4

Contents

1. Important instructions ..........................................................................

2. Orientations ........................................................................................

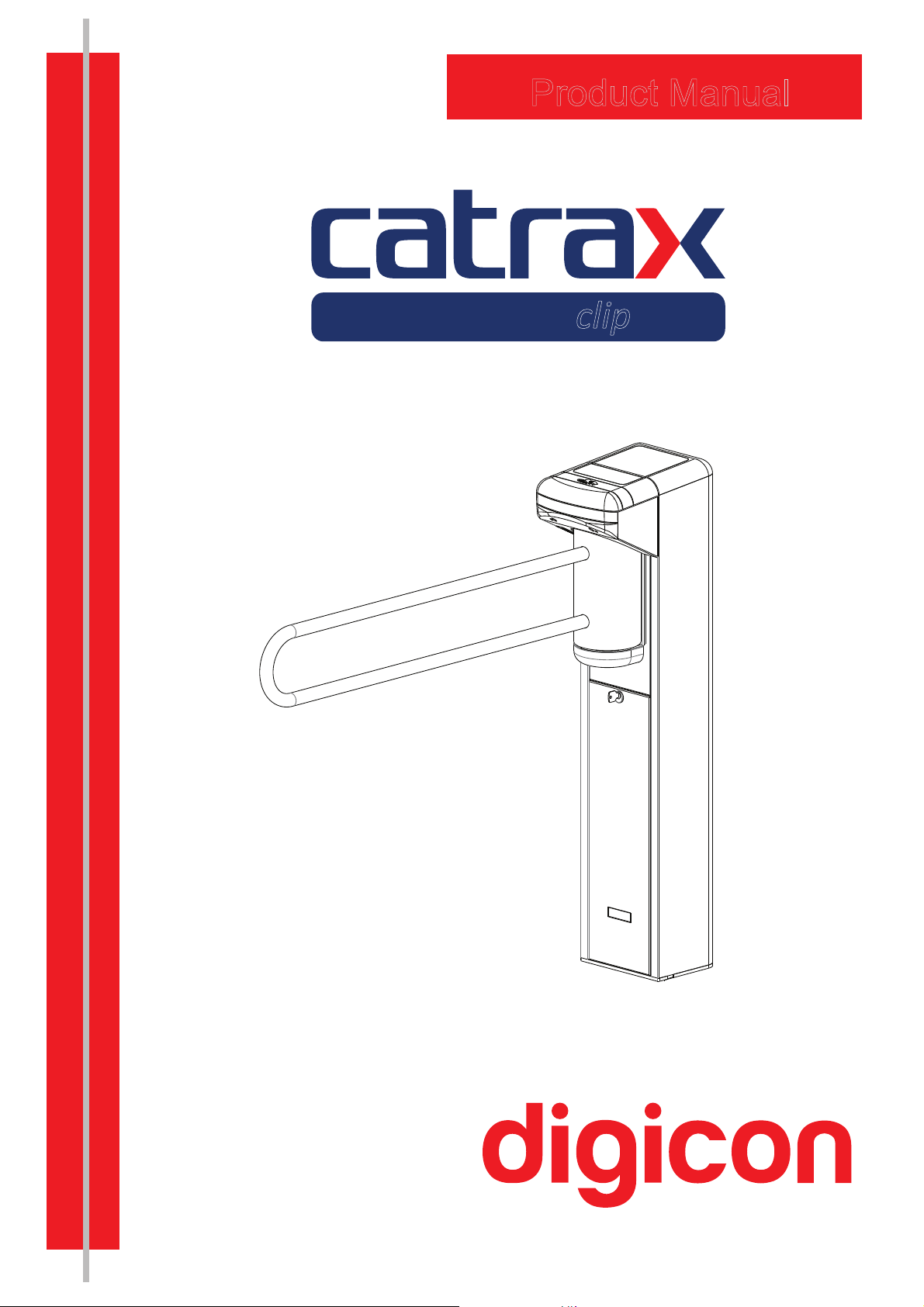

3. Introduction ........................................................................................

4. Features of Catrax Clip ........................................................................

4.1 OperationCatrax Clip ........................................................................

5. Installing/Assembling ...........................................................................

5.1 Unboxing...........................................................................................

5.2 Floor drilling and column fixation ..........................................................

5.3 Assembling arms and covers ................................................................

5.4 Access to Catrax Clip after assembly ....................................................

6. Installing/Assembling optional items .......................................................

6.1 ................................................................................

Collecting box kit

6.1.1 Connection of collecting box kit to control board ..................................

6. Operational pictogram kit ...................................................................2

6. Power supply.....................................................................................3

6. Control Board ....................................................................................4

6. .1 Inputs............................................................................................4

6. .1.1 Connection scheme ......................................................................4

6. .1.2 Pictogram ....................................................................................4

6. .2 Control board configuration4 ...............................................................

6. .3 Outputs4 ..........................................................................................

6. .3.1 Return signals4 ..............................................................................

6. .3.2 Electromagnets4 ............................................................................

6. .3.3 Sound alarm4 ................................................................................

6. .4 Examples of some configurations4 .......................................................

7. Maintenance ........................................................................................

7.1 ......................................

Preventive and corrective routine maintenance

7.2 Solving problems ...............................................................................

8. Technical characteristics ........................................................................

8.1 Dimensions .......................................................................................

8.2 Other information...............................................................................

9. Cleaning .............................................................................................

9.1 Maintenance and conservation of stainless steel .....................................

10. .........................................................Warranty and technical assistance

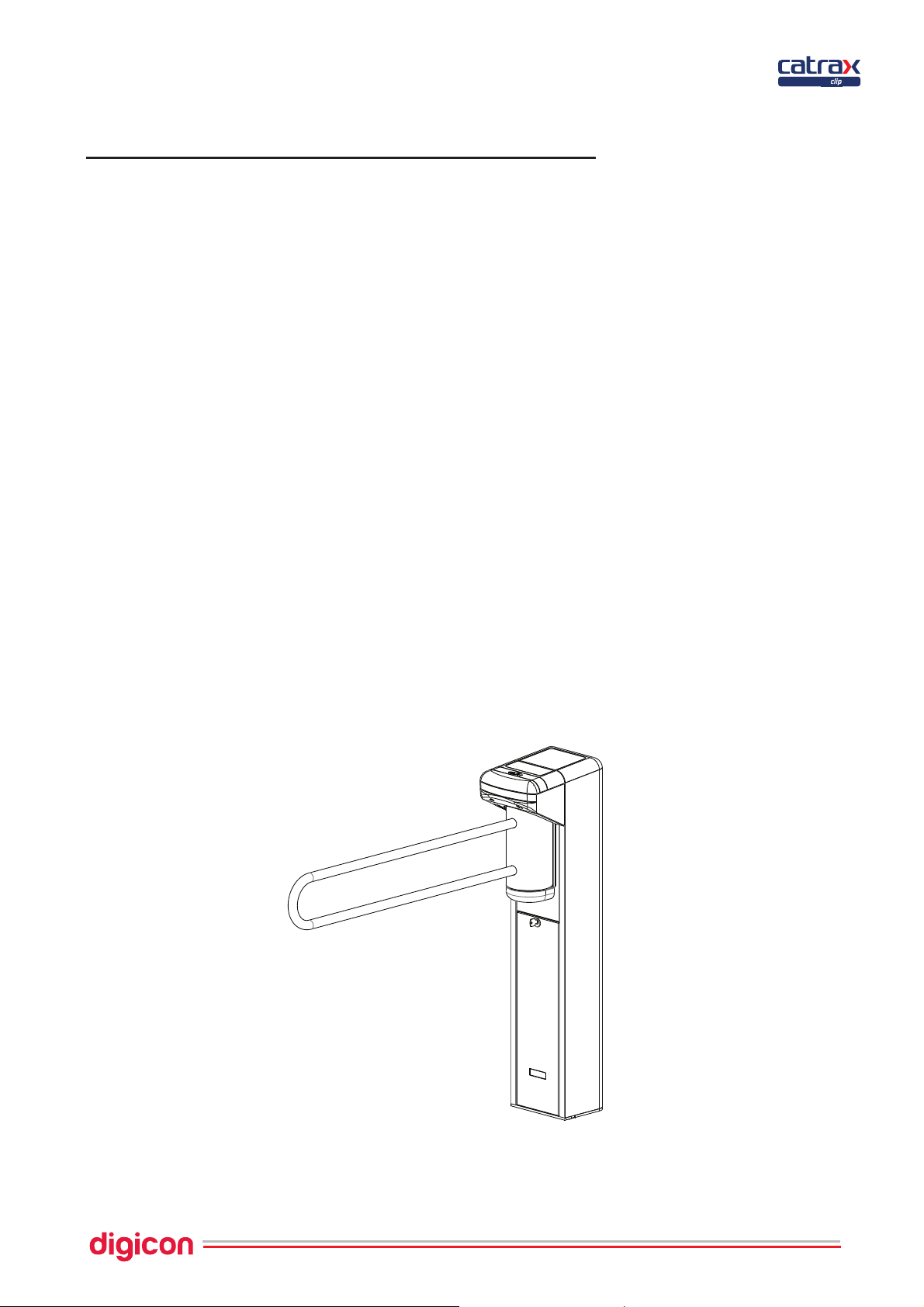

clip

05

06

06

07

08

09

09

10

11

12

13

13

14

15

15

16

18

18

19

19

20

20

21

21

21

22

22

24

25

25

26

27

27

29