European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH

Document No. D211-00-611-IS

Issue 1

20-08-22

Sheet 4 of 9

++

S2 S3

S2

S3

L

N

E

C

S2

S3

+

-

E

The voltage drop depends on:

- The total current draw if the devices installed on this

cable run

- The wire size and total length of the cable run,

determining the total resistance of this cable run

- The minimum output voltage supplied by the power

supply

The voltage drop and input voltage at the point of use can be

calculated as follows:

Total Wire resistance =

Wire resistance / 1000ft x length of cable run x 2

(length of cable run needs to be multiplied by two to account

for two wires going to and from the unit)

Total current draw =

Current draw per unit x number of units

Voltage Drop = Total current draw x Total wire resistance

Minimum output of power supply =

Min. voltage at point of use + voltage drop

For ambient temperatures over +45ºC the cable entry

temperature may exceed +70ºC. Therefore suitable heat

resisting cables and cable glands, rated to min. 75ºC must be

used.

If a high IP (Ingress Protection) rating is required then a

suitable sealing washer must be fitted under the cable glands

or blanking plugs.

For use in explosive dust atmospheres, a minimum ingress

protection rating of IP6X must be maintained.

For use in explosive gas atmospheres, a minimum ingress

protection rating of IP54 must be maintained.

NPT plugs should be greased before insertion.

8) Cable Connections

Electrical connections are to be made into the terminal blocks

on the PCBA located in the enclosure. See section 6 of this

manual for access to the enclosure.

Wires having a cross sectional area between 0.5 mm² to

2.5mm² can be connected to each terminal way. If an input

and output wire is required the 2-off Live/Neutral or +/-

terminals can be used. If fitting 2-off wires to one terminal way

the sum of the 2-off wires must be a maximum cross sectional

area of 2.5mm². Strip wires to 8mm. Wires may also be fitted

using ferrules. Terminal screws need to be tightened down

with a tightening torque of 0.56 Nm / 5 Lb-in. When

connecting wires to the terminals great care should be taken

to dress the wires so that when the cover is inserted into the

chamber the wires do not exert excess pressure on the

terminal blocks. This is particularly important when using

cables with large cross sectional areas such as 2.5mm².

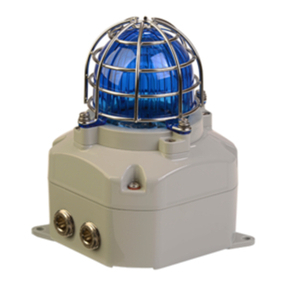

9) AC Wiring

The Strobe is powered via factory installed wires connected to

the sounder. The wires connecting the alarm horn and strobe

can be removed if the user wishes to power the strobe

separately.

For further wiring schematics refer to document D211-06-611

Fig 4. AC Terminals

10) DC Wiring

The Strobe is powered via factory installed wires connected to

the alarm horn. The wires connecting the alarm horn and strobe

can be removed if the user wishes to power the strobe

separately.

For further wiring schematics refer to document D211-06-611

Fig. 6 DC Terminals

11) Earthing

The unit has both internal and external earth terminals, (please

see fig 2).

Internal earthing connections should be made to the internal

earth terminal on the PCBA, (please see fig 4 for AC, fig 6 for

DC). The earth conductor should be at least equal in size and

rating to the incoming power conductors. The internal earth

bonding wire connects the PCBA earth terminal to the internal

earth terminal in the enclosure back box.

External earth connections should be made to the M5 earth

stud, using a ring crimp terminal to secure the earth conductor

to the earth stud. The external earth conductor should be at

least 4mm2 in size. The external earth crimp ring should be

located between the two M5 plain washers provided and

securely locked down with the M5 spring washer and M5 nut.

DC Alarm Horn

Terminals