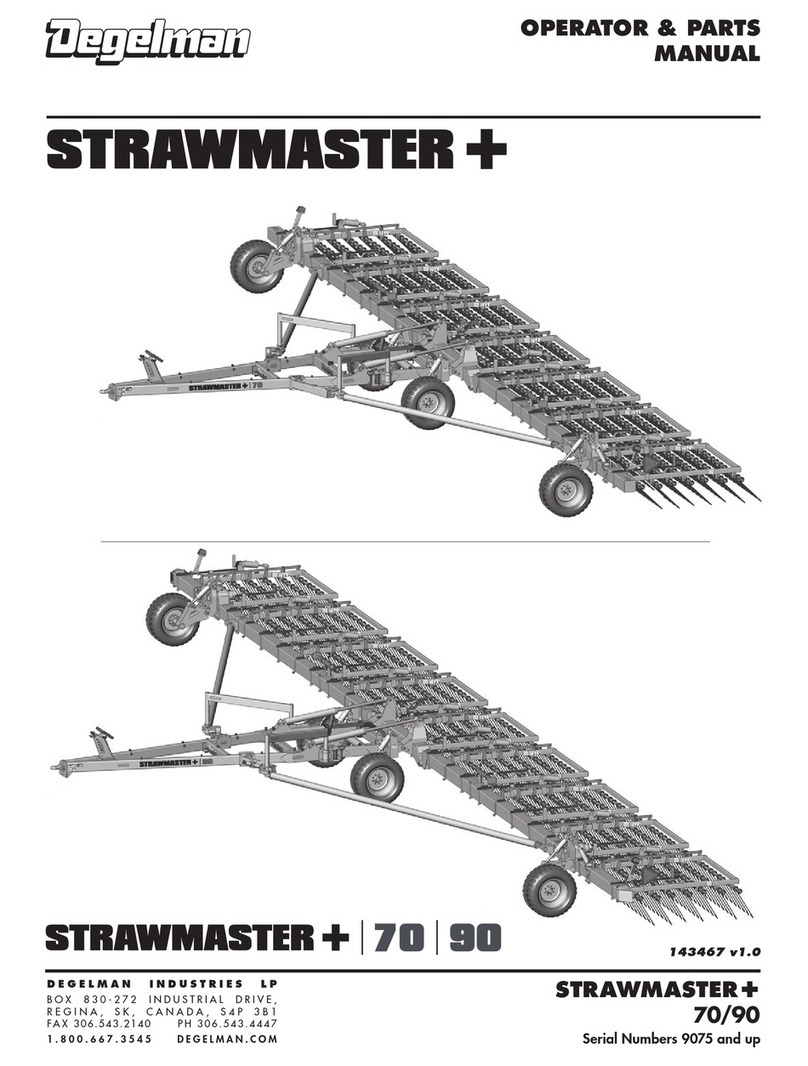

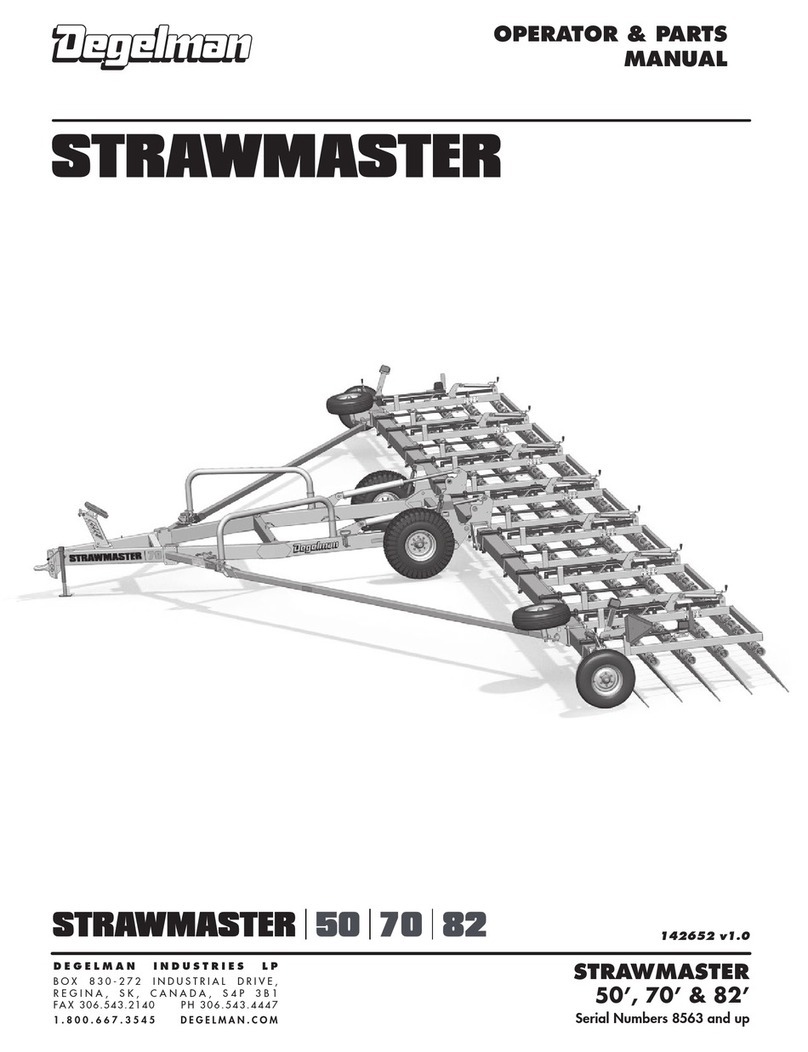

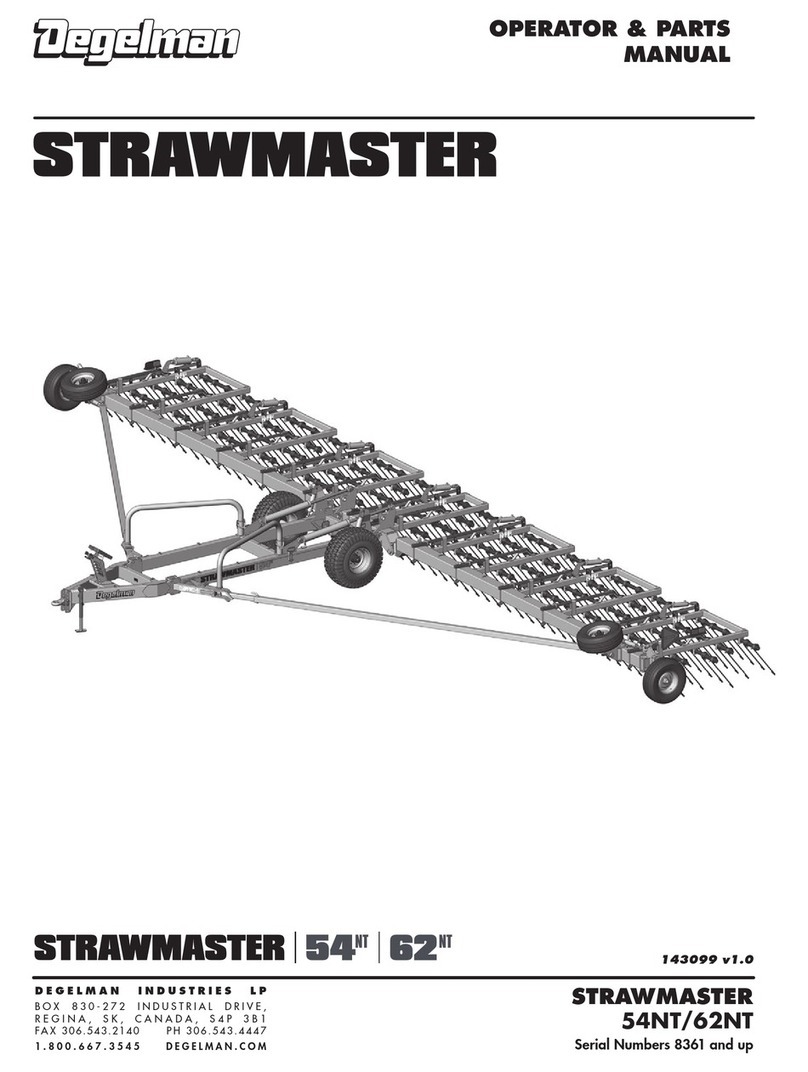

CSetting Tine Angle, Pressure & Frame

NOTE: Strawmaster®can have either manual or hydraulic adjustment. Trailer height & tine angle are set by either ratchet/sidewind jacks or hydraulics.

When trailer height is set correctly,

it will be even with harrows and...

Front & back tines apply equal pressure Front tines not applying pressure Front tines applying too much pressure

If trailer is too high... If trailer is too low...

Hydraulic or Manual (with the use of two ratchet jacks, located on trailer wheel arms)

Trailer Height Adjustment

To manually adjust trailer height:

• Begin with the machine in field position. Make sure the tine angle has been set (if necessary).

• Using the ratchet jack handle for adjustment, adjust ratchet jacks evenly until tines are set to the desired height.

• When adjustments are complete, check that the trailer frame is parallel to the ground.

• If not, adjust clevis height and re-check. Repeat if necessary.

Tine Angle Adjustment

There are no standard angles for running the tines, the operator may

adjust the tine angles as needed to achieve desired results.

Manual models - Use the manual jacks

located on each harrow section. Start

at one end, set as desired. Set all the

other sections to the same setting.

(Manual shown)

Hydraulic models - Retract

rephasing tine angle

cylinders to raise tines.

Extend cylinders to lower.

Note: Actual settings will vary

with tine wear. Ensure trailer

and frame are leveled properly.

(Refer to Height Adjustment)

Wing Beam Height Adjustment

• The Wing beams and Center beam

should be at the same height, parallel to

the ground.

• Adjust the wing beam height when the

tine angles are adjusted, the trailer height

is adjusted, or as the tines wear down.

Manual models:

Use the manual jacks

to raise or lower the

wing beam section until desired

height/level is achieved.

Fine Adjustment

Hydraulic models:

Adjust the fine adjustment

rod located on the top of

the endwheel linkage until

desired height/level is

achieved.

Remember When Operating:

• Straw should be dry.

• A speed of 8 to 12 MPH (12 to 16 KPH) is suggested

to efficiently shatter and spread straw and residue.

• The harrow sections can be set in float position, where

the section drags the ground under its own weight.

• If machine leaves clumps of straw, apply slight down

pressure by extending hydraulic lift cylinders.

FIELD PACKING

4321

BREAKING &

SPREADING STRAW 4321

CHEMICAL INCORPORATION 4321 RAKING 4321

The following are suggested tine angle settings only, adjust as required:

Refer to Operator’s Manual for more suggested tine angle setting info.

1) Turn the transport wheel’s spindle over so the rear transport tires will be completely upright (both sides).

2) Operate the lift hydraulics to fully raise the harrow sections.

3) Carefully drive forward. The wing beams should fold back into transport position.

4) Install the frame transport pins (both sides). On hydraulic models, also install the cylinder transport pins (both sides).

5) On the 50’ model with a telescopic truss beam, shorten length into transport position and secure with pin.

6) Ensure SMV sign and reectors are cleanand lights are working. Follow all local transport laws when transporting.

DMoving Into Transport Position

1

• Check for missing, worn or damaged parts.

• Working points & pins

Maintenance

(Check Machine Daily)

• Hydraulic Connections & Hoses

• Hubs & Spindles

* Refer to operators manual for complete safety and operation info.

Hydraulic models - Re-syncronize the tine section cylinders by fully

extending the rephasing cylinders and holding for 30 seconds.

This should be repeated a few times daily or as needed.

1