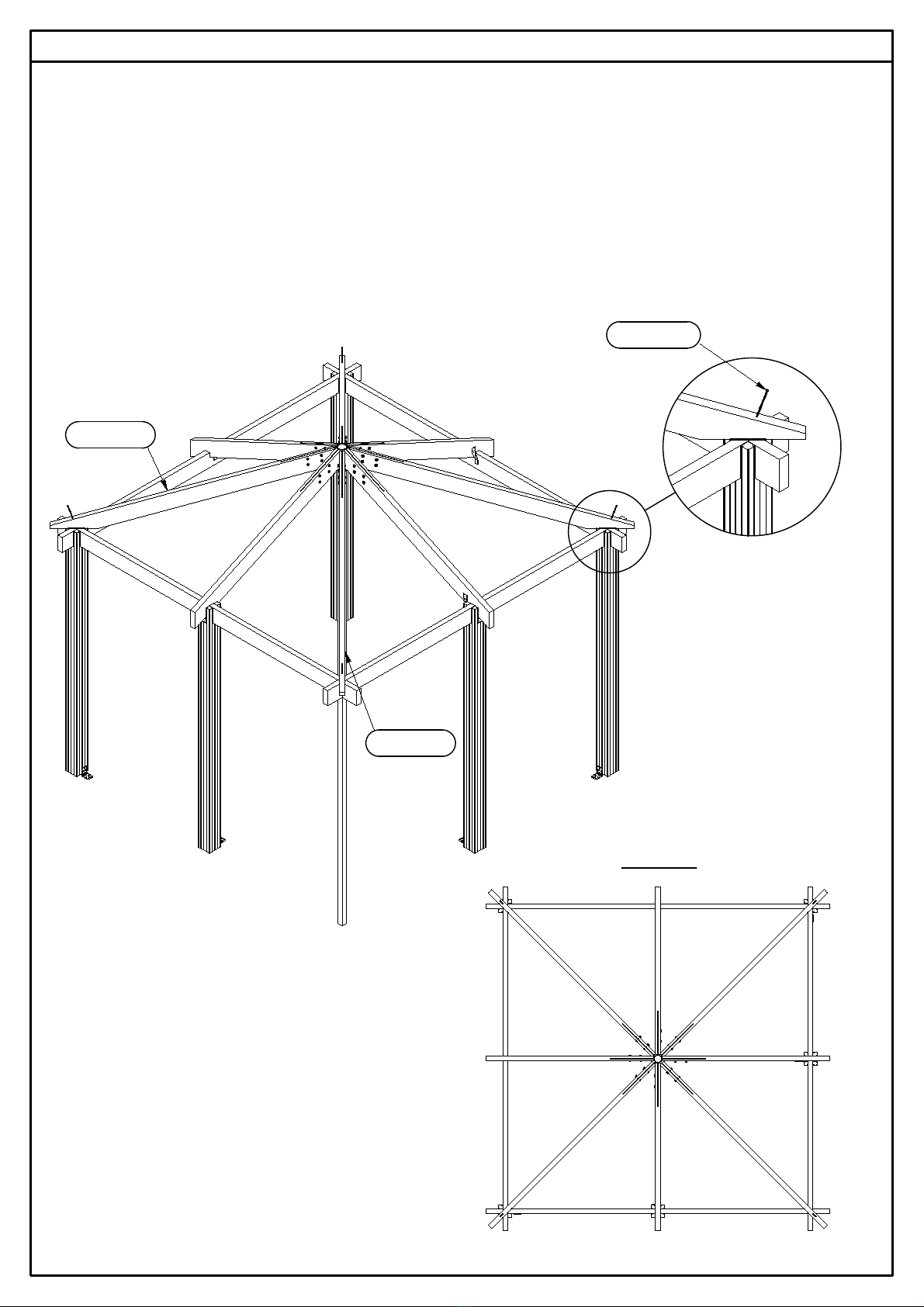

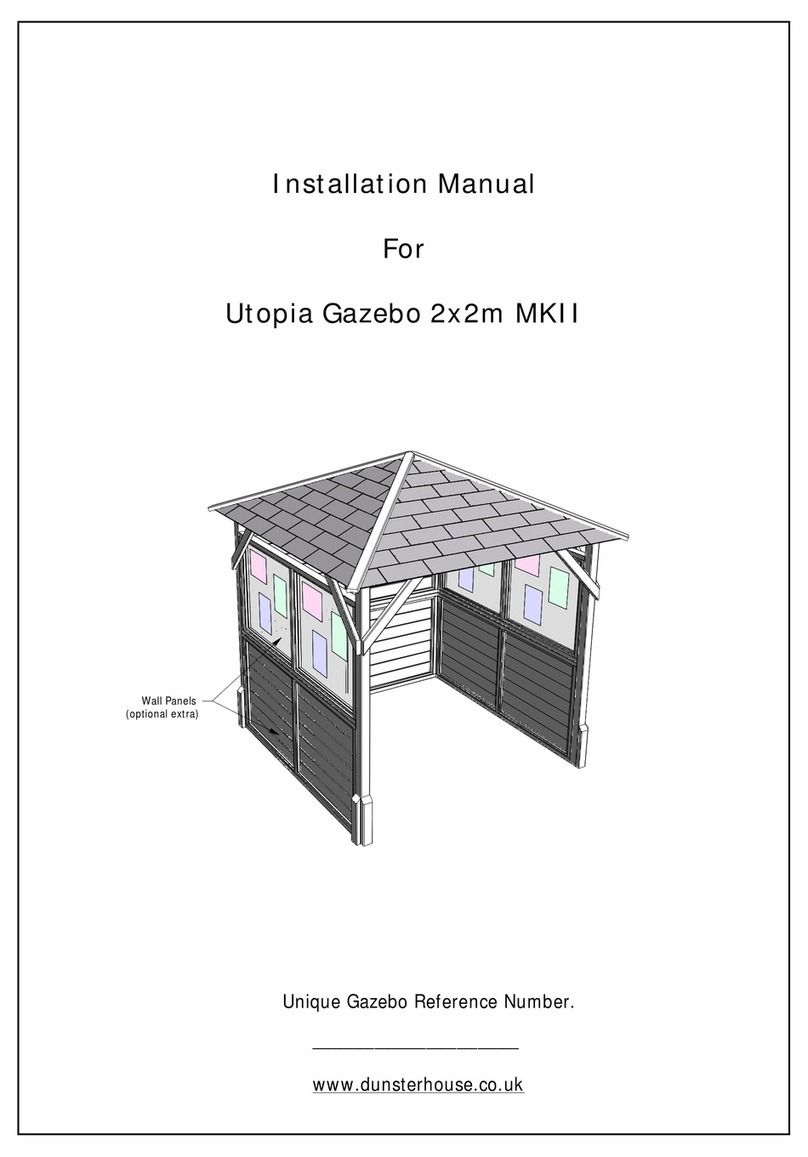

Dunster House P5-3030CORGAZ User manual

Other Dunster House Outdoor Furnishing manuals

Dunster House

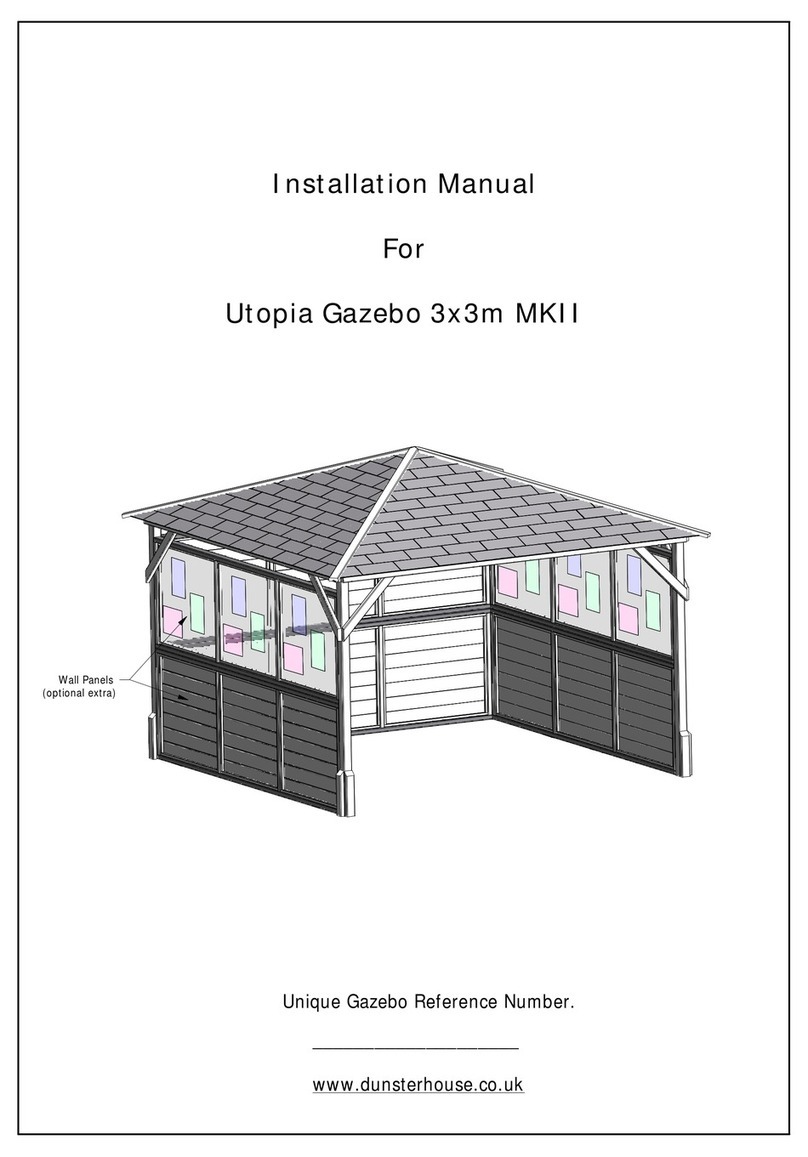

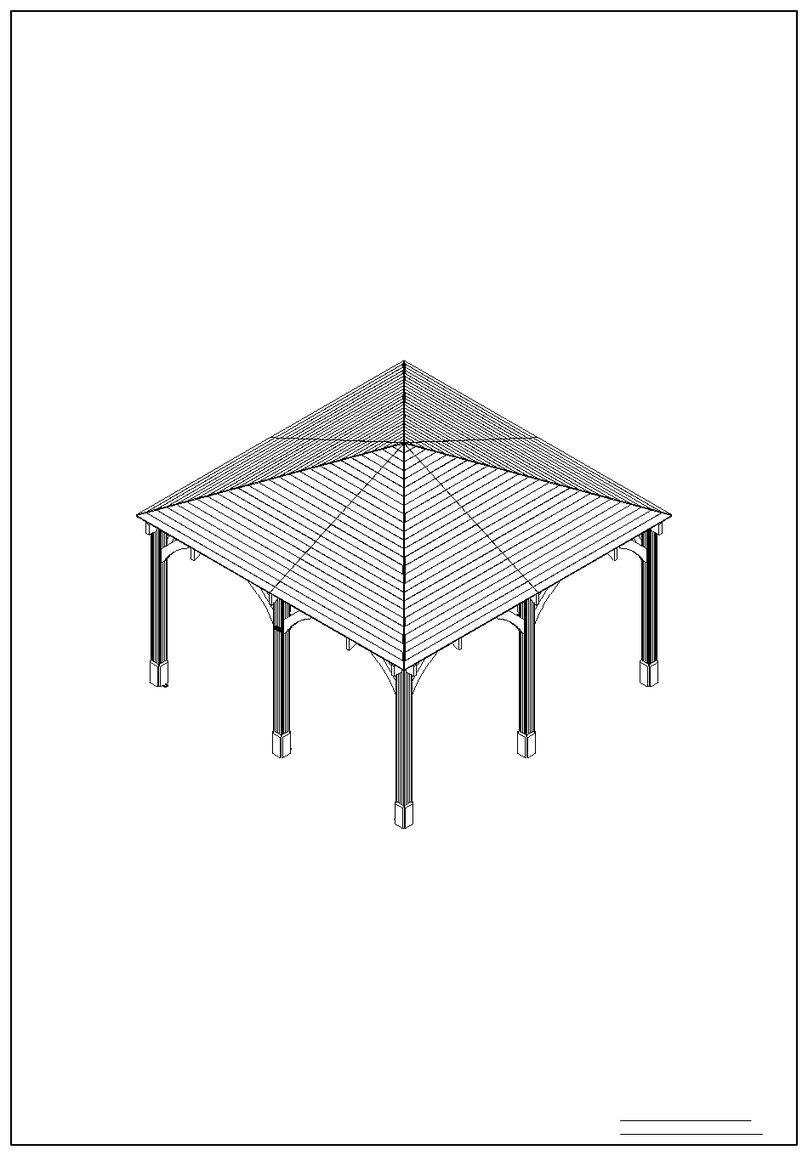

Dunster House Utopia 3x3m MKII User manual

Dunster House

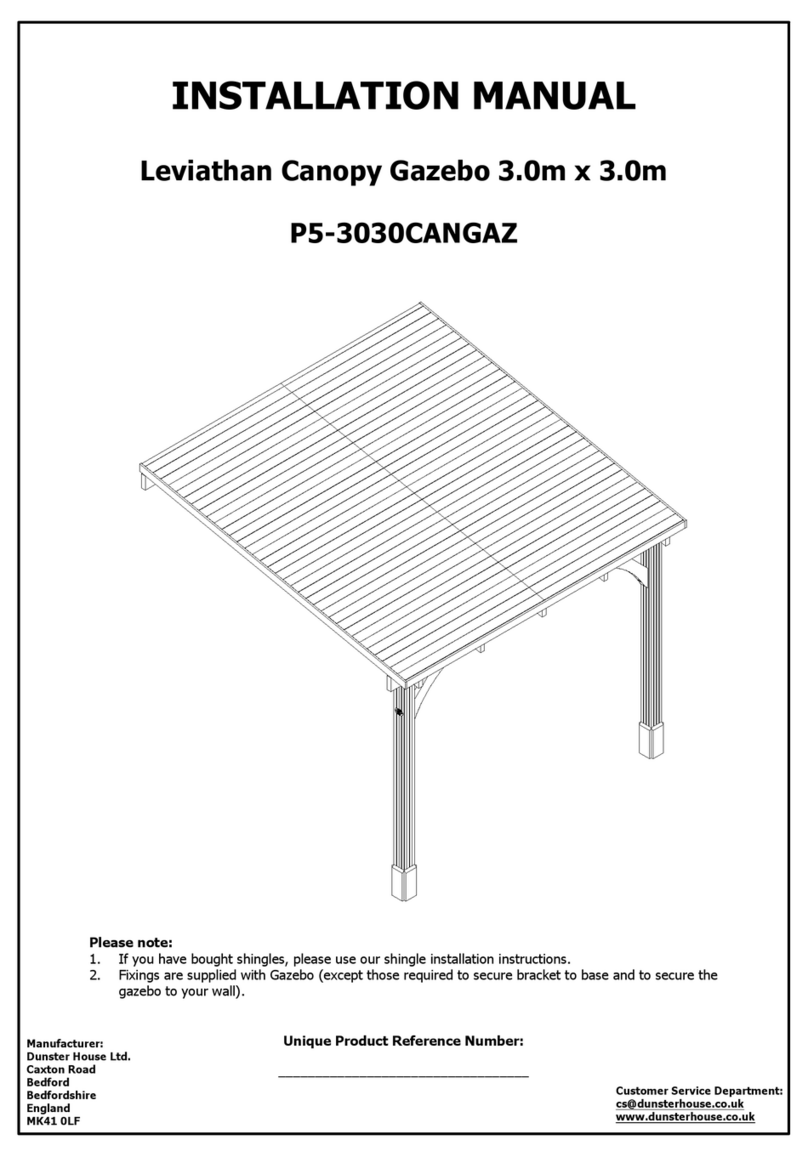

Dunster House P5-3030CANGAZ User manual

Dunster House

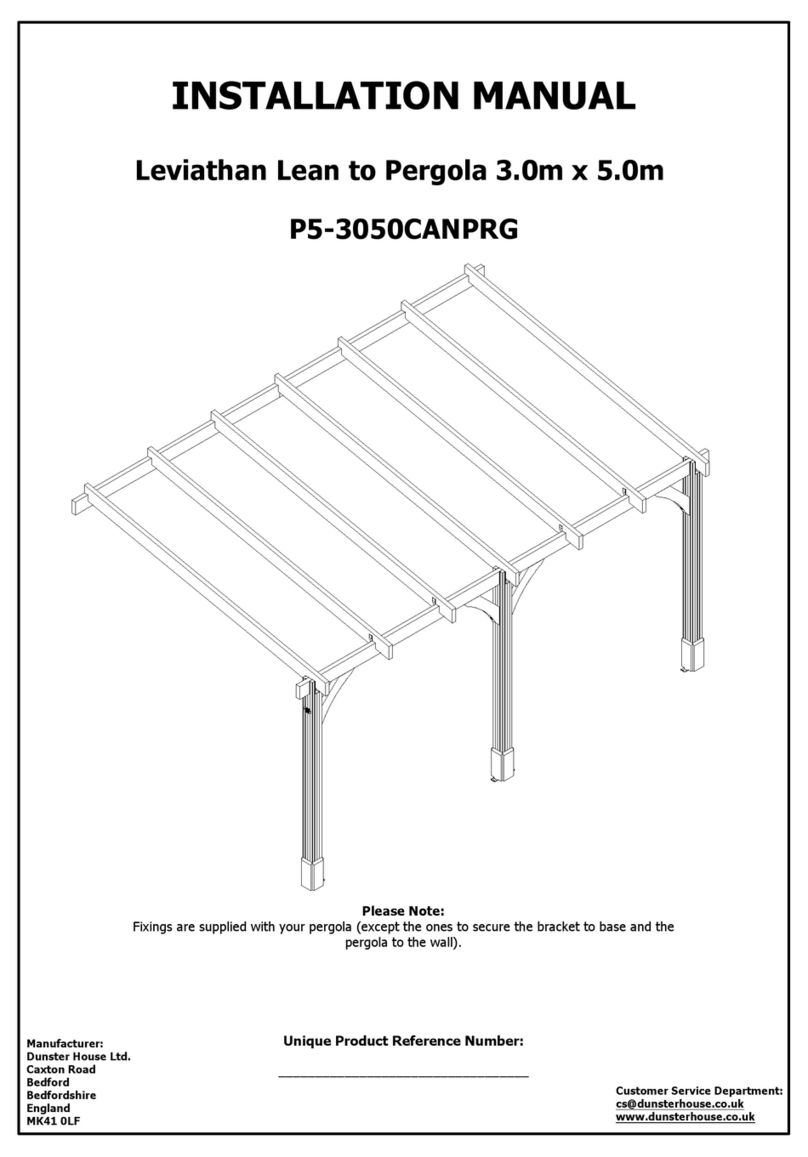

Dunster House P5-3050CANPRG User manual

Dunster House

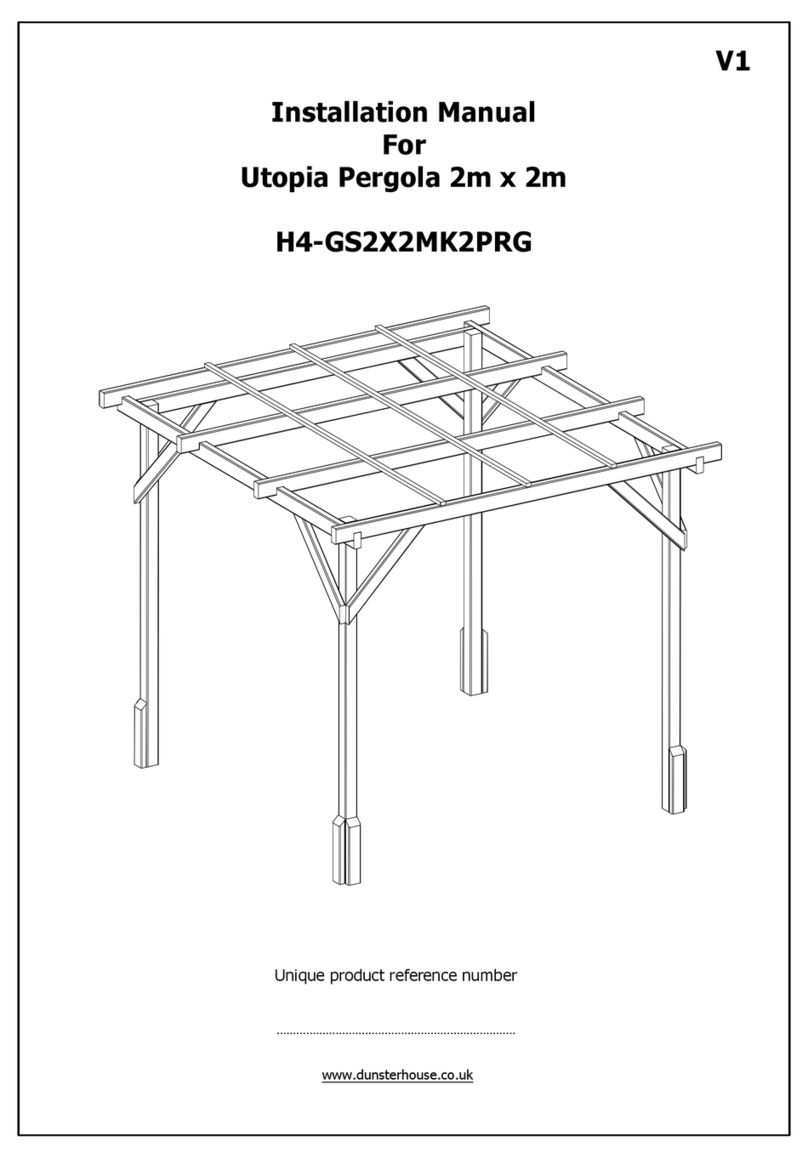

Dunster House H4-GS2X2MK2PRG User manual

Dunster House

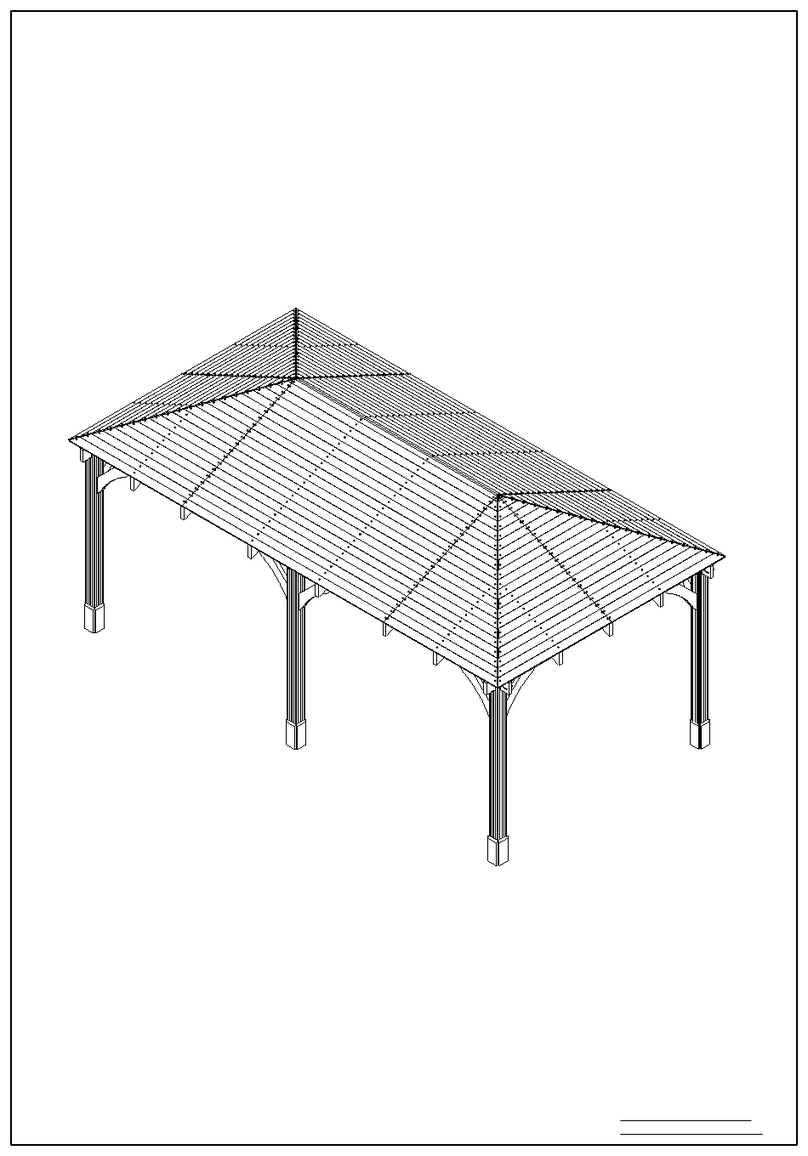

Dunster House ATLAS P5-3060PRG User manual

Dunster House

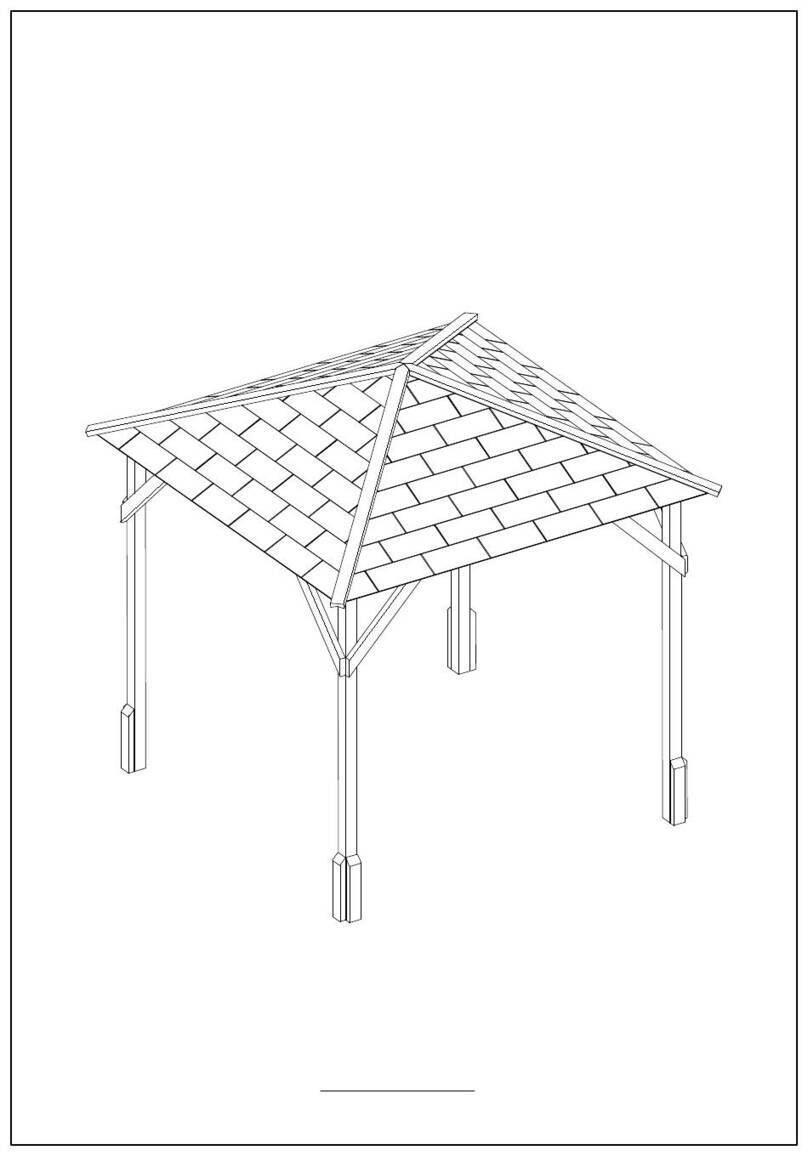

Dunster House Utopia 200 H3-GS2X2MK2 User manual

Dunster House

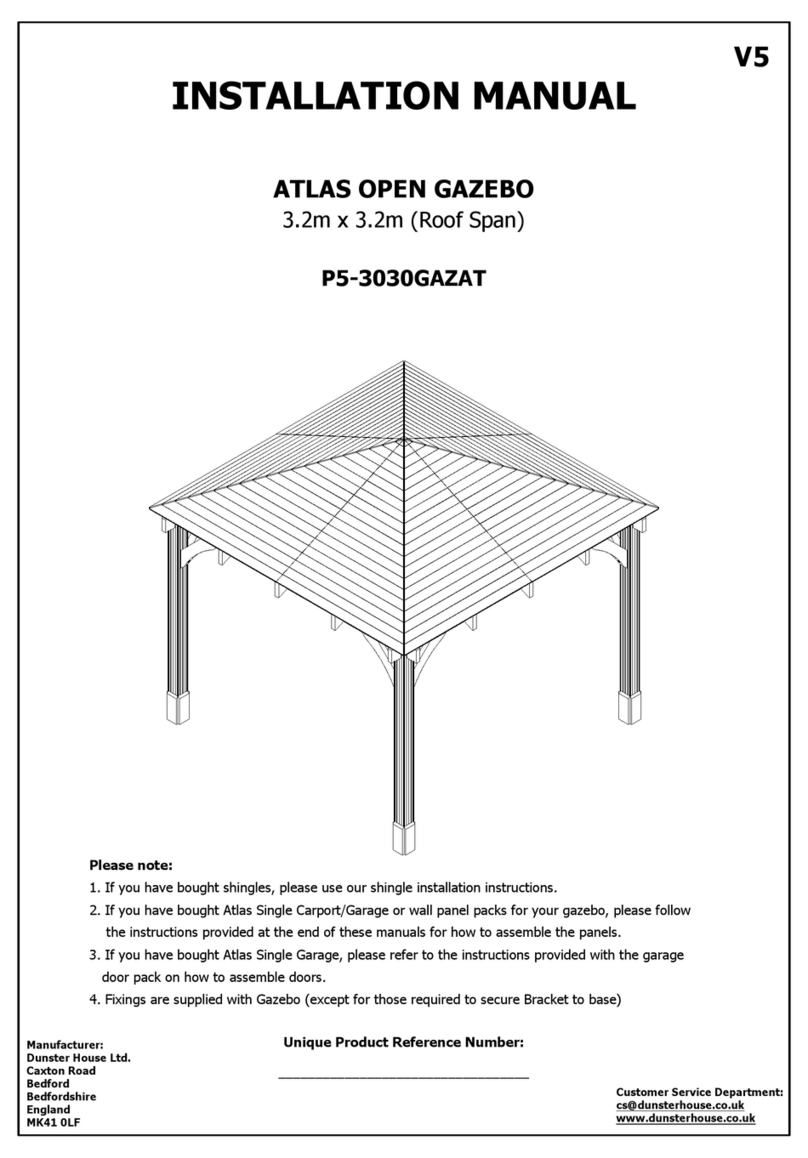

Dunster House P5-3030GAZAT User manual

Dunster House

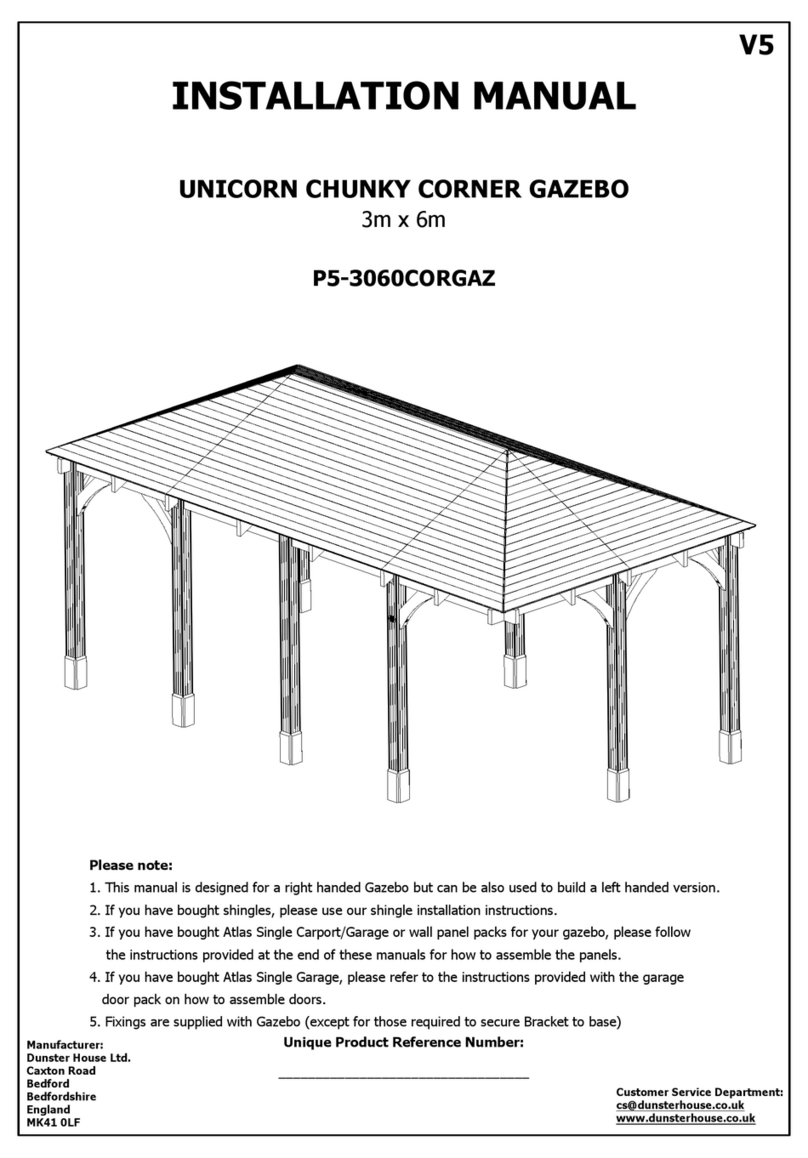

Dunster House P5-3060CORGAZ User manual

Dunster House

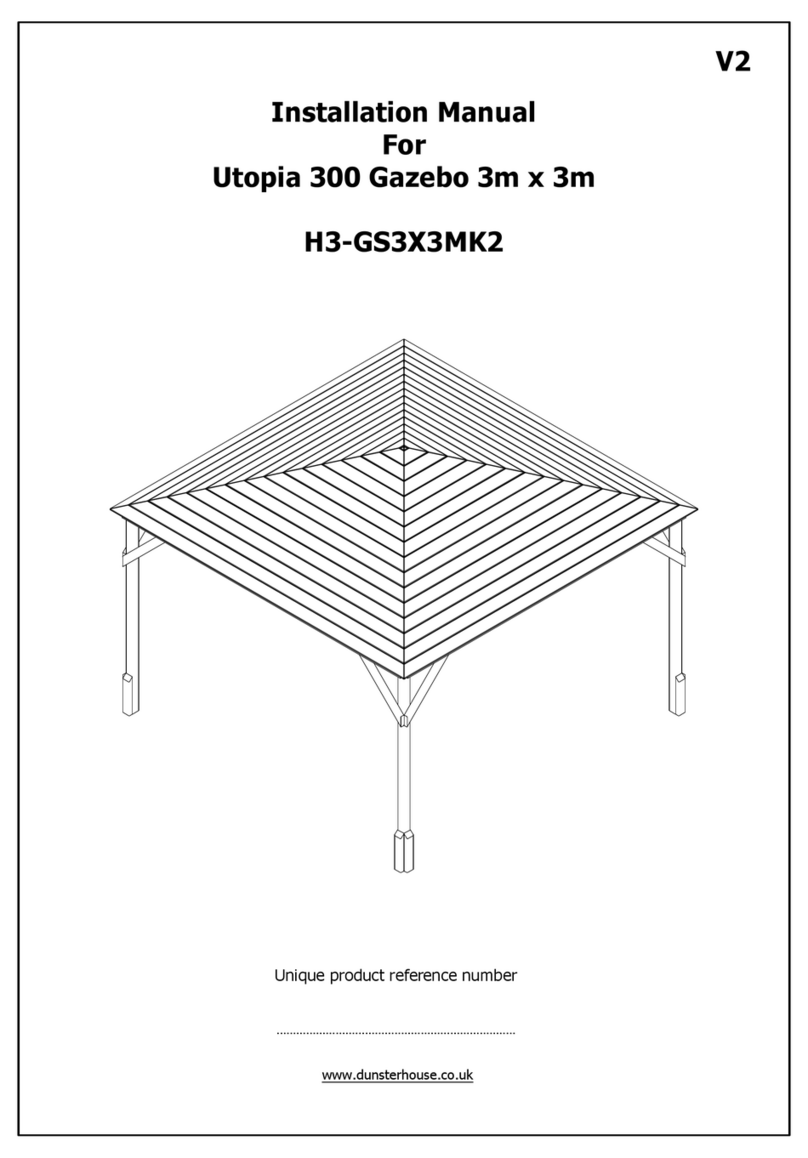

Dunster House Utopia 300 User manual

Dunster House

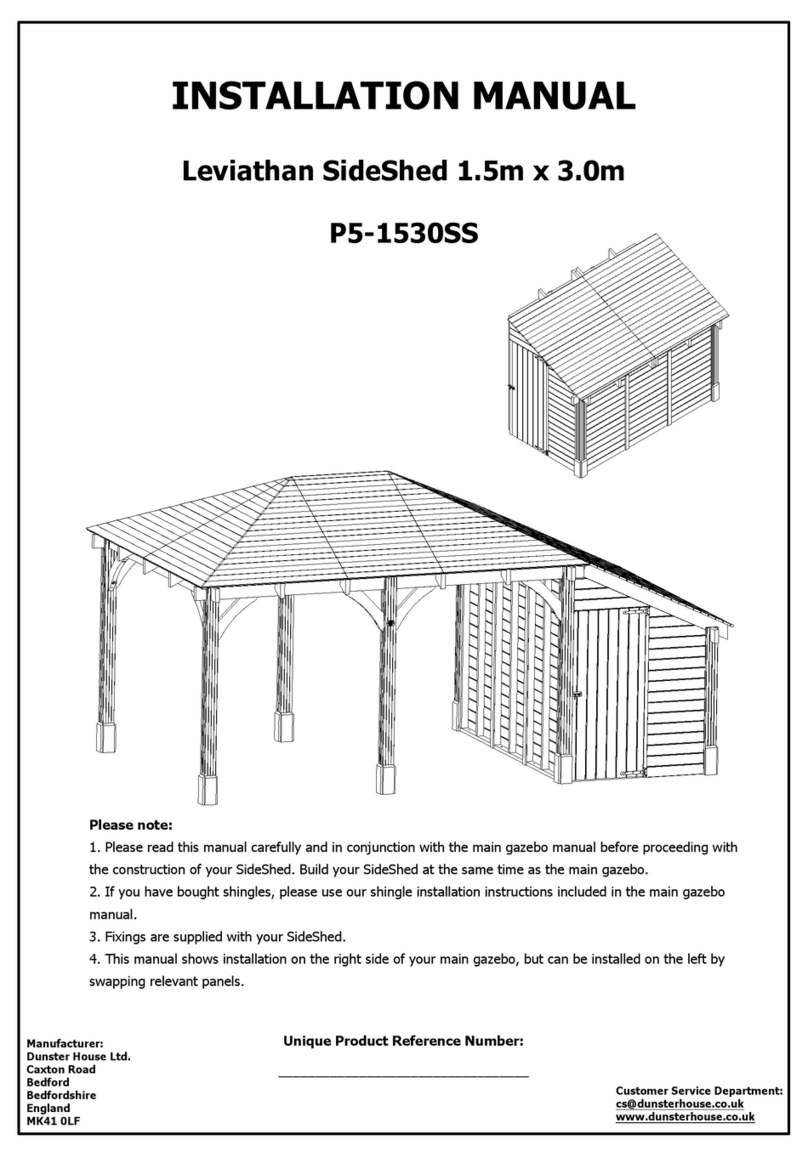

Dunster House Leviathan SideShed P5-1530SS User manual

Dunster House

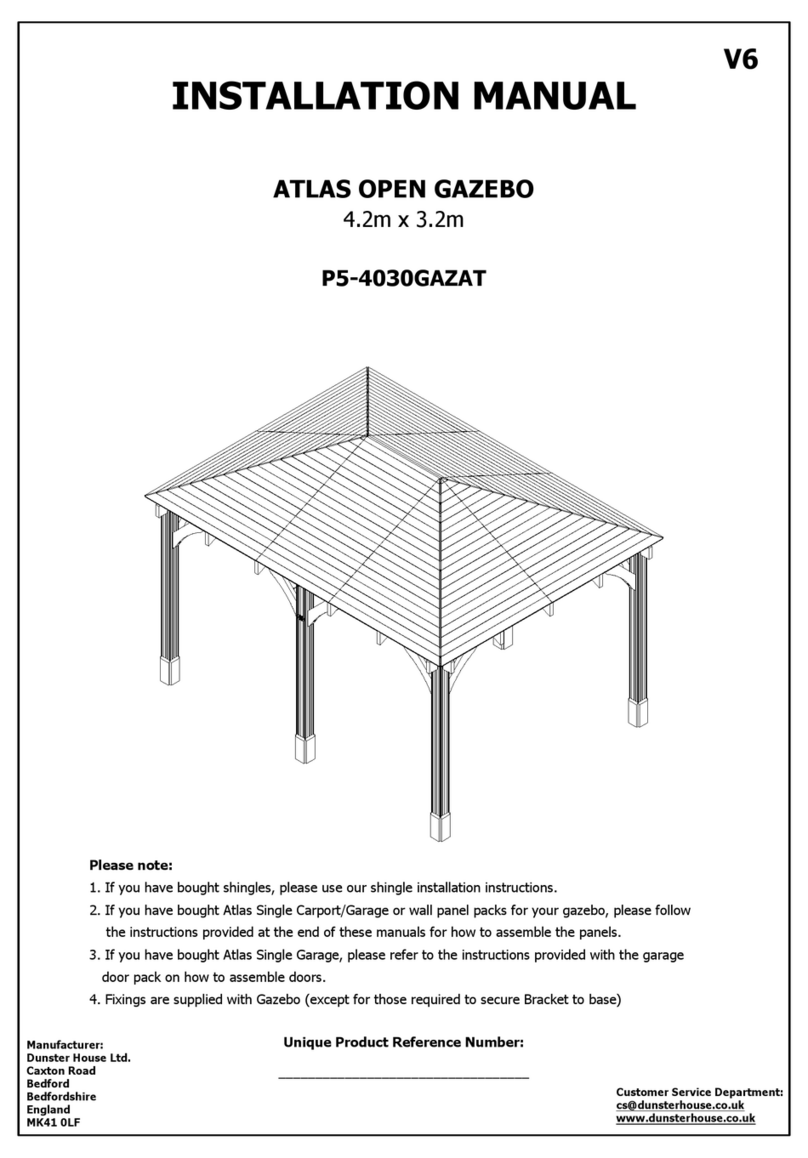

Dunster House ATLAS P5-4030GAZAT User manual

Dunster House

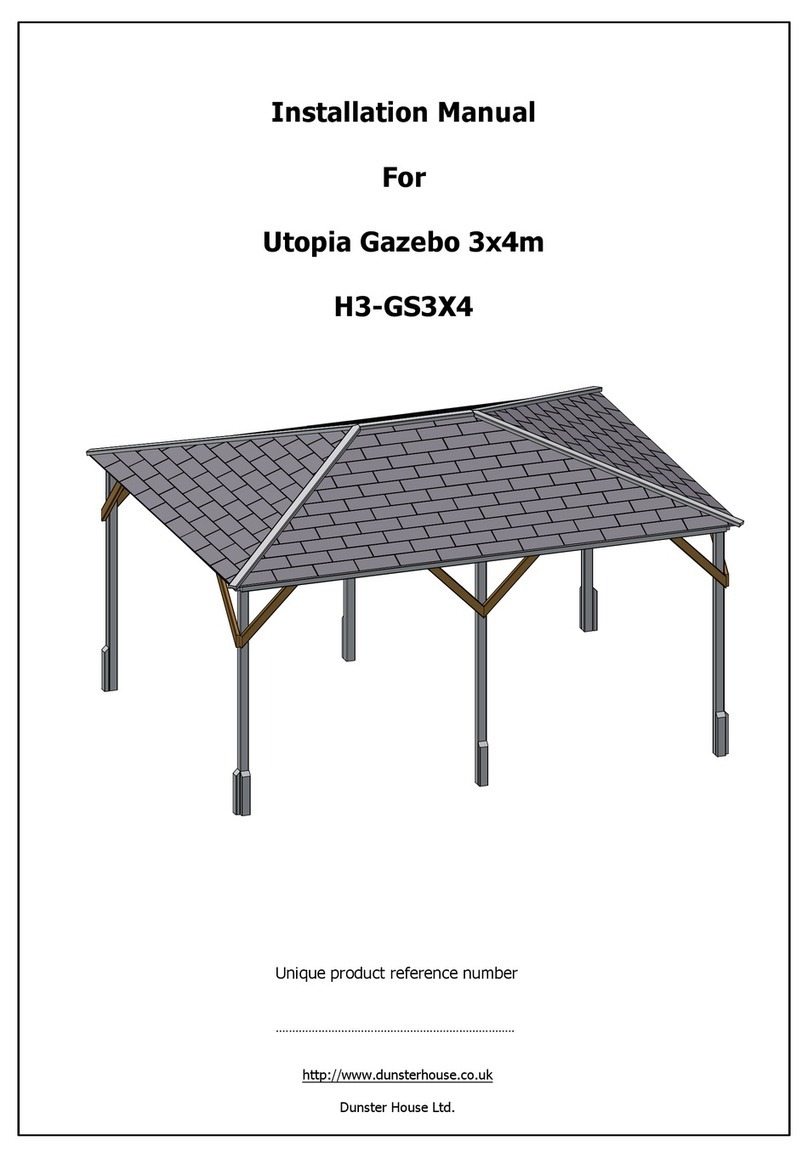

Dunster House H3-GS3X4 User manual

Dunster House

Dunster House P5-6030GAZAT User manual

Dunster House

Dunster House Atlas User manual

Dunster House

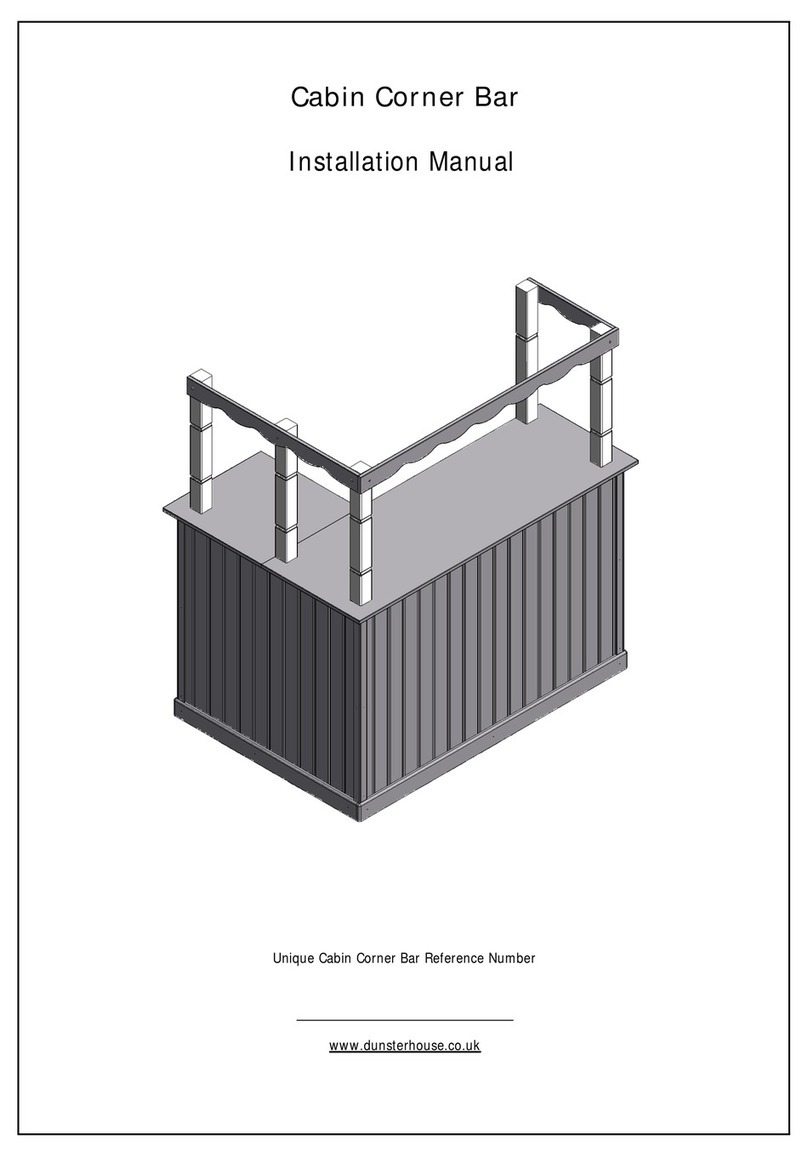

Dunster House Unique Cabin Corner Bar User manual

Dunster House

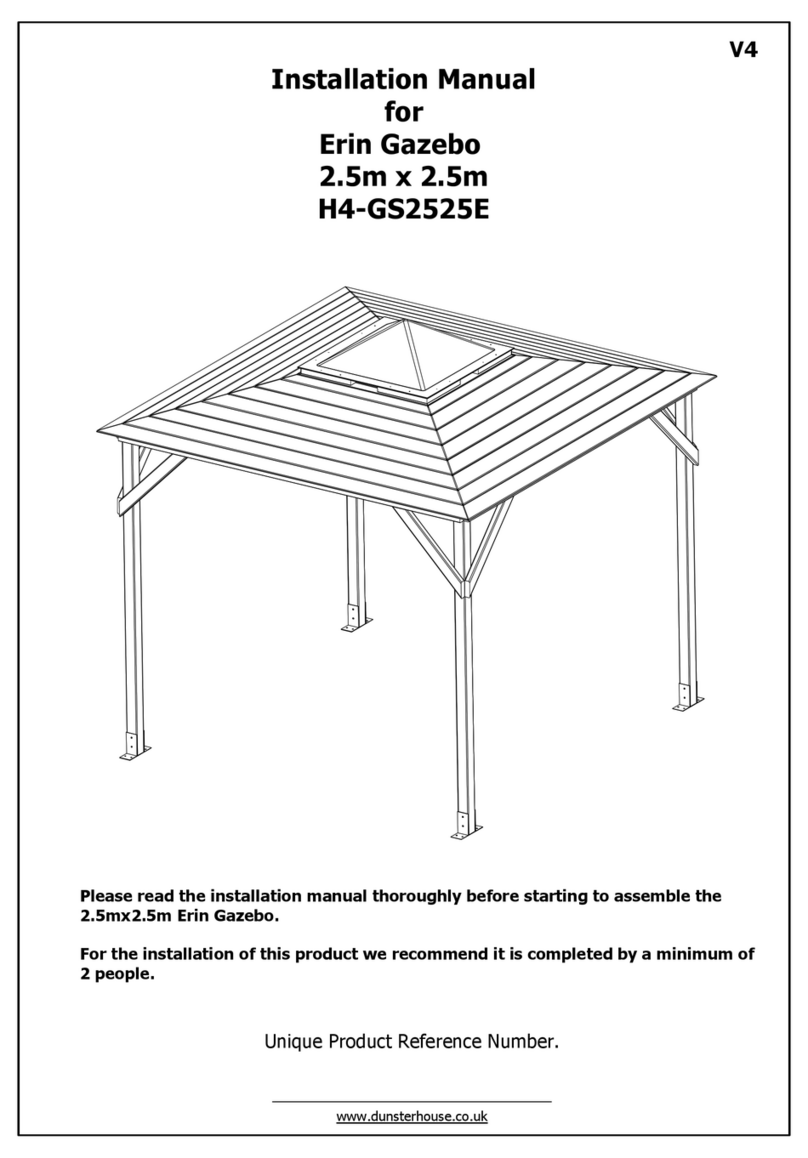

Dunster House Erin H4-GS2525E User manual

Dunster House

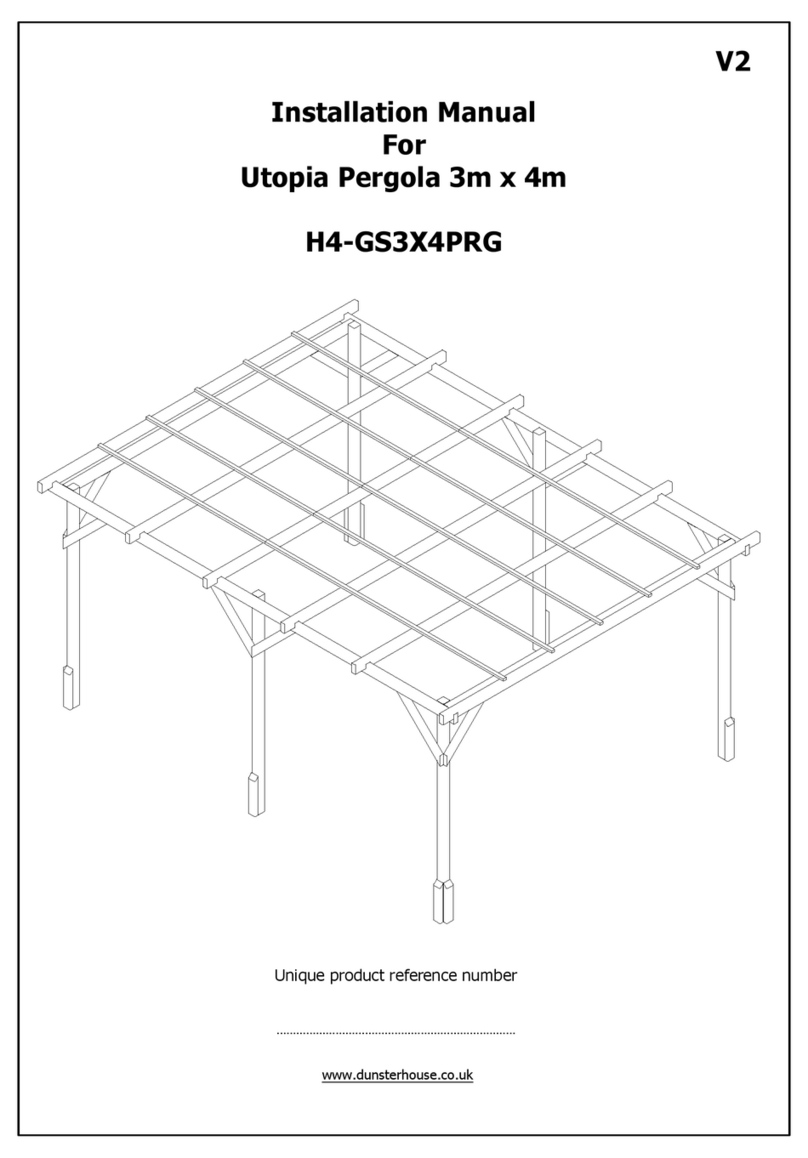

Dunster House H4-GS3X4PRG User manual

Dunster House

Dunster House Utopia User manual

Dunster House

Dunster House Leviathan P5-4040GAZAT User manual

Popular Outdoor Furnishing manuals by other brands

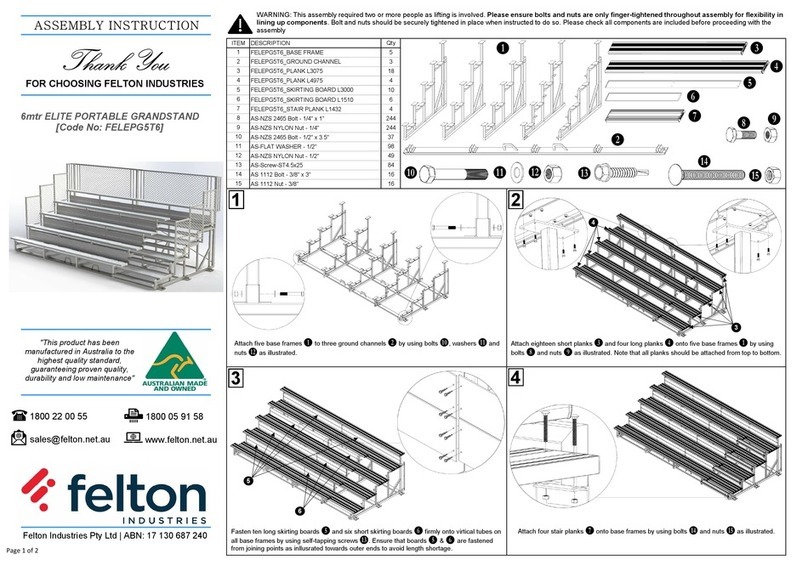

felton industries

felton industries FELEPG5T6 Assembly instruction

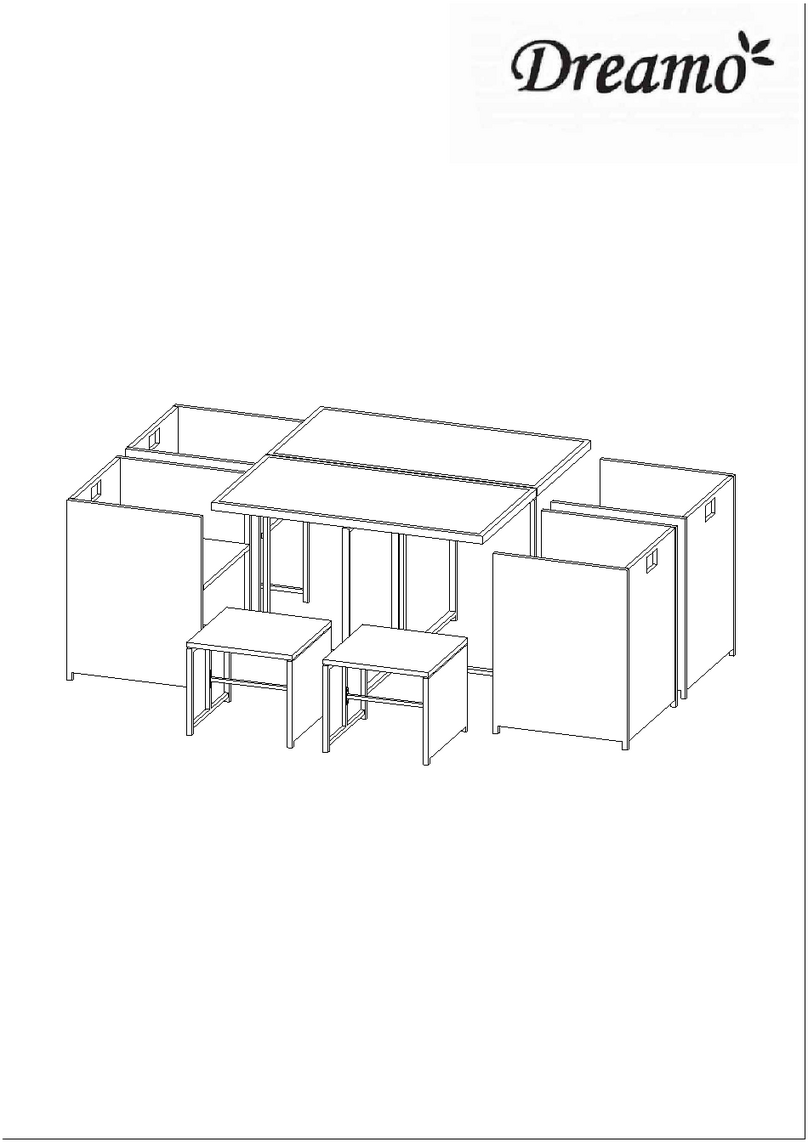

Dreamo

Dreamo OTF-503S quick start guide

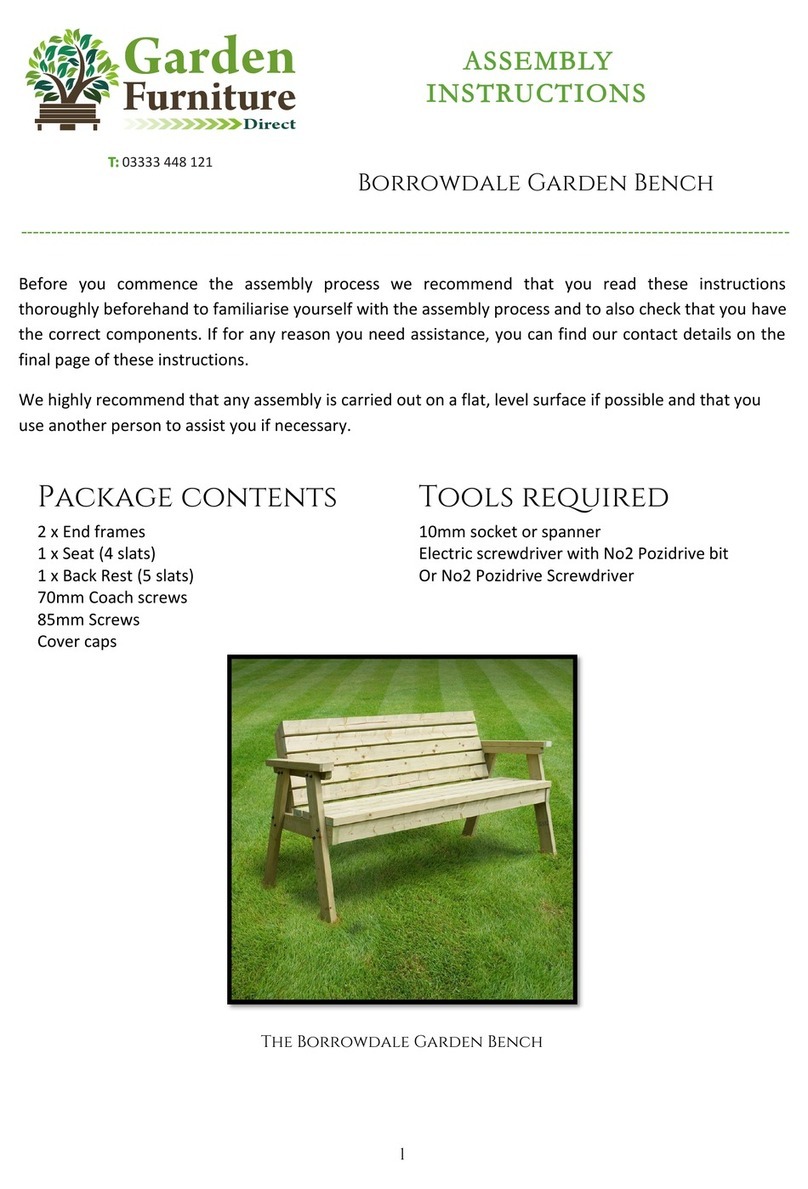

Garden Furniture Direct

Garden Furniture Direct Borrowdale Assembly instructions

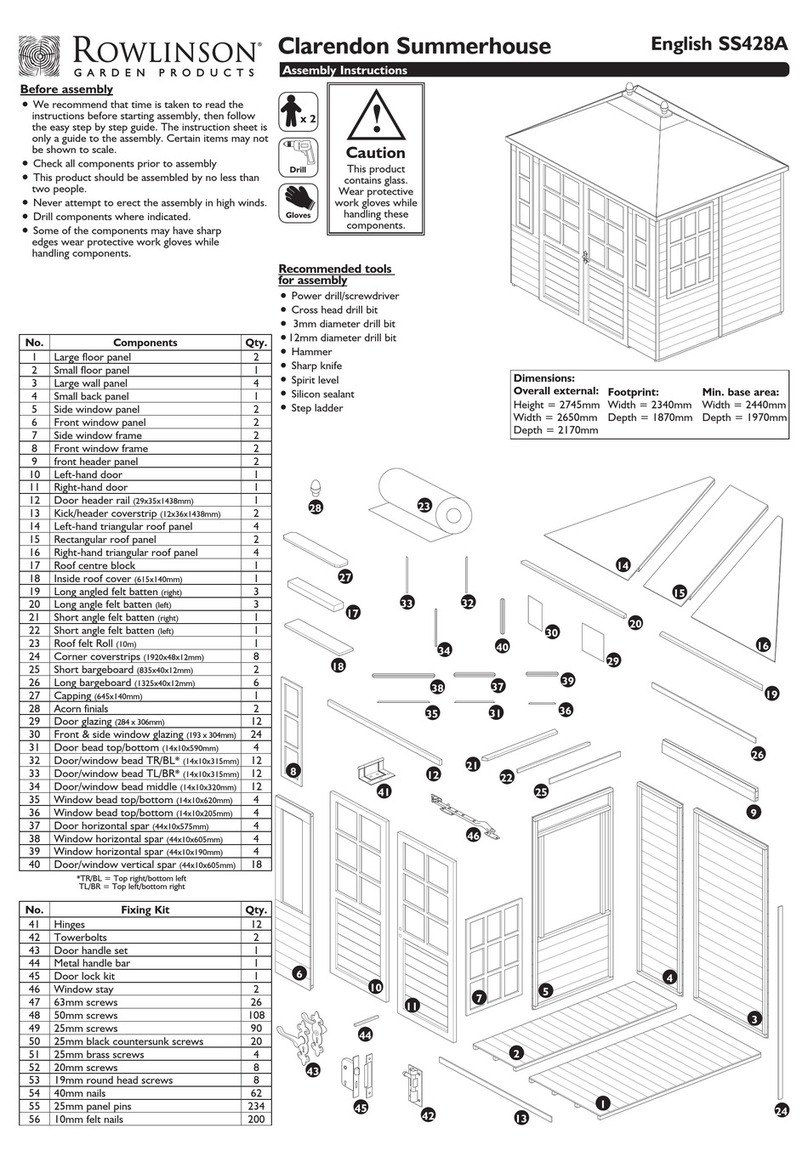

Rowlinson

Rowlinson Clarendon Assembly instructions

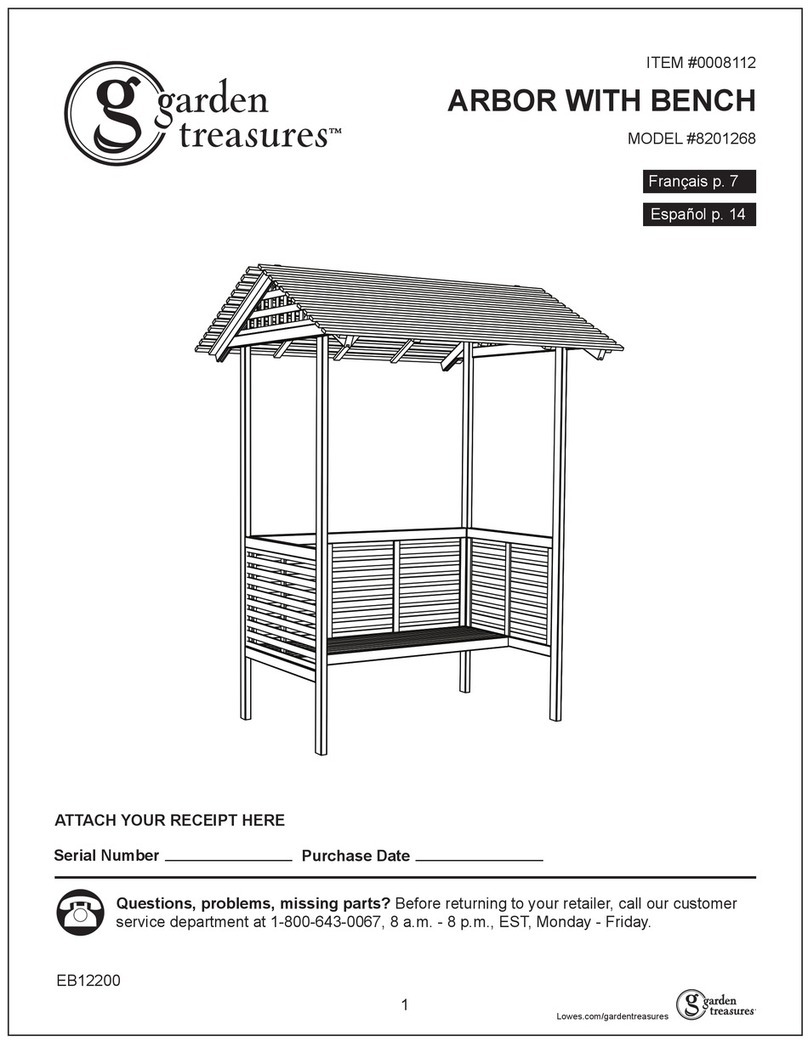

Garden Treasures

Garden Treasures 8201268 Assembly instructions

Safavieh Outdoor

Safavieh Outdoor Marson PAT7062 quick start guide

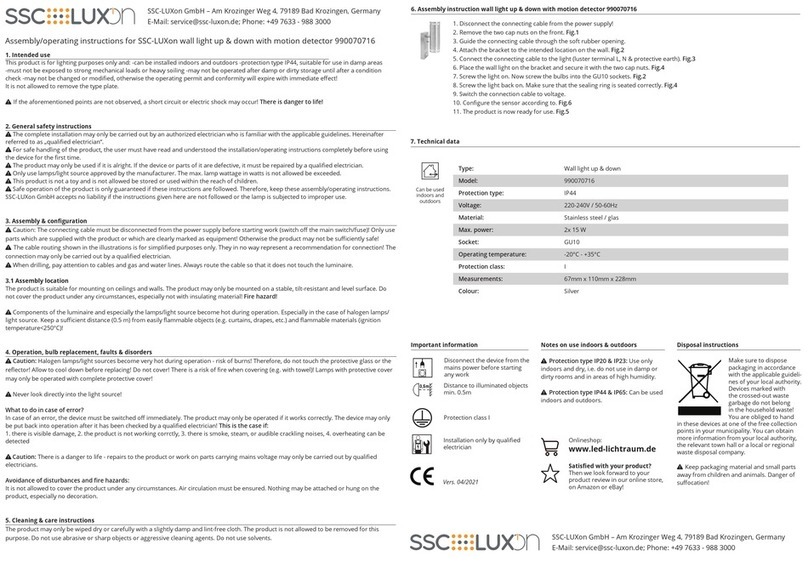

SSC-LUXon

SSC-LUXon 990070716 Assembly & operating instructions

supremo LEISURE

supremo LEISURE 2-Seat Stool 110*40cm Assembly instruction

Hatteras Hammocks

Hatteras Hammocks DCA1-K-HH instructions

Lemeks

Lemeks Palmako PA120-5959 Assembly, installation and maintenance manual

OLT

OLT 24 Assembly manual

forest-style

forest-style HACIENDA 2354 Building instructions

Courtyard Creations

Courtyard Creations RUS0188-WM Assembly instructions

kingsley-bate

kingsley-bate MC-55 Assembly instructions

Weltevree

Weltevree Carrier product manual

Grange Fencing

Grange Fencing Elite Arch Assembly instructions

Grosfillex

Grosfillex AUVENT YR14 Assembly instructions

X-METAL

X-METAL EAGLE 33511 Assembly instructions