October 2016

INS DB5 Rev 9

Instruction sheet

MTL process alarm equipment

RTK DB5

MTL intrinsically safe sounder type DB-5

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

www.mtl-inst.com

© 2016 Eaton

All Rights Reserved

Publication No. INS DB5 Rev 9

October 2016

Description

The RTK DB5 sounder is a strong, lightweight warning

sounder, CENELEC certified to Ex II 1G EExia IIC T4 (Ta

-20°C to 55°C) with 26 user-selectable tones, and an

output level of over 100dB.

Also available certified to CSA, FM standards and for use

in mines.

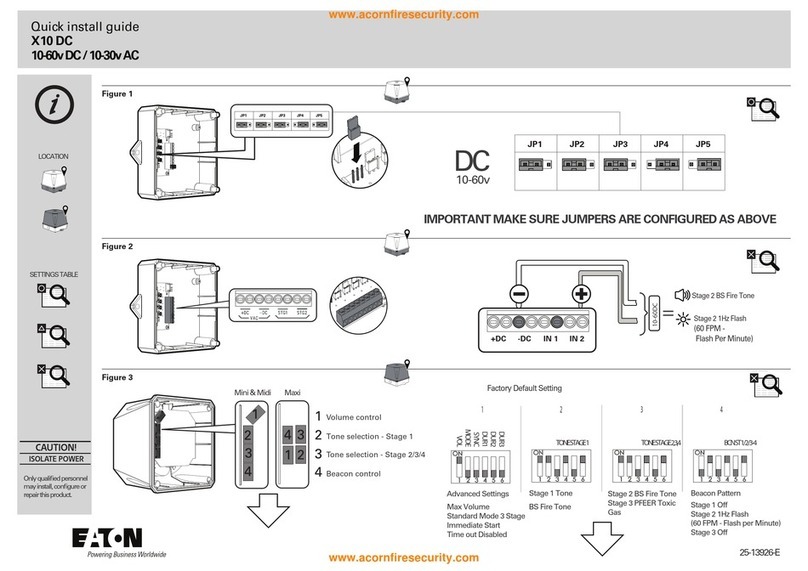

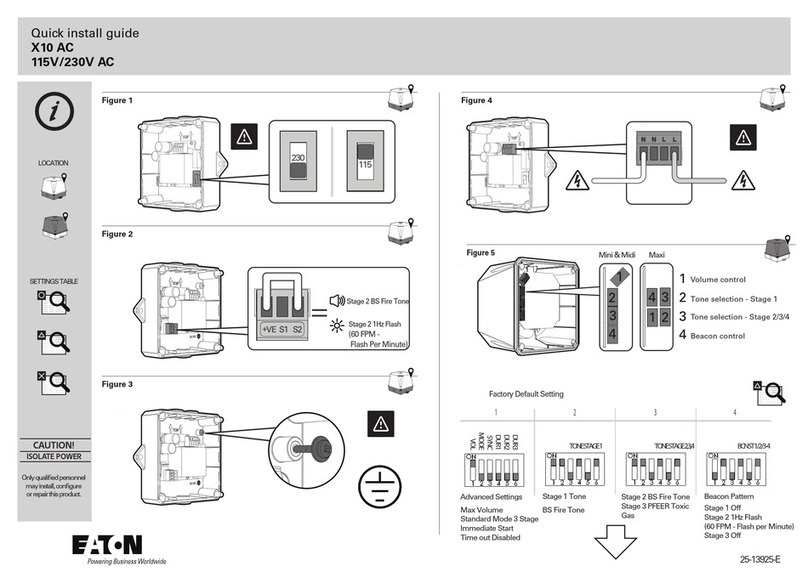

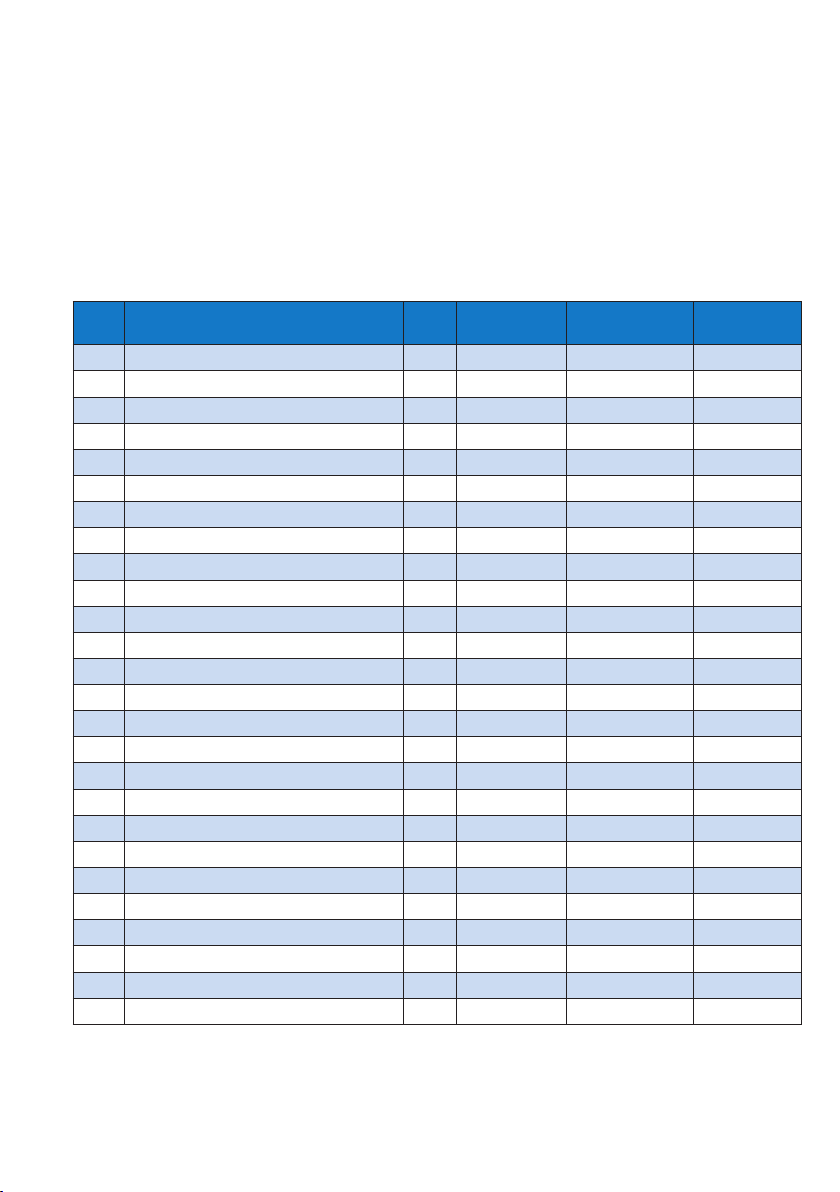

Connection details

1 +ve common

2 +ve common

3 -ve 1st tone

4 -ve 1st tone

5 -ve 2nd tone

6 -ve 2nd tone

To generate the first tone simply connect supply +ve to

terminals 1 or 2, and supply –ve to terminals 3 or 4. To

generate the second tone simply connect supply +ve to

terminals 1 or 2, and supply –ve to terminals 5 or 6. Note,

if +ve is connected to 2nd sound, it will permanently

damage the sounder.

Each terminal is duplicated and internally connected to

allow for ease of connecting subsequent horns or end-of-

line (EOL) resistors.

Installation

Mounting

The sounder should be positioned using the two available

fixing holes in the base. It is recommended that stainless

steel nuts and bolts be used if the environment is corrosive.

The sounder will operate in any attitude, from horizontal to

vertical. However, it is important to note that the alignment

and mounting of the sounder should ensure that:

• Dust or debris cannot lodge in the re-entrant horn.

Water from hose’s, jets or rain cannot settle in the

re-entrant horn.

• The sounder should be installed in accordance with

certified parameters.

Removing and replacing the cover

Remove the cover/horn of the sounder by rotating the

top of the sounder anti-clockwise, and pulling the cover/

horn gently away from the base. Replacing the cover/

horn is a reverse process of the above, but care should

be taken to ensure that the seal is securely located in its

groove during re-assembly.

Wiring

Cable termination should be in accordance with

specifications applying to the application. It is

recommended that all cables and cores should be

fully identified. Ensure that only the correct glands are

used and that the assembly is shrouded. Refer to the

connection details below.

The twinned-pair inlet terminals and deep base are

convenient for looping to other circuits or for siting end-

of-line resistors. The base has three knockouts, two on

the side and one on the base, to accommodate a 20mm

conduit or M20 cable glands. The units are polarised and

a chain may be fitted with an “end of line” resistor for

reverse polarity testing and to permit line monitoring.

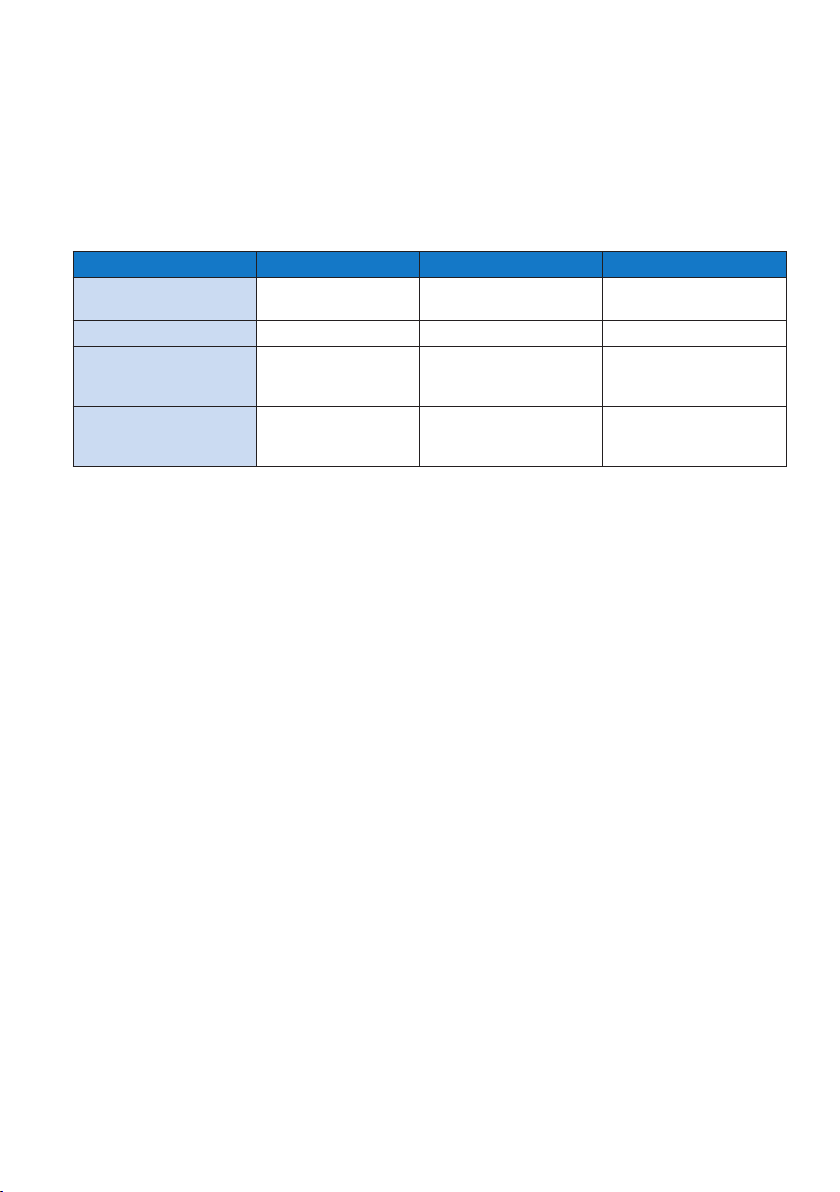

Recommended cable

0.5 to 2.5mm2with earthed screen and insulating

sheath. Cable parameters are determined by the output

parameters of the interface selected.

Safe area use

In safe areas, the sounders can be powered directly from

24VDC/12VDC. The absence of any current limitation

increases the output by approx 4dB.

Sound

The sound level for each of the individual tones in shown

in Table 2. This is assuming one DB5 set at full volume,

driven from a suitable IS interface. Where two sounders

are driven from the same IS source, the output will

decrease by 1.5dB. Three sounders will decrease by

2.2dB. A single turn potentiometer is provided to reduce

the volume level by a minimum of 15dB.