PowerSeries Neo Installation Guide

Safety Instructions for Service Personnel

Warning: When using equipment connected to the telephone network, always follow the

basic safety instructions provided with this product. Save these instructions for future

reference. Inform the end-user of the safety precautions that must be observed when

operating this equipment.

Before Installing The Equipment

Ensure your package includes the following items:

lInstallation and User manuals, including the SAFETY INSTRUCTIONS.

READ and SAVE these instructions!

Follow all WARNINGS AND INSTRUCTIONS specified within this

document and/or on the equipment.

lHS2016/HS2016/2032/2064/2128 alarm controller

lPower Supply, direct plug-in

lMounting hardware

Selecting A Suitable Location For The Alarm Controller

Use the following list as a guide to find a suitable location to install this equipment:

lLocate near a telephone socket and power outlet.

lSelect a location free from vibration and shock.

lPlace alarm controller on a flat, stable surface and follow the installation

instructions.

Do NOT locate this product where people may walk on the secondary circuit

cable(s).

Do NOT connect alarm controller to electrical the same circuit as large

appliances.

Do NOT select a location that exposes your alarm controller to direct

sunlight, excessive heat, moisture, vapors, chemicals or dust.

Do NOT install this equipment near water. (e.g., bath tub, kitchen/laundry

sink, wet basement, near a swimming pool).

Do NOT install this equipment and accessories in areas where risk of

explosion exists.

Do NOT connect this equipment to electrical outlets controlled by wall

switches or automatic timers.

AVOID interference sources.

AVOID installing equipment near heaters, air conditioners, ventilators, and

refrigerators.

AVOID locating equipment close to or on top of large metal objects (e.g., wall

studs).

See "Locating Detectors and Escape Plan" on page 20 for information on locating smoke

and CO detectors.

SAFETY Precautions Required During Installation

lNEVER install this equipment and/or telephone wiring during a lightning

storm.

lNEVER touch uninsulated telephone wires or terminals unless the telephone

line has been disconnected at the network interface.

lPosition cables so that accidents can not occur. Connected cables must NOT

be subject to excessive mechanical strain.

lUse only the power supply provided with this equipment. Use of unau-

thorized power supplies may cause damage.

lFor direct plug-in versions, use the transformer supplied with the device.

WARNING: THIS EQUIPMENT HAS NO MAINS ON/OFF SWITCH. THE PLUG OF

THE DIRECT PLUG-IN POWER SUPPLY IS INTENDED TO SERVE AS THE

DISCONNECTING DEVICE IF THE EQUIPMENT MUST BE QUICKLY

DISCONNECTED. IT IS IMPERATIVE THAT ACCESS TO THE MAINS PLUG AND

ASSOCIATED MAINS SOCKET/OUTLET IS NEVER OBSTRUCTED.

IMPORTANT NOTE FORNORTHAMERICA!

This alarm system must be installed and used within an environment that provides the

pollution degree max 2 and over-voltages category II NON-HAZARDOUS

LOCATIONS, indoor only. The equipment is DIRECT PLUG-IN (external transformer)

and is designed to be installed, serviced and/or repaired by service persons only;

[service person is defined as a person having the appropriate technical training and

experience necessary to be aware of hazards to which that person may be exposed in

performing a task and of measures to minimize the risks to that person or other persons].

This equipment has no mains on/off switch; if the equipment must be quickly

disconnected, the plug of the direct plug-in power supply is intended to serve as the

disconnecting device; it is imperative that access to the mains plug and associated mains

socket/outlet, is never obstructed. There are no parts replaceable by the end-user within

this equipment. The wiring (cables) used for installation of the alarm system and

accessories, shall be insulated with PVC, TFE, PTFE, FEP, Neoprene or Polyamide.

(a) The equipment enclosure must be secured to the building structure before operation.

(b) Internal wiring must be routed in a manner that prevents:

- Excessive strain or loosening of wire on terminal connections;

- Damage of conductor insulation

(c) Disposal of used batteries must be made in accordance with local waste recovery and

recycling regulations.

(d) Before servicing, DISCONNECT the power and telephone connection.

(e) DO NOT route any wiring over circuit boards.

(f) The installer is responsible to ensure that a readily accessible disconnect device is

incorporated in the building for permanently connected installations.

The power supply must be Class II, FAIL SAFE with double or reinforced insulation

between the PRIMARY and SECONDARY CIRCUIT/ENCLOSURE and be an approved

type acceptable to the local authorities. All national wiring rules must be observed.

Installation

Mounting the Enclosure

Locate the panel in a dry area, preferably near an unswitched AC power

source and the incoming telephone line. Complete all wiring before

applying AC or connecting the battery.

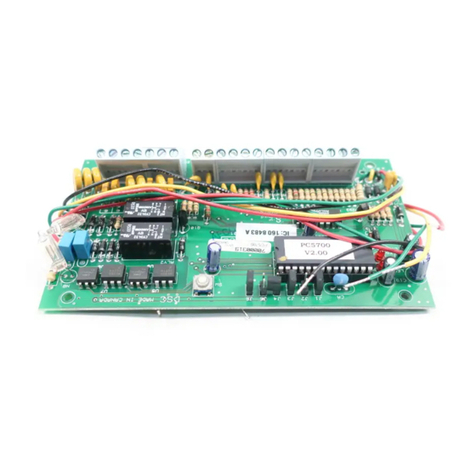

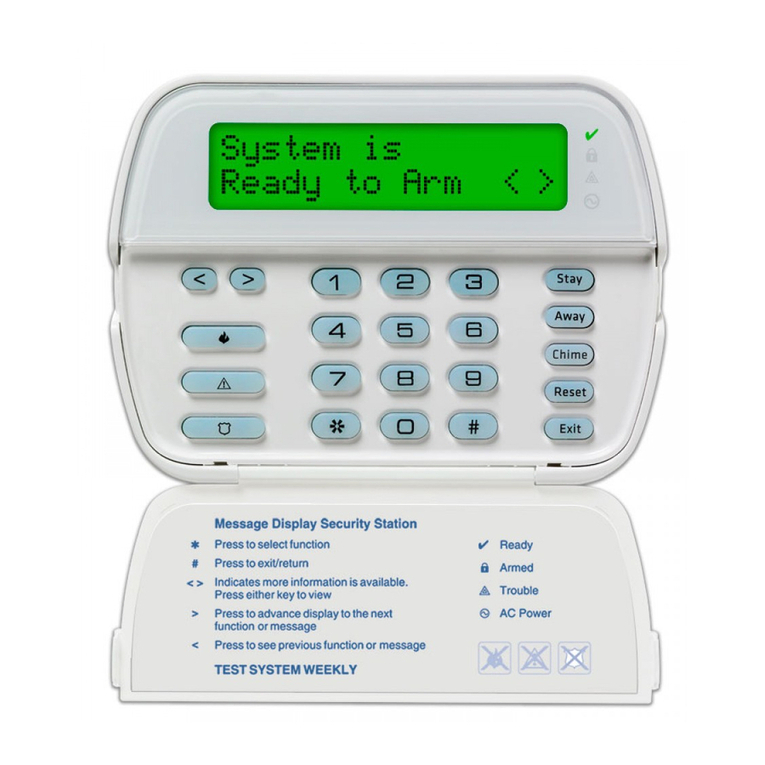

Terminal Descriptions

The following terminals are available on the PowerSeries Neo alarm

controller.

Terminal Description

BAT+,

BAT-

Battery terminals. Use to provide backup power and additional current

when system demands exceed the power output of the transformer, such

as when the system is in alarm.

Do not connect the battery until all other wiring is complete.

AC Power terminals.

Connect the battery before connecting the AC. Do not connect the battery

or transformer until all other wiring is complete.

AUX+,

AUX-

Auxiliary terminals. Use to power modules, detectors, relays, LEDs, etc.

(700mA MAX). Connect the positive side of device to AUX+, the

negative side to AUX-.

BELL+,

BELL-

Bell/Siren power (700mA MAX). Connect the positive side of any alarm

warning device to BELL+, the negative side to BELL-.

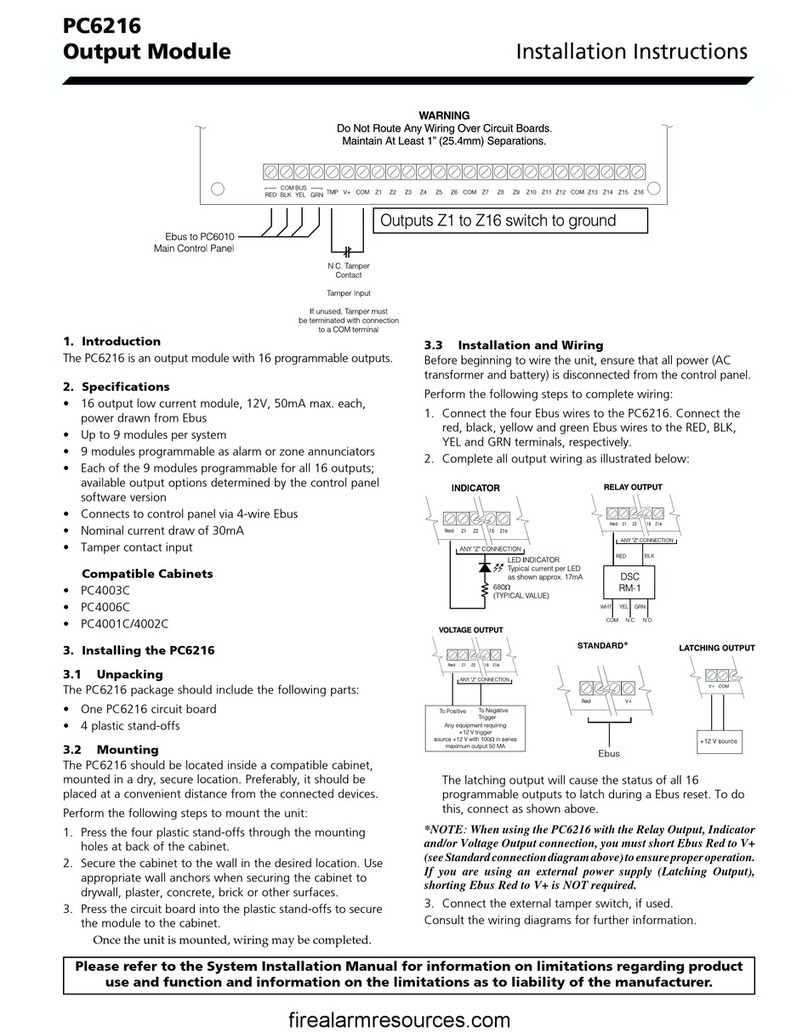

RED, BLK,

YEL, GRN

Corbus terminals. Use to provide communication between the alarm

controller and connected modules. Each module has four Corbus

terminals that must be connected to the Corbus.

PGM1 to

PGM4

Programmable output terminals. Use to activate devices such as LEDs.

(PGM1, PGM3, and PGM4: 50mA PGM2: 300mA or can be configured

as an input)

Z1 to Z8

COM

Zone input terminals. Ideally, each zone should have one detection

device; however, multiple detection devices can be wired to the same

zone.

EGND Earth ground connection.

TIP, RING,

T-1, R-1

Telephone line terminals.

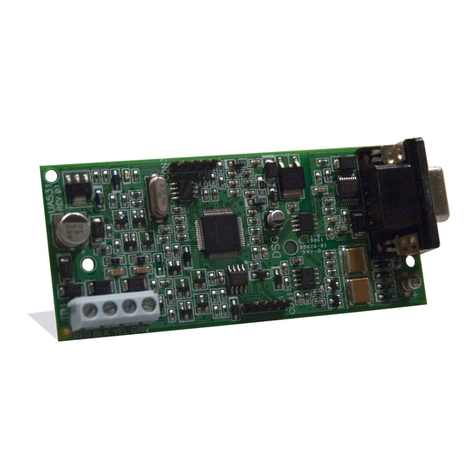

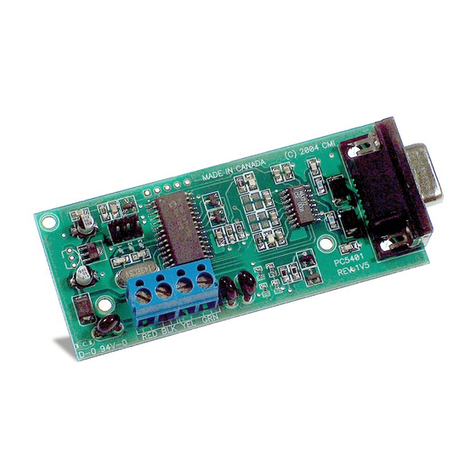

PCLINK_1 DLS/SA

PCLINK_2 DLS/SA, Alternate Communicator

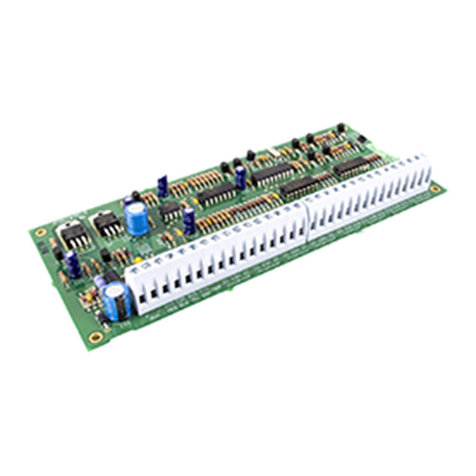

Corbus Wiring

The RED and BLK Corbus terminals are used to provide power while

YEL and GRN are used for data communications. The 4 Corbus terminals

of the alarm controller must be connected to the 4 Corbus terminals or

wires of each module.

The following conditions apply:

lCorbus should be run with minimum 22 gauge quad, two pair

twisted preferred.

lThe modules can be home run to the panel, connected in series or

- 2 -