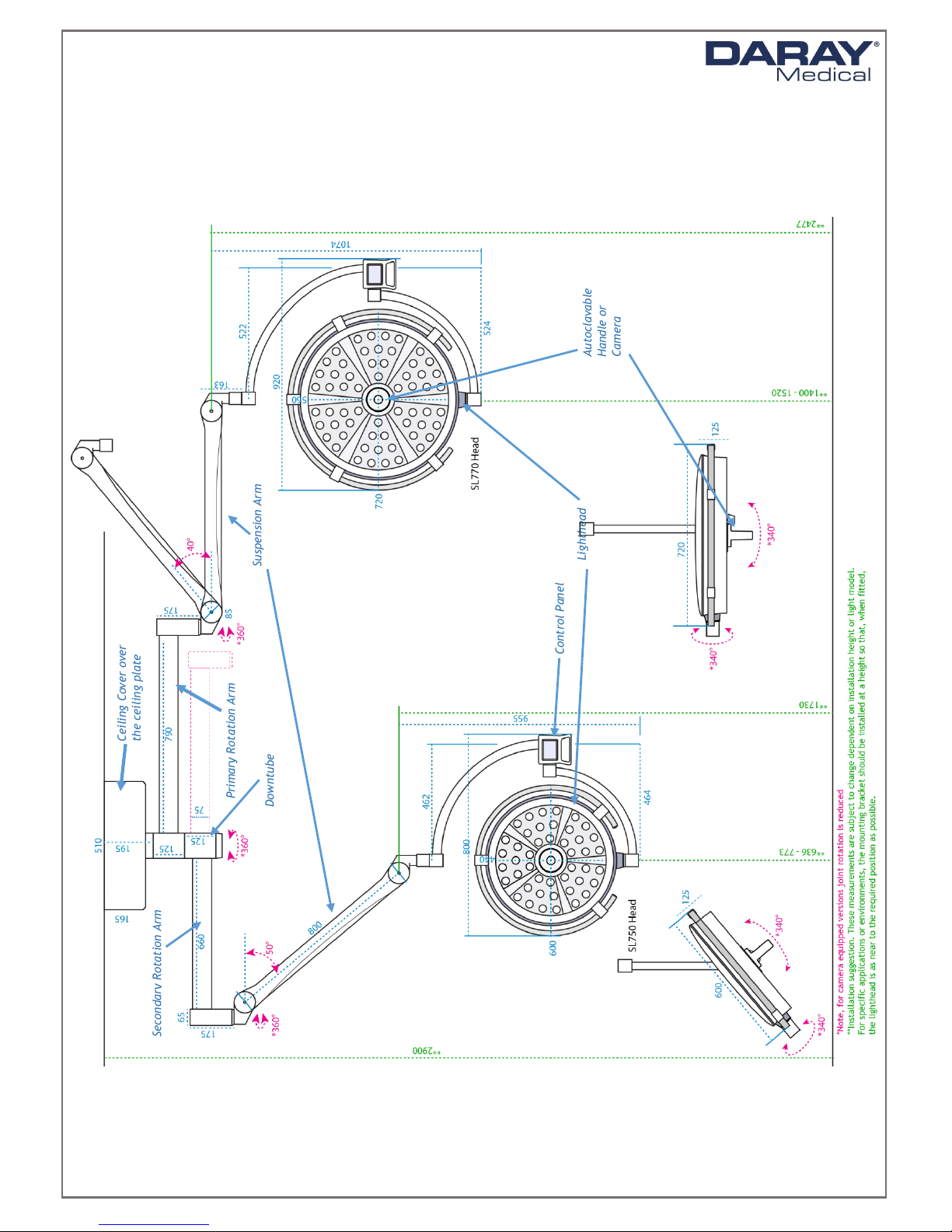

2.1 Range of Motion ........................................................8

2.2 Pre-Start Checks........................................................9

2.3 Battery Back-up ........................................................9

2.4 Powering On & Variable Intensity....................................9

2.5 Adjusting the Lighthead ............................................. 10

2.6 The SL7 Camera ...................................................... 11

2.7 How to operate the Monitor and Camera Attachments ......... 12

3. Installation Guide Section............................................... 13

3.1 Considerations ........................................................ 14

3.2 Ceiling Mounted Lights .............................................. 15

3.2.1 Attachment methods and void suspension ..................... 15

3.3 Lighting configuration ............................................... 15

3.3.1 Affixing the Ceiling plate ......................................... 15

3.3.2 Wiring and transformer layout ................................... 16

3.3.3 Fixing the arms and main installation .......................... 18

3.3.4 Mounting the Monitor Bracket.................................... 20

3.3.5 Lighthead Attachment ............................................ 21

3.3.6 Lights with Camera’s and monitor displays .................... 23

3.3.7 Attaching the Camera ............................................. 24

3.3.8 Attaching the Ceiling Cover ...................................... 25

3.4 Wall Mounted Bracket Assembly ................................... 26

3.4.1 Considerations...................................................... 26

3.4.2 Placement and Installation ....................................... 27

3.5 Mobile Mount Assembly.............................................. 30

4. Maintenance............................................................... 33

4.1 Maintenance schedule ............................................... 33

4.2 Safety Precautions ................................................... 33

4.3 Fuses and their replacement ....................................... 33

4.4 Product cleaning & care guidelines................................ 34

4.5 Adjustments........................................................... 35

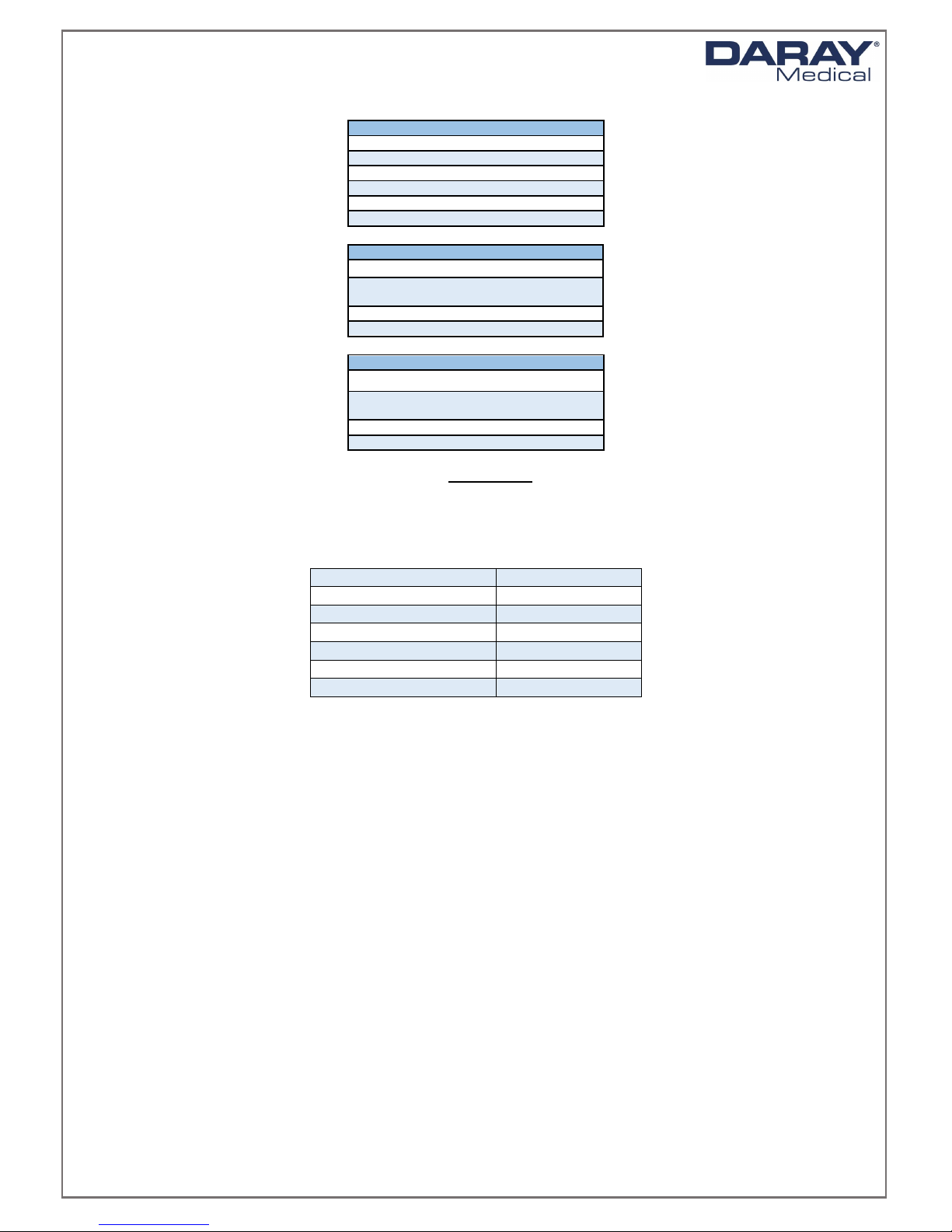

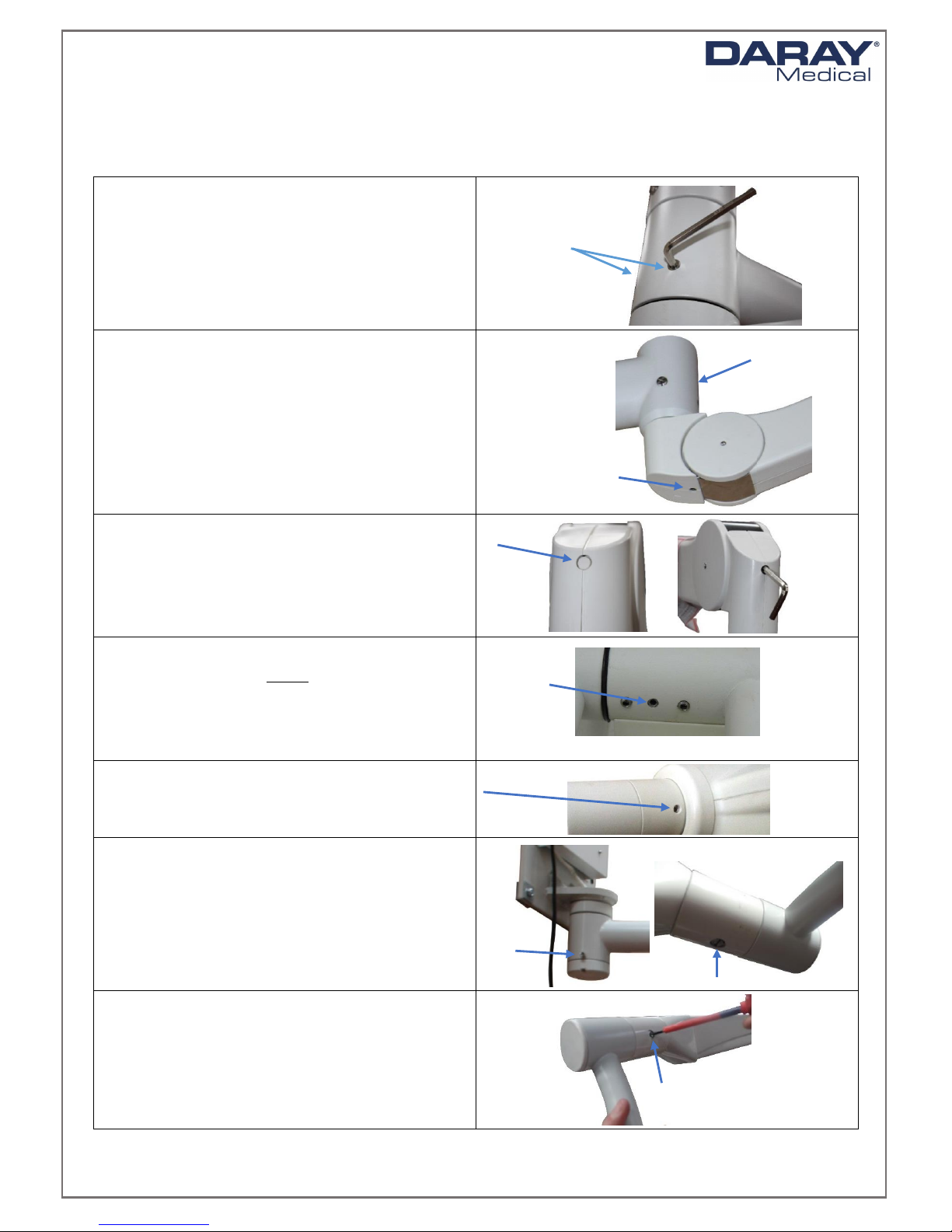

4.5.1 Ceiling and Wall Mounted Adjustments ......................... 35

4.5.2 Mobile Adjustments................................................ 36

4.5.3 Replacing the LED Bulbs .......................................... 36

5. Troubleshooting Guide................................................... 37

6. Camera & Monitor Troubleshooting Guide ............................ 38

7. Replacement Parts ....................................................... 38

8. Warranty Information .................................................... 39

8.1 Returns Policy......................................................... 39

8.2 Warranty Details...................................................... 40