__________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. D189-00-001-IS Issue: 901-06-16 Sheet 3 of 7

(Ingress Protection) rating is required then a suitable sealing

washer must be fitted under the cable gland. For use in

explosive gas atmospheres a minimum ingress protection

rating of IP54 must be maintained. For use in explosive dust

atmospheres a minimum ingress protection rating of IP64 must

be maintained.

Only the front cover is to be used for access to the enclosure

for installation, service and maintenance. Once the product is

opened, the Type Rating cannot be maintained anymore

unless a full verification of the gasket material is done and

there is no damage.

Connections are to be made into the terminal blocks using

solid or stranded wire, sizes 0.5-2.5mm2 / AWG 20-14. Wire

insulation needs to be stripped 6-7mm. Wires may be fitted

securely with crimped ferrules. Terminal screws need to be

tightened down with a tightening torque of 0.56 Nm / 5 Lb-in.

Internal earthing connections should be made to the Internal

earth terminal on the PCBA. The earth conductor should be at

least equal in size and rating to the incoming power

conductors. The internal earth bonding wire connects the

PCBA earth terminal to the internal earth terminal in the

enclosure back box.

External earthing connections should be made to the M5 earth

stud, using a ring crimp terminal to secure the earth conductor

to the earth stud. The external earth conductor should be at

least 4mm2/ AWG 11 in size.

Check that the earth bonding wire between the two castings is

secure and the ‘O’ ring seal is in place and in good condition.

4.2 Maintenance, Repair and Overhaul

Maintenance, repair and overhaul of the equipment should only

be carried out by suitably qualified personnel in accordance

with the current relevant standards:

EN60079-19 / IEC60079-19 Explosive atmospheres -

Equipment repair, overhaul and reclamation

EN 60079-17/ IEC60079-17 Explosive atmospheres -

Electrical installations inspection and maintenance

Units must not be opened while an explosive atmosphere is

present.

If opening the unit during maintenance operations a clean

environment must be maintained and any dust layer removed

prior to opening the unit.

Electrostatic charging hazard - Clean only with a damp cloth

5) Installation

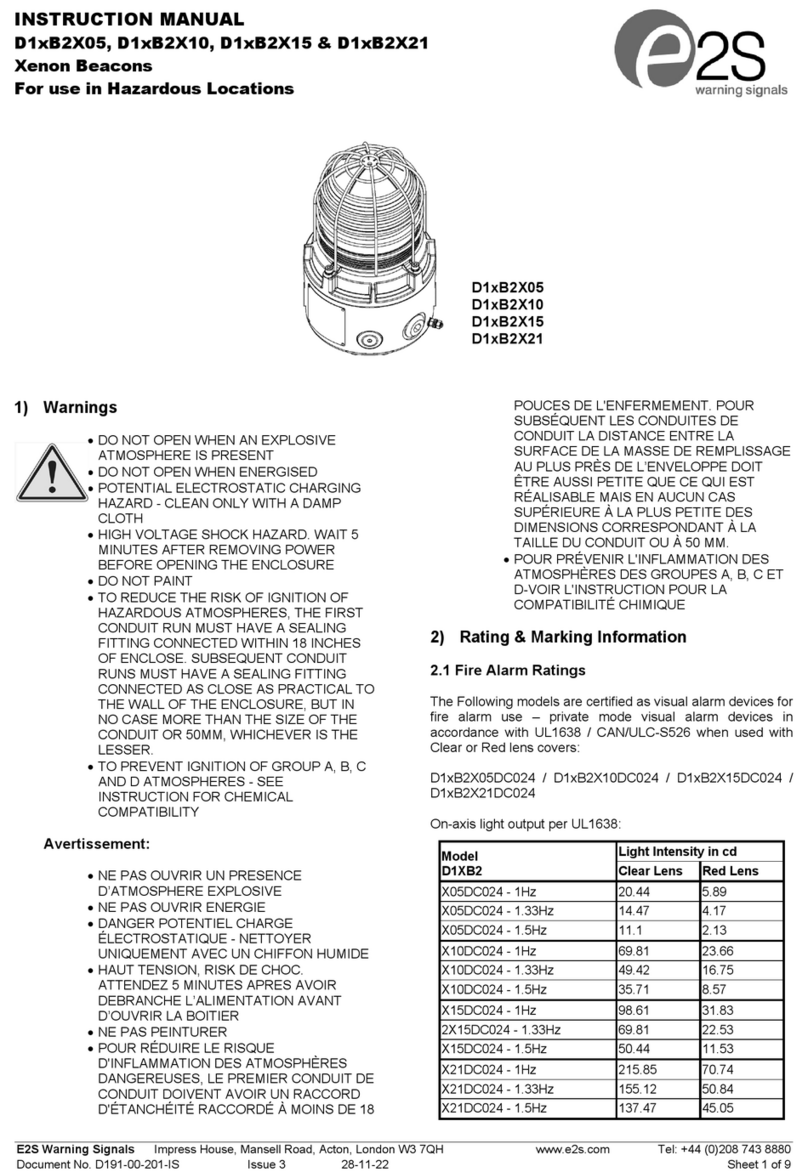

Fig. 1 Fixing locations.

D2xS1 alarm horn should only be installed by trained

competent personnel.

5.1 Mounting

The D2xS1 alarm horn may be secured to any flat surface

using the two 9.7 x 6.7mm, 147mm pitch fixing holes. The

enclosure provides IP66 protection and is suitable for

installation in exterior locations providing it is positioned so that

water cannot collect in the horn, and the cable entry is sealed.

5.2 Installation procedure

a) Remove Secure the D2xS1 alarm horn to a flat

surface

via the two 9.7 x 6.7mm, 147mm pitch fixing holes in

the mounting feet.

b) Remove the front of the alarm horn by unscrewing the

four captive cover screws and pulling the front away

from the enclosure.

c) Fit an M20x1.5 suitably rated, certified cable gland or

conduit entry into the hole in the enclosure and

connect the field wiring to the appropriate alarm horn

terminals as shown in section 9 and fig 8 (DC) or

section 8 fig 5 (AC) of this manual. The power supply

terminals are duplicated so that alarm horns may be

connected in parallel and for DC units only an end of

line monitoring resistor may be fitted. If the second

M20x1.5 entry is not used a suitably rated, certified

stopping plug must always be fitted.

d) Select the required output tone by positioning the six

switches as shown in Table 1 and Fig 2.

e) Adjust the internal volume control to provide the

required sound level. (Refer to section 6)

f) Check that the O-ring seal in the front cover is in good

condition and not damaged.

g) Replace the front of the alarm horn and tighten the

four captive cover screws.

6) Volume Control

The output level of the D2xS1 alarm horn can be set by

adjusting the volume control potentiometer (see Fig 2). For

maximum output, set the potentiometer fully clockwise.

Fig. 2 Location of field controls

7) Cable Routing and Tone Selection

7.1 Cable Routing

Due to the compact design of the D2x units, it is important that

the user strips off the outer sheath and biases any cables over

the size of 1mm2as shown below.