Delta DFC-304R3-240 User manual

Other Delta Controllers manuals

Delta

Delta RMC150 User guide

Delta

Delta VFD-L User manual

Delta

Delta C2000 Series User manual

Delta

Delta DAC-633 User manual

Delta

Delta VFD-B Series User manual

Delta

Delta RMC70 User guide

Delta

Delta ASDA-A2 Series User manual

Delta

Delta AH Series User manual

Delta

Delta ASDA-A2 Series User manual

Delta

Delta VFD-L Series User manual

Delta

Delta 5CN-220T Series User manual

Delta

Delta VFD7A5MS23ANSHA User manual

Delta

Delta DVP30EX2 User manual

Delta

Delta VFD-E User manual

Delta

Delta DVP-ES2 User manual

Delta

Delta DVP-15MC Series User manual

Delta

Delta AH Motion Series User manual

Delta

Delta AH500 series Owner's manual

Delta

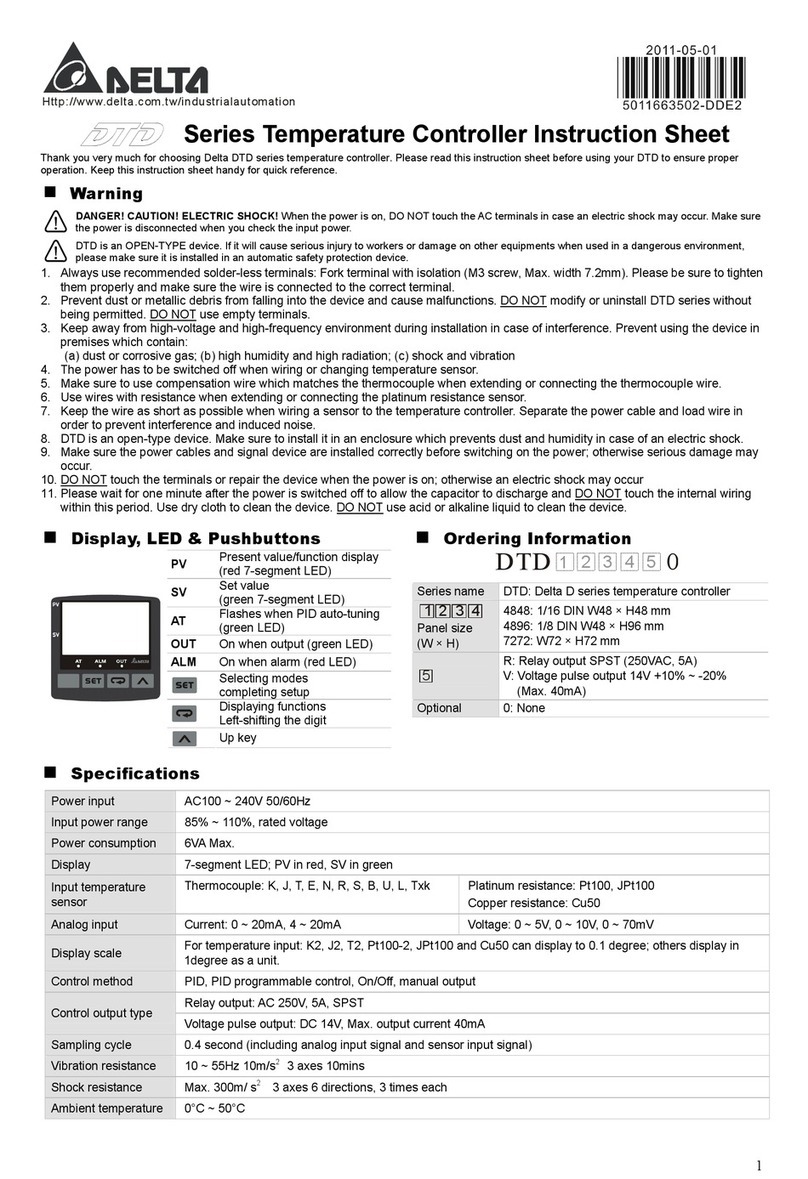

Delta DTD Series User manual

Delta

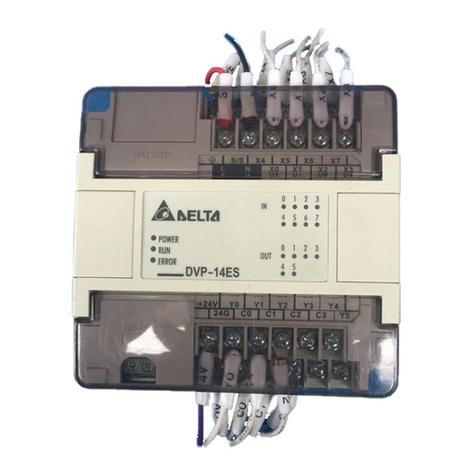

Delta DVP14ES00R2 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions