Table of contents

1

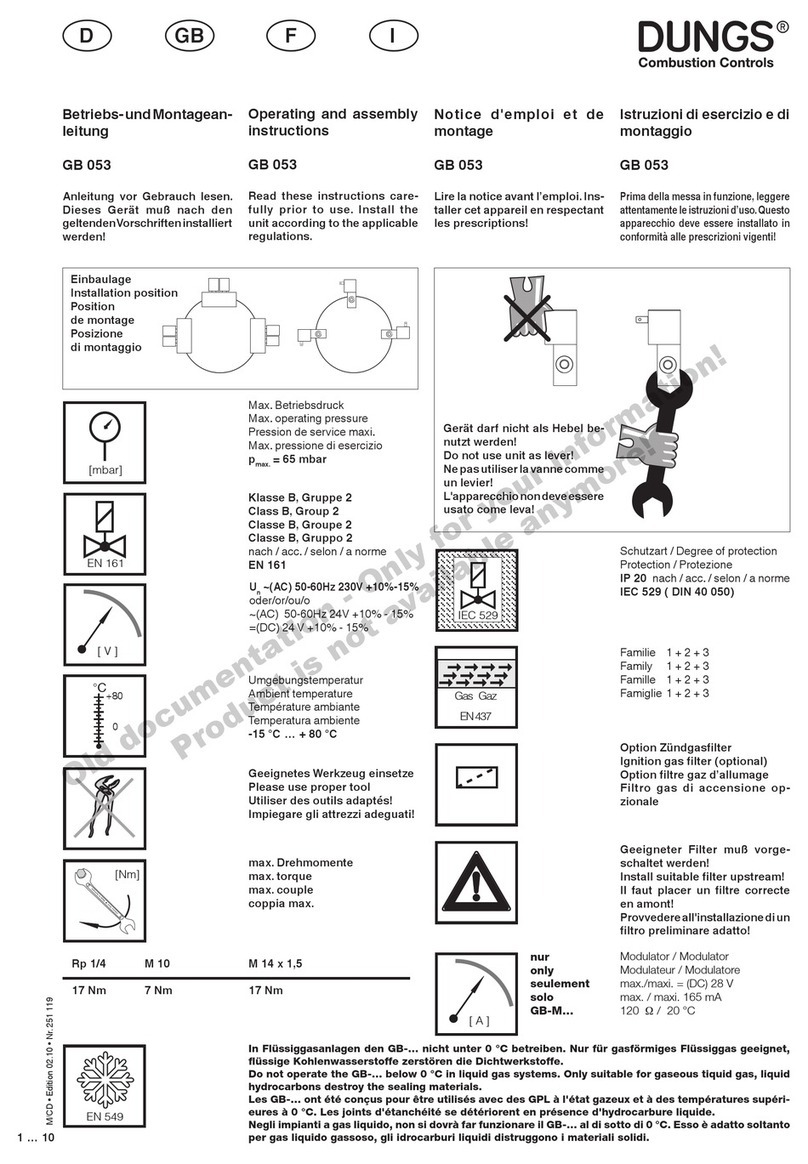

Introduction and purpose of these operating instructions.............................................................3

2

General safety instructions..........................................................................................................4

3

Systemoverview.........................................................................................................................6

3.1 Functional description ..........................................................................................................6

3.2 Intended use and misuse.....................................................................................................8

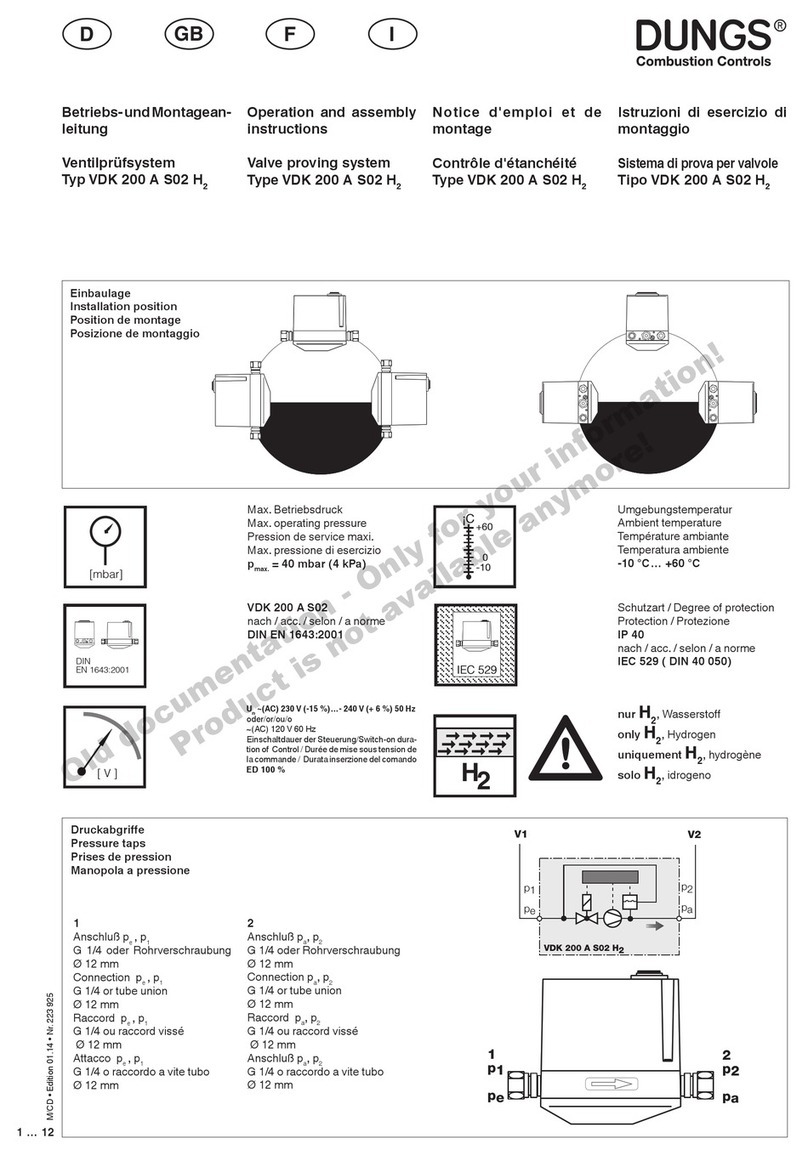

3.3 Technical data .....................................................................................................................9

3.4 Function of the control unit.................................................................................................12

4

Transport and storage...............................................................................................................13

5

Installation and commissioning..................................................................................................13

5.1 Scope of delivery................................................................................................................13

5.2 Integration into the machine...............................................................................................14

5.3 Checking the installation ....................................................................................................16

5.4 Commissioning ..................................................................................................................17

6

Manufacturer settings................................................................................................................19

7

Operation..................................................................................................................................20

8

Product and capacity changes ..................................................................................................21

9

Maintenance and servicing........................................................................................................21

10

Cleaning ...................................................................................................................................22

11

Malfunctions..............................................................................................................................22

12

Decommissioning and disposal.................................................................................................22

13

Documents and drawings..........................................................................................................23

List of illustrations

Table 1: Standard versions of the HeatEngine ......................................................................................7

Table 2: Flame length of the standard versions...................................................................................10

Table 3: Default setting of important MPA parameters ........................................................................10

Table 4: Standard values for setting the main volume throttle .............................................................20

Table 5: Service life of the components...............................................................................................21

Figure 1: P&ID diagram of the HeatEngine............................................................................................6

Figure 2: Type code of the HeatEngine.................................................................................................9

Figure 3: Mounting flange and seals of the HeatEngine (left: line-style burner, right: point-style burner)

............................................................................................................................................................14

Figure 4: HeatEngine in process chamber with outer and inner lining/insulation (line-style burner

system) ...............................................................................................................................................15

Figure 5: HeatEngine in process chamber with outer and inner lining/insulation (point-style burner

system) ...............................................................................................................................................15

Figure 6: Diagram for setting the main volume throttle ........................................................................19