4

1. GENERAL DESCRIPTION

The DARAY Illumin8 SL200 is a powerful minor-surger light which is available in wall, ceiling

or mobile versions. The SL200 differs from its predecessor in having variable intensit and a

more robust method of mounting the light-head.

The SL200 is for use during minor procedures, although it is also suitable for diagnosis where

a powerful light of natural da light colour is required. The light uses a sophisticated

reflector to produce a ‘clean’ light-patch with virtuall no heat in the beam. A

pol carbonate diffuser gives good shadow reduction whilst protecting the light-head’s

components. A BioProtect

®

handle is provided. All surfaces are smooth to aid cleaning and

sterilisation.

The SL200C comprises 4 parts: a ceiling mount containing a transformer to convert mains

voltage to a safe low voltage to power the light, a variable intensit controller and a

suspension arm and a light-head.

The SL200W each comprises 4 parts: a wall mounting containing a transformer to convert

mains voltage to a safe low voltage to power the light, a variable intensit controller and a

suspension arm and a light-head.

There are 2 versions of the wall mounted power-suppl module: one for use where the

mains-electrical suppl cables are ‘chased’ into a wall, and the other fitted with an IEC inlet

so the mains ma be supplied via a plug-in flex from a standard mains socket.

The SL200M comprises 3 parts: a base, an up-stand with a control box containing a variable

intensit controller and a transformer to convert mains voltage to a safe low voltage to

power the light, a suspension arm and a light-head assembl .

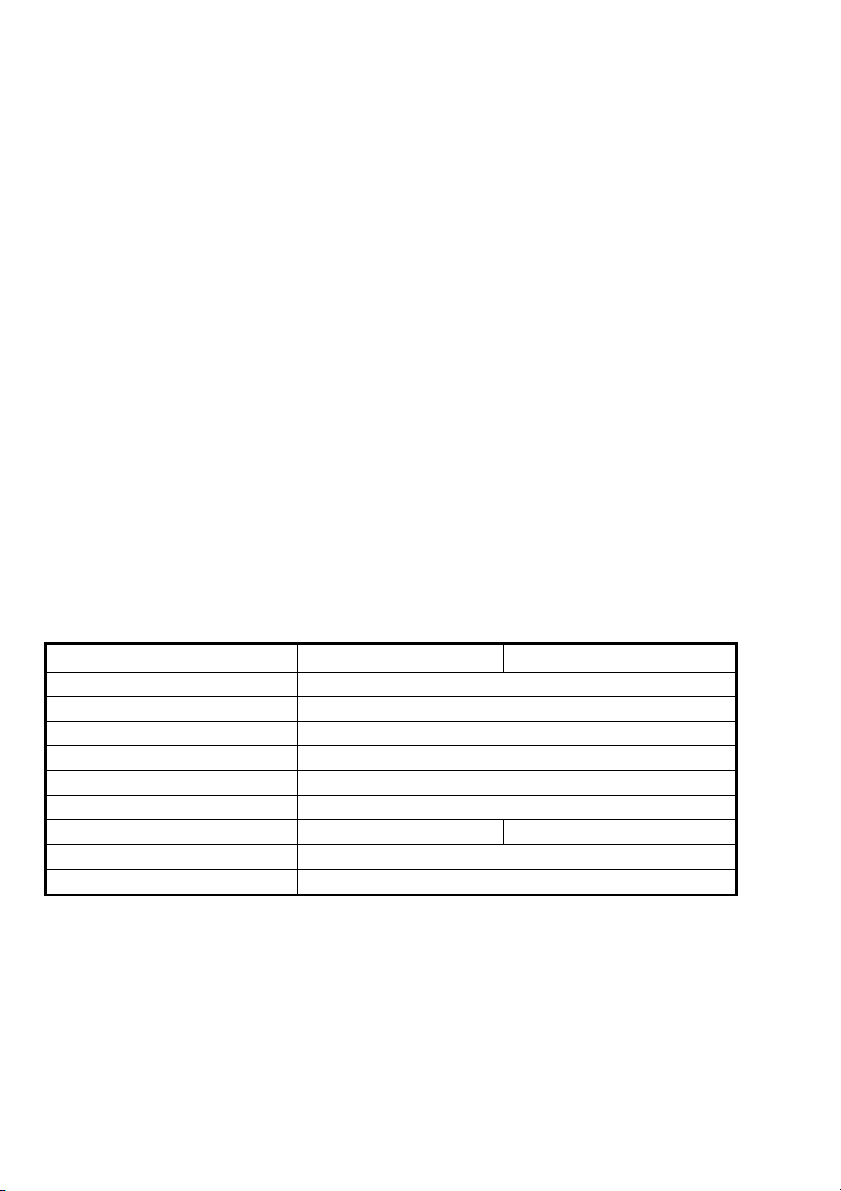

2. SPECIFICATION

230 V 50 Hz mains, class 1 (earthed)

Jib arm vertical movement

Device Directive 93/42/EEC, EN60601

Serial Numbers and Labelling

Each SL200 is assigned a unique serial number located on the mounting arm, and is also

identified b a label on the arm.

The power-suppl module carries its own identification and serial number.