European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH

Document No. D157-00-651-IS

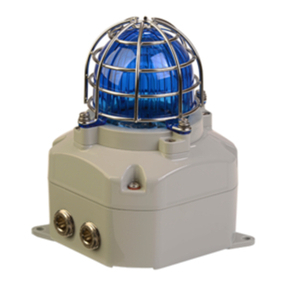

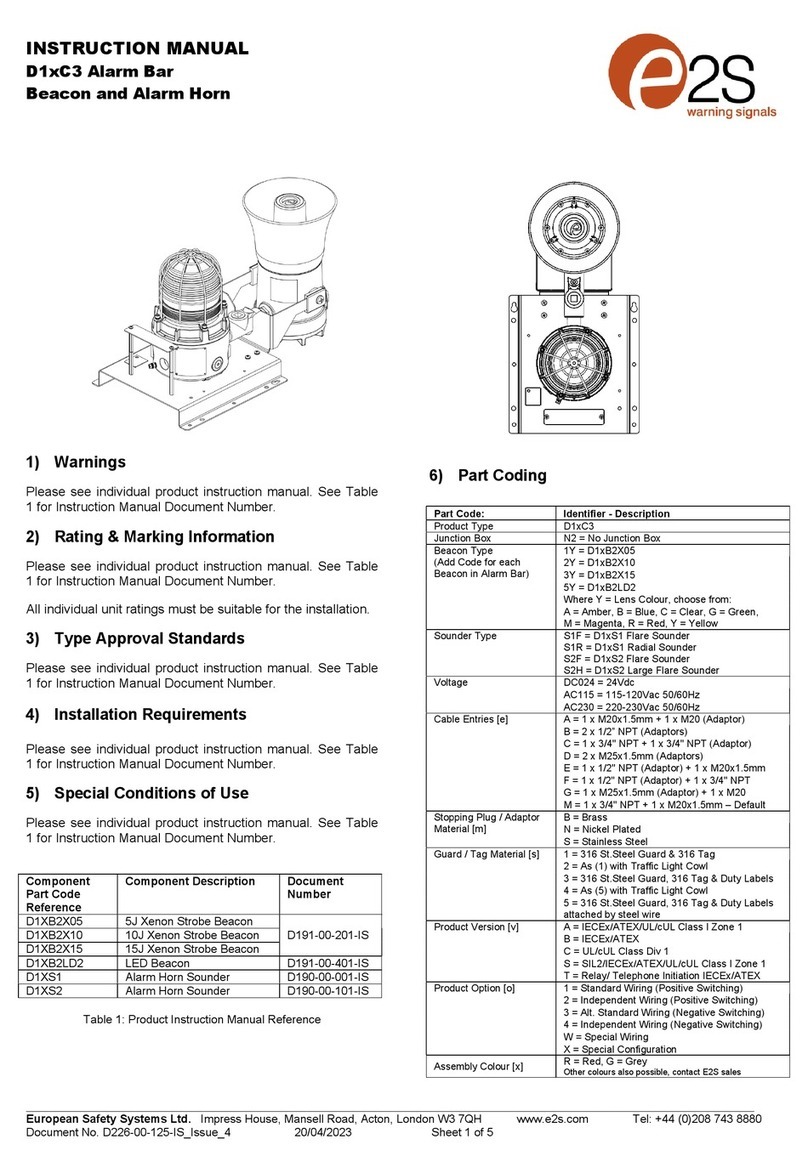

6) Product Mounting and Access

6.1. Location and Mounting

The sounder should be secured to any flat surface using the

three 7mm fixing holes (see figure 2). The angle can then be

adjusted as required but the mounting restrictions must be

observed (see outline drawings for details, D157-05-001 for

GNExS1F). This can be achieved by loosening the two large

bracket screws in the side of the unit, which allow adjustments

in steps of 18°.

Figure 2: Fixing Location for GNEx[S1F] Sounder.

On completion of the installation the two large bracket

adjustment screws on the side of the unit must be fully

tightened to ensure that the unit cannot move in service.

The enclosure provides IP66 protection and is suitable for

installation in exterior locations providing it is positioned so that

water cannot collect in the horn, and the cable entry is sealed.

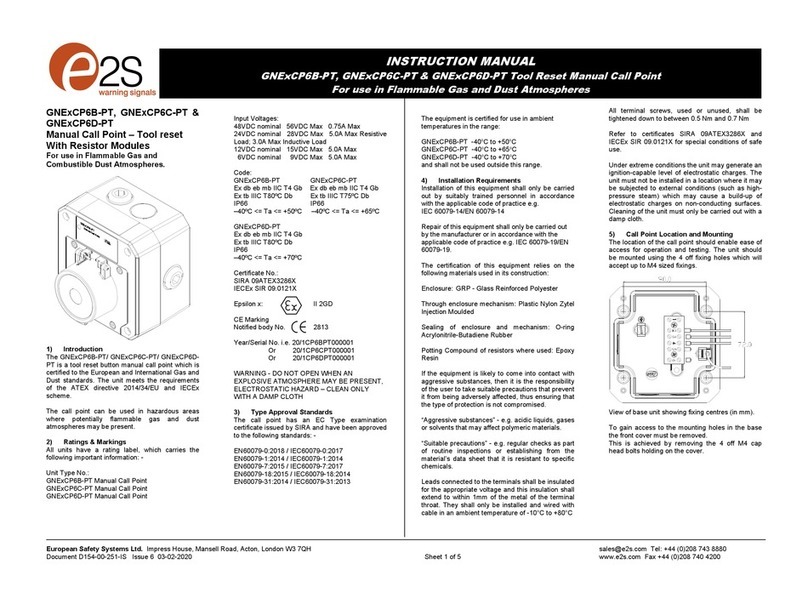

6.2. Access to the Flameproof Enclosure

Warning –Hot surfaces. External

surfaces and internal components

may be hot after operation, take

care when handling the equipment.

In order to connect the electrical supply cables to the sounder

it is necessary to remove the flameproof cover to gain access

to the flameproof chamber. To achieve by loosening the M3

Grub Screw within the flameproof cover, and then unscrew

the flameproof cover, taking extreme care not to damage the

flameproof joints in the process (see figure 3).

Figure 3: Accessing the Explosion Proof Enclosure.

On completion of the cable wiring installation the flameproof

joints should be inspected to ensure that they are clean and

that they have not been damaged during installation.

Ensure that the ‘O’ ring seal is in place and undamaged.

When fitting the flameproof cover ensure the thread is

engaged correctly. Fully tighten the cover all the way, ensure

no gap is visible between the cover and base of the sounder

enclosure. Tighten the M3 grub screw.

7) Installation Requirements

7.1. Installation Standards Compliance

Warning –High voltage may be

present, risk of electric shock.

DO NOT open when energised,

disconnect power before opening.

The sounder must only be installed by suitably qualified

personnel in accordance with the latest issues of the relevant

standards.

ATEX / IECEx / UKEx installation standards:

EN60079-14:2008 / IEC60079-14:2007 (Ed4): Electrical

Installations in Hazardous Areas (other than mines).

EN60079-10-1:2009 / IEC60079-10:2008 (Ed1):

Classification of Areas, Gas Atmosphere

The installation of the units must also be in accordance with

any local codes that may apply and should only be carried out

by a competent electrical engineer who has the necessary

training.

7.2. Cable Selection and Connections

When selecting the cable size, consideration must be given to

the input current that each unit draws (see table 1), the number

of sounders on the line and the length of the cable runs. The

cable size selected must have the necessary capacity to

provide the input current to all the sounders connected to the

line.

Electrical connections are to be made into the terminal blocks

on the PCBA located in the flameproof enclosure using solid

wire 0.5-4mm² / AWG 20-12 or stranded wire, sizes 0.5-

2.5mm² / AWG 24-14. Wire insulation needs to be stripped

8mm. Wires may be fitted securely with crimped ferrules.

Figure 4: Wire Preparation.

Terminal screws need to be tightened down with a tightening

torque of 0.45 Nm / 5 Lb-in. An 8-way terminal block is

provided on the AC Sounder, and a 6-way terminal block is

provided on the DC Sounder.