Dräger Medical NM6000 User manual

Other Dräger Medical Medical Equipment manuals

Dräger Medical

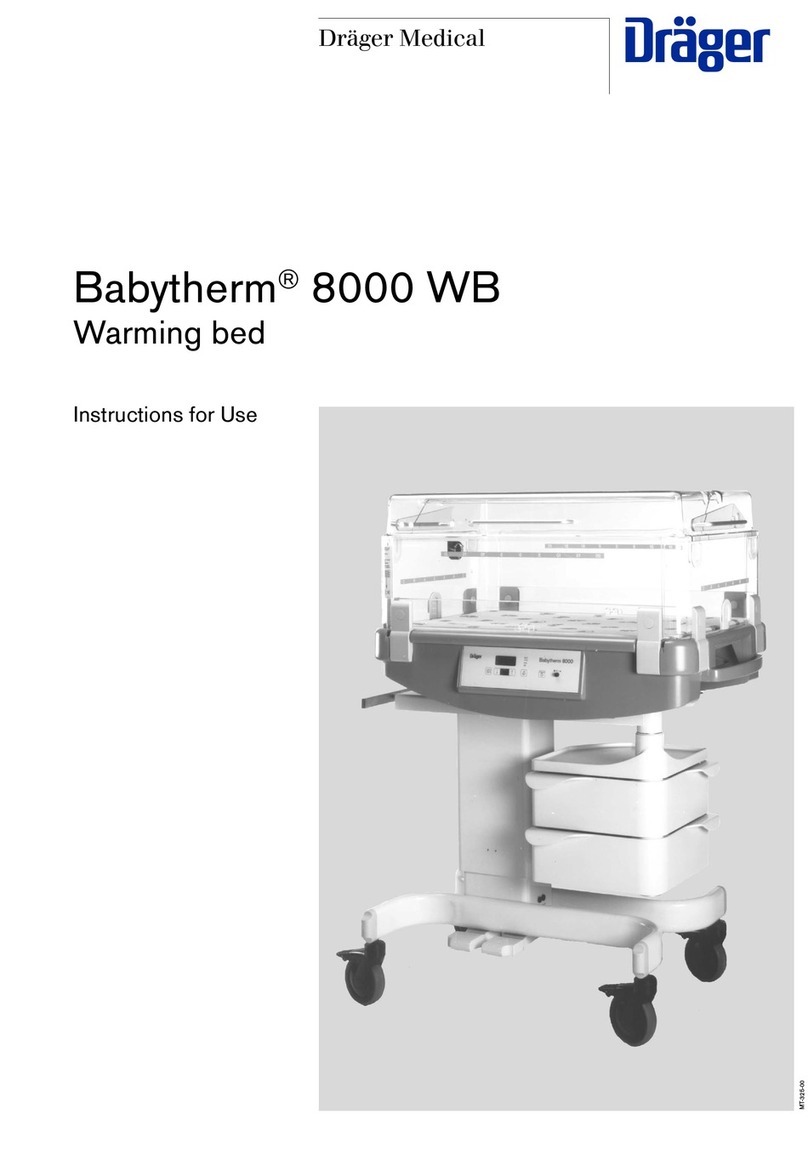

Dräger Medical Babytherm 8000 WB User manual

Dräger Medical

Dräger Medical Babytherm 8004 User manual

Dräger Medical

Dräger Medical Narkomed MRI-2 Assembly instructions

Dräger Medical

Dräger Medical Narkomed Mobile Operating manual

Dräger Medical

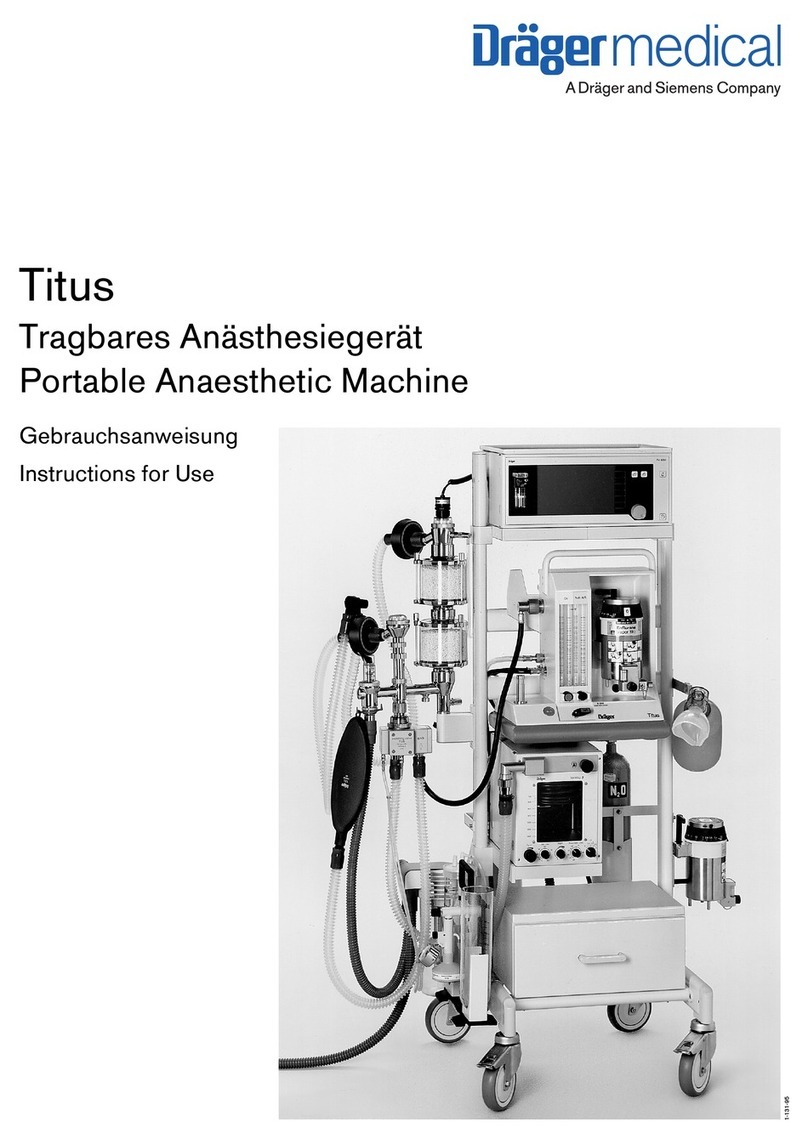

Dräger Medical Titus User manual

Dräger Medical

Dräger Medical X2 Setup guide

Dräger Medical

Dräger Medical SP00180 User manual

Dräger Medical

Dräger Medical Fabius GS Instruction Manual

Dräger Medical

Dräger Medical SP00169 User manual

Dräger Medical

Dräger Medical Fabius GS Operating manual

Dräger Medical

Dräger Medical Evita 4 DC Operating instructions

Dräger Medical

Dräger Medical Fabius Tiro Operating manual

Dräger Medical

Dräger Medical Narkomed Mobile Assembly instructions

Dräger Medical

Dräger Medical CF 800 Guide

Dräger Medical

Dräger Medical Zeus Guide

Dräger Medical

Dräger Medical Narkomed GS Assembly instructions

Dräger Medical

Dräger Medical Narkomed 6400 Assembly instructions

Dräger Medical

Dräger Medical Narkomed GS Operating and safety instructions

Dräger Medical

Dräger Medical Caleo User manual

Dräger Medical

Dräger Medical NeoFlow Operating instructions

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual