-4-

143415 - Silage King Blade (01-June-2022)

Operation

1. Wheel Spacing

Important: To avoid possible damage from

over stressing tractor axles, use no tire combination

which results in overall width greater than the

width of the angle blade.

Important: Before beginning operation, turn

the wheel fully to the right and left to be sure there

is sufficient clearance between the tires and the

angling cylinders. If necessary, move the wheels

to a wider setting to provide clearance. See your

Tractor Operator's Manual.

2. Rear Wheel Weight and Tire Inflation:

Add necessary rear end weights for efficient

operation and safety. Any of the cast-iron weights

recommended for your tractor or liquid in the tires,

may be used for necessary ballast. Be sure the

weight is distributed equally on each rear wheel.

Inflate front and rear tires to proper pressure as

recommended in the Tractor Operator’s Manual for

heavy front-mounted implements.

3. Checking Hydraulic Oil Level:

Check the oil level in the tractor hydraulic system

daily. Refer to your tractor operator's Manual for

Instructions. Keep the oil supply up to the proper

level. Before checking oil supply, fully extend

and retract angle and lift cylinders 3 - 4 times and

return the blade to the ground.

TRACTOR PREPARATION

NOTE: Please refer to the assembly section of this

manual - for full instructions for attaching your

specific tractor and blade model.

ATTACHING THE DOZER BLADE

Before beginning operation, bleed the hydraulic

system to remove any air. To do this, cycle the

hydraulics several times by holding the cylinder

fully extended for several seconds. This will cause

any trapped air to be purged from cylinder.

BLEEDING THE HYDRAULICS

To assure smooth operation in cold weather, cycle

the cylinders several times to warm the oil in the

hydraulic system.

COLD WEATHER OPERATION

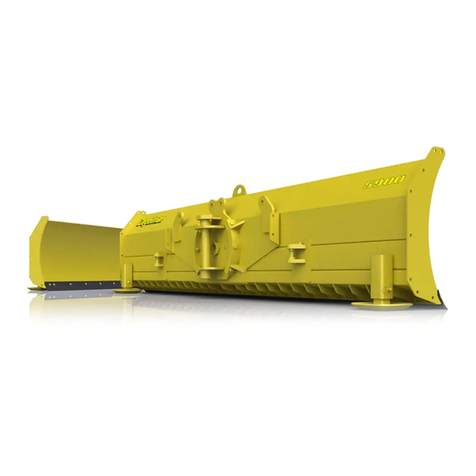

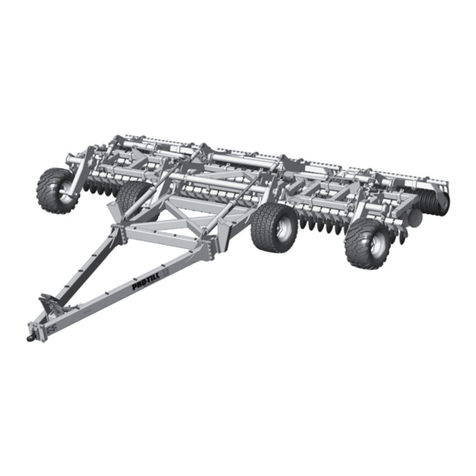

The Degelman Silage King Dozer Blade is a push

type tractor attachment designed primarily for

working with silage.

It is the owners or operators responsibility to read

this manual carefully to learn how to operate

the machine safely and how to set it to provide

maximum efficiency. Safety is everyone’s business.

By following safe operating practices, a safe

environment is provided for the operator and

bystanders.

The manual will take you step-by-step through

your working day. By following the operating

instructions in conjunction with a good

maintenance program your machine will provide

many years of trouble-free service.

TO THE NEW OPERATOR OR OWNER

Although there are no operational restrictions on

the Dozer Blade when it is new, there are some

mechanical checks that must be done to ensure

the long term integrity of the unit. When using the

machine for the first time, follow this procedure:

A. Before using:

1. Read Operator's Manual.

2. Lubricate all points shown in the

Maintenance Section.

3. Check all bolt tightness.

B. After operating for 2 hours:

1. Check all hardware.

2. Check all hardware tightness.

3. Check all hydraulic system connections.

Tighten if any are leaking.

C. After operating 10 hours:

1. Repeat Step B.

2. Go to the service schedule as outlined in the

Maintenance Section.

BREAK-IN

The dozer blade consists of a blade/cutting edge

unit attached to a pivot-main frame combination

suspended from the tractor by the front and side

mount brackets. By driving the tractor forward with

the blade straight and allowing the cutting edge to

run along or just under the ground surface - silage

or other material is relocated as desired.

PRINCIPLES OF OPERATION