65

65

MAX/MIN key

Recalls the following parameters to the second display : first

push recalls peak, second push recalls valley, third push

recalls tare (or offset). If the integrator option is enabled, the

fourth push recalls total and, if not enabled but the logic

function nº30 (totalizer+batch) is programmed to one of the

user inputs a new push shows the number of batch

operations. The last push after this sequence blanks the

lower displays.

The auxiliary display indicates which variable is being read in

the second display : "HI" = peak, "Lo" = valley, "tA" = tare,

"oF" = offset, "bA" = nº of batches. The total value needs all

8 digits to be displayed.

ny selected parameter is permanently displayed and

continuously updated if no action is taken.

TO RESET PEAK, VALLEY, TOTAL or BATCH :

RESET key

Press MAX/MIN until desired parameter appears on the second

display. This parameter may be peak ('HI'), valley ('Lo'),

total (auxiliary digits blank or hi part of the total reading) or

number of batch operations ('bA').

When desired variable is being read on the lower displays,

hold the RESET key and press MAX/MIN . Release first MAX/MIN ,

then RESET .

tare or tare reset operation updates automatically the peak

and valley readings to the current display value.

ENTER key

momentary push of the ENTER key gives access to the

programming mode.

ENTER key (3s)

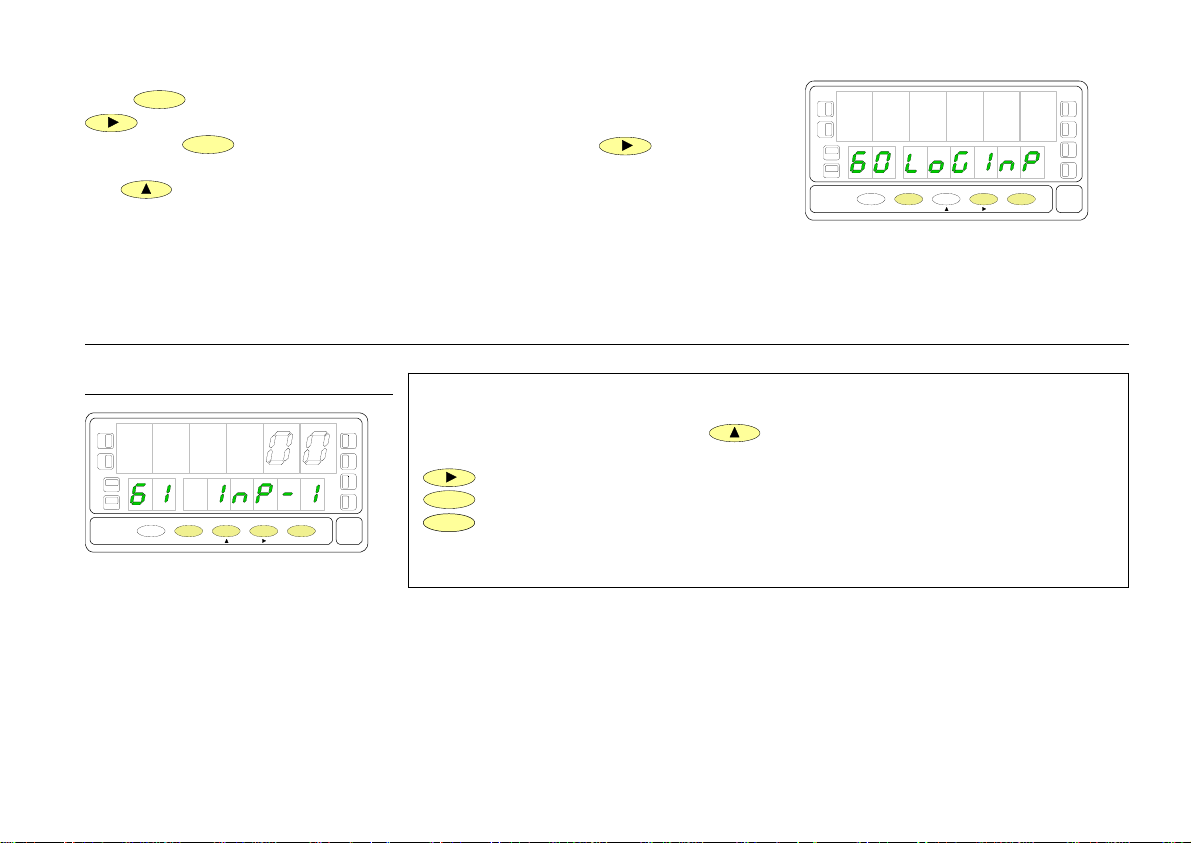

Gives access to the program lock-out routine. Hold ENTER

for approximately 3s, at the end of which the meter prompts

the indication '- - - -' to enter the security code.

RESET + ENTER (3s)

press of 3s of both RESET and ENTER restores the factory

settings to the memory of the instrument.

Press RESET first, then ENTER and hold both until the

indication "StorE" appears on the second display.

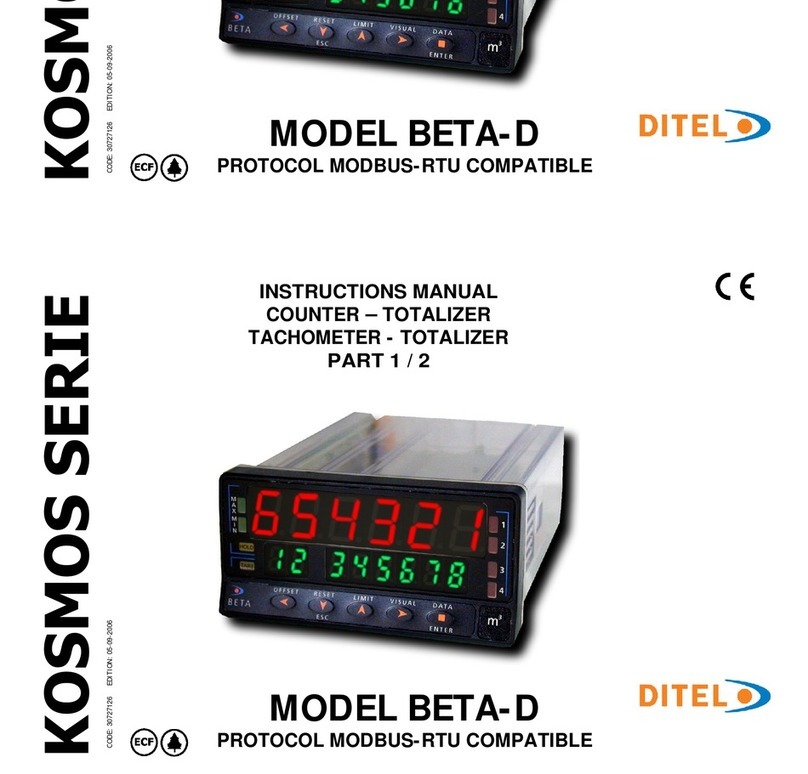

TARE RESET LIMIT MAX/MIN DATA

ESC ENTER

M

A

X

M

I

N

HOLD

TARE

1

2

3

4

TARE RESET LIMIT MAX/MIN DATA

ESC ENTER

M

A

X

M

I

N

HOLD

TARE

1

2

3

4

MAX/MIN key

Recalls the following parameters to the second display : first

push recalls peak, second push recalls valley, third push

recalls tare (or offset). If the integrator option is enabled, the

fourth push recalls total and, if not enabled but the logic

function nº30 (totalizer+batch) is programmed to one of the

user inputs a new push shows the number of batch

operations. The last push after this sequence blanks the

lower displays.

The auxiliary display indicates which variable is being read in

the second display : "HI" = peak, "Lo" = valley, "tA" = tare,

"oF" = offset, "bA" = nº of batches. The total value needs all

8 digits to be displayed.

ny selected parameter is permanently displayed and

continuously updated if no action is taken.

TO RESET PEAK, VALLEY, TOTAL or BATCH :

RESET key

Press MAX/MIN until desired parameter appears on the second

display. This parameter may be peak ('HI'), valley ('Lo'),

total (auxiliary digits blank or hi part of the total reading) or

number of batch operations ('bA').

When desired variable is being read on the lower displays,

hold the RESET key and press MAX/MIN . Release first MAX/MIN ,

then RESET .

tare or tare reset operation updates automatically the peak

and valley readings to the current display value.

ENTER key

momentary push of the ENTER key gives access to the

programming mode.

ENTER key (3s)

Gives access to the program lock-out routine. Hold ENTER

for approximately 3s, at the end of which the meter prompts

the indication '- - - -' to enter the security code.

RESET + ENTER (3s)

press of 3s of both RESET and ENTER restores the factory

settings to the memory of the instrument.

Press RESET first, then ENTER and hold both until the

indication "StorE" appears on the second display.

TARE RESET LIMIT MAX/MIN DATA

ESC ENTER

M

A

X

M

I

N

HOLD

TARE

1

2

3

4

TARE RESET LIMIT MAX/MIN DATA

ESC ENTER

M

A

X

M

I

N

HOLD

TARE

1

2

3

4