GENERAL NOTES

This Instruction Manual is an integral art of the device and as such must always be ke t with the device. This is also

the case when the heater is sold to another user. The Manual must therefore be conserved and consulted carefully

before any action. In the case of damage or loss, you can at any time ask the local After Sales Service for a co y of the

Manual.

After removing the ackaging, first make sure that the contents are com lete and undamaged. If the heater does not

match with the Manual in any way, contact the Agency that sold the heater.

Installation of the BG series WARM AIR HEATER must be carried out by qualified com anies under Law 5 March 1990

n°46. On com letion of the job, they rovide the owner with a declaration of conformity of the correctly carried out

installation, that is according to the current a licable Norms requires and according to the indications rovided by the

Manufacturer in this Instruction Manual.

The heaters have been manufactured for room heating and they must be used for this ur ose, com atibly with their

erformance characteristics. The Manufacturer acce ts no contractual or extracontractual res onsibility for damage

caused to eo le, animals or ro erty, due to errors in installation, adjustment and maintenance or to im ro er use.

Excessive tem erature re resents a risk for health and a waste of energy. Avoid leaving rooms closed for long eriods of

time. O en the windows eriodically to ensure an adequate air change.

During the first start-u , there may be smells and smoke due to eva oration of the liquid used to rotect the heat

exchanger during storage; this is a normal henomenon that will disa ear after a brief o eration time. The rooms must

be adequately aerated.

On leaving the heater unused for a long eriod, you should carry out at least the following o erations:

• Turn off the main heater switch and the main lant switch.

• Close the main fuel su ly valve.

If the heater is not used for a long eriod of time, we suggest you contact the After Sales Service or other rofessionally

qualified ersonnel for restarting.

All heaters must be fitted exclusively with original accessories. The Manufacturer is not res onsible for any damage

caused by im ro er use of the heater and by the use of accessories that are not original.

All references to Law, standards, directives and technical rules in this manual are to be considered as informative only

and valid at the date of rinting of the Manual. The enforcing of new dis ositions or the alteration of current ones do not

create any Manufacturer obligations towards third arties.

Re airs and maintenance must be carried out by the After Sales Service or by qualified ersonnel as s ecified in this

Manual. Do not alter or tam er with the heater: this can create dangerous situations and the Manufacturer will not be

res onsible for any damage.

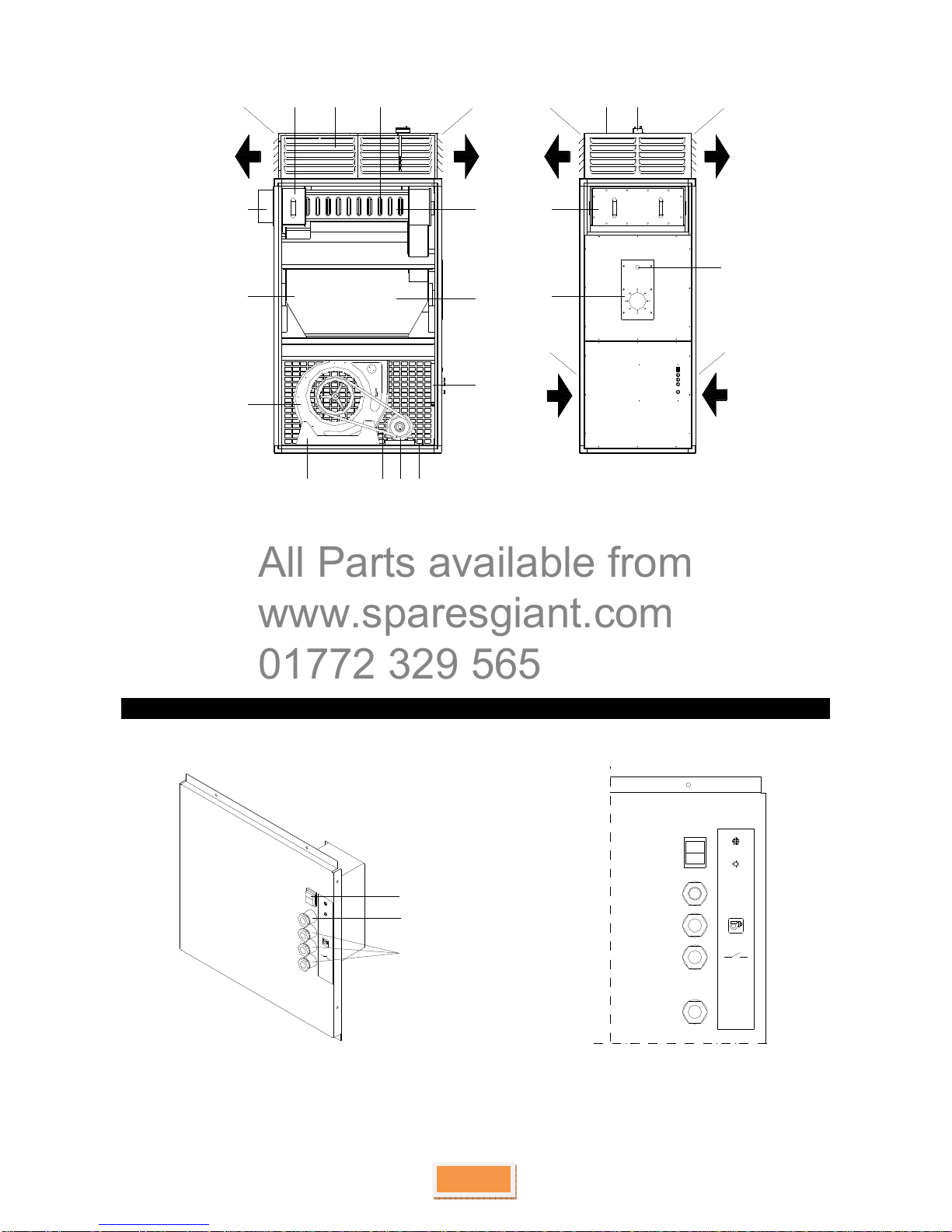

The systems that must be installed (oil i es, electrical su lies, etc.) have to be suitably fastened and must not

re resent any obstacle that could cause tri ing.

The Manufacturer is res onsible for conformity of his roduct to laws, directives and instructions standards current at

the date of sale. Knowledge and observation of legislative instruments and of standards for the design of systems, and

for installation, o eration and maintenance are the exclusive res onsibility of res ectively the designer, the installation

ersonnel and the user.

The Manufacturer is not res onsible for failure to observe the instructions in this Manual, for the consequences of any

o eration carried out that is not s ecifically foreseen, or for any translations causing erroneous inter retations.

The heater is designed for o eration at the thermal ower and the airflow rate as s ecified in the Technical Data

Cha ter. A thermal ower that is too low and/or an airflow that is too high can lead to condensation in the flue, with

consequent irre arable corrosion to the heat exchanger. A thermal ower that is too high and/or an airflow that is too

low cause abnormal overheating of the heat exchanger with consequent actuation of the safety systems and damage to

the heat exchanger.