K1121V11

Eaton

Wheatley Hall Road, Doncaster, South Yorkshire, DN2 4NB

Sales

T: +44 (0)1302 303303

F: +44 (0)1302 367155

E: sales@cooper-ls.com

General

+44 (0)1302 321541

+44 (0)1302 303220

technical@cooper-ls.com

International Sales

+44 (0)1302 303250

+44 (0)1302 303251

export@cooper-ls.com

Safe Operation

1. Check the rating label for voltage and frequency before connecting this

luminaire to the electrical supply.

2. Ensure that the mains supply is switched off when working on this

luminaire, whether installing or carrying out any other servicing.

3. Do not mount luminaire on or close to readily flammable materials.

4. To prevent damage to driver, do not mix with conventional magnetic

ballasts on the same electrical circuit.

5. Where use in more onerous situations is required, e.g. In part-

completed buildings before “drying-out” is completed, or areas where

ambient temperatures are outside the normal temperature range, then

consult our Sales Office.

6. The light source contained in this luminaire shall only be replaced by the

manufacturer or his service agent or a similar qualified person.

7. When used as intended this product complies with the EMC Directive

2014/30/EU and Low Voltage Directive 2014/35/EU.

Servicing and Disposal

1. At commissioning and handing over of installation ensure that a copy of

these instructions is presented to the authority responsible for the

operation and maintenance of the luminaries.

2. Servicing, e.g. cleaning, must only be carried out after the electricity

supply has been switched off. It must not be assumed that luminaries

with LEDs not lit are switched off, always check before servicing.

3. Cleaning should be carried out at regular intervals to ensure that dirt

does not accumulate to an extent that will impair the thermal safety or

optical performance of the luminaire. Regular cleaning will also ensure

that the optical performance of the luminaries is maintained.

4. Avoid touching the LED array surface. To clean - Blow surface with

either dry air or nitrogen gas.

5. At the end of life the luminaire is classed as WEEE under directive

2012/19/EU and should be disposed of in accordance with local

legislation.

Luminaire Service

Luminaire Cleaning

End of Life and Components Disposal

WEEE

February 2020

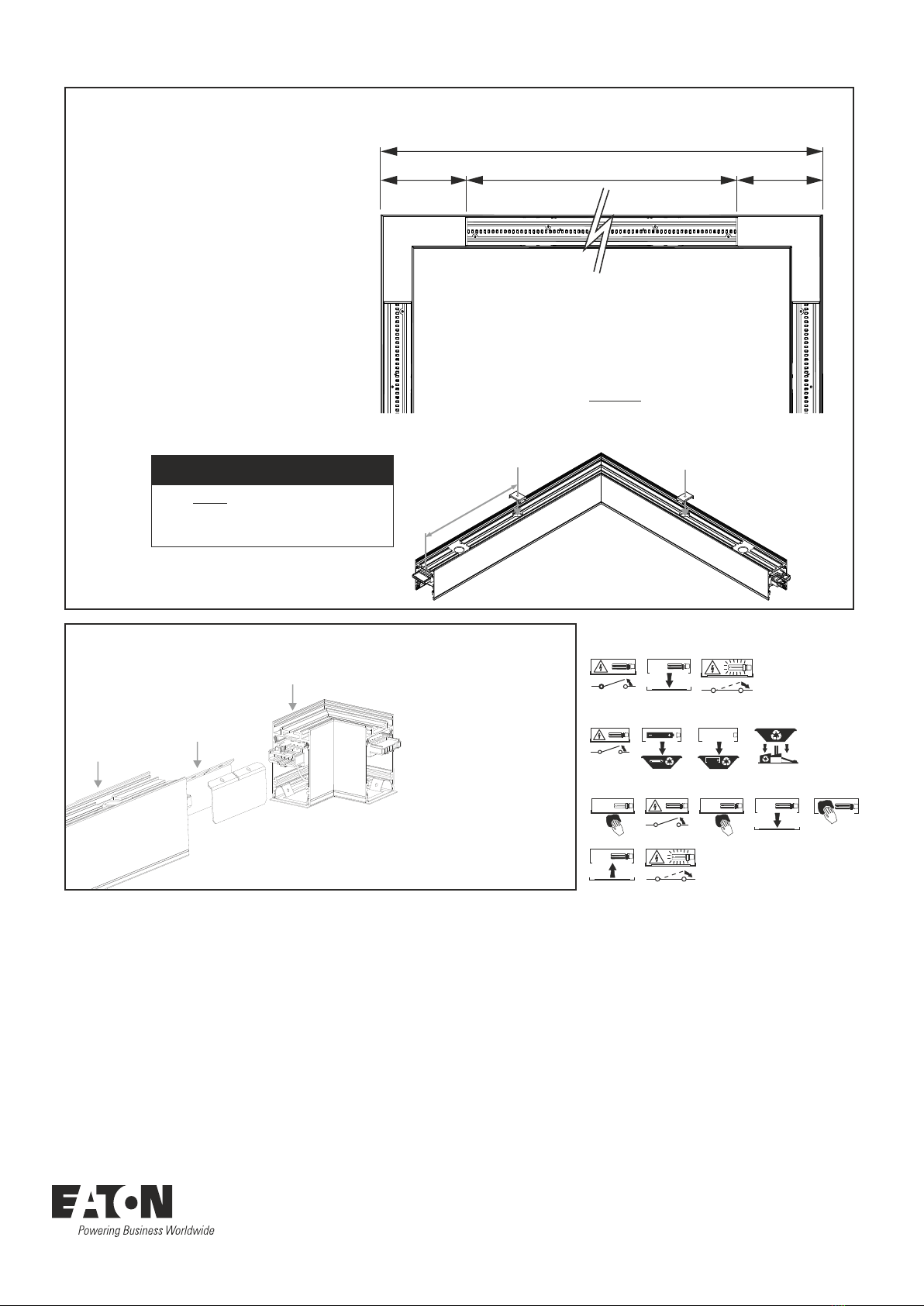

Leat

Leat

Connecting Plates

Leat Corner Remove front cover from corner

Offer up the Leat Corner up to

the continuous Leat with the

Connecting Plates in position

holding both parts together (See

‘Connector Plates’ in step 4).

Screw the plates to both parts,

ensuring they are butted up

together.

Connect the plug and socket from

both parts. Corner through wiring

can be swapped around to switch

corner direction.

Fix front cover back on the Leat

Corner

Leat Corner (100mm) - Sold Seperatley

Leat Corner (500mm) - Sold Seperatley

A (External)

B

A = Overall Length (measured)

B = Diffuser Cut Length

(A - 0.280m) x 0.9994 = B

e.g. 10.068m - 0.280m = 9.788m

9.788m x 0.9994 = 9.782m

0.140m 0.140m

Follow steps ‘a, b, c, d’ and ‘f’ under

‘Continuous Installation’ on page 3.

After step ‘f’ cut the diffuser, using the

formula on the right to ascertain the

diffuser cut length

Instruction Manual - K1121V11

Suspension Wire

Location

Suspension Wire

Location

270mm

Fit both suspensions wires as

before, over the 21mm diameter

holes.

!! CRITICAL TO QUALITY !!