6

EASTMAN

Form CR-50-0433

OPERATION

CAUTION

Before connecting power supply, make sure voltage

rating is same as stamped on terminal block. Damage

to control unit may result if incorrect power supply is

used.

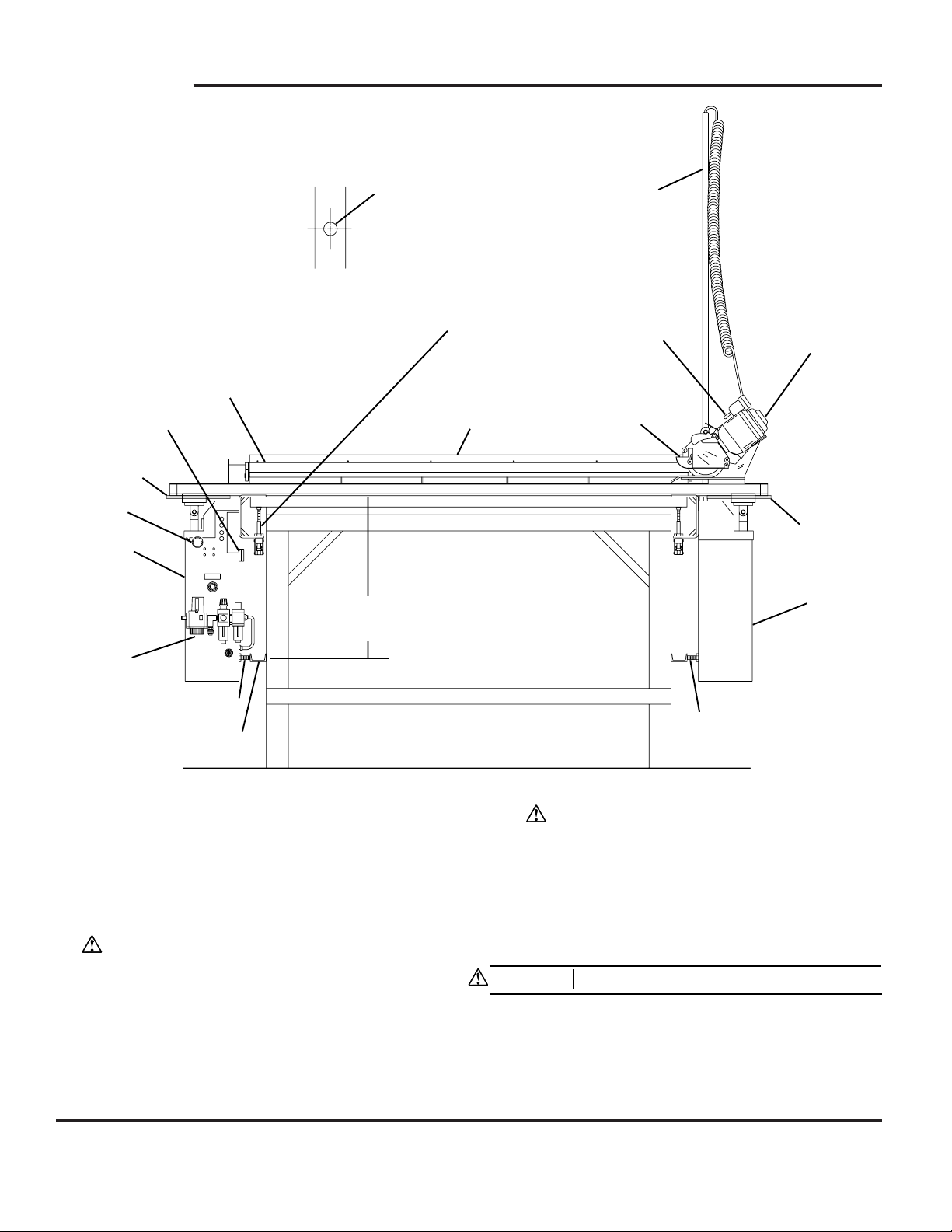

When power supply is properly connected, air line is con-

nected and harnesses are attached, the Blue Jay is ready

for operation.

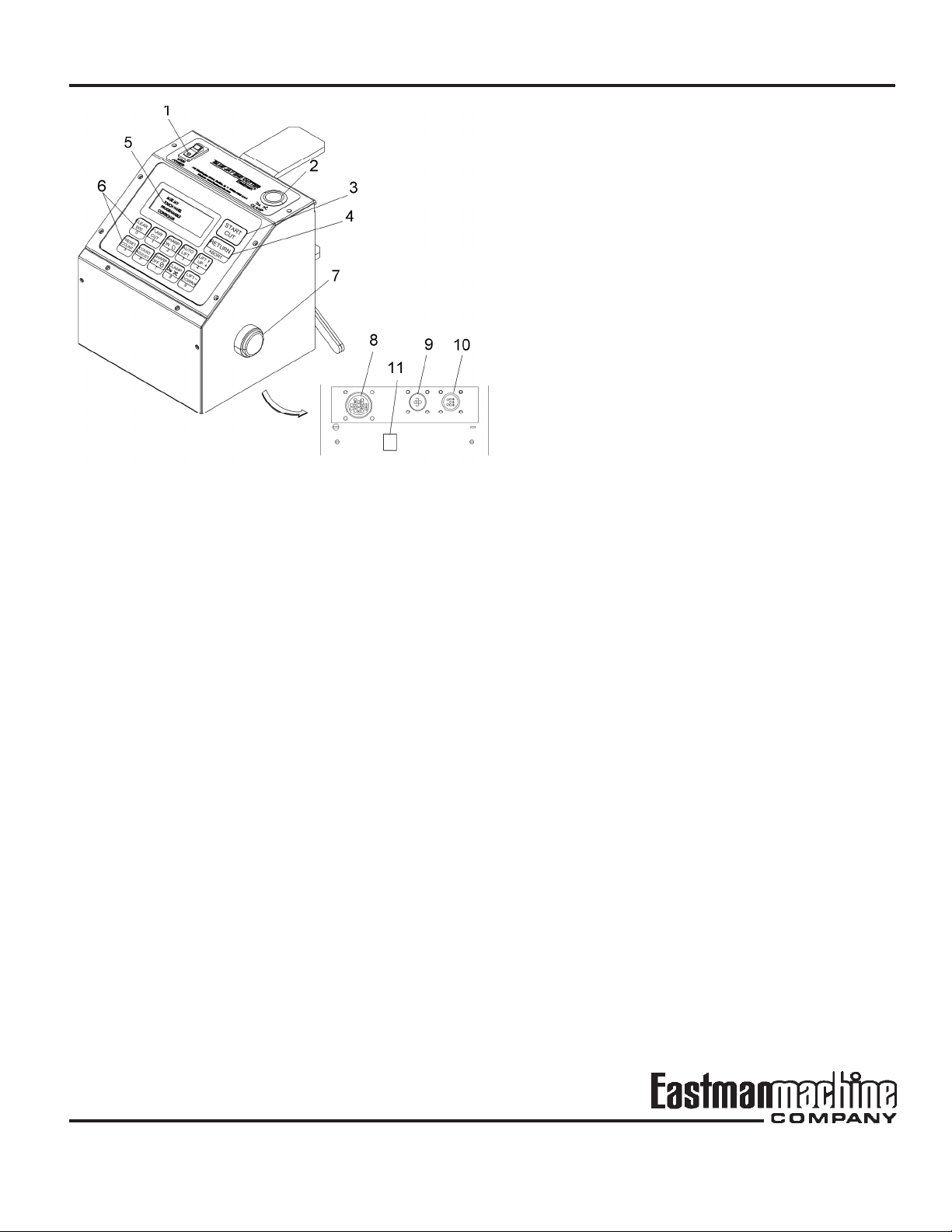

Activate main power by pressing MAIN POWER switch to

ON position. The LCD display will go on and the display will

show "000". The control box can now be programmed.

To program the number of plies desired, press the Preset

Count key. Use the Number keys to set the desired number

of plies.

NOTE: If "000" is programmed, the Blue Jay will count the

number of plies without interruption.

After the ply count is programmed, the Auto Lift should

display On. Switch the cutter to the ON position and the Blue

Jay is now ready for operation.

Press the Clamp key to open the Power Clamp.

Thread the material between the clamp and the chute.

Using an operator on each side of the table, pull the material

to the desired length. Smooth and align the edges of the

material. Press the START key to cut and clamp the first ply

of material. Continue this cycle until desired number of plies

have been spread and cut.

To remove the material, press the Lift Up key to raise the

track. Remove the material. Press Lift Down key to lower

the track. The track will lower and the blue Jay in ready to

continue.

CAUTION

The lift is designed to raise track with force. To Prevent

injury, Personnel should stand well clear of track when

in operation. All operators should be trained in the

operation of the machine prior to use.

IMPORTANT: To stop the Blue Jay at any point during

operation, press the power ON-OFF switch

to OFF position or hit the Emergency Stop

button on the main lift module.

Simplified Operating Instructions

1) Activate Main Power.

2) Program Ply Counter.

3) Thread material and Spread to length.

4) Press Remote Start Button to begin cut.

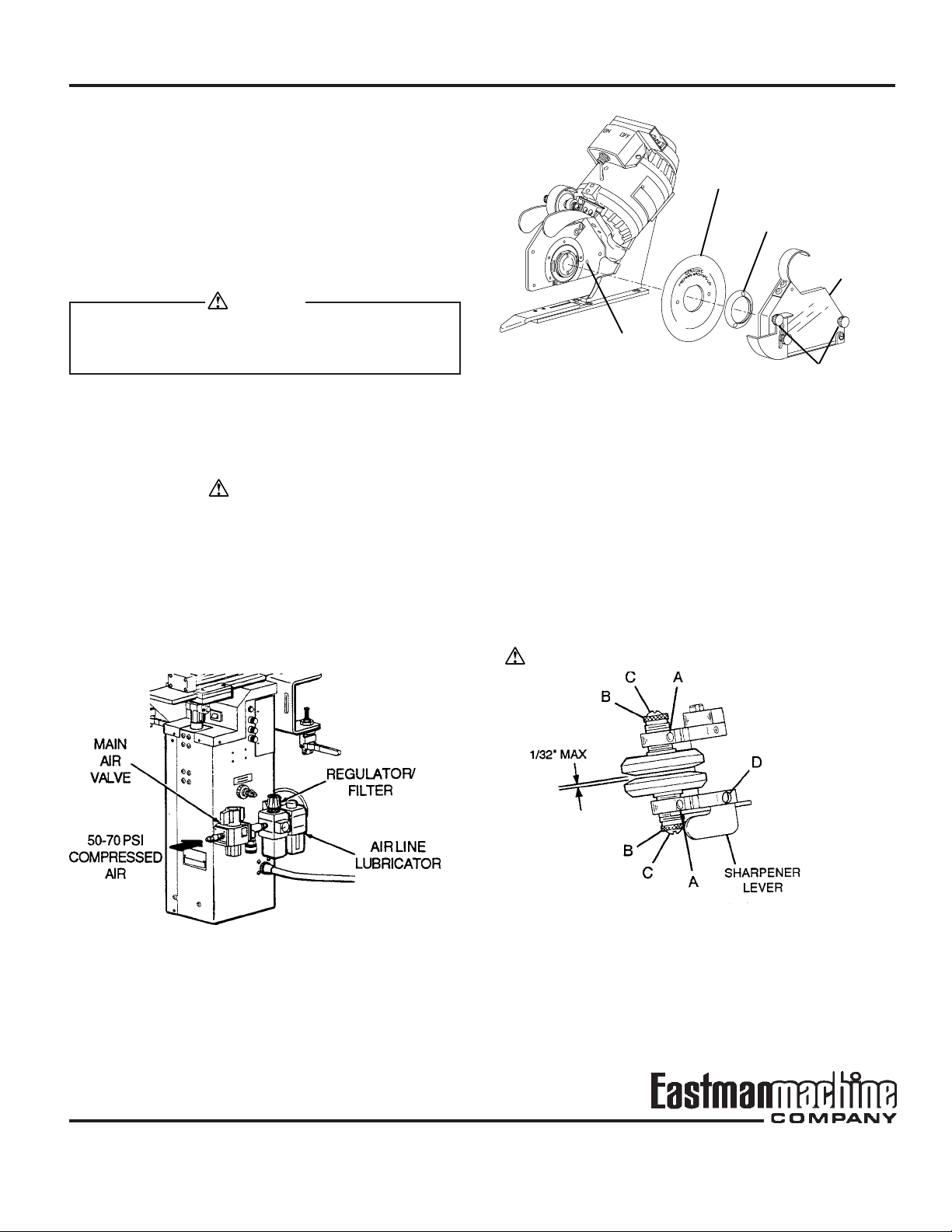

Operating Adjustments

This machine is adjusted and tuned at the factory for optimal

performance. No adjustments other than normal setup are

necessary. However, if after continued use the perfor-

mance level becomes unacceptable, the following proce-

dures should be carried out before repairs are considered.

Power Clamp Pressure

The power clamp pressure may vary slightly depending on

the material. To adjust Clamping Pressure, remove the

covers for the main drive module. Locate the speed control

fittings on the clamp valve. Turn knobs for proper adjust-

ment. Proper adjustment will firmly clamp the material to the

chute without excess force then release the fabric gently.

Track Clamping Pressure

The track clamping pressure may vary slightly depending

on the material or method of spreading. To adjust Clamping

Pressure, locate to Switch Actuating Lever under the Track

and Chute assembly. Loosen the setscrew and adjust

accordingly. Do Not Adjust Track Feelers. Proper adjust-

ment will clamp the material to the table without excess

force. Replace covers.

Main Drive Belt Adjustment

The drive belt tension is set during installation and may need

to be adjusted from time to time. To Set tension, remove

both main drive side covers and lower the track and chute

assembly. Release both hand clamps. Loosen the tension

bars and slide bars up to increase tension. Do Not Over

tighten or damage to drive shaft may occur. Replace side

covers.

Note: The drive belts raise and lower track evenly. If track

misalignment occurs loosen the main drive pulleys. Align

the track and secure the pulleys.

Cutting Speed

The cutting speed will vary slightly depending on material to

be cut. To adjust cutting speed, locate to Knife Travel knob

on the main lift module. Turn the knob clockwise to increase

the speed of the cutter moving down the track and counter-

clockwise to decrease speed. If cutter tends to lag when

cutting, less speed is required.