DEMA 801GAP User manual

I-951 Page 1 of 8

Rev. F-43693 2/14/2018

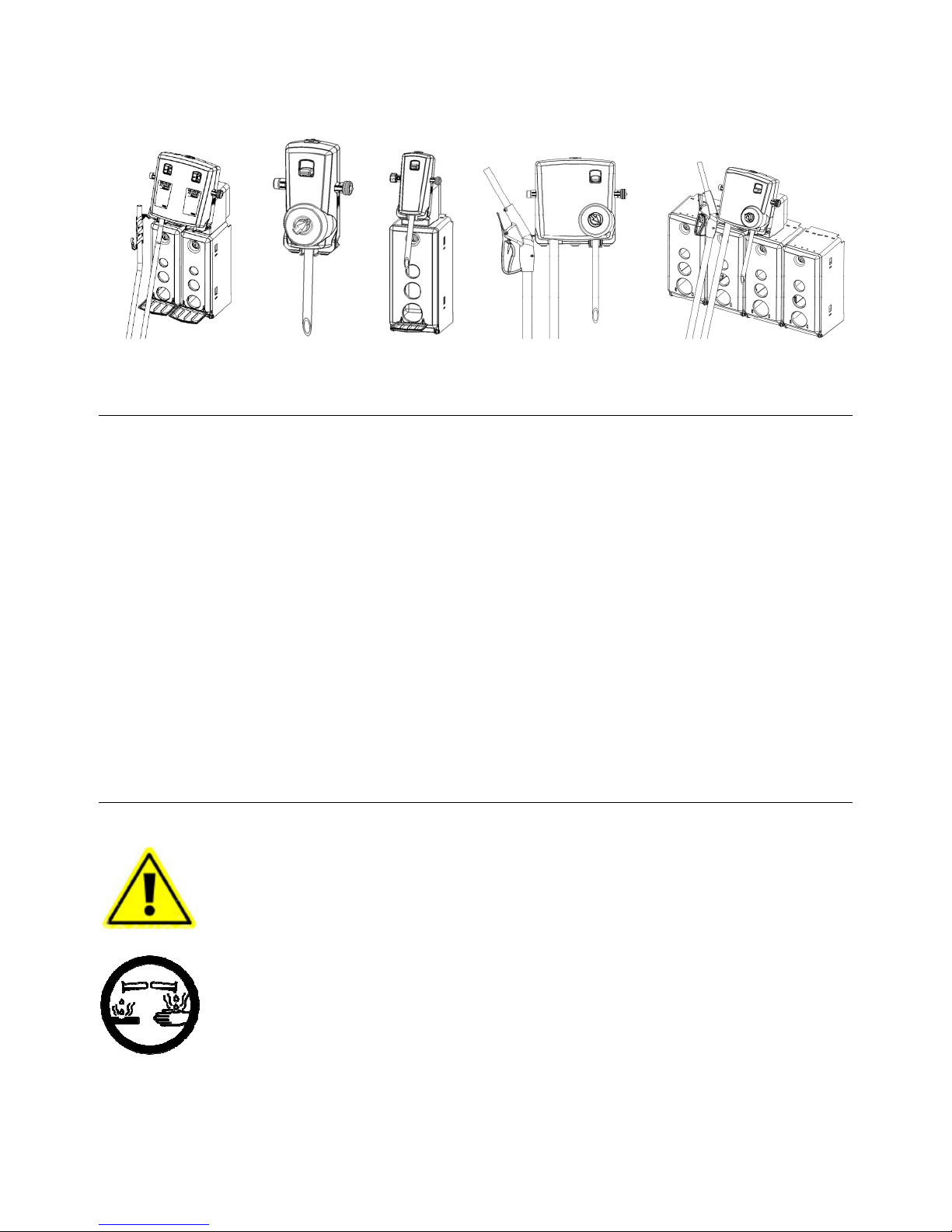

DEMA DILUTION-AT-HAND EXTREME

800 Series Chemical Dispensers

Overview

The DILUTION-AT-HAND EXTREME chemical dispenser series combines the proven technology

of the DEMA DILUTION-AT-HAND with a new look and modular chemical enclosures.

The dispenser series accurately dilutes chemical concentrates with water and dispenses the diluted

mixture at either a high flow rate to fill buckets and scrubbers or a low flow rate to fill bottles and

small containers.

Each dispenser can be set up to meet specific application needs with the ability to offer:

High and low flow dispensing

2 Liter or 1 Gallon (5 Liter) chemical cabinets

Selector valve option to dispense more than

one chemical per dispensing unit

Bottle filling or bucket filling

Option of a remote gun for bucket or scrubber

filling

Dilution ratios up to 3:1 for low flow

dispensing and up to 7:1 for high flow

dispensing

Supplied metering tips allow for leaner ratios

of dilution

Warnings

All installations must conform to local plumbing codes and use approved backflow

prevention devices. A pressure indicating tee is to be installed with existing faucets

according to local plumbing codes in the state of Wisconsin and any other state that

requires the use of a pressure indicting tee.

ALWAYS WEAR PROTECTIVE CLOTHING AND EYEWEAR WHEN

WORKING WITH CHEMICAL PRODUCTS.

I-951 Page 2 of 8

Rev. F-43693 2/14/2018

Packing List

Part

Number Description

801GAP

801GAP-S2L

803GAP

803GAP-Q2L

802GAPRF

804GAPRF

820GAP

830GAP

822GAPRF

830GAPRF

830GAP-Q2L

820GAP-D2L

822GAP-S2L

L1107 CHEMICAL

LABELS 1 1 1 1 1 1 1 1 1 1 1 1 1

100-15K METERING

TIP KIT 1 1 1 1 1 1 1 1 1 1 1 1 1

61-107-2 SMALL

CERAMIC

WEIGHT 1 1 4 4 1 4 2 5 2 5 5 2 2

98-42-2 TUBE 1 1 1 1 2 1 1 1 1 2 1

100-16E-1 TUBING &

FOOT VALVE

1/4" X 8' 1 4 1 4 2 5 2 5

100-16E-3 TUBING &

FOOT VALVE

1/4" X 32" 1 4 5 2 2

66-21K KEY SET 1 1 1 1 1

89-10-1 DRIP TRAY 1 1 1 2 1

89-30-GAP

89-30-AG

OUTLET

TUBING

HANGER

HOSE ASSY

1 1 1

98-46-3 OUTLET

TUBE 1/2" X

6' 1 1 1

66-53-4 MOUNTING

SCREW 2 2 2 8 2 2 4 4 4 4 8 4 2

66-52 WALL

ANCHOR 2 2 2 8 2 2 4 4 4 4 8 4 2

Operational Requirements

Water Supply Requirements

Minimum Maximum

Water Pressure 20 psi (1.38 bar) 125 psi (8.62 bar)

Water Temperature - 150ºF (65.5ºC)

** Recommended water pressure is between 20 psi (1.38 bar) and 80 psi. (5.52 bar). If pressure

exceeds 80 psi, it is recommended that a 66.43 regulator is used.

I-951 Page 3 of 8

Rev. F-43693 2/14/2018

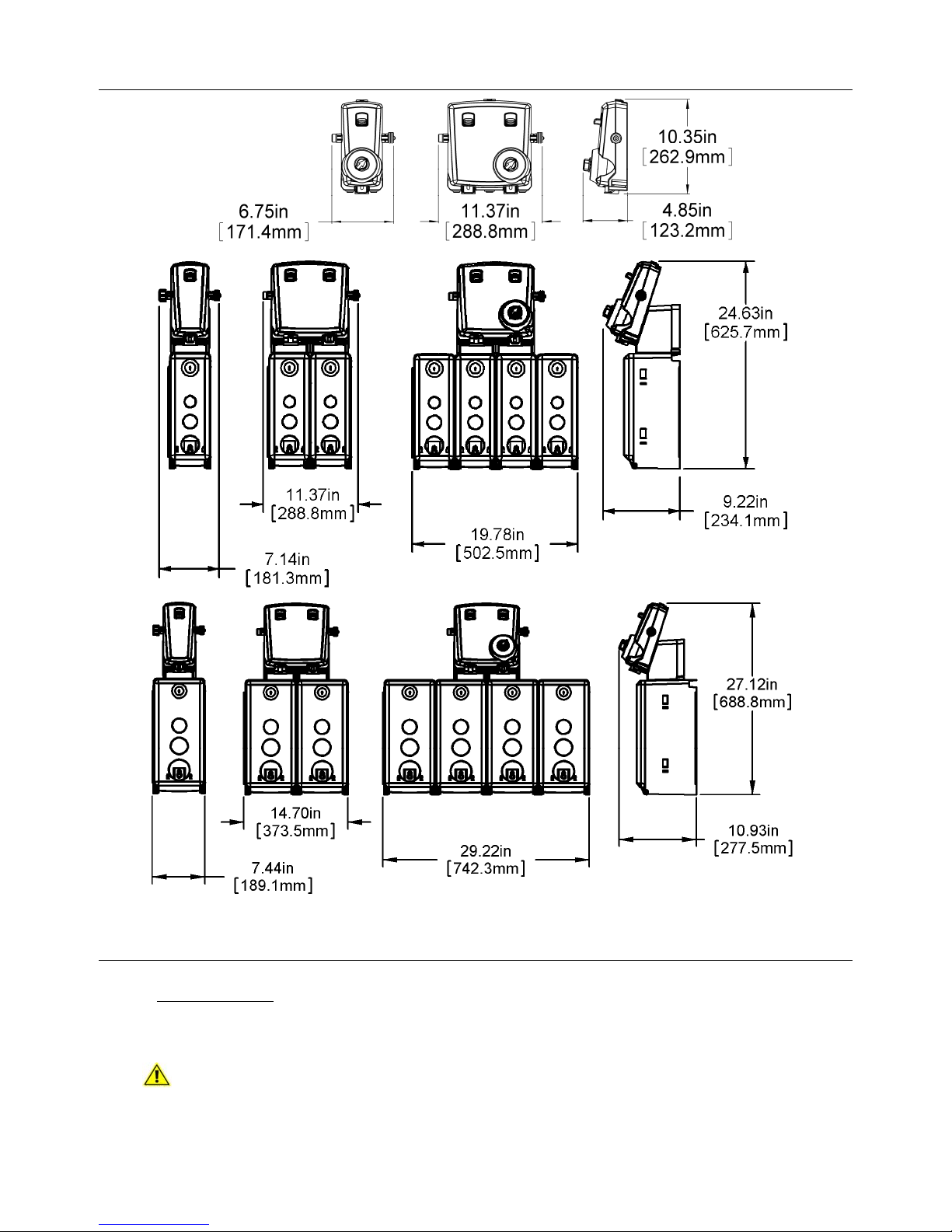

Overall Size

Installation

Mounting

Dispenser Only

1. Remove selector knobs (if installed) by pulling on the knobs.

2. Remove the dispenser cover by depressing the tab on the top of the cover.

3. Position the dispenser on the wall and mark the screw locations.

4. Chemical containers can be no greater than 6’ (1.83 meters) below the dispenser.

5. Install the supplied anchors in the wall.

6. Mount the dispenser to the wall with the supplied screws.

7. Replace the cover and any selector knob.

I-951 Page 4 of 8

Rev. F-43693 2/14/2018

Dispenser with Chemical Cabinets

1. Open the door(s) of the chemical cabinet(s) using the supplied key.

2. Position the dispenser on the wall and mark the screw locations.

3. Install the supplied anchors in the wall. Use two anchors and two screws for each

chemical cabinet.

4. Mount the dispenser to the wall with the supplied screws.

Metering Tips & Chemical Supply Tubes

1. Each dispenser is supplied with at least one metering tip

kit. Chose the appropriate color metering tip based on the

supplied chemical induction chart.

2. Remove any selector knobs (if installed) by pulling on the

knobs.

3. Remove the dispenser head by depressing the tab on the top

of the cover.

4. Screw the metering tip into the chemical barb on the

dispenser head.

5. Cut to length the chemical supply tube to remove excess

tubing.

6. Install a supplied ceramic weight onto the tube.

7. Push the tubing onto the proportioner barb.

8. Replace the cover and any selector knobs

9. Place the ceramic weight, tubing, and foot valve into the

chemical.

Water Supply

1. Water supply must have a pressure between 20 psi (1.38 bar) and 125 psi (8.62 bar).

2. Attach a garden hose to the water inlet of the unit.

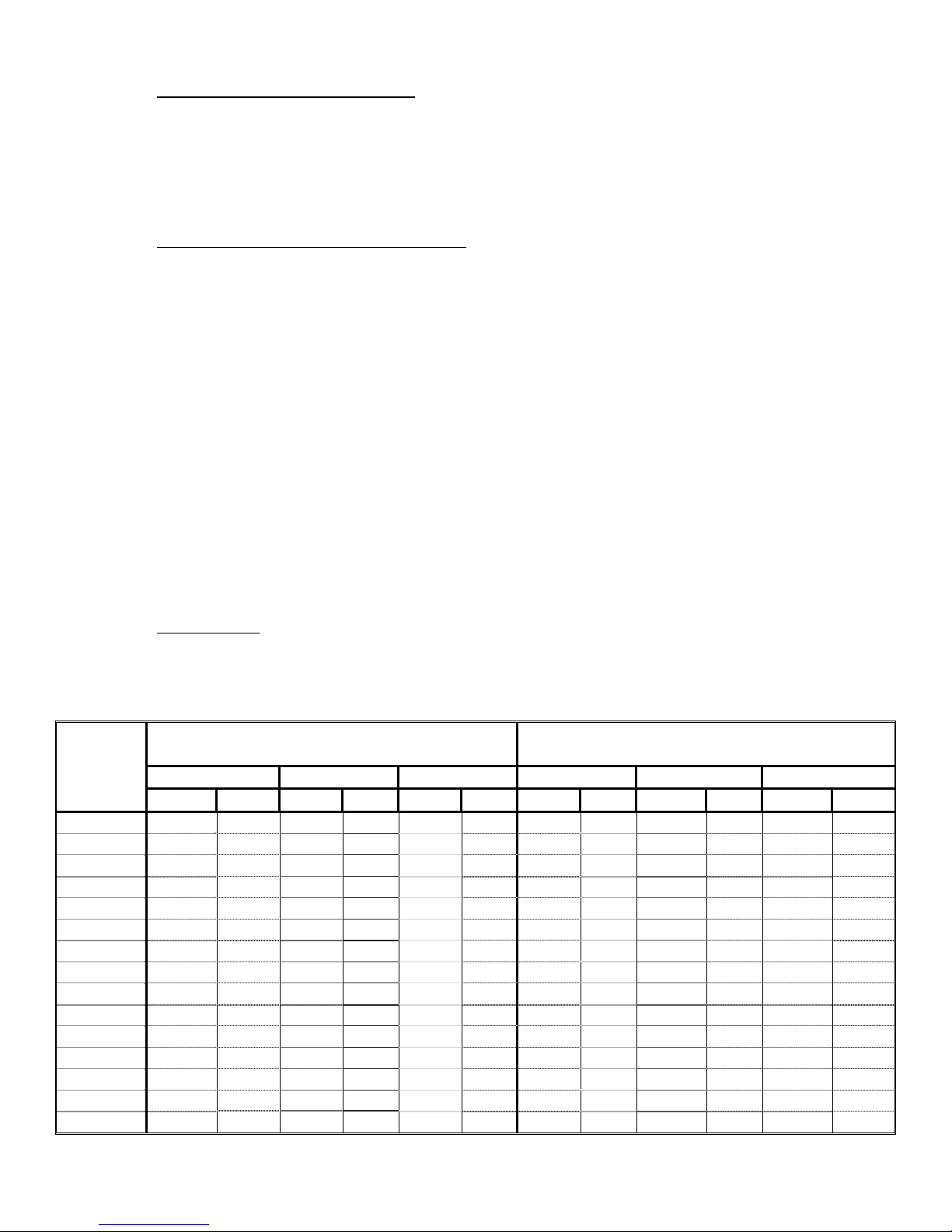

Table 1: “Action Gap”/Proportioner Induction Flow Rates w/Standard 1/4" Barb and Tubing

Metering

Tip

Color

(1 GPM Flow Rate Action Gap Proportioner)

Injection Rates For Viscosities Shown (4 GPM Flow Rate Action Gap Proportioner)

Injection Rates For Viscosities Shown

1 cps 75 cps 200 cps 1 cps 75 cps 200 cps

Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio

Tan 1.03 125-1 0.76 168-1 0.38 333-1 0.33 387-1 0.26 500-1 0.12 1090-1

Orange 1.24 103-1 0.98 130-1 0.53 241-1 0.42 307-1 0.32 430-1 0.17 735-1

Turquoise 1.43 89-1 1.07 119-1 0.61 211-1 0.51 251-1 0.34 382-1 0.19 676-1

Pink 2.47 52-1 1.58 81-1 0.92 139-1 0.78 165-1 0.56 230-1 0.3 422-1

Light Blue* 3.05 42-1 2.1 61-1 1.06 121-1 0.87 147-1 0.67 192-1 0.33 391-1

Brown 3.48 37-1 2.31 55-1 1.15 111-1 0.99 129-1 0.74 174-1 0.37 345-1

Red 4.38 29-1 2.83 45-1 1.23 104-1 1.37 93-1 0.91 141-1 0.44 289-1

White 5.33 24-1 3.1 42-1 1.37 93-1 1.52 84-1 1.04 123-1 0.48 264-1

Green 6.38 20-1 3.63 35-1 1.4 91-1 1.72 74-1 1.22 105-1 0.52 244-1

Blue 6.77 19-1 3.78 34-1 1.45 88-1 2.13 60-1 1.27 101-1 0.54 239-1

Yellow 9.90 13-1 5.1 25-1 1.48 86-1 3.05 42-1 1.71 75-1 0.56 229-1

Black 15.00 9-1 6.54 20-1 1.53 84-1 4.50 28-1 1.96 65-1 0.57 224-1

Purple 24.94 5-1 7.28 18-1 1.57 82-1 7.75 17-1 2.4 53-1 0.59 217-1

Gray 35.94 4-1 8.5 15-1 1.64 78-1 9.86 13-1 2.54 50-1 0.63 204-1

No Tip 42.2 2-1 9.35 14-1 1.87 69-1 19.63 7-1 3.16 40-1 0.67 190-1

I-951 Page 5 of 8

Rev. F-43693 2/14/2018

Table 2: “Air Gap” Proportioner Induction Flow Rates w/Standard 1/4" Barb and Tubing

Metering

Tip

Color

164 BAG (1 GPM Flow Rate Air Gap Proportioner)

Injection Rates For Viscosities Shown 163 BAG (4 GPM Flow Rate Air Gap Proportioner)

Injection Rates For Viscosities Shown

1 cps 75 cps 200 cps 1 cps 75 cps 200 cps

Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio Oz/Gal Ratio

Tan 1.25 102-1 0.90 142-1 0.60 213-1 0.30 427-1 0.20 640-1 0.15 853-1

Orange 1.70 75-1 1.20 107-1 0.80 160-1 0.40 320-1 0.30 427-1 0.25 512-1

Turquoise 2.15 60-1 1.55 83-1 1.10 116-1 0.60 213-1 0.40 320-1 0.30 427-1

Pink 3.00 43-1 2.00 64-1 1.50 85-1 0.80 160-1 0.50 256-1 0.40 320-1

Light Blue* 3.90 33-1 2.75 47-1 1.80 71-1 1.00 128-1 0.70 183-1 0.45 284-1

Brown 4.55 28-1 3.00 43-1 2.00 64-1 1.20 107-1 0.80 160-1 0.50 256-1

Red 5.80 22-1 3.60 36-1 2.30 56-1 1.50 85-1 0.90 142-1 0.60 213-1

White 7.00 18-1 4.45 29-1 2.70 47-1 1.85 69-1 1.10 116-1 0.70 183-1

Green 7.90 16-1 5.00 26-1 3.00 43-1 2.00 64-1 1.25 102-1 0.80 160-1

Blue 9.80 13-1 5.75 22-1 3.30 39-1 2.50 51-1 1.50 85-1 0.82 156-1

Yellow 14.80 9-1 7.35 17-1 3.55 36-1 4.00 32-1 1.85 69-1 0.90 142-1

Black 20.15 6-1 8.50 15-1 3.70 35-1 5.50 23-1 2.00 64-1 0.94 136-1

Purple 27.80 5-1 9.80 13-1 3.80 34-1 8.80 15-1 2.40 53-1 0.96 133-1

Gray 31.60 4-1 10.50 12-1 3.90 33-1 11.65 11-1 2.50 51-1 1.00 128-1

No Tip 35.70 3.6-1 11.80 11-1 4.50 28-1 16.20 8-1 3.00 43-1 1.20 107-1

Note: All induction flow rates are based on a water pressure of 40 psi.

Leaner dilutions can be achieved by ordering DEMA ultra lean metering tip kit 100-15KU.

*Metering tip color was formerly clear.

Service Note: Standard size ¼” hose barbs and metering tips that come with this model are used for water thin (1cps) products.

Ratios as low as parts-per-million, can be achieved with the use of a capillary metering tip. More viscous products (75cps – 200cps)

may require larger 3/8” hose barbs and metering tips. If you are having difficulty achieving the ratio you require, call DEMA and ask

for the technical department.

Operation

Dispensing of diluted chemical can be performed in a number of ways

depending on the dispenser.

Lever / Button Activation – The unit can be operated by

pushing up on the lever. This lever can be locked in an “On”

position by depressing the lever inward. To unlock the “On”

position, either depress the lever or push up on the bottle fill

lever.

Bottle Fill Activation – Slide a bottle up to the bottom of the

unit and push up on the shown lever.

Remote Fill Activation - Depress the trigger on the handle of

the remote gun. The remote gun can be locked “On” by

rotating the red lever downward. To disengage this lever,

depress the trigger.

I-951 Page 6 of 8

Rev. F-43693 2/14/2018

Troubleshooting

(Some models may not include all items listed below)

Symptom Probable Cause Remedy

Proportioner fails to draw

chemical properly.

1. Insufficient water supply pressure.

2. Foot valve has dirt/chemical build-up.

3. Proportioner metering tip clogged with

dried chemical.

4. Mineral deposits are located on Air

Gap nozzle.

5. Bucket fill (4 GPM) side appears to

have slow flowing water stream.

1. 20 PSI is the minimum allowable pressure. Seek

Plumber if necessary to increase water pressure.

2. Soak in hot water to clean.

3. Soak in hot water to clean interior passages.

4. Soak nozzle and inlet screen in hot water or

product such as CLR to clean mineral deposits.

5. Flow disc assembly must be removed from lower

section of water valve assembly if installed.

“Air Gap” Proportioner is

dripping or spraying a mist

(fan pattern) of water.

1. Mineral deposits are located on Air

Gap nozzle. 1. Soak nozzle and inlet screen in hot water or off

the shelf product such as CLR to clean and remove

mineral deposits.

Water valve is not shutting

off completely. 1. “Sliding lever” return spring may be

missing.

2. “Sliding lever” is not returning all the

way down due to interference between

the sliding lever and either the

chemical supply and/or outlet tubing.

3. Bucket fill outlet hose is catching the

bottom edge of the sliding lever during

normal usage.

1. Remove cover and visually check for sliding lever

return spring. Replace if missing.

2. Remove cover and visually check for any tubes

rubbing the sliding lever. Routing of chemical

supply and outlet tubing must not restrict the

movement of the sliding lever. Reroute tubing.

3. Don’t pull the bucket fill outlet hose too tight from

either side otherwise sliding lever may not return

properly.

Water valve is leaking. 1. Enclosing tube nut is too loose.

2. One or more of the valve o-ring

connections are out-of-position.

Identify each leak before disassembly.

1. Shut water supply off first. Hand-tighten the

enclosing Hose nut. Do not overtighten w/tool.

2. “O-ring” seals may be pushed out of place or

missing when sub-assembling valve together.

Threaded connections are

leaking water. 1. The connection between the blend

center and water supply line is too

loose or rubber washer is missing.

2. Backflow prevention devices and/or

proportioners are too loose.

1. Shut water supply off first. Carefully tighten the

female hose coupling on the blend center to the

inlet water supply line. Do not overtighten.

2. Tighten loose connection(s) with tools if

necessary. Do not overtighten if using tools.

Proportioner continues to

draw chemical after water

valve is closed.

1. Concentrated chemical is positioned

higher than the proportioner.

1. Move the concentrated chemical so it is lower than

the proportioner.

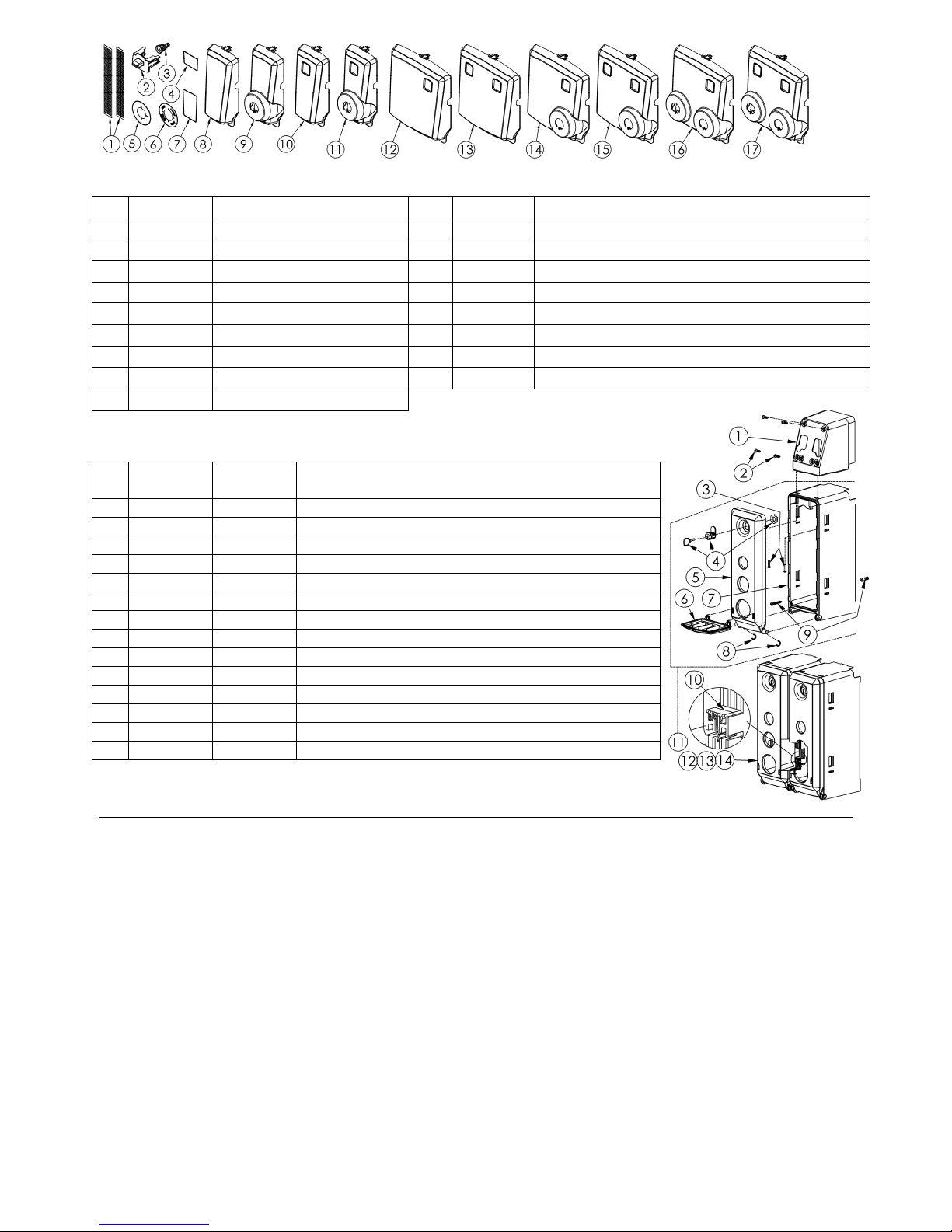

Parts List (See pages 6-8)

BOTTLE/HOSE FILL APPLICATIONS

NO. PART NO. DESCRIPTION

1 63-35 Magnet

2 98-7-2 Enclosing Tube Nut

3 41-7-25 Enclosing Tube

4 98-41-1 Spring

5 98-24-1 Plunger

6 41-15-10 Diaphragm With Center Hole EPDM

7 98-25-1 Bottle/Hose Repair Kit

8 89-20-1 Flow Disc Assembly (1 GPM only)

I-951 Page 7 of 8

Rev. F-43693 2/14/2018

REMOTE FILL APPLICATION

REMOTE FILL APPLICATION

BACK FLOW & PROPORTIONING DEVICES

NO. PART NO. DESCRIPTION

1 98-5-2 Nut, Diaphragm

2 98-26-1 Diaphragm Without Center Hole EPDM

3 26-35 O-ring (EPDM)

4 98-15-1 Elbow

5 58-60 #6 Hi Lo Screw ½” Lg. (2 Required)

NO. PART NO. DESCRIPTION

1 40-731-1 Remote Gun Fill Half (R.H.)

2 40-737-1 Trigger Return Spring

3 40-734-1 Hook

4 40-775-1 Valve Assembly

5 40-730-1 Remote Gun Fill Half (L.H.)

6 58-60 #6 Hi Lo Screw ½” Lg. (4 Required)

7 21-009-6 #6 Hi Lo Screw 1” Lg. (1 Required)

8 40-736-1 Remote Fill Assembly

9 40-735-1 Activation Lever ASM

NO. PART NO. DESCRIPTION

1 61-32BAG-2 Proportioner Assembly (1 GPM)

2 61-22-3BAG-EL2 Proportioner Assembly (4 GPM)

3 16-30 Action Gap Assembly

4 61-99-2 Proportioner Assembly (1 GPM)

5 61-22-3 Proportioner Assembly (4 GPM)

6 63-96-3AFL Selector and Knob Assembly (Aflas)

7 63-82 Tube, 3/16” I.D. Outlet

8 98-43-1 Tube, 9/16” I.D. Outlet

9 98-30-AG Outlet 9/16" I.D. Hose W/Hanger (6' LG)

10 98-42-2 Tube, 1/2” I.D. Outlet

11 89-30-GAP Outlet 1/2" I.D. Hose W/Hanger (6' LG)

12 100-15K Metering Tip Kit (14 Sizes)

13 100-12 /100-12E Hose, 7/32” I.D. x 8’ Lg./7/32” I.D. x 50’ Lg.

14 61-107-2 Ceramic Weight, 3/8” I.D.

15 100-16E Foot Valve Assembly (EPDM)

16 63-111-2 Knob

17 58-60 Screw, Hi/Low, #6 x ½”

18 89-28-1 Hose hanger, Action Gap Hose style

19 89-28-2 Hose hanger, Air Gap Hose style

I-951 Page 8 of 8

Rev. F-43693 2/14/2018

LABELS, LIFT BUTTON AND COVERS

2 LITER AND 1 GALLON (5 LITER) STORAGE BOX ASSEMBLIES

Warranty

Merchandise Returns

No merchandise will be returned for credit without DEMA’S written permission. Returned merchandise

authorization number is required in advance of return.

Product Warranty

DEMA products are warranted against defective material and workmanship under normal use and service for

one year from the date of manufacture. This limited warranty does not apply to any products that have a

normal life shorter than one year or failure and damage caused by chemicals, corrosion, physical abuse, or

misapplication. Rubber and synthetic rubber parts such as “O”-rings, diaphragms, PVC tubing, and gaskets are

considered expendable and are not covered under warranty. This warranty is extended only to the original

buyer of DEMA products. If products are altered or repaired without prior approval of DEMA, this warranty is

void.

Defective units or parts should be returned to the factory with transportation prepaid. If inspection shows them

to be defective, they will be repaired or replaced without charge, F.O.B. factory. DEMA assumes no liability

for damages. Return merchandise authorization number must be granted in advance of returned units for repair

or replacement (See “Merchandise Returns” above).

NO. PART NO. DESCRIPTION NO. PART NO. DESCRIPTION

1 L1107 Chemical Label 10 89-2-3 Cover, Single (Lift Button)

2 89-5-1 Lift Button 11 89-2-4 Cover, Single (Lift Button & Selector)

3 63-36 Lift Button Return Spring 12 89-4-1 Cover, Dual (RH Lift Button)

4 L1074 DEMA Label, Small 13 89-4-2 Cover, Dual (LH & RH Lift Buttons)

5 L1075 Selector label, Blank 14 89-4-3 Cover, Dual (RH Lift Button & RH Selector)

6 L1108 Selector label, 4-Dilution 15 89-4-4 Cover, Dual (Both Lift Buttons & RH Selectors)

7 L1073 DEMA Label, Large 16 89-4-5 Cover, Dual (RH Lift Buttons & Both Selectors)

8 89-2-1 Cover, Single (Plain) 17 89-4-6 Cover, Dual (Both Lift Buttons & Both Selectors)

9 89-2-2 Cover, Single (Selector)

NO. 2 LITER

PART NO. 1GALLON

PART NO. DESCRIPTION

1 89-11-1 89-11-1 Mounting Support (1for Single & 2 for Dual Unit)

2 44-116-5 44-116-5 #8 Hi-Lo Screws (4 Per Dispenser Unit)

3 44-116-1 44-116-5 #8 Hi-Lo Screws (2 per Mounting Support)

4 81-69 81-69 Cabinet Lock with Key / Key Only (66-21K)

5 89-8-1 89-9-1 Storage Box Door

6 89-10-1 89-10-1 Drip Tray

7 89-6-1 89-7-1 Storage Box Base

8 89-19-1 89-19-1 Door Retaining Clip (2 per Box Assy.)

9 98-40-1 98-40-1 #10 Screw & Anchor Set (Qty. 2 /Set)

10 89-12-1 89-12-1 Box Retaining Clip (2 for 2 Boxes +2 per Box)

11 89-16-1 89-17-1 Single Box Assy. Kit (1 Drip Tray & Mtg. Hardware)

12 89-16-2 89-17-2 Dual Box Assy. Kit (1 Drip Tray & Mtg. Hardware)

13 89-16-3 89-17-3 Triple Box Assy. Kit (1 Drip Tray & Mtg. Hardware)

14 89-16-4 89-17-4 Quad Box Assy. Kit (1 Drip Tray & Mtg. Hardware)

This manual suits for next models

12

Table of contents

Other DEMA Dispenser manuals

DEMA

DEMA Super Sink Series Assembly instructions

DEMA

DEMA SQUIRT DRAIN UNIT User manual

DEMA

DEMA 652AG User manual

DEMA

DEMA 607T-MC User manual

DEMA

DEMA 302-2 User manual

DEMA

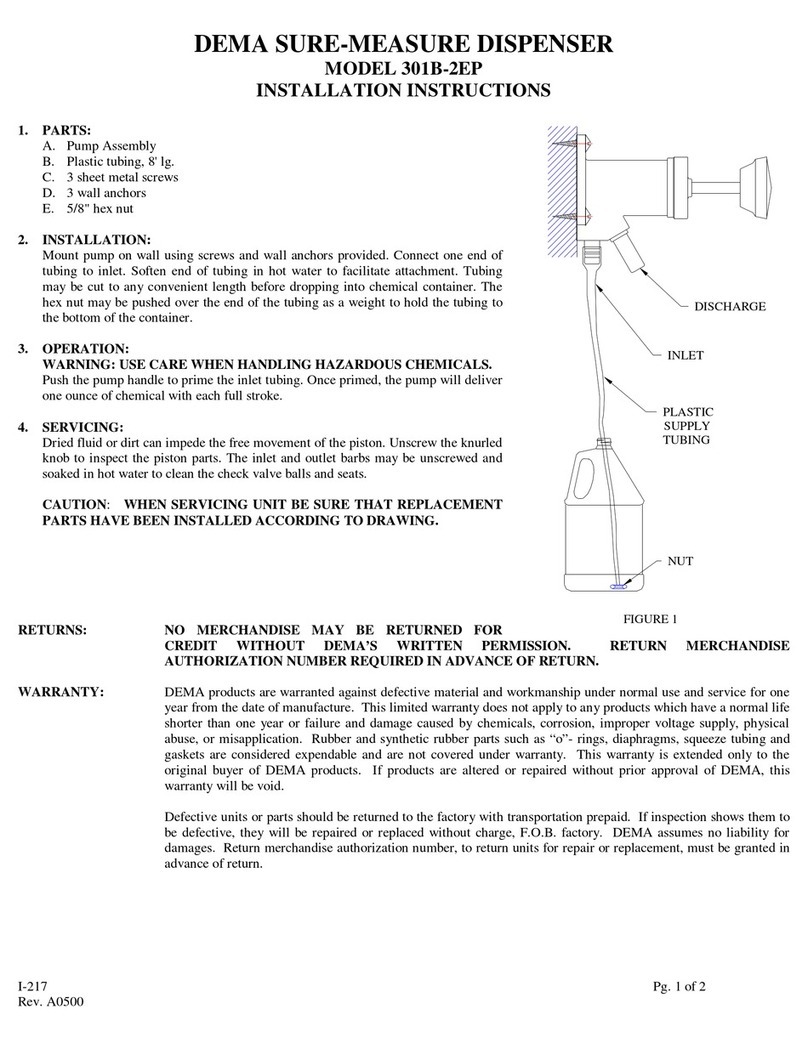

DEMA 301B-2EP User manual

DEMA

DEMA Laundry Master 830 User manual

DEMA

DEMA Nitro Parts list manual

DEMA

DEMA 693T FOAM STATION II User manual

DEMA

DEMA Nitro User manual

Popular Dispenser manuals by other brands

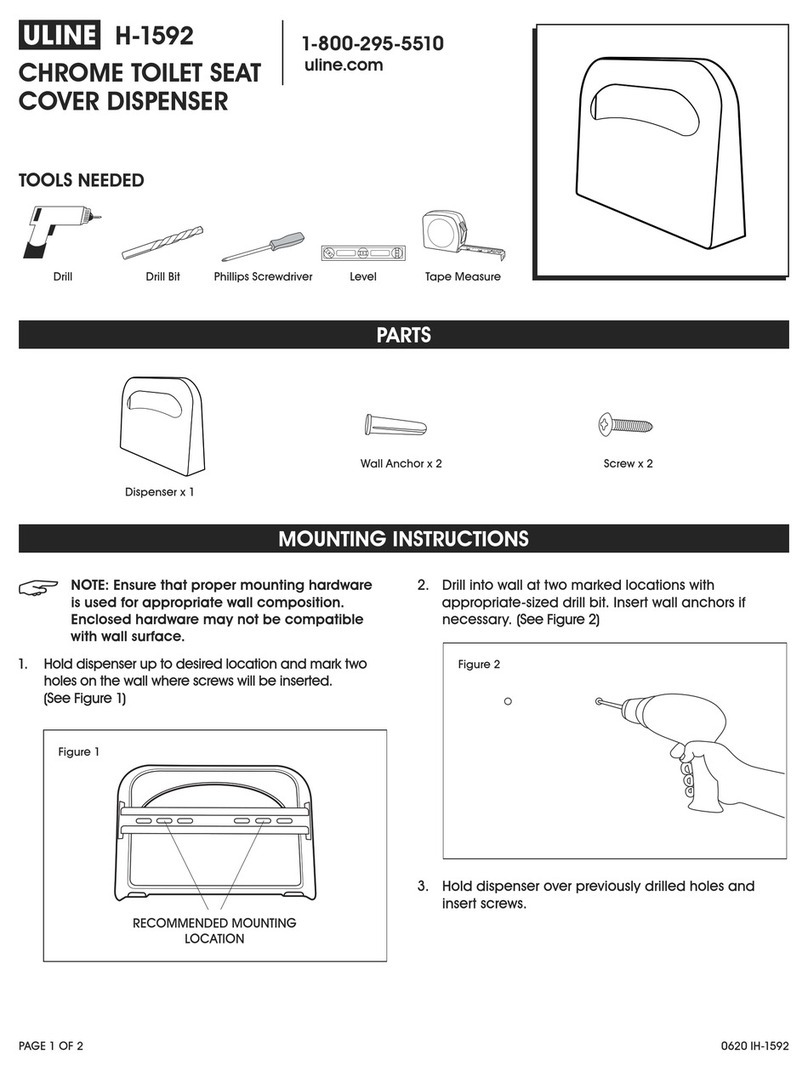

U-Line

U-Line H-1592 quick start guide

PolyJohn

PolyJohn MiniSan MSN01-1000 Product instructions

Party Robotics

Party Robotics Bartendro ShotBot Getting started guide

Tatung

Tatung BM-40U3 user manual

Georgia Pacific

Georgia Pacific GP PRO Dixie Ultra SmartStock DUSSTDSP3 reference guide

Hydro

Hydro AccuDose 38741GB Quick user guide