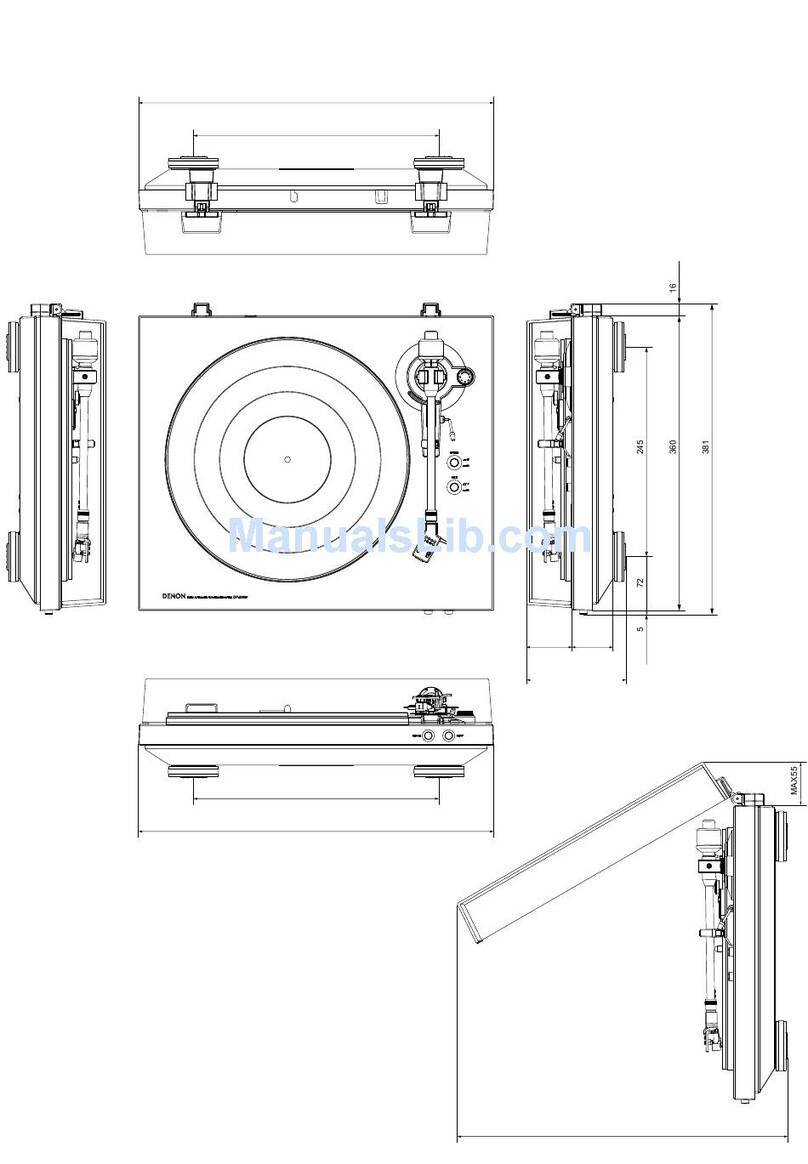

Denon DP-35F User manual

Other Denon Turntable manuals

Denon

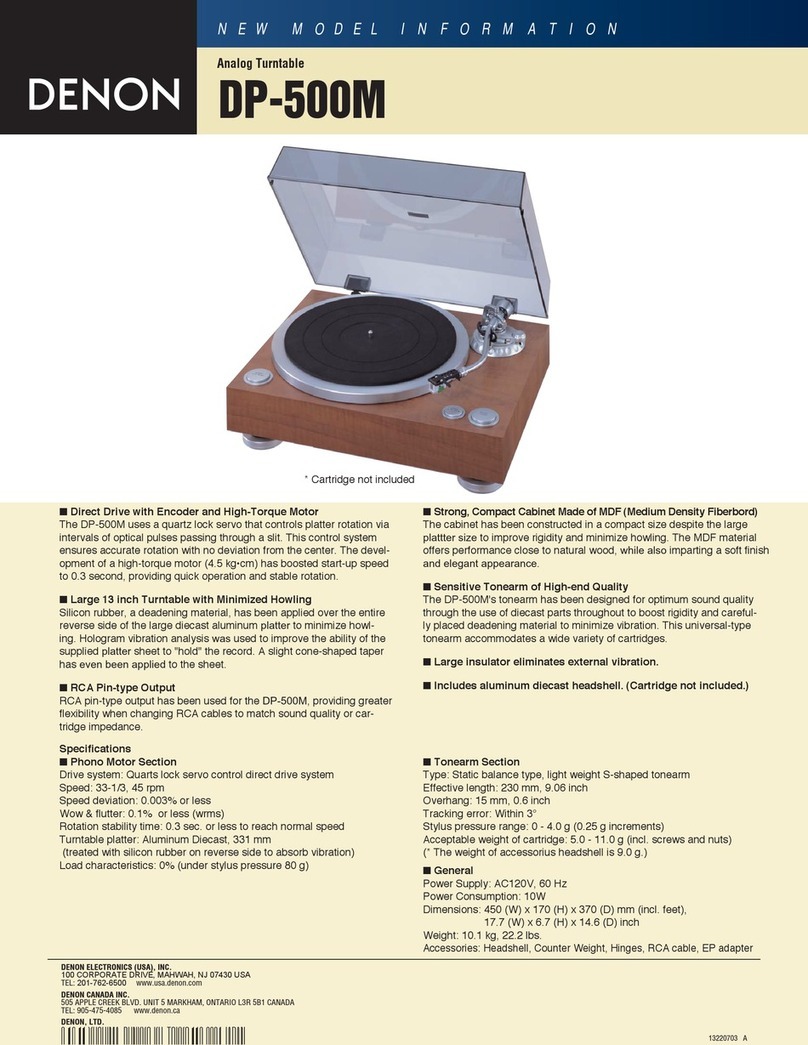

Denon DP-500M User manual

Denon

Denon DP-A100 User manual

Denon

Denon DN-C615 User manual

Denon

Denon DP-300F User manual

Denon

Denon DP-450USB User manual

Denon

Denon DP-500M User manual

Denon

Denon DP-37F User manual

Denon

Denon DP-300F User manual

Denon

Denon DP-6700 User manual

Denon

Denon DP DP-300F User manual

Denon

Denon DP-47F User manual

Denon

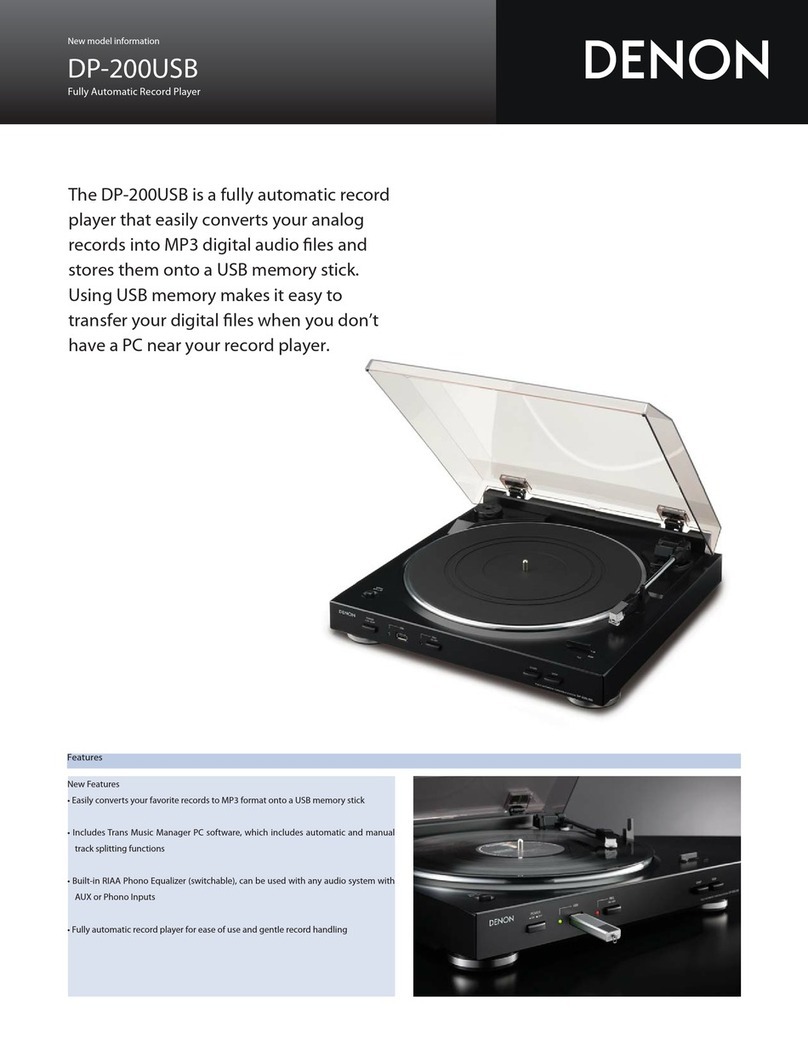

Denon DP-200USB User manual

Denon

Denon DP-23F User manual

Denon

Denon DP-29F User manual

Denon

Denon DVD-1730 User manual

Denon

Denon DP-300F User manual

Denon

Denon DP-200USB User manual

Denon

Denon DP-200USB User manual

Denon

Denon DP-300F Instructions and recipes

Denon

Denon DP-400 User manual