DEMA Trapper User manual

I-1246 Page 1 of 9

Rev. E-43816 3/23/18

Trapper

Drain Maintenance/Odor Control Chemical Dispensing

Overview

The DEMA® Trapper is a digital chemical dispenser that is designed to deliver chemicals for both drain and odor

control. The system will operate from wall or battery power.

Warnings

InstallationofDEMAproductsmustmeetallapplicableelectricalcodesandregulationsestablished

bynational,city,county,parish,provincialorotheragencies.Itispossiblethatelectricalcodesand

regulationsrequirethatacertifiedelectricalcontractororengineerperformtheelectrical

installation.Forquestions,contactacertifiedelectrician.

Allinstallationsmustconformtolocalplumbingcodesanduseapprovedbackflowprevention

devices.Apressureindicatingteeistobeinstalledwithexistingfaucetsaccordingtolocalplumbing

codesinthestateofWisconsinandanyotherstatethatrequirestheuseofapressureindicating

tee.

ALWAYSWEARPROTECTIVECLOTHINGANDEYEWEARWHENWORKINGWITHCHEMICALPRODUCTS.

I-1246 Page 2 of 9

Rev. E-43816 3/23/18

Trapper Models

Trapper can be ordered with the following configurations:

Drain or Odor Control

AC wall power (115/230VAC) or Battery Power

Three different squeeze tube choices

2507B.E

BaseSystem

2508A=TrapperOC‐w/115VAC(OdorControl)

2508B=TrapperOC‐BatteryOperated(OdorControl)

SqueezeTube

E=EPDMSqueezeTube

P=Supertube(PVCSqueezeTube)

V=VitonSqueezeTube

2507A=Trapper‐w/115VACWallTransformer

2507B=Trapper‐BatteryOperated

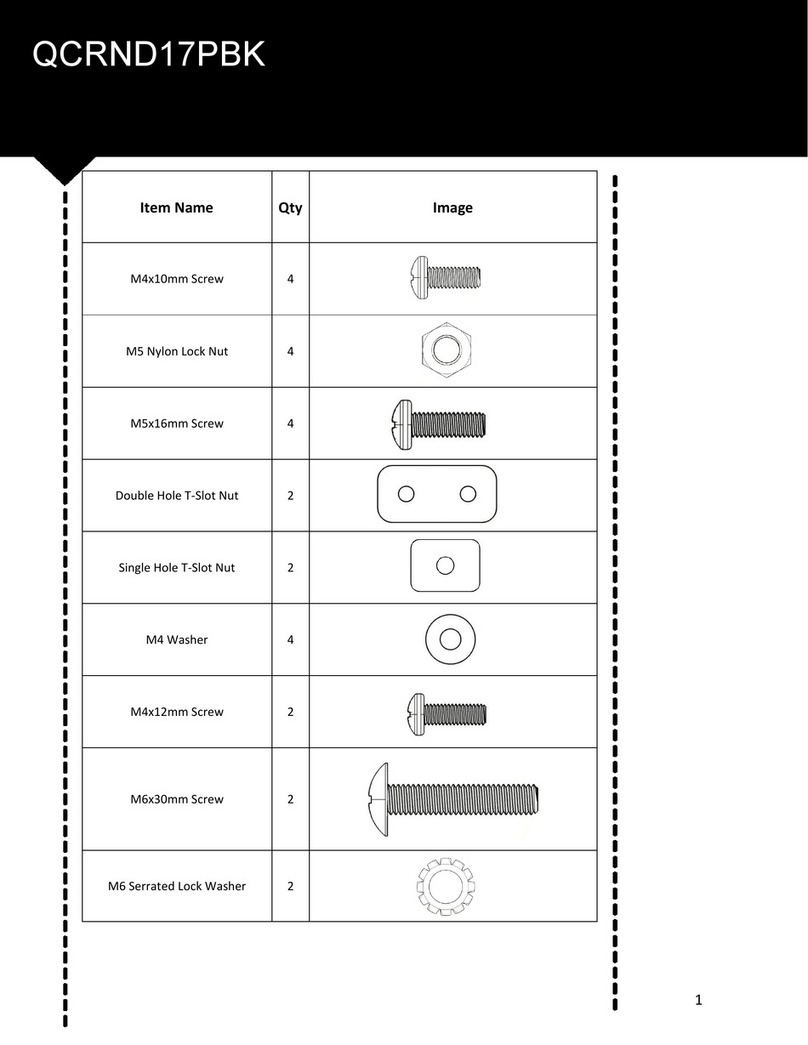

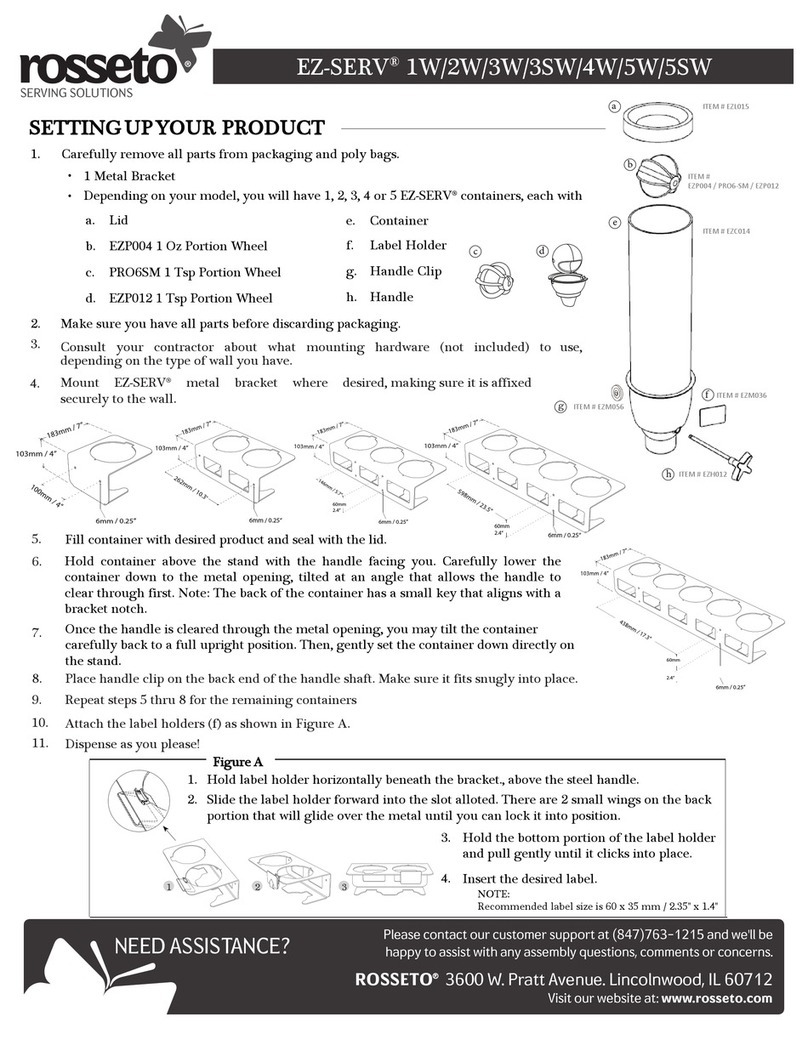

Packing Kit List

InstallationandAccessoryPartsforDrainApplications

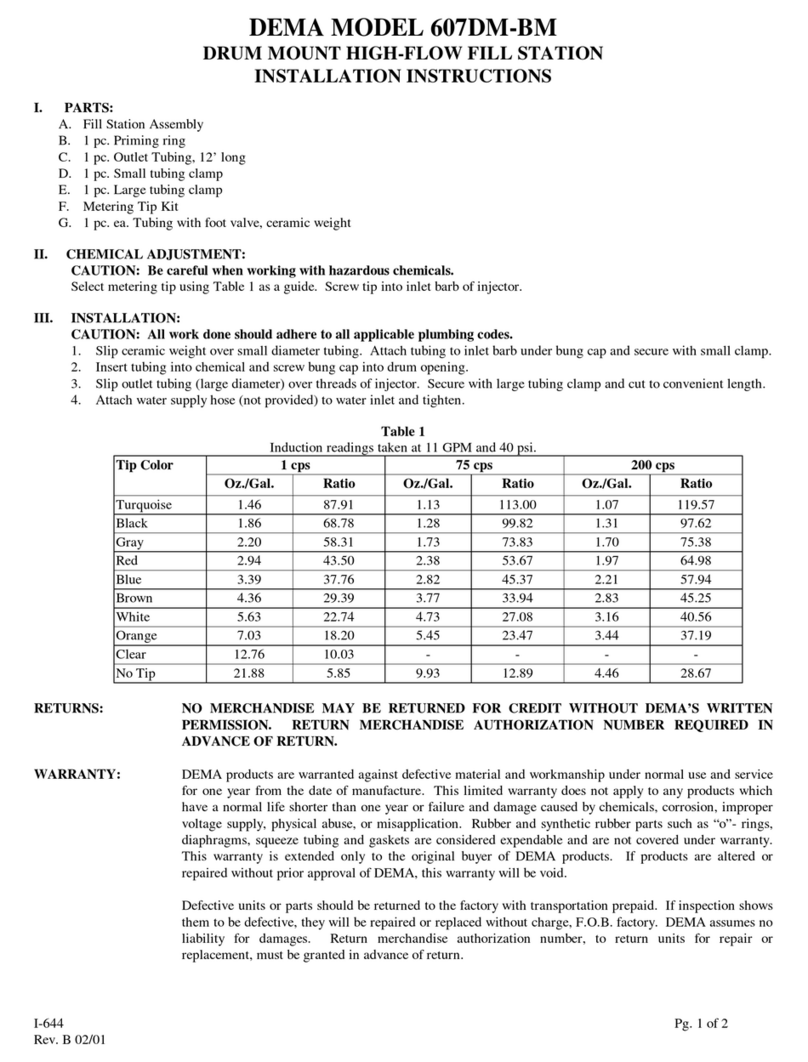

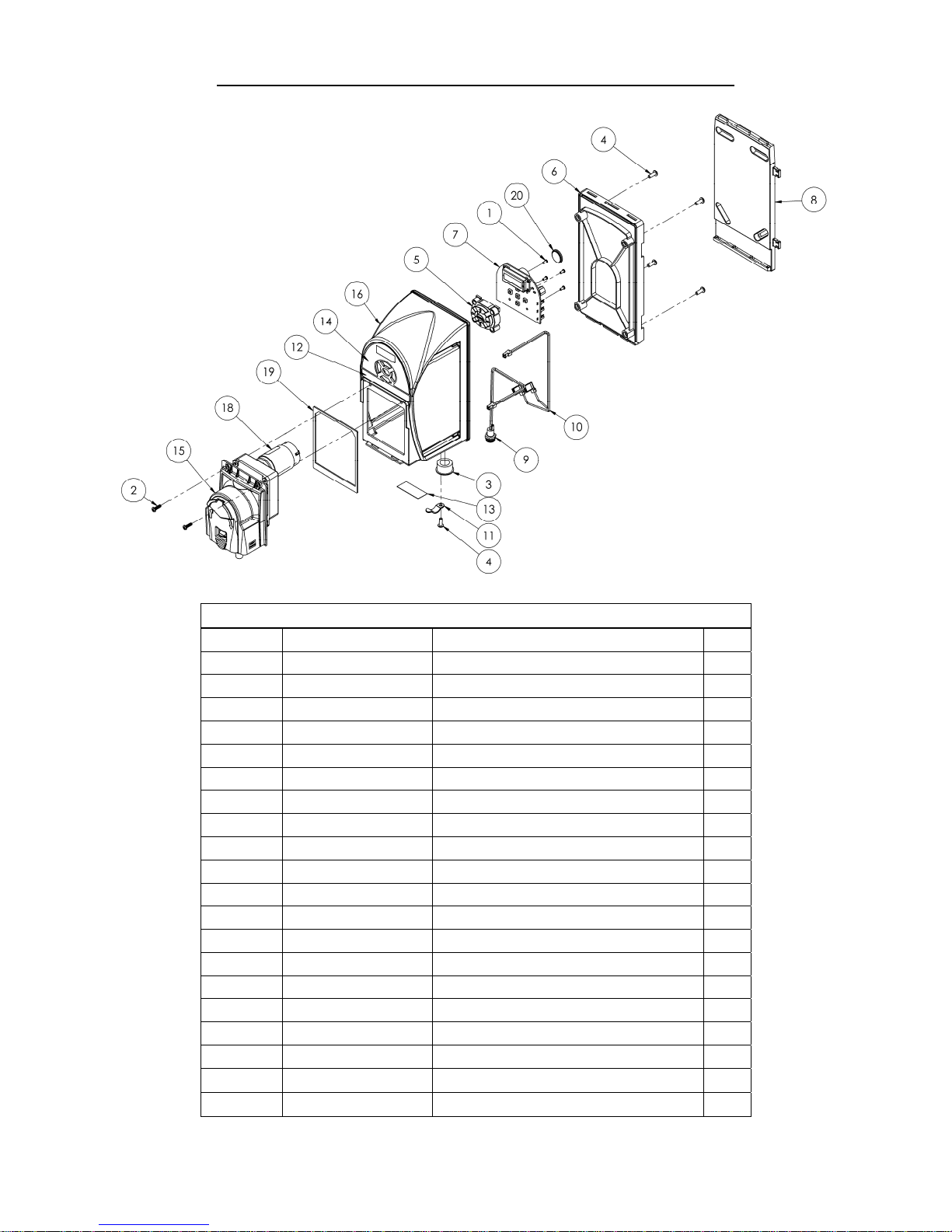

NoPartNo.DescriptionTrapper(Drain)TrapperOC

125‐235‐1CompressionFitting(Drainsystem)1‐

225‐215SprayNozzle(Deodorizingsystem)‐ 1

325‐68‐201/4"LDPETubing20feet11

484‐183‐11/4x1/4QCUnionFittingKit(2unions)11

581‐312‐1TubeStiffener11

6

81‐177‐1SqueezeTubeEPDM1*1*

81‐177‐5SqueezeTubeViton1*1*

81‐177‐10SqueezeTubePVC1*1*

725‐236‐01ACAdapterU.S.A.120Volt1*1*

25‐236‐02ACAdapterInternational120‐240Volt1*1*

866‐123#8Screw&AnchorKit(4pack)1**1**

*SpecificsqueezetubeandACadapteraredeterminedbymodelordered.

**Batterymodelsaresuppliedwithtwoanchorscrewkits.

I-1246 Page 3 of 9

Rev. E-43816 3/23/18

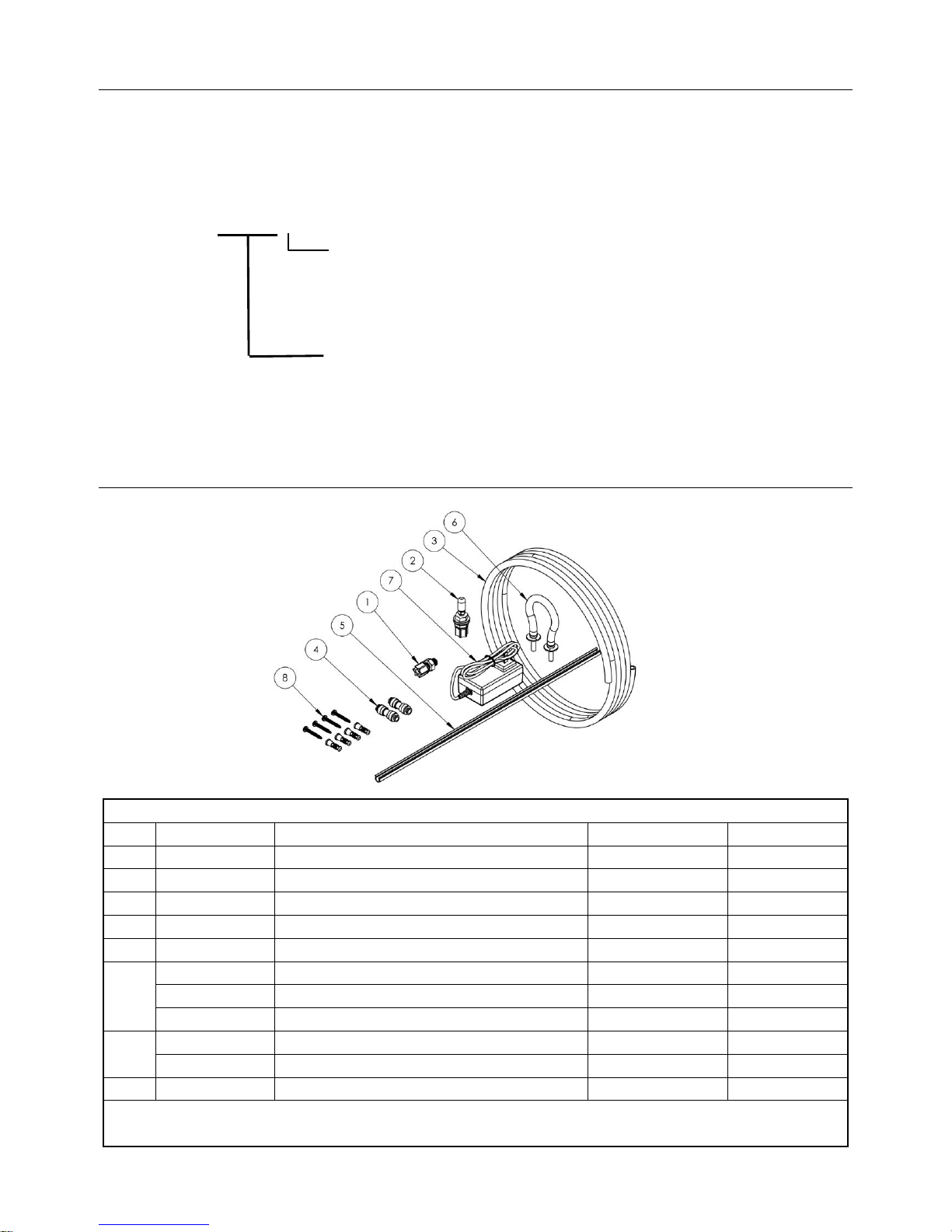

Operational Requirements

FORINDOORUSEONLY

MainPower12VDC‐2.0Aminfrom8xD‐cellbatteries

or115VACor100‐240VACwalladapters

Motor/SolenoidRating12VDC‐1.25Amax.

PumpRate14oz/min(420ml/min)

EnclosureMaterialABS

ShippingWt.(AC)2.3kg5.0lbs.

ShippingWt.(Battery)2.8kg6.1lbs.

InstalledWt.(AC)1.3kg2.7lbs.

(w/batteries)*1.6kg3.4lbs.

*Batteriessuppliedbyuserorinstaller.

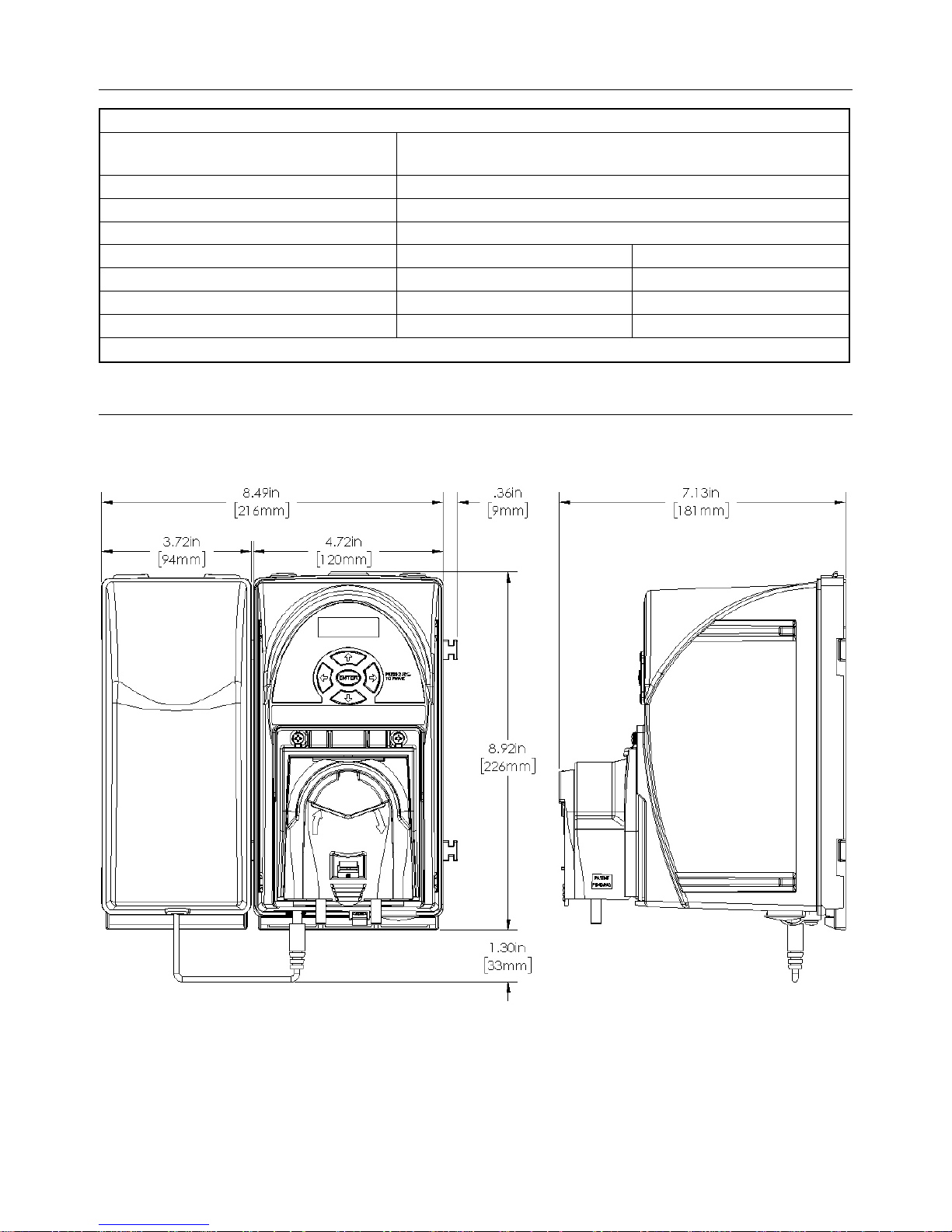

Overall Size

I-1246 Page 4 of 9

Rev. E-43816 3/23/18

Installation

WARNING: INSTALLATION OF DEMA PRODUCTS MUST MEET ALL APPLICABLE

ELECTRICAL CODES AND REGULATIONS ESTABLISHED BY NATIONAL, CITY,

COUNTY, PARISH, PROVINCIAL OR OTHER AGENCIES. IT IS POSSIBLE THAT

ELECTRICAL CODES AND REGULATIONS REQUIRE THAT A CERTIFIED

ELECTRICAL CONTRACTOR OR ENGINEER PERFORM THE ELECTRICAL

INSTALLATION. FOR QUESTIONS, CONTACT A CERTIFIED ELECTRICIAN.

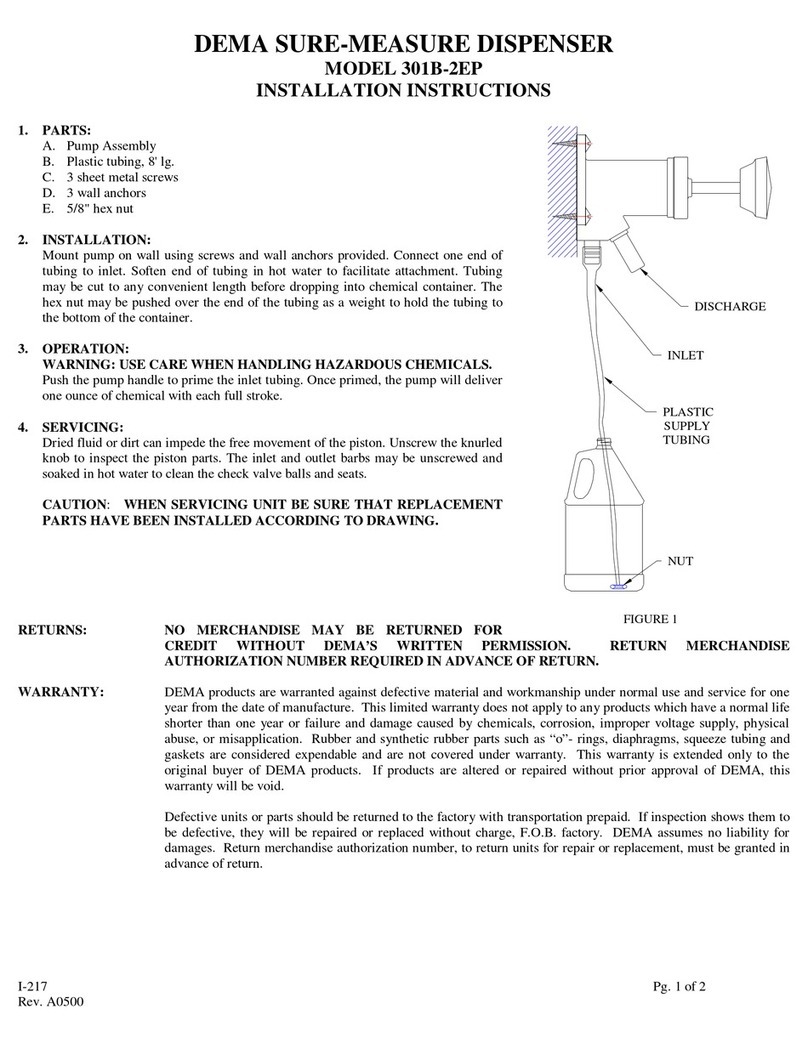

1. Determine a suitable location to mount Trapper. The following should be considered:

a. tubing going to and from the pump

b. chemical location

c. drain pipe injection point

d. Electrical wall outlet when using the plug in AC version.

2. Attach the mounting bracket (included) for the Trapper using appropriate screws and wall anchors.

a. When using the battery operated version, mount the battery enclosure mounting bracket next to the

Trapper mounting bracket. The Trapper and battery mounting brackets can be meshed together to

create a single mounting bracket installation.

3. If using a battery version, install 8 “D” cell heavy duty batteries in the battery holder.

4. Mount the Trapper pump and battery enclosures on the mounting bracket.

5. Install injection fitting (drain application) or spray nozzle (deodorizing application).

a. Drain Application: Install the ¼” compression fitting to the desired drain pipe.

i. Note: Alternative saddle or pipe fittings can be used; Trapper is setup to use ¼” LDPE

tubing.

b. Deodorizing Application: Install the spray nozzle so that it will mist over the desired area to be

treated.

6. Install the ¼” LDPE tubing from the chemical to the pump and from the pump to the drain pipe fitting or spray

nozzle fitting.

a. Note: The Trapper pump is setup with ¼” push on fittings for easy connection.

7. Apply power to the Trapper by plugging the 115/230VAC wall power plug or the battery module to the round

electrical power connector on the bottom of the Trapper.

a. There is a plastic clip near the power connector to retain the power cable to secure the power line

from coming disconnected.

8. Program the Trapper (see programming section in this instruction manual).

9. Prime the pump.

a. Press any button 1 time to wake up the control.

b. With the display on, press and hold the right arrow for 2 seconds to start prime.

c. Press again to stop prime.

I-1246 Page 5 of 9

Rev. E-43816 3/23/18

Use U

p

and Down Button to move throu

g

h menu

Programming for Drain Application

MONDAY 11:23

POWER LEVEL 100%

CLOCK STYLE

24hr

CURRENT TIME

11:24

CURRENT DAY

MONDAY

SELECT MODE

DRAIN

SELECT SMTWTFS

DAYS ON *******

CHARGES PER DAY

02

CHARGE# START

01 01:30 AM

RUN TIME mm:ss

01:30

ENTER PASSCODE

0000

Idle screen – Day, Time and Power Level for Battery Life Option –

Press ENTER to access programming.

Enter the passcode to access programming and press ENTER –

default passcode out of the box is “0000”

AUDIBLE ALERT

NO

CHANGE PASSCODE

0000

EXIT PROGRAMMING

PRESS ENTER

Select 12 or 24hr clock format - Press ENTER, use LEFT and

RIGHT to select 12hr or 24hr clock format, Press ENTER to save.

What is the current time? Press ENTER. Use LEFT and RIGHT to

move to hours and minutes and UP and DOWN to change the hour

and minute. Press ENTER to save.

What is the current day of the week? Press ENTER. Use UP and

DOWN button to select the day. Press ENTER to save.

Is this a Drain or Deodorizer application? Press ENTER, use LEFT

and RIGHT button to select Drain or Deodorizer. Press ENTER to

save.

What days should the pump run? Press ENTER, use LEFT and

RIGHT to move through days. The asterisk (*) signifies that the

pump will run that day. Use UP to add asterisk and DOWN to

remove the asterisk. Press ENTER to save.

How many pump operations per day? Press ENTER, use UP and

DOWN to move through choices. Press ENTER to save up to 24

operations max.

When should the pump operations run? Press ENTER, use UP and

DOWN to select the Charge# and then use the LEFT and RIGHT to

move the time and UP and DOWN to change the charge the start

time. Press ENTER to save up to 24 operations max.

How long should the pump run? Press ENTER, use LEFT and

RIGHT to select minutes and seconds. Press ENTER to save. Run

Time applies to all charges, with maximum of 10 minutes.

Is an audible beep desired for alerting low battery or out of

chemical product (out of product sensor required)? Press ENTER,

use UP and DOWN to select Yes or No. Press ENTER to save.

Modify the passcode? Press ENTER, use LEFT and RIGHT to

select the digit, UP and DOWN to change the value of digit. Press

ENTER to save.

Press ENTER to exit programming.

I-1246 Page 6 of 9

Rev. E-43816 3/23/18

Use U

p

and Down Button to move throu

g

h menu

Programming for Deodorizing Application

MONDAY 11:23

POWER LEVEL 100%

CLOCK STYLE

24hr

CURRENT TIME

11:24

CURRENT DAY

MONDAY

SELECT MODE

DEODORIZE

SELECT SMTWTFS

DAYS ON *******

START STOP

06:00am 11:00PM

FREQUENCY

hh:mm 00:10

RUN TIME mm:ss

01:30

ENTER PASSCODE

0000

Idle screen – Day, Time and Power Level for Battery Life Option –

Press ENTER to access programming.

Enter the passcode to access programming and press ENTER –

default passcode out of the box is “0000”

AUDIBLE ALERT

NO

CHANGE PASSCODE

0000

EXIT PROGRAMMING

PRESS ENTER

Select 12 or 24hr clock format - Press ENTER, use LEFT and

RIGHT to select 12hr or 24hr clock format, Press ENTER to save.

What is the current time? Press ENTER. Use LEFT and RIGHT to

move to hours and minutes and UP and DOWN to change the hour

and minute. Press ENTER to save.

What is the current day of the week? Press ENTER. Use UP and

DOWN button to select the day. Press ENTER to save.

Is this a Drain or Deodorizer application? Press ENTER, use LEFT

and RIGHT button to select Drain or Deodorizer. Press ENTER to

save.

What days should the pump run? Press ENTER, use LEFT and

RIGHT to move through days. The asterisk (*) signifies that the

pump will run that day. Use UP to add asterisk and DOWN to

remove the asterisk. Press ENTER to save.

What window of time should the pump run its routine? Press

ENTER, use LEFT and RIGHT to move to different digits of the

start time and UP and DOWN to adjust hours, min and am/pm.

How often should the pump run? Press ENTER, use the LEFT and

RIGHT to move between hours and minutes, use the UP and

DOWN to adjust the hours and minutes. It can be 5 minutes to

2 hours max.

How long should the pump run? Press ENTER, use LEFT and

RIGHT to select minutes and seconds. Press ENTER to save. Run

Time applies to all charges. It can be 5 seconds to 10 minutes max.

Is an audible beep desired for alerting low battery or out of

chemical product (out of product sensor required)? Press ENTER,

use UP and DOWN to select Yes or No. Press ENTER to save.

Modify the passcode? Press ENTER, use LEFT and RIGHT to

select the digit, UP and DOWN to change the value of digit. Press

ENTER to save.

Press ENTER to exit programming.

I-1246 Page 7 of 9

Rev. E-43816 3/23/18

Replacement Parts and Reference Information

Pump/ControlModuleReplacementParts

ItemNo.DEMAP/NDescriptionQTY.

181‐20‐1#4x1/4"StainlessSteelScrew4

241‐40‐2#6‐32x1/2StainlessSteelScrew2

381‐47‐47/8"HolePlug1

444‐116‐1#8x1/2"StainlessSteelScrew5

581‐147‐15‐ButtonRubberKeypad1

625‐228‐1PumpHousing‐Rear1

725‐231‐1TrapperControlBoard1

825‐227‐1PumpMountingBracket1

925‐252‐1PowerInlet,DC1

1025‐253‐1PowerCable,Motor1

1125‐232‐1RetainerSpringClip‐Nylon1

12L1733‐1Label,Banner1

13L1710‐1RatingLabel1

14L1719‐1UpperLabel‐Control1

15SEETABLEPumpAssembly(withoutmotor)1

1625‐229‐1PumpHousing‐Front1

1781‐16‐1TieWrap(notshown)3

1880‐59‐102MK‐12VGearmotor1

1981‐159‐1Gasket1

2080.99Battery1

I-1246 Page 8 of 9

Rev. E-43816 3/23/18

BatteryEnclosureReplacementParts

ITEMNO.DEMANO.DESCRIPTIONQTY.

125‐222‐1BatteryBoxMountingBracket1

281‐183‐7CableStrainRelief1

325‐224BatteryHousing‐Front1

425‐223‐1BatteryHousing‐Rear1

581‐16‐1CableTie2

625‐251‐1BatteryHolderw/DCPlug‐8D‐cell1

25.221.1–BatteryHolderKit–includesallcomponentslistedabove

(batteriesnotincluded)

I-1246 Page 9 of 9

Rev. E-43816 3/23/18

PumpReplacementParts

ItemNo.DEMANo.DescriptionQTY.

180.59.102MK.12VGearmotor1

281.128.2PumpBase1

325.85.2#10‐32x1/2"StainlessSteelScrew1

4a81.177.1SqueezeTubeAssembly‐EPDM1

4b81.177.5SqueezeTubeAssembly‐Viton1

4c81.177.10SqueezeTubeAssembly‐Supertube1

581.174.1PumpCover2

681.172.32‐RollerBlockAssembly‐Fixed1

Warranty

Merchandise Returns

No Merchandise will be Returned for Credit Without DEMA’S Written Permission. Returned Merchandise

Authorization Number is Required in Advance of Return.

Product Warranty

DEMA products are warranted against defective material and workmanship under normal use and service for

one year from the date of manufacture. This limited warranty does not apply to any products that have a

normal life shorter than one year or failure and damage caused by chemicals, corrosion, physical abuse, or

misapplication. Rubber and synthetic rubber parts such as “O”-rings, diaphragms, PVC tubing, and gaskets are

considered expendable and are not covered under warranty. This warranty is extended only to the original

buyer of DEMA products. If products are altered or repaired without prior approval of DEMA, this warranty is

void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection shows them

to be defective, they will be repaired or replaced without charge, F.O.B. factory. DEMA assumes no liability

for damages. Return merchandise authorization number must be granted in advance of returned units for repair

or replacement (See “Merchandise Returns” above).

Table of contents

Other DEMA Dispenser manuals

DEMA

DEMA 301B-2EP User manual

DEMA

DEMA 652GAP User manual

DEMA

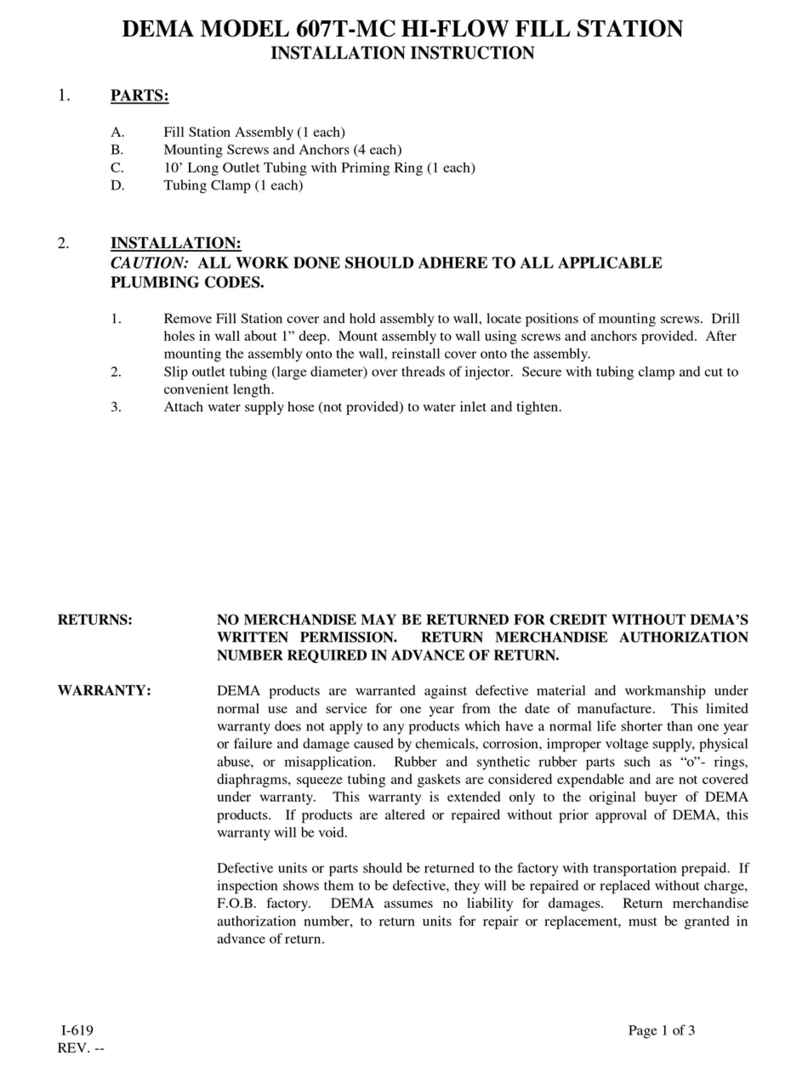

DEMA 607T-MC User manual

DEMA

DEMA Laundry Master 830 User manual

DEMA

DEMA 301B-SY User manual

DEMA

DEMA 302-2 User manual

DEMA

DEMA 5800V.BV User manual

DEMA

DEMA TITAN II Assembly instructions

DEMA

DEMA SQUIRT DC User manual

DEMA

DEMA Nitro User manual

Popular Dispenser manuals by other brands

STRATOS

STRATOS STRX637 Installation and operating instructions

Bobrick

Bobrick Designer B-840 troubleshooting guide

San Jamar

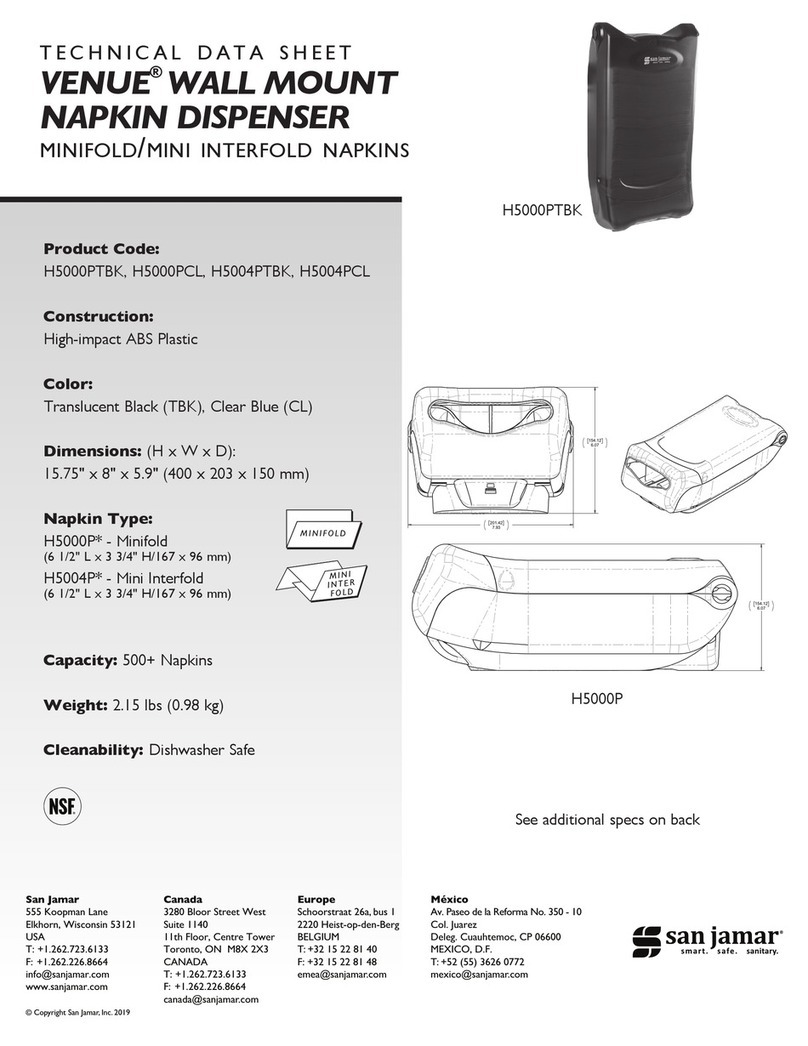

San Jamar VENUE H5000PTBK Technical data sheet

rosseto

rosseto EZ-SERV 1W quick start guide

Franke

Franke RODX600E Installation and operating instructions

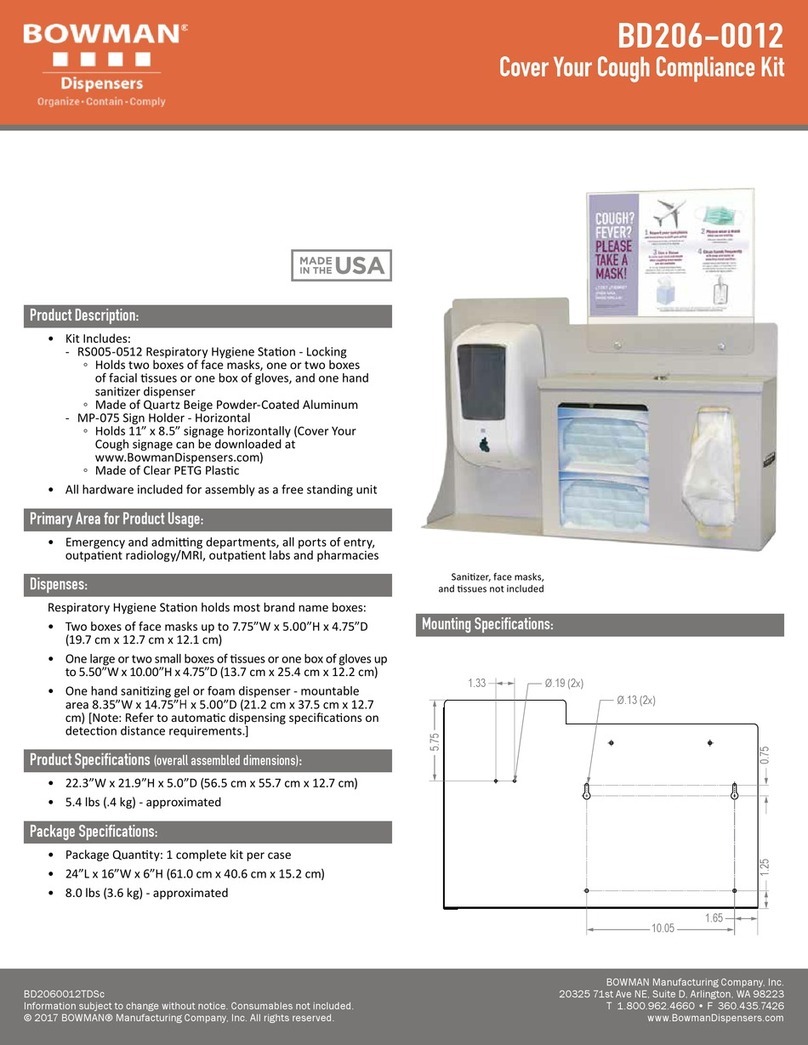

BOWMAN

BOWMAN BD206-0012 Assembly instructions