EBARA CSC Operating and maintenance manual

This manual suits for next models

2

Other EBARA Water Pump manuals

EBARA

EBARA GSD Series User manual

EBARA

EBARA DL Manual

EBARA

EBARA DLFU User manual

EBARA

EBARA OPTIMA Series Operating instructions

EBARA

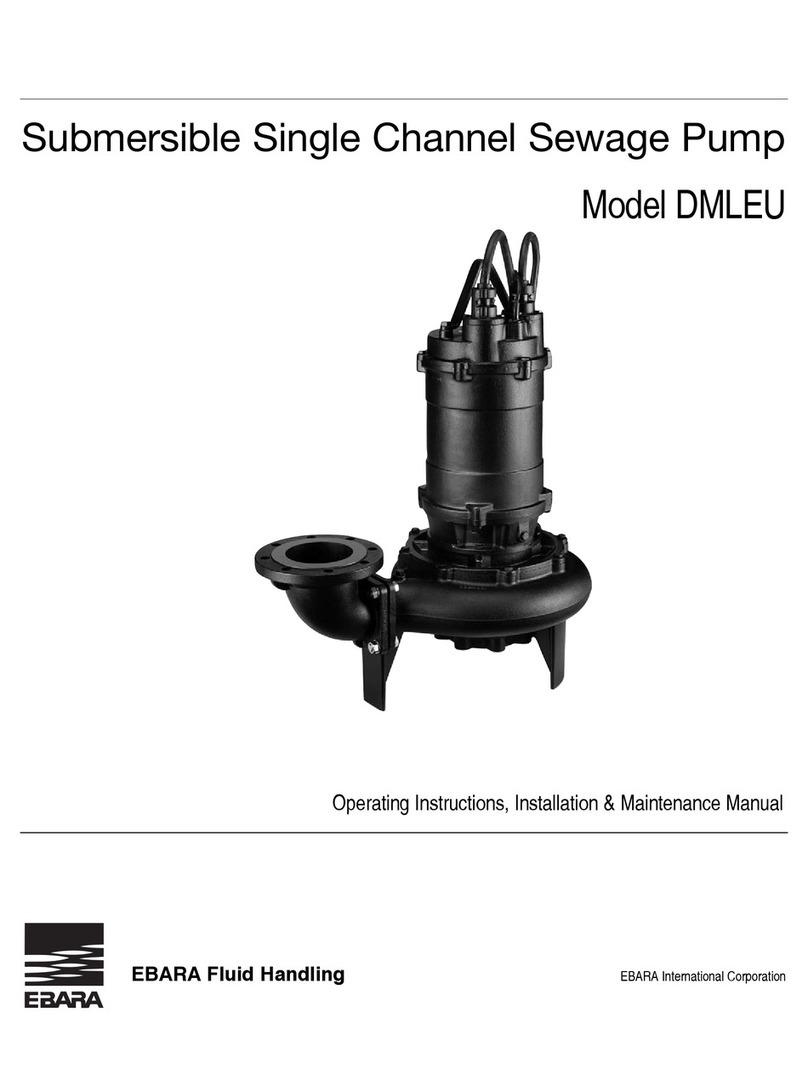

EBARA DMLEU Operating and maintenance manual

EBARA

EBARA CDX 70 User manual

EBARA

EBARA SB3 User guide

EBARA

EBARA Ego B slim Operating instructions

EBARA

EBARA GP Operating instructions

EBARA

EBARA FSA User manual

EBARA

EBARA Ego Operating instructions

EBARA

EBARA JEX Operating instructions

EBARA

EBARA EVM User manual

EBARA

EBARA DDLFU Operating and maintenance manual

EBARA

EBARA WINNER Operating instructions

EBARA

EBARA ENR Instructions for use

EBARA

EBARA A70W User manual

EBARA

EBARA EVMS 1 Operating instructions

EBARA

EBARA 3U Operating and maintenance manual

EBARA

EBARA DAR Series User manual

Popular Water Pump manuals by other brands

Shenchen Precision Pump

Shenchen Precision Pump Lab M Series manual

Victor Pumps

Victor Pumps R 250 Series Instruction and maintenance manual

MULTIQUIP

MULTIQUIP ST-1500 Operation and parts manual

SMC Networks

SMC Networks PAX1 12 Series Operation manual

HERON

HERON 8895105 Translation of the original user manual

PRETUL

PRETUL BOS-1LPP manual

ROTOS

ROTOS PTM Series instruction manual

SMC Networks

SMC Networks PAP3310 Series Operation manual

Grundfos

Grundfos Unilift KP 150 Installation and operating instructions

Penguin

Penguin PX Series Installation & maintenance

DAB

DAB K 36/200 Instruction for installation and maintenance

Edwards

Edwards STP Series instruction manual