3.4 Wiring

Please note that:

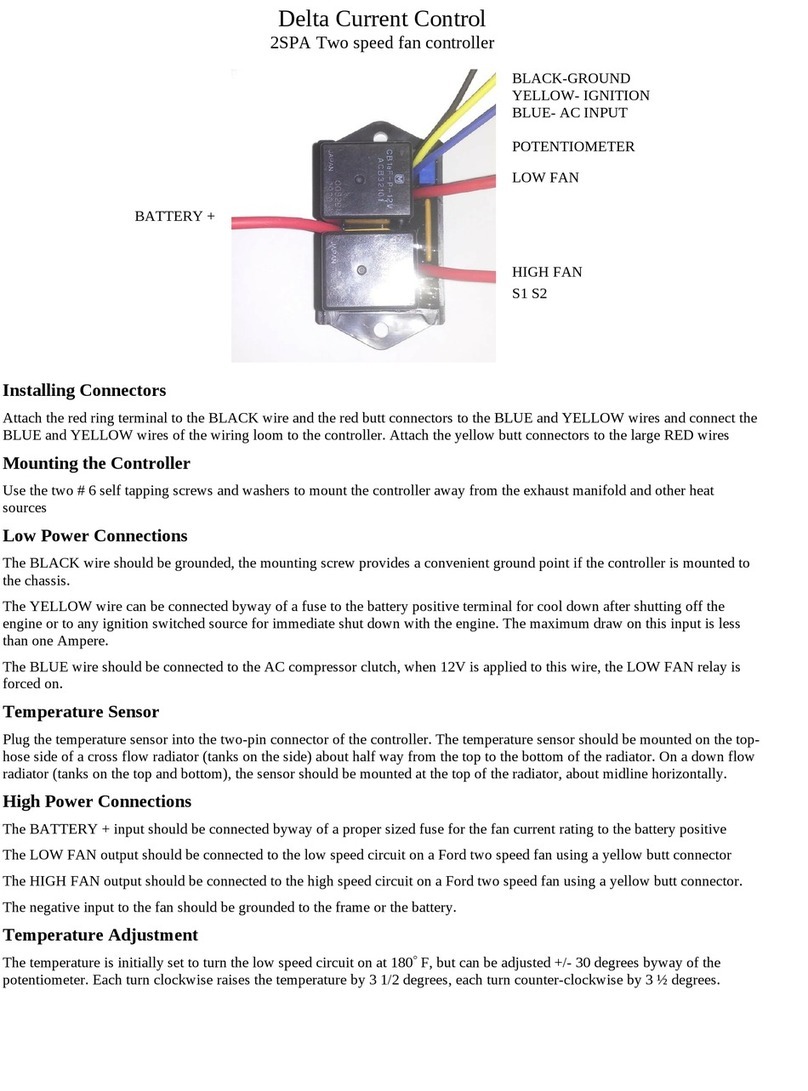

1. Use O-type or Y-type terminal. See the figure in the right for its

specification. PLC terminal screws should be tightened to 5 ~ 8

kg-cm (4.3 ~ 6.9 in-Ibs) and please use only 60/75 ºC copper

conductor.

2. DO NOT wire empty terminal •

3. DO NOT drop tiny metallic conductor into the PLC while screwing

and wiring. Tear off the sticker on the heat dissipation hole for

preventing alien substances from dropping in, to ensure normal

heat dissipation of the PLC.

To suit M3.5 screw terminals

Below 6.2

Below 6.2

3.5 Power input wiring

The power input of DVP-EH2 series is AC. When operating the PLC, please make sure that:

1. The input voltage should be current and its range should be 100VAC ~ 240VAC. The power should be

connected to L and N terminals. Wiring AC110V or AC220V to +24V terminal or input terminal will result in

serious damage on the PLC.

2. The AC power input for PLC MPU and I/O extension modules should be ON or OFF at the same time.

3. Use wires of 1.6mm (or longer) for the grounding of PLC MPU.

4. The power shutdown of less than 10 ms will not affect the operation of the PLC. However, power shutdown time

that is too long or the drop of power voltage will stop the operation of the PLC and all outputs will go OFF. When

the power supply turns normal again, the PLC will automatically return to its operation. Please be aware of the

latched auxiliary relays and registers inside the PLC when programming.

AC Power Input

L N

2.0 A

DC/DC +5V

+24V 24G S/S X0 X1 X2

100~240VAC

0.5A is the maximum power supply for +24V power supply output terminal. DO NOT connect other external

power supplies to this terminal. Every input terminal requires 6 ~ 7mA to be driven; e.g. the 16-point input will

require approximately 100mA. Therefore, +24V cannot give output to extermal load that is more than 400mA.

3.6 Safety wiring

Since a PLC controls many devices, actions of any device may affect actions of other devices and the breakdown

of any one device may cause the breakdown of the whole auto-control system and danger. Therefore, we suggest

you wire a protection circuit at the power input terminal, as shown in the figure below.

c

AC power supply load

d

Power circuit protection fuse (3A)

e

Power indicator

f

Emergency stop

This button can cut off the system power supply when accidental

emergency takes place.

g

System circuit isolation device

The device is made of electromagnetic contactor and relay as the

switch to prevent the instability of system when the power is

intermittently supplied.

h

DVP-PLC (main processing unit)

i

Earth

MC

MC

NL

4

5

6

8

Guard

Limit

j

Power supply

AC: 100 ~ 240VAC, 50/60Hz

3.7 Input point wiring

There are two types of DC inputs, SINK and SOURCE.

Input point loop equivalent circuit Wiring loop

DC Signal IN

S/S

X0

Sinking

SINK mode

(common port for current input

S/S)

24VDC

24G

X0

S/S

+24V SINK

+5V

24G S/S X0 X1 X2+24V

Sink Type

Input point loop equivalent circuit Wiring loop

DC Signal IN

S/S

X0

Sourcing

SOURCE mode

(common port for current

output S/S)

24VDC

24G

X0

S/S

+24V SOURCE

+5V

24G S/S X0 X1 X2+24V

Source Type

3.8 Output point wiring

Relay (R) contact circuit wiring

Y0

RY

LED

C0

LOAD

POWER

DVP-**-**-**-R

RELAY OUTPUT

2

3

1

C0 Y0 Y1 C1 Y3 Y4 C2 Y6

9

6

c

Flywheel diode: To extend the life span of contact d

Emergency stop: Uses external switch

e

Fuse: Uses 5 ~ 10A fuse at the common port of output contacts to protect the output circuit.

f

Varistor: To reduce the interference on AC load g

Empty terminal: not in use

h

DC power supply i

Neon indicator

j

AC power supply k

Incandescent light (resistive load)

l

Manually exclusive output: Uses external circuit and forms an interlock, together with the PLC internal program, to ensure

safety protection in case of any unexpected errors.

Transistor (T) contact circuit wiring

Y0

LED

C0

< 0.5A

2

3

1

C0 Y0 Y1 C1 Y4 Y5 Y6 Y7

4

3

4

c

DC power supply d

Emergency stop

e

Circuit protection fuse f

Flywheel diode + inductive load

g

Manually exclusive output: Uses external circuit and forms an interlock, together with the PLC internal program, to ensure

safety protection in case of any unexpected errors.

[Trial Operation

Power indication

The “POWER” LED indicator on the front panel of PLC MPU (or extension module) will be on (in green) when the

MPU is powered. That the MPU is powered but the indicator is not on indicates that the 24VDC power supply of the

PLC is overloaded. You have to remove the wiring at terminal +24V and 24G and have another DC24V power

supply ready. That the “ERROR” LED indicator flashes continuously indicates that the +24V power supply for the

PLC is insufficient.

Low voltage indication

That the “LOW.V” indicator on the front panel of the PLC extension module is on indicates that the input voltage is

insufficient. All outputs of the module are disabled at this time.

Preparation

1. Before powering DVP-EH2, be sure that you have checked if the I/O wiring is correct. You may damage the

PLC if AC110V or AC220V is directly supplied to input terminals or the output wiring is short-circuited.

2. When the peripheral devices are used to write program into PLC: If the ERROR indicator does not flash, the

program you are using is legal and PLC is waiting for RUN instruction from you.

3. You can use HPP to test “force On/Off” of output contacts.

Operation & test

1. If the ERROR indicator does not flash, you can use RUN/STOP switch or peripheral device (HPP or WPLSoft)

to give RUN instruction and the RUN indicator should be continuously on at this time. That the RUN indicator

does not flash indicates PLC has no program in it.

2. When PLC is in operation, use HPP or WPLSoft to monitor the set value or temporarily saved value in the

timer, counter, and register and force On/Off of output contacts. That the ERROR indicator is on (not flashes)

indicates that part of the program exceeds the preset time-out. In this case, you have to check the program

and set On/Off of the power again (PLC automatically returns to STOP status at this time).

I/O response time

How to calculate the response time from the input signal to output operation of the PLC:

Response time = input delay time + program scan time (executed by the user) + output delay time

Input delay time 10ms (default); 0 ~ 60ms (adjustable). See the reference on how to use special register

D1020 ~ D1021.

Program scan time See the reference on how to use special register D1010.

Output delay time Approx. 10ms for relay modules, 20 ~ 30us for transistor modules

\How to identify abnormality of PLC

To identify abnormality from the indicators on the panel, please check:

POWER indicator

When PLC is powered, the POWER indicator on the front panel will be on (in green). If this indicator is not on when

the PLC is powered, remove the wiring of +24V terminal. If this indicator turns on at this time, the +24V DC output

is overloaded. In this case, DO NOT use DC power supply at +24V terminal and have another DC24V power

supply ready. If this indicator turns off after the overload is eliminated, your PLC is malfunctioned. Send your PLC

back to your distributor for repair.

RUN indicator

Check your PLC status. When PLC is running, this indicator will be on. You can use HPP, the ladder diagram

editing program or the switch on the panel to RUN or STOP PLC.

ERROR indicator

1. If you enter illegal program into PLC or use instructions or devices that exceed their range, this indicator will

flash (approx. every 1 sec.). When this happens, you have to obtain the error code from D1004 and save the

address where the error occurs in register D1137 (if the error is a general circuit error, the address of D1137 will

be invalid). Find out the cause of the error, amend the program and resend the program to PLC. If you cannot

connect to PLC and this indicator keeps flashing quickly (approx. every 0.2 sec.), there should be insufficient

24VDC power supply. Please check if the 24VCD is overloaded.

LFor details of error codes (in D1004, hex coding), see “DVP-PLC Application Manual: Programming”

2. If the ERROR indicator keeps flashing, you have to check the special relay M1008. M1008 is on indicates that

the execution time of program loop exceeds the preset time-out (in D1000). In this case, turn the RUN/STOP

switch to STOP, check the special register D1008 and obtain the location in the program where the time-out

takes place. We suggest you use WDT instruction to correct this problem.

BAT.LOW indicator

BAT.LOW indicator will be on when the battery is in low voltage. When this happens, change the battery as soon as

possible in case your program and data saved in the latched area will be lost.

LThe changing of battery has to be completed within 1 minute when the PLC is not powered in order to save your

procedures and data in the PLC.

After the power is switched off, the data in the latched area are stored in SRAM memory and its power is supplied

by the battery. Therefore, when the battery is in low voltage and the power-off has been lasted for more than 1

minute, the data in the latched area will be lost. If you need to permanently save the data in the latched area in the

program and device D, refer to “Flash ROM permanently saved and recover mechanism” as stated below.

Permanently saved mechanism

You can use WPLSoft (Options -> PLC<=>Flash) to indicate whether to permanently store the data in the

latched area in Flash ROM memory (new indicated data will replace all data previously saved in the memory).

Recover mechanism

If the battery is in low voltage (before the power is switched off when the BAT.LOW indicator is on) and the

power is off for more than 1 minute, PLC will automatically restore the data in the latched area in the program

and device D of Flash ROM into SRAM memory next time when it is re-powered.

Battery life:

Temperature (ºC) 0 25 50 70

Life (year) 9 8 6 5

Input indicator

On/Off of input point is indicated by input indicator or monitored by HPP. When the action criteria of the input point

are true, this indicator will be on. If abnormality is identified, check if the indicator and input circuit are normal.

Output indicator

On/Off of output point is indicated by output indicator. When the output indicator (On/Off) does not correspond to

the action of its load, please be aware of the follows:

1. The output contact may be melted or blocked out of overloading or short-circuited load, which will result in poor

contact.

2. If you are suspicious that the output point may execute undesired action, check the output wiring circuit and

whether the screw is properly tightened.

Accuracy (month/second) of RTC

Temperature (ºC/ºF) 0/32 25/77 55/131

Max. inaccuracy (second) -117 52 -132

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or

download the most updated version at http://www.delta.com.tw/industrialautomation