IL05003002E.pdf

5011629803-AN03

2007-05-08

ELC-AN04ANNN

Analog to Digital Converter Module

Instruction Sheet

WARNING

•This Instruction Sheet only provides descriptions for electrical specifications, general

specifications, installation & wiring, troubleshooting and peripherals. For more information about

the optional peripherals, please see ELC Application Manual.

•This is an OPEN TYPE Controller. The ELC should be kept in an enclosure away from airborne

dust, humidity, electric shock risk and vibration. Also, it is equipped with protective methods

such as some special tools or keys to open the enclosure, so as to avoid the hazard to users

and the damage to the ELC. Do NOT touch terminals when power on.

•Never connect the AC main circuit power supply to any of the input/output terminals, as it will

damage the ELC. Check all the wiring prior to power up. To avoid any electromagnetic noise,

make sure the ELC is properly grounded .

•Warning – Do not disconnect while circuit is live unless area is known to be non-hazardous.

•Power, input and output (I/O) wiring must be in accordance with Class 1, Div. 2 wiring methods -

Article 501-10(B)(1) of the National Electrical Code.

•Suitable for use in Class 1, Division 2, Groups A, B, C, D or Non-Hazardous locations only.

•Warning – Explosion hazard - Substitution of components may impair suitability for Class 1,

Division 2.

•Warning – Explosion Hazard - Do not disconnect equipment unless power has been switched

off or the area is known to be Non-Hazardous.

1 INTRODUCTION

1.1 Model Explanation and Peripherals

Thank you for choosing Eaton Logic Controller (ELC) series products. The analog input module

receives external 4-point analog signal input (voltage or current) and transforms it into 14 bits digital

signal. The analog input module of ELC-AN04ANNN can read/write the data of analog input module

by using commands FROM / TO via ELC program. There are 49 CR (Control Register) in each

module and there are 16 bits in each register.

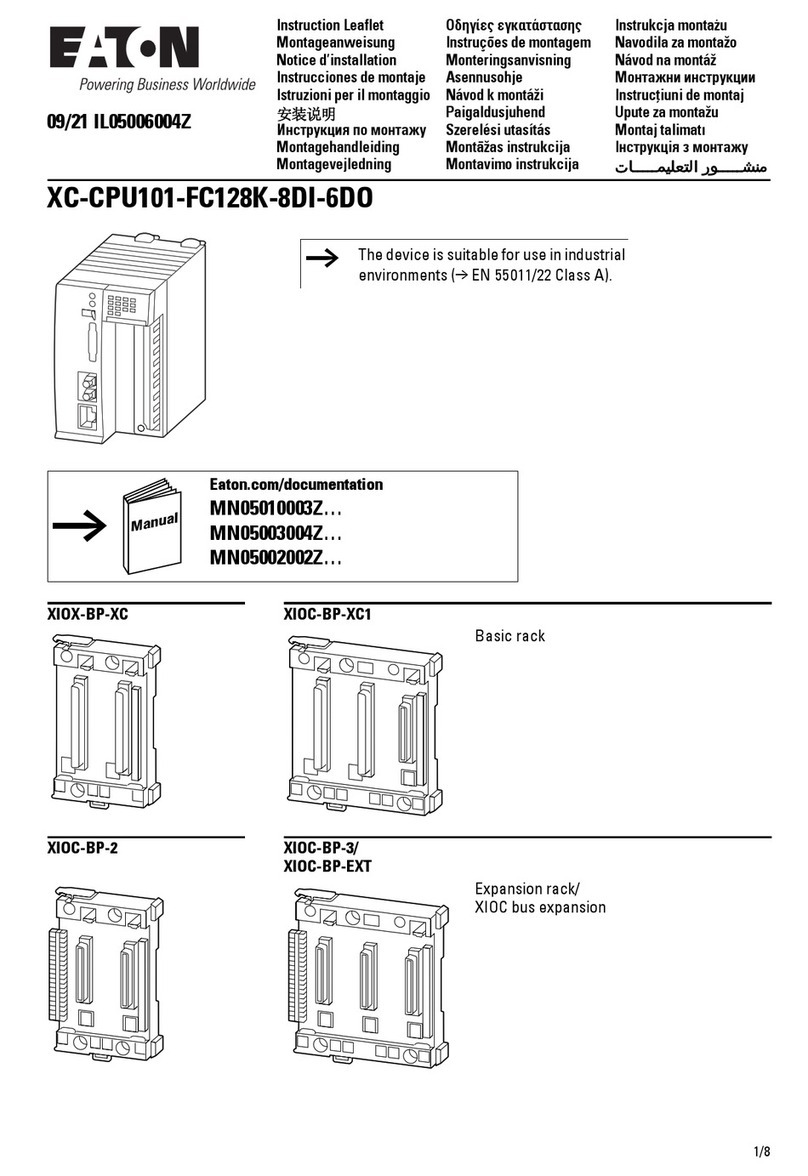

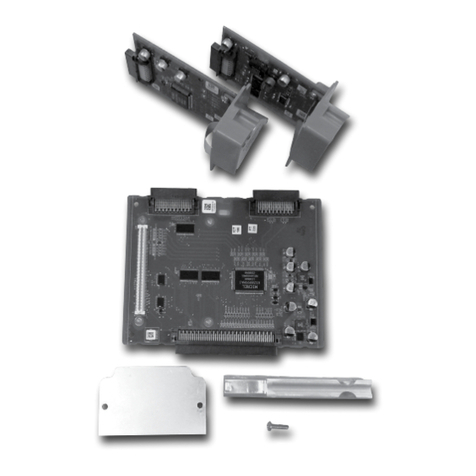

1.2 Product Profile and Outline

12

13 14

11

M

C

H

3

C

H

1

C

H

2

M

M

EXTENSION

PORT

1

3

2

3

568

7

4

8

9

10

60

90

ELC-AN04ANNN

3

C

H

4

M

25.2

3

Units: mm

1. Status indicator (Power, RUN and ERROR) 2. Model Name

3. Extension unit clip 4. Input/output terminal

5. DIN rail clip 6. Mounting hole of the extension unit

7. Nameplate 8. Extension unit clip

9. DIN rail (35mm) 10. Extension port

11. RS-485 Communication port 12. 2 pin removable terminal (standard accessory)

13. DC power input 14. Power input cable (standard accessory)

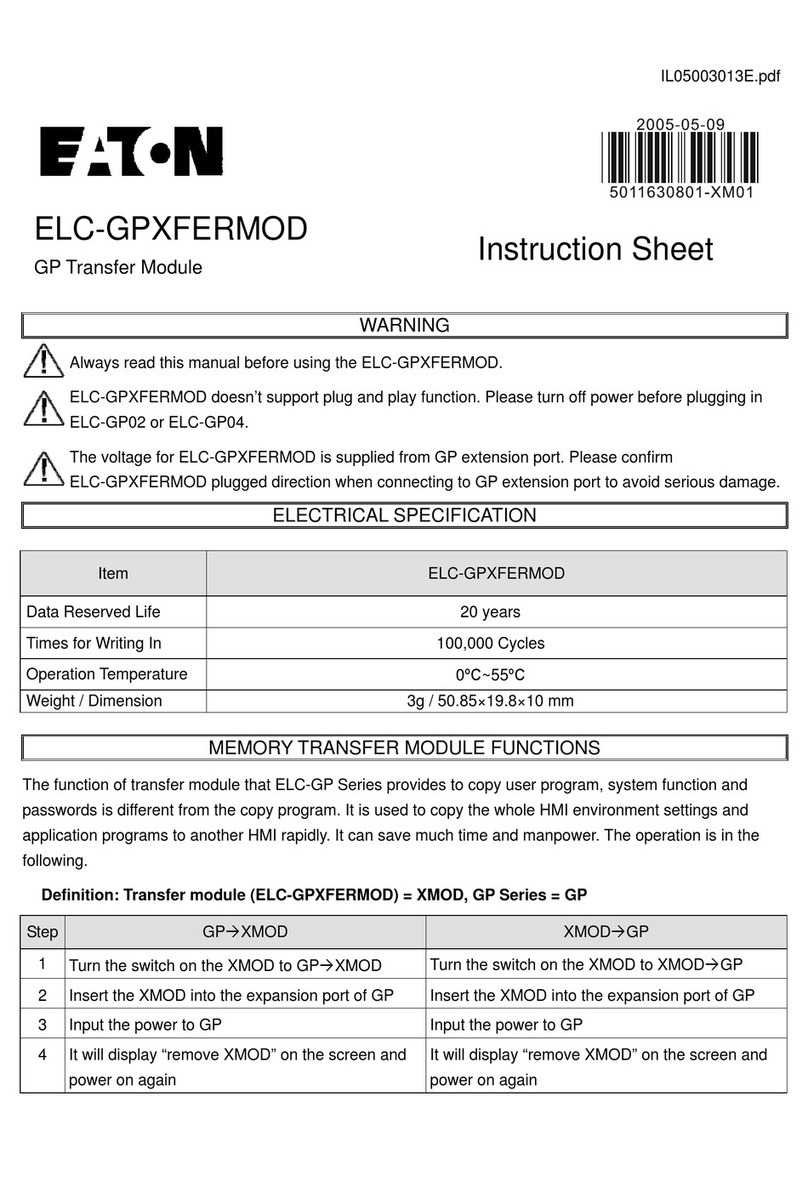

1.3 External wiring

Volta

e In

ut

-10V ~ +10V

Current In

ut

-20mA ~ +20mA

V+

COM

Isolation Wire 1¡@

*

*5

FG

I+ 250 Ω

~

~

V+

FG

I+

*2

CH1

CH4

250 Ω

24+

24-

*3

AG

+15V

-15V

DC/DC

Converter

*4

System

Grounding

Class 3 Grounding

100 or less

Ω

COM

CH1

CH4

104.7K

104.7K

AG

104.7K

104.7K

AG

Isolation Wire 1¡@

*

terminal of

power module

Warning: DO NOT wire to the No function terminal. Use

Copper Conductor Only, 60/75 °C.

Note 1: Please isolate analog input and

other power wiring.

Note 2: If connect to current signal,

please short circuit between V+ and I+

terminals.

Note 3: If noise is too loud, please

connect FG to grounding.

Note 4: Please connect terminal

of power module and terminal of

analog input module to system earth

point and make system earth point be

grounding or connects to machine

cover.

Note 5: If wave of input terminal of

loaded is too big that noise interferes

wiring, please connect capacitance with

0.1~0.47uf 25V.

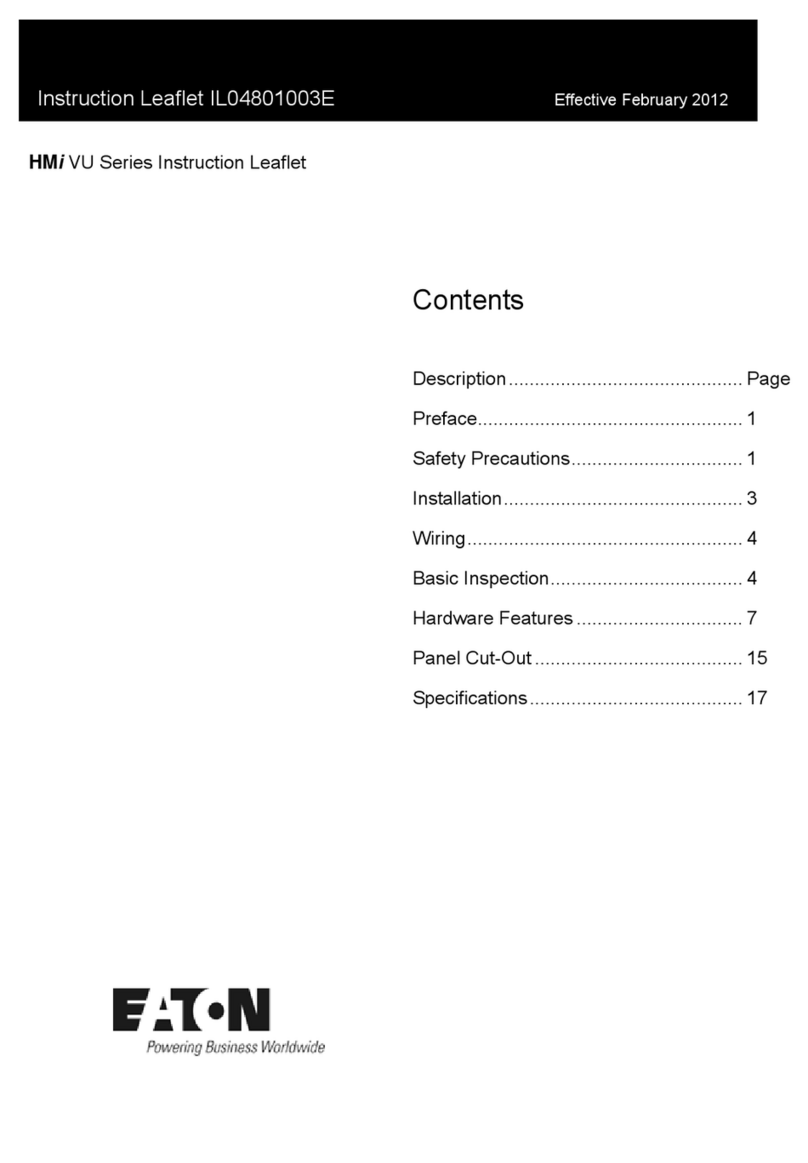

1.4 Terminal of analog module layout

AN04ANNN AN02NANN AN04NANN AN06AANN PT04ANNN TC04ANNN

ELC-AN04 NANN

●

COM

FG

COM

FG

V+

V+

I+

I+

●

COM

FG

COM

FG

V+

V+

I+

I+

ELC-AN02NANN

●

COM

FG

COM

FG

V+

V+

I+

I+

POWER

ERROR

D/A

COM

FG

●

I+

COM

FG

V+

COM

I+

V+

●

FG

V+

I+

COM

V+

FG

I+

ELC-AN04NANN

COM

COM

V+

V+

I+

I+

ELC-AN06AANN

DA

ER ROR

POW ER

COM

I+

V+

COM

COM

V+

V+

I+

I+

COM

I+

V+

I-

L+

FG

L-

ELC-PT04ANNN

●

I-

L+

FG

L-

I-

L+

FG

L-

●

I-

L+

FG

L-

SLD

L+

L-

●

ELC-TC04ANNN

SLD

L+

L-

●

●

SLD

L+

L-

●

SLD

L+

L-

●

●

2 STANDARD SPECIFICATIONS

2.1 Function Specifications

FOUR CH. A/D MODULE VOLTAGE INPUT CURRENT INPUT

Power supply voltage 24 VDC(20.4VDC~28.8VDC) (-15%~+20%)

Analog input channel 4 channel / each module

Analog input range ±10V ±20 mA

Digital conversion range ±8,000 ±4,000

Resolution 14 bits(1LSB=1.25 mV) 13 bits (1LSB=5μA)

Input impedance 200 KΩand above 250Ω

Overall accuracy ±0.5% of full scale at 25℃(77℉)

±1% of full scale during 0~55℃(32~131℉)

Response time 3 ms ×channels

Isolation method It has isolation between digital area and analog area. There is no isolation

among channels.

Isolation

Field to Digital Area: 500V

Field to Analog Area: 500V

Analog area to Digital Area: 500V

Field to 24VDC: 500V

Absolute input range ±15 V ±32 mA

Digital data format 2’s complementary of 16-bit, 13 Significant Bits

Average function Yes (CR#2~CR#5 can be set and setting range is K1~K100)

Self diagnose function Upper and lower bound detection / channels

Communication mode (RS-485)

MODBUS ASCII/RTU Mode. Communication baud rate of 4,800 / 9,600 /

19,200 / 38,400 / 57,600 / 115,200 bps. For ASCII mode, date format is

7Bits, even, 1 stop bit (7,E,1). For RTU mode, date format is 8Bits, even, 1

stop bit (8,E,1). The RS-485 is disabled when the ELC-AN04ANNN is

connected in series to an ELC.

Connect to ELC in series

The input point of the first analog extension unit it connects from the near to

the distant is from 0 to 7. The Max. is 8 modules and it won’t waste digital

I/O point.

Max. rated consuming power 24 VDC(20.4VDC~28.8VDC) ( –15%~+20%), 2W, supply from external

power

Noise Immunity

ESD(IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT(IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV,

Analog & Communication I/O: 1KV

RS(IEC 61131-2, IEC 61000-4-3): 26MHz~1GHz, 10V/m

Grounding

The diameter of the grounding wire cannot be smaller than that of terminals

24V and 0V (if numerous ELCs are used at the same time, make sure that

each ELC is grounded respectively to the ground poles)

Vibration/Shock Immunity International Standard Regulations: IEC61131-2, IEC 68-2-6 (TEST Fc)/

IEC61131-2 & IEC 68-2-27 (TEST Ea)

Operation/Storage Environment Operation: 0℃~55℃(temperature), 50~95% (humidity), pollution degree: 2;

Storage: -25℃~70℃(temperature), 5~95% (humidity)

Agency Approvals

UL508

UL1604, Class1,Div2 Operating temperature code: T5

European community EMC Directive 89/336/EEC and Low Voltage

Directive 73/23/EEC

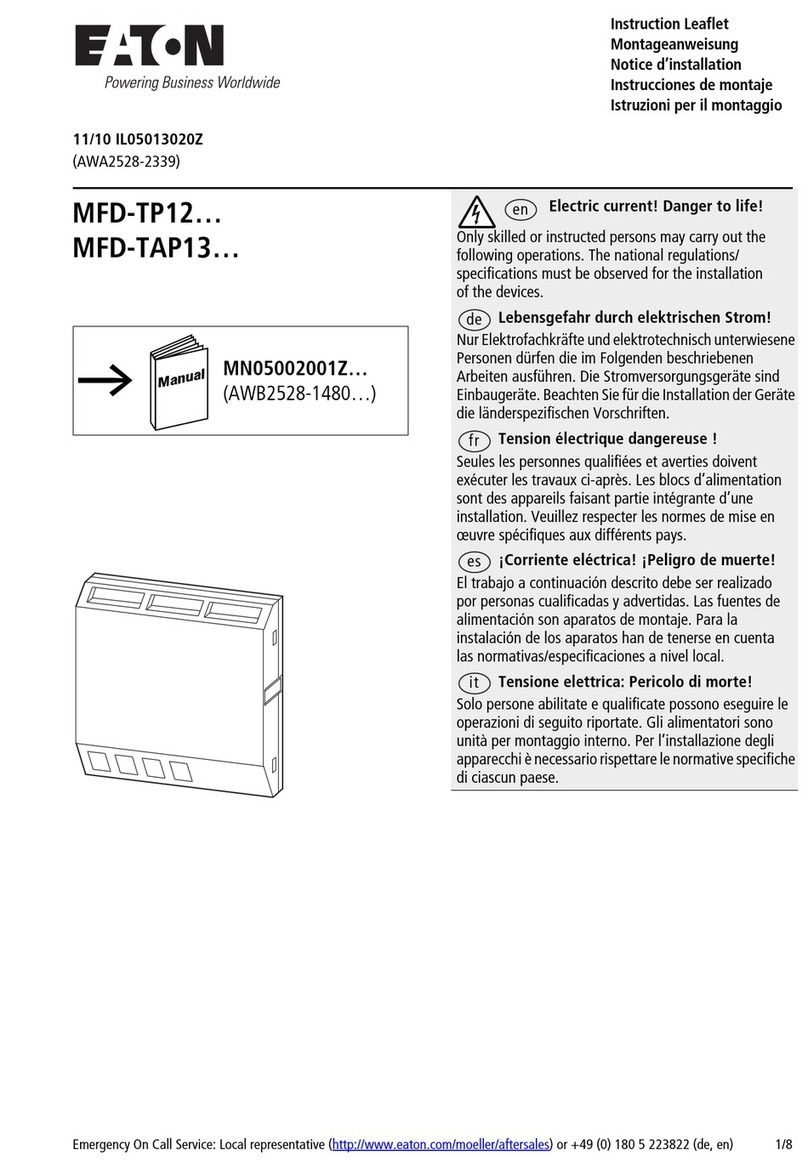

3CR (CONTROL REGISTER)

ELC-AN04ANNN EXPLANATION

CR

No.

Comm.

address Latched Register name b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

#0 H 4000 O R Model type System used, data length is 8bits (b7~b0).

ELC-AN04ANNN model code =H 88

#1 H 4001 O R/W Input mode setting

Reserved CH4 CH3 CH2 CH1

Input mode setting: factory setting is H0000.

Mode 0: input voltage mode (-10V~+10V).

Mode 1: input voltage mode (-6V~+10V).

Mode 2: input current mode (-12mA~+20mA)

Mode 3: input current mode(-20mA~+20mA)

Mode 4: Reserved.

#2 H 4002 O R/W CH1 average number

Average numbers setting of channel CH1~CH4. Setting range is K1~K100

and factory setting is K10.

#3 H 4003 O R/W CH2 average number

#4 H 4004 O R/W CH3 average number

#5 H 4005 O R/W CH4 average number

#6 H 4006 X R Average value of CH1 input

signal

Display average value of CH1~CH4 input signal

#7 H 4007 X R Average value of CH2 input

signal

#8 H 4008 X R Average value of CH3 input

signal

#9 H 4009 X R Average value of CH4 input

signal

#10 ~ #11 Reserved

#12 H 400C X R Present value of CH1 input

signal Display present value of CH1~CH4 input signal

#14 H 400E X R Present value of CH3 input

signal Display present value of CH1~CH4 input signal

#15 H 400F X R Present value of CH4 input

signal

#16 ~ #17 Reserved

#18 H 4012 O R/W To adjust OFFSET value of

CH1

Offset setting of CH1~CH4. Factory setting is K0 and unit is LSB.

Voltage input: setting range is K-4,000 ~K4,000

Current input: setting range is K-4,000 ~K4,000

#19 H 4013 O R/W To adjust OFFSET value of

CH2

#20 H 4014 O R/W To adjust OFFSET value of

CH3

#21 H 4015 O R/W To adjust OFFSET value of

CH4

#22 ~ #23 Reserved

#24 H 4018 O R/W To adjust GAIN value of CH1 GAIN setting of CH1~CH4. Factory setting is K4,000 and unit is LSB.

Voltage input: setting range is K-3,200 ~K16,000.

Current input: setting range is K-3,200 ~K10,400.

#25 H 4019 O R/W To adjust GAIN value of CH2

#26 H 401A O R/W To adjust GAIN value of CH3

#27 H 401B O R/W To adjust GAIN value of CH4

#28 ~ #29 Reserved

#30 H 401E X R Error status It is the data register to save all error status. Please refer to fault code chart

for detail.

#31 H 401F O R/W Communication address

setting

Setting RS-485 communication address. Setting range is 01~255 and

factory setting is K1

#32 H 4020 O R/W Communication baud rate

setting

It is used to set communication baud rate (4,800, 9,600, 19,200, 38,400,

57,600, 115,200bps). Communication format: ASCII mode is 7Bit, even bit, 1

stop bit (7,E,1). Communication format of RTU mode is 8Bit, even bit, 1 stop

bit (8,E,1).

b0: 4,800 bps (bit/sec). b1: 9,600 bps (bit/sec). (factory setting)

b2: 19,200 bps (bit/sec). b3: 38,400 bps (bit/sec).

b4: 57,600 bps (bit/sec). b5: 115,200 bps (bit/sec).

b6~b13: reserved.

b14: exchange low and high byte of CRC check code (only for RTU mode)

b15: ASCII / RTU mode selection

#33 H 4021 O R/W

Reset to factory setting and set

characteristics adjustable

priority

b15 b14 B13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Reserved CH4 CH3 CH2 CH1

Output latched setting, factory setting H0000

Give CH1 setting for example:

1. When b0=0, user can set OFFSET and GAIN value of CH1 (CR#18,

CR#24). When b0=1, inhibit user to adjust OFFSET and GAIN value of

CH1 (CR#18, CR#24).

2. b1 means if characteristic register is latched. b1=0 (factory setting,

latched), b1=1 (not latched).

3. When b2 is set to 1, all settings will reset to factory setting.