5

Instruction Leaflet IL 29C702E

Eective April 2015

Installation Instructions for the HKDDC

Circuit Breaker and Molded Case Switch

EATON CORPORATION www.eaton.com

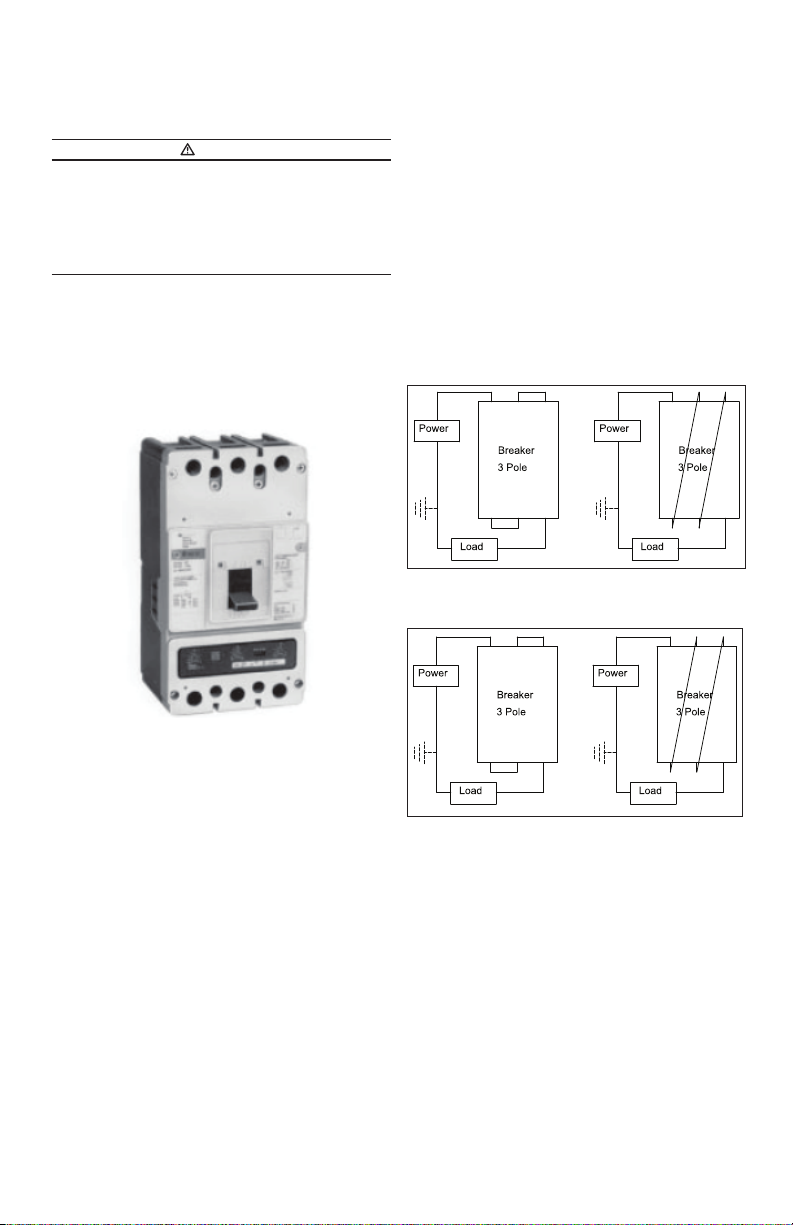

2-6. To mount the circuit breaker, perform the following steps:

a. For individual surface mounting, drill mounting panel using the

drilling plan shown in Fig. 10 . For panelboard mounting, only load

end support mounting holes are required. For dead front cover

applications, cut out cover to correct escutcheon dimensions, see

Fig. 11 .

b. If circuit breaker includes factory or eld installed internal acces-

sories, make sure that accessory wiring can be reached when

the circuit breaker is mounted.

NOTICE

LABELS WITH ACCESSORY CONNECTION SCHEMATIC DIAGRAMS ARE

PROVIDED ON THE SIDE OF THE CIRCUIT BREAKER. A NOTE SHOULD BE

MADE OF THE DIAGRAMS IF THE LABELS CANNOT BE SEEN WHEN THE

CIRCUIT BREAKER IS MOUNTED.

c. Position circuit breaker on mounting surface.

d. Install circuit breaker mounting screws, washers, and nuts.

Tighten screws rmly, but do not exceed 28 pound-inches (3

N.m).

CAUTION

WHEN ALUMINUM CONDUCTORS ARE USED, THE APPLICATION OF

A SUITABLE JOINT COMPOUND IS RECOMMENDED TO REDUCE THE

POSSIBILITY OF TERMINAL OVERHEATING. OVERHEATING CAN CAUSE

NUISANCE TRIPPING AND DAMAGE TO THE CIRCUIT BREAKER.

When a dual conductor terminal (Catalog No. TA400K, TA401K, or

T400K) is installed on the circuit breaker and a single conductor is

used, the conductor should be installed in the terminal opening near-

est to the circuit breaker terminal mounting conductor.

Figure 10. Circuit Breaker Mounting Bolt Drilling.

Figure 11. Circuit Breaker Escutcheon Dimensions for 3-Pole

Circuit Breakers.

2-7. Connect line and load conductors and accessory leads.

2-8. If required, install terminal shield on circuit breaker cover with

mounting screws provided.

2-9. After the circuit breaker is installed, check all mounting hard-

ware and terminal connecting hardware for correct torque loading.

Torque values for line/load terminals are given in Table 2 and on the

circuit breaker nameplate.

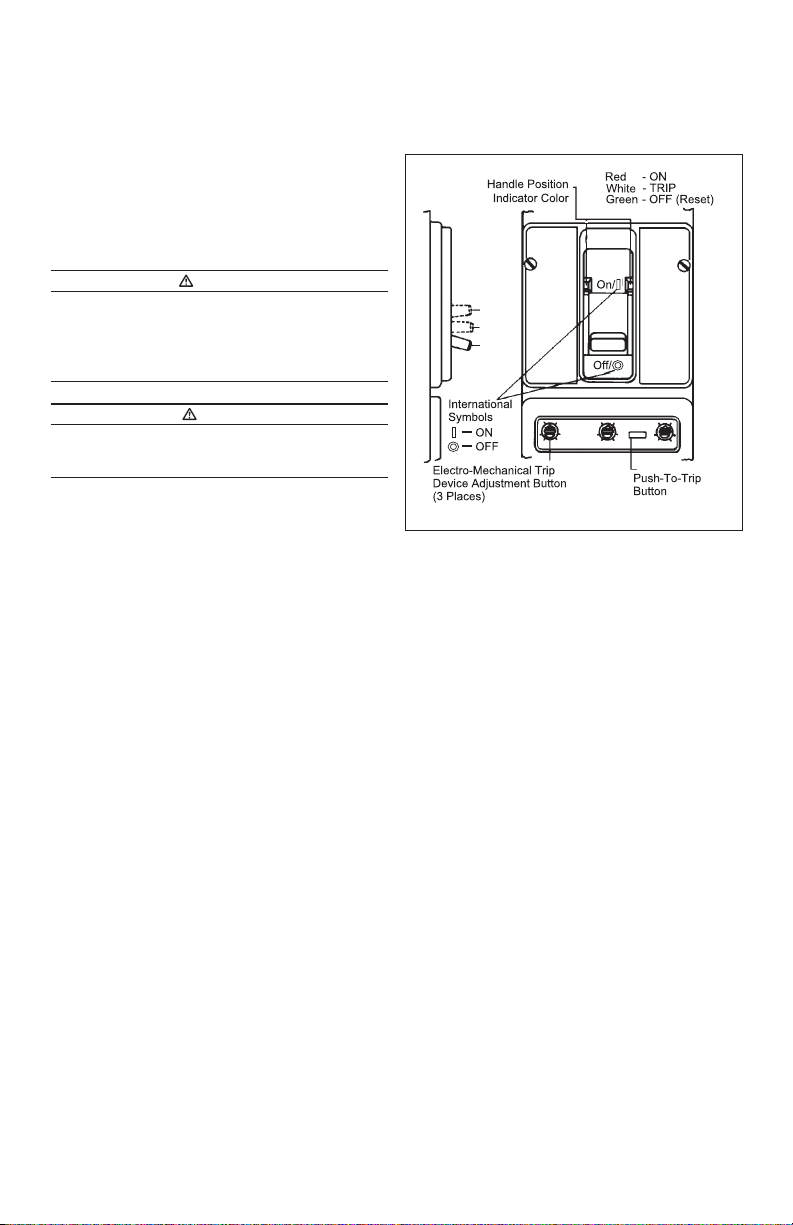

Manual Operation

Manual operation of the circuit breaker is controlled by the circuit

breaker handle and the PUSH-TO-TRIP button in the trip unit.The cir-

cuit breaker handle has three positions, two of which are shown on

the cover with raised lettering to indicate ON and OFF. On the sliding

handle barrier, ON, OFF, and trip are also shown by a color-coded

strip for each circuit breaker handle position: red for ON, white for

tripped, and green for OFF. (See Fig. 12 ).

Circuit Breaker Reset

After an automatic or accessory initiated trip, or a manual PUSH-

TO-TRIP operation, the circuit breaker is reset by moving the circuit

breaker handle to the extreme OFF position.

NOTICE

IN THE EVENT OF A THERMAL TRIP IN A THERMAL MAGNETIC TYPE TRIP

UNIT, THE CIRCUIT BREAKER CANNOT BE RESET UNTIL THE THERMAL

ELEMENT IN THE TRIP UNIT COOLS. NO CIRCUIT BREAKER SHOULD BE

RECLOSED UNTIL THE CAUSE OF TRIP IS KNOWN AND THE SITUATION

RECTIFIED.

PUSH-TO-TRIP Button

The PUSH-TO-TRIP button checks the circuit breaker tripping func-

tion and is used to periodically exercise the operating mechanism in

thermal-magnetic trip units. The button is designed to be operated

by a small screwdriver.

Trip Units

For additional information on thermal-magnetic trip units, refer to l.L.

29C603 (IL supplied with trip unit.)