Duke RUF-48 M User manual

Other Duke Commercial Food Equipment manuals

Duke

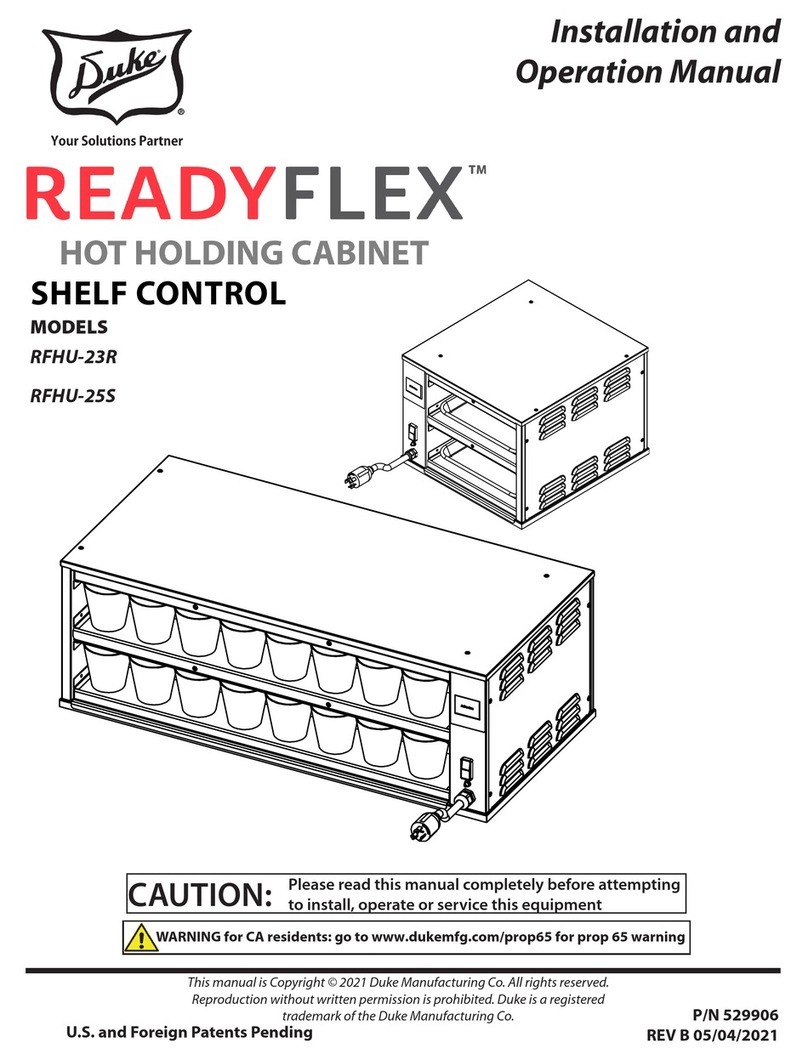

Duke ReadyFlex RFHU-23R User manual

Duke

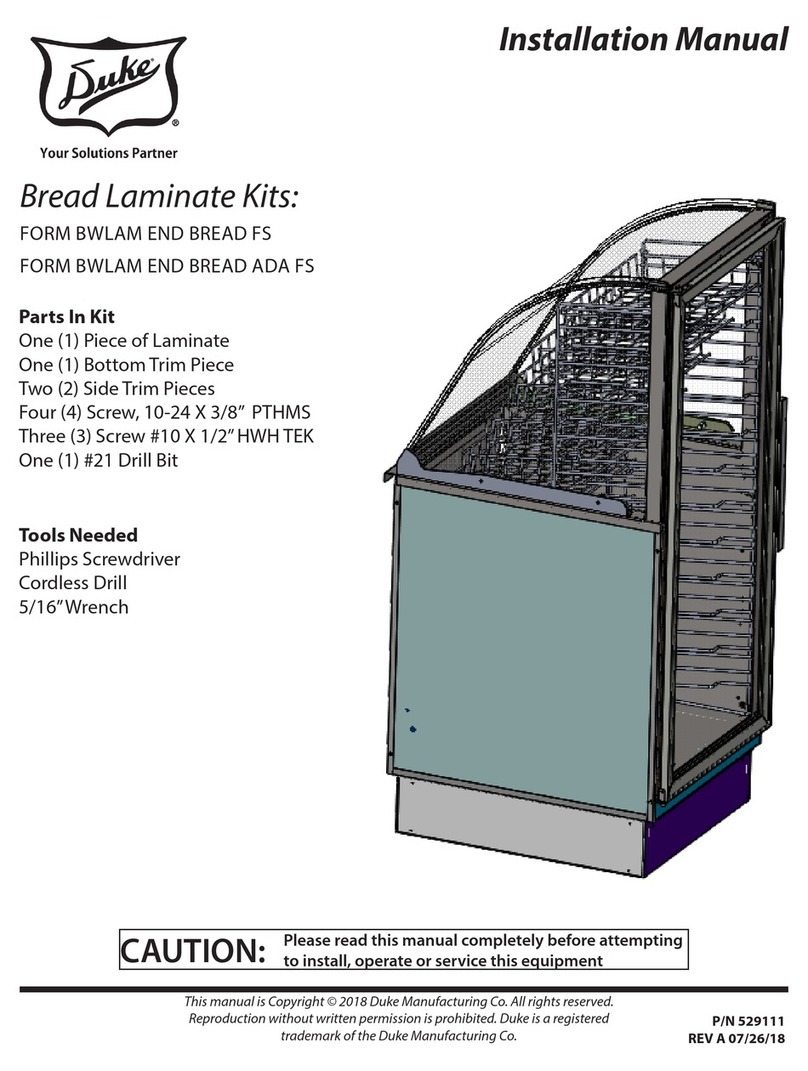

Duke FORM BWLAM END BREAD FS User manual

Duke

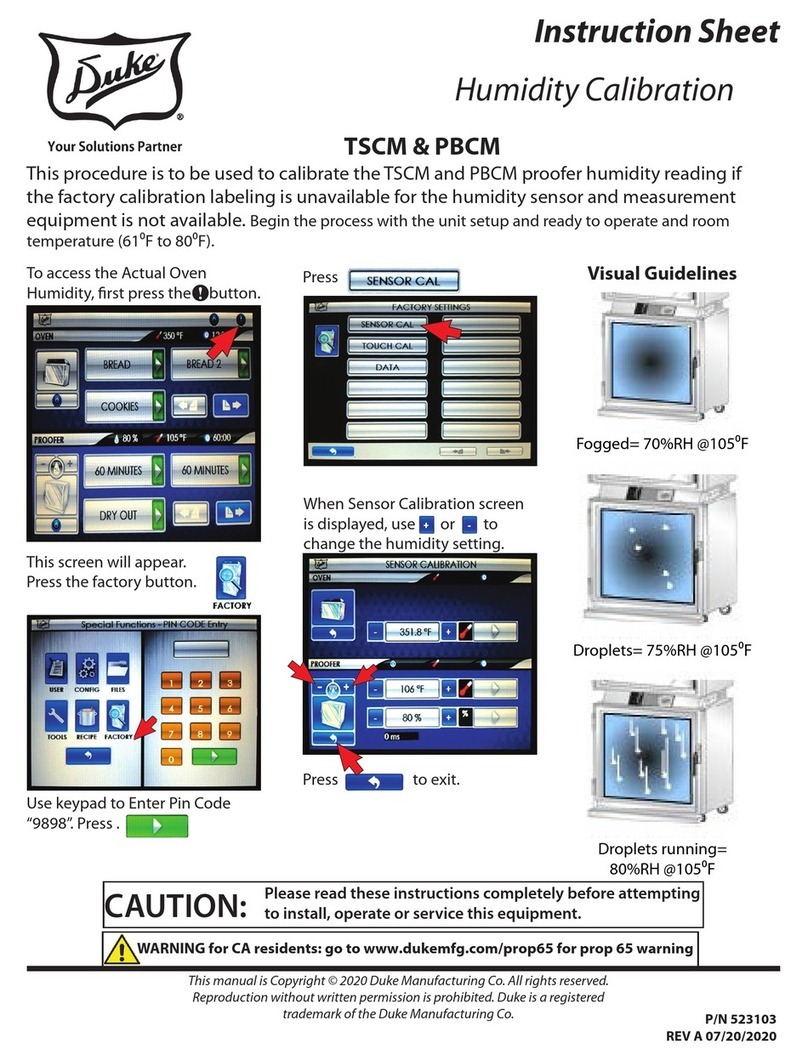

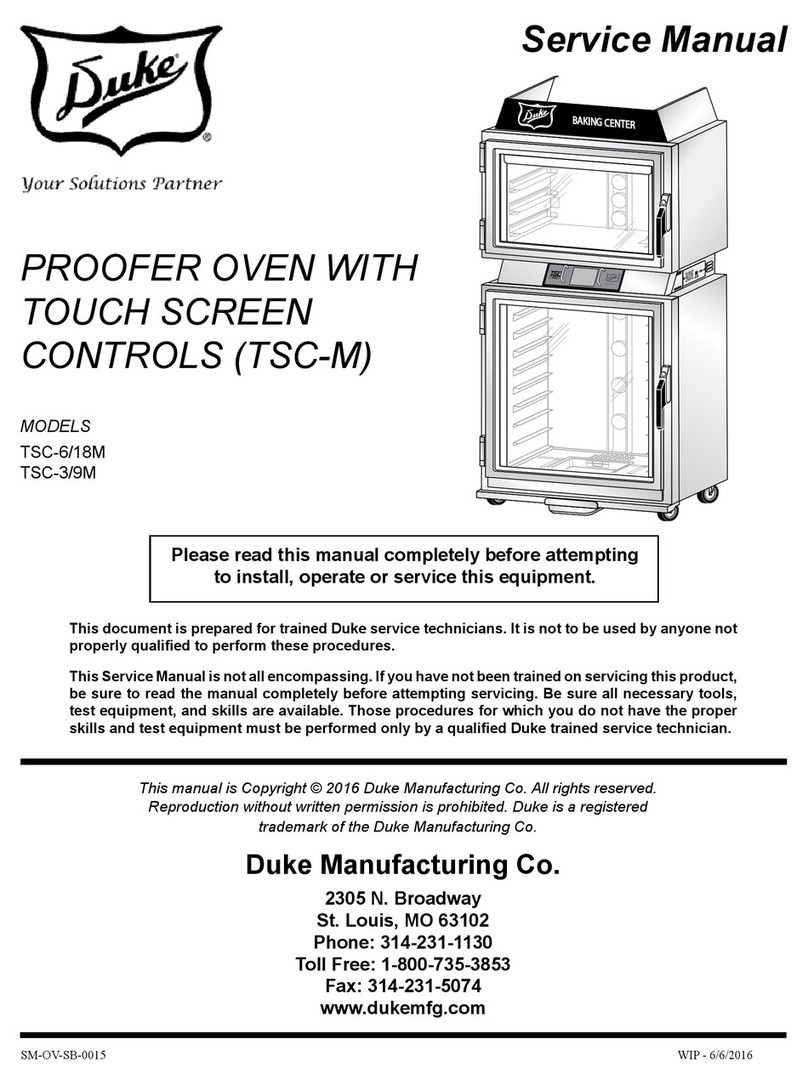

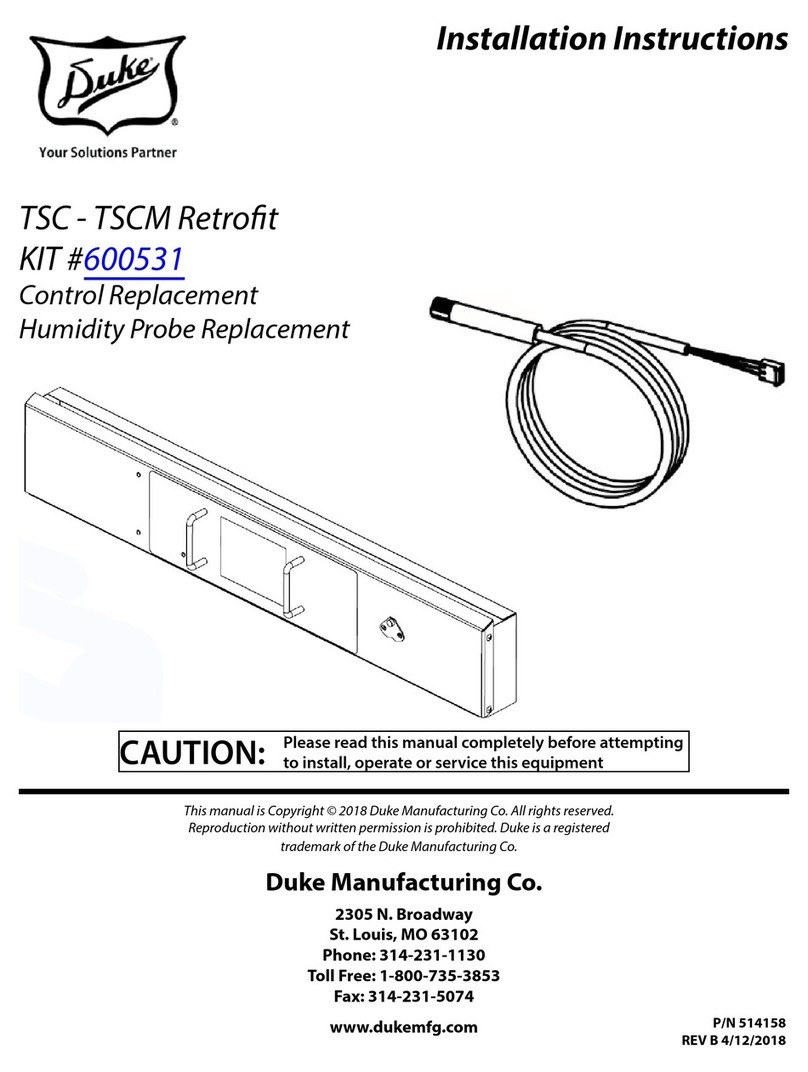

Duke TSCM User manual

Duke

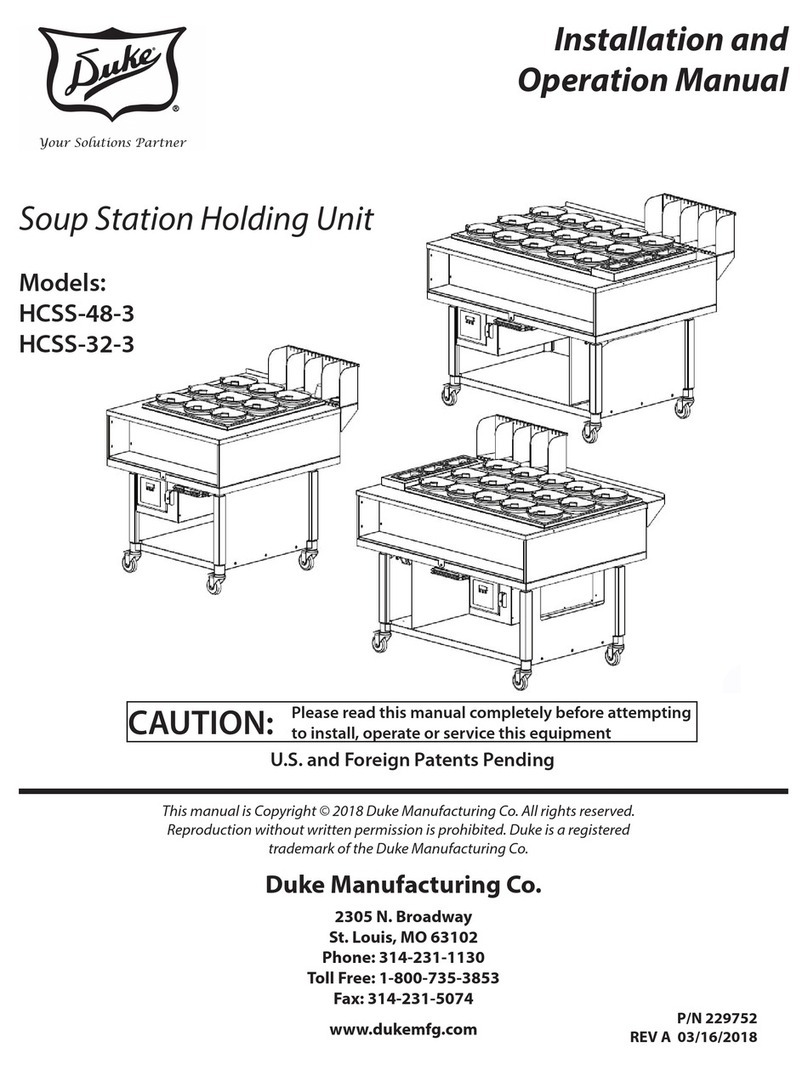

Duke HCSS-48-3 User manual

Duke

Duke FLM200 User manual

Duke

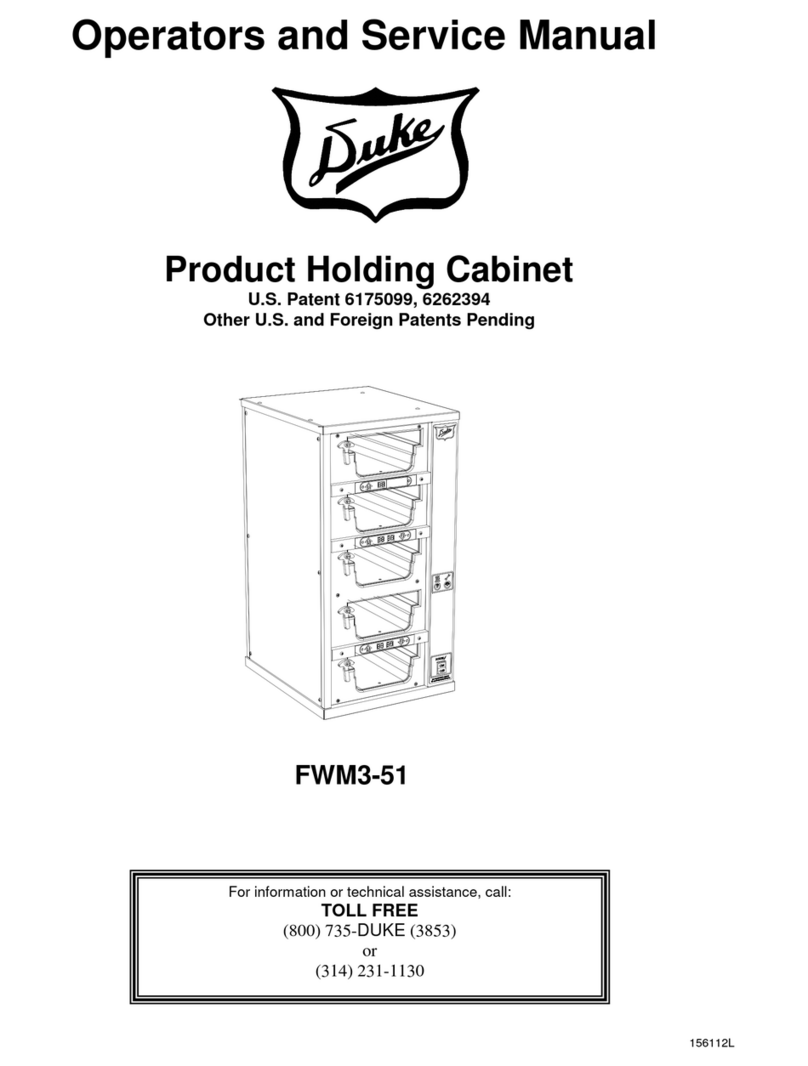

Duke FWM3-51 100 Operating manual

Duke

Duke TSC User manual

Duke

Duke FWM3-22 User manual

Duke

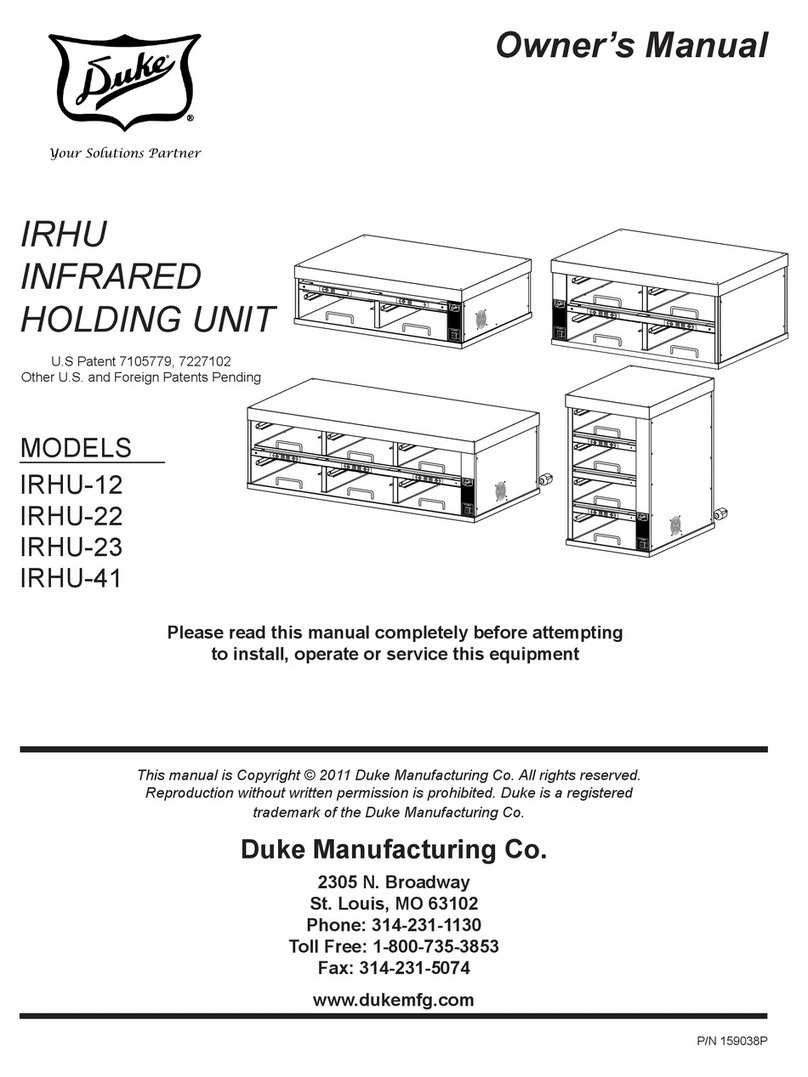

Duke IRHU Series User manual

Duke

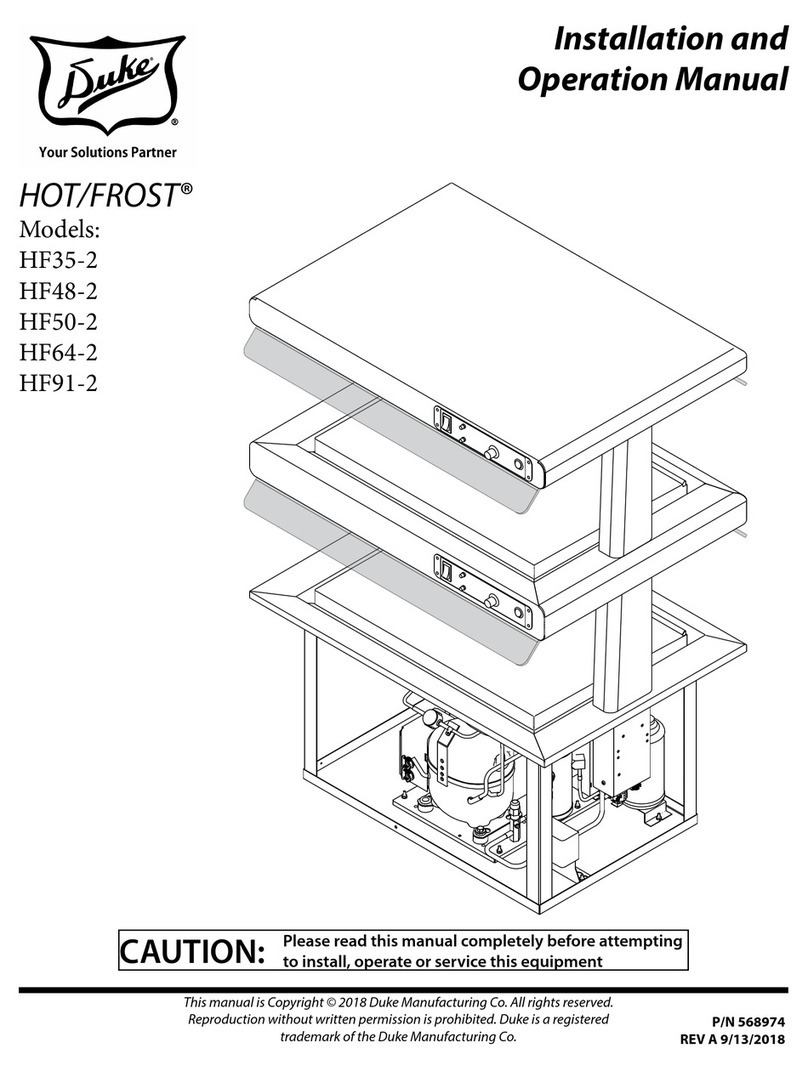

Duke HOT/FROST HF35-2 User manual

Duke

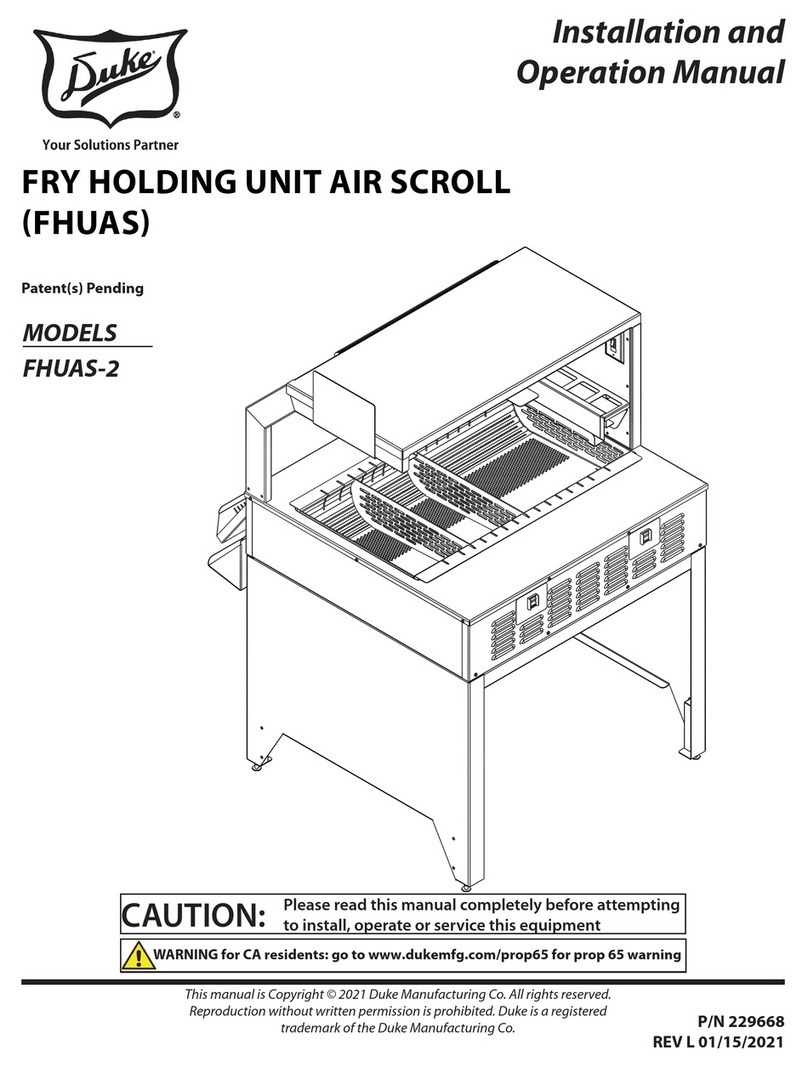

Duke FHUAS-2 User manual

Duke

Duke ReadyFlex RFHU-35M User manual

Duke

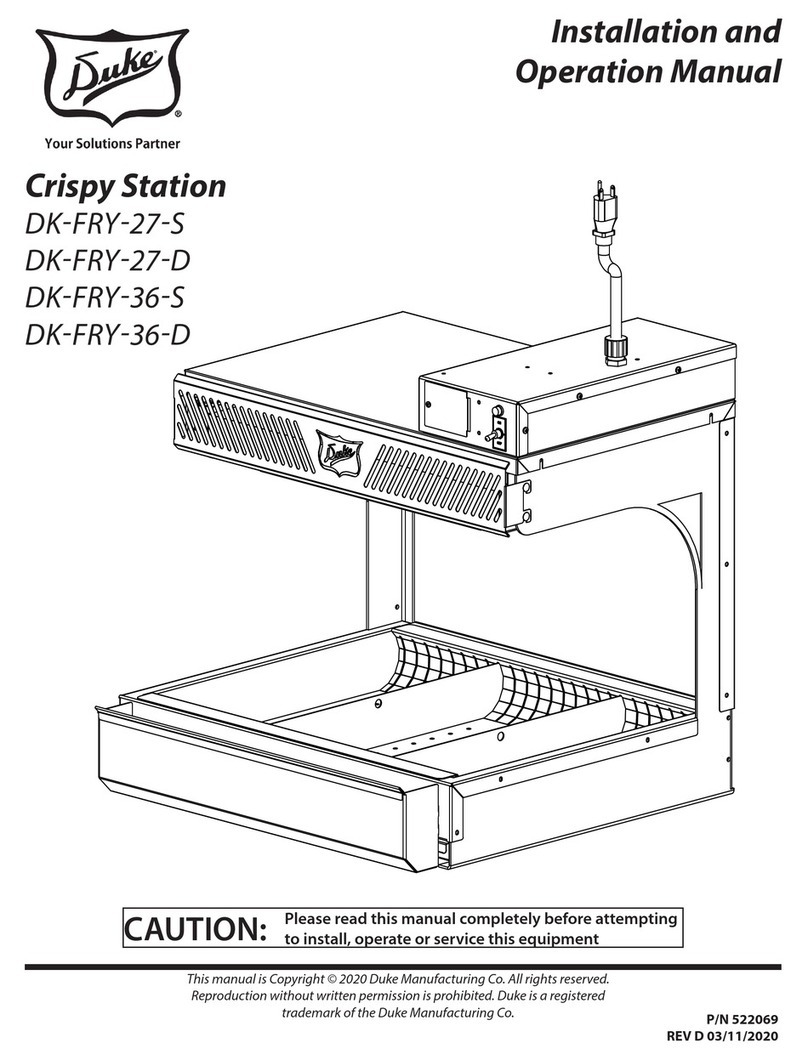

Duke DK-FRY-27-S User manual

Duke

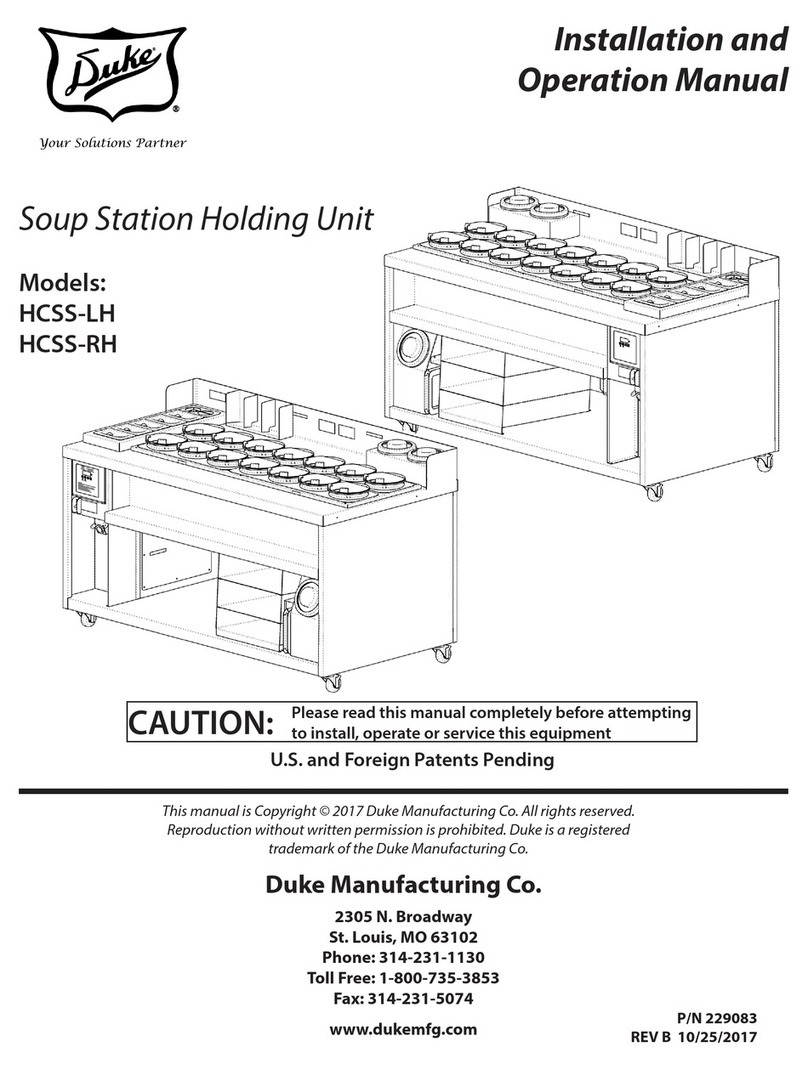

Duke HCSS-LH User manual

Duke

Duke TSC User manual

Duke

Duke Readyflex User manual

Duke

Duke INTERSECT User manual

Duke

Duke FWM3-22 Operating manual

Duke

Duke RFHU-22 User manual

Duke

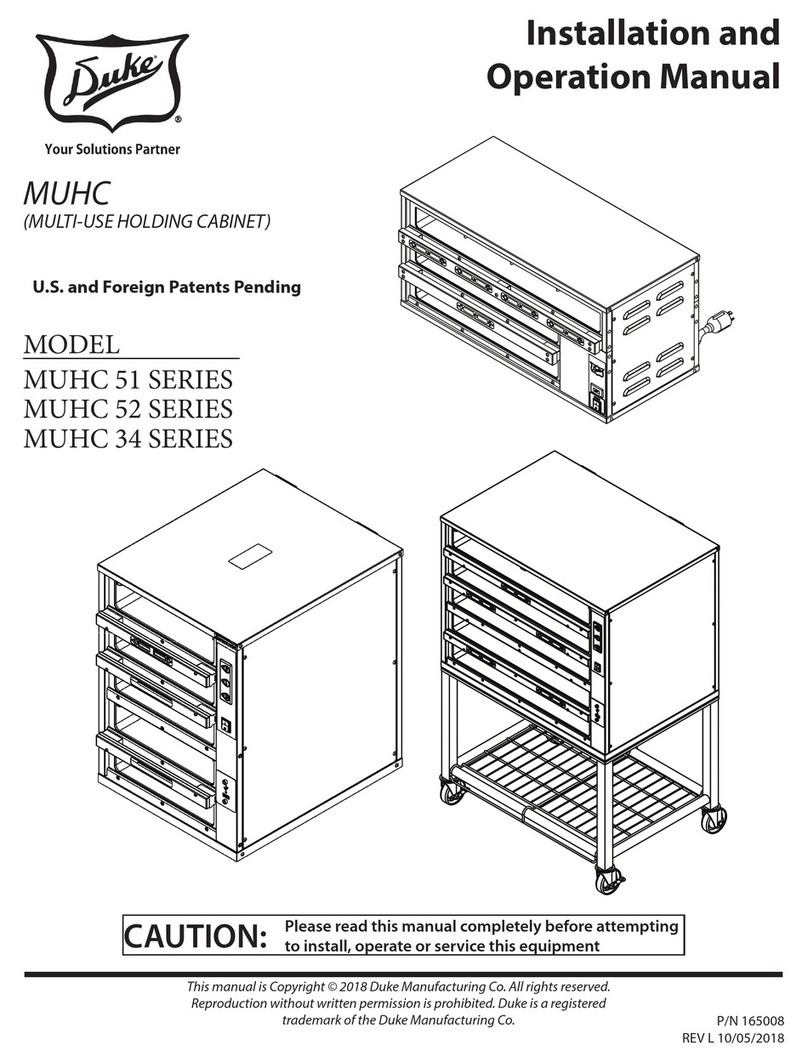

Duke MUHC-51-120 User manual

Popular Commercial Food Equipment manuals by other brands

Blue Seal

Blue Seal EF30 Installation & operation manual

Tecfrigo

Tecfrigo Snelle 400 GS installation instructions

Follett

Follett PFT Series Operation and maintenance manual

MEFE

MEFE CAT 206 PTR User manual and maintenance

Premier

Premier 900cl Product manua

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Cambro

Cambro IBSD37 Setup guide and user manual