EBS Ink-Jet Systeme GmbH D-51588 Nümbrecht-Elsenroth, Germany, Alte Zie elei 19-25 +49 (0)2293-939-0, +49 (0)2293-939-3 e-mail: mail@ebs-inkjet.de

4

signature: 2010/02/00086#1 EN ed. March 24, 2010

2

NOTE!

In order to use the printer characteristics fully, please follow all the recommendations contained in this

description. If any of the hints is not followed, a malfunction of the printer may occur or part of the printer's

functionality may be lost, whereas in extreme cases permanent damage that is not covered by guarantee

may occur.

Climatic conditions: operating temperature from +5°C to +40°C,

relative humidity up to 90% without condensation.

Mechanical conditions: vibration of max. 1 g, at max. 10 Hz, impact of max.1 g, over max. 2 ms.

Tools required: cross point screwdriver, 5 mm imbus key

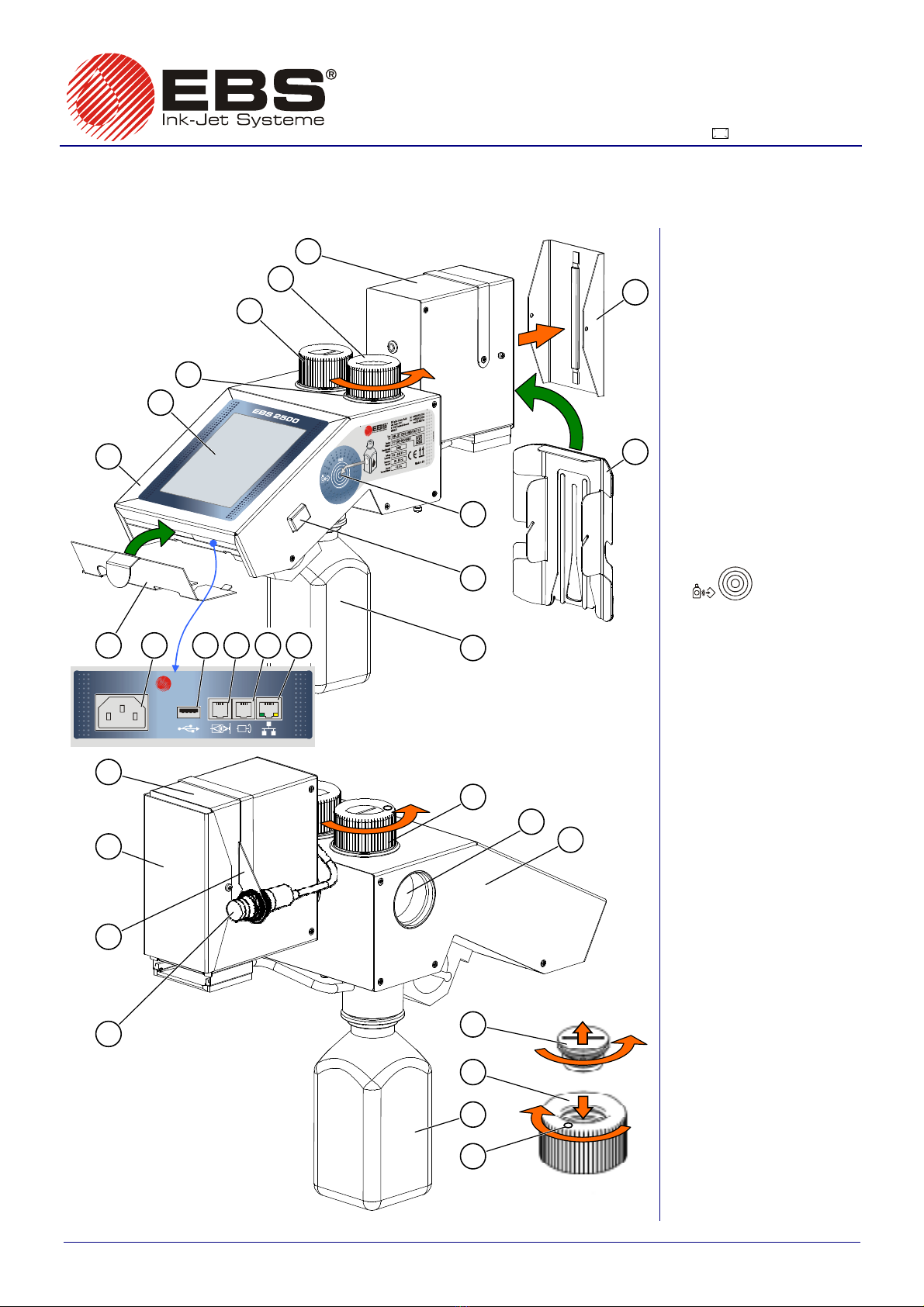

I MECHANICAL INSTALLATION OF PRINTER IN WORKPLACE

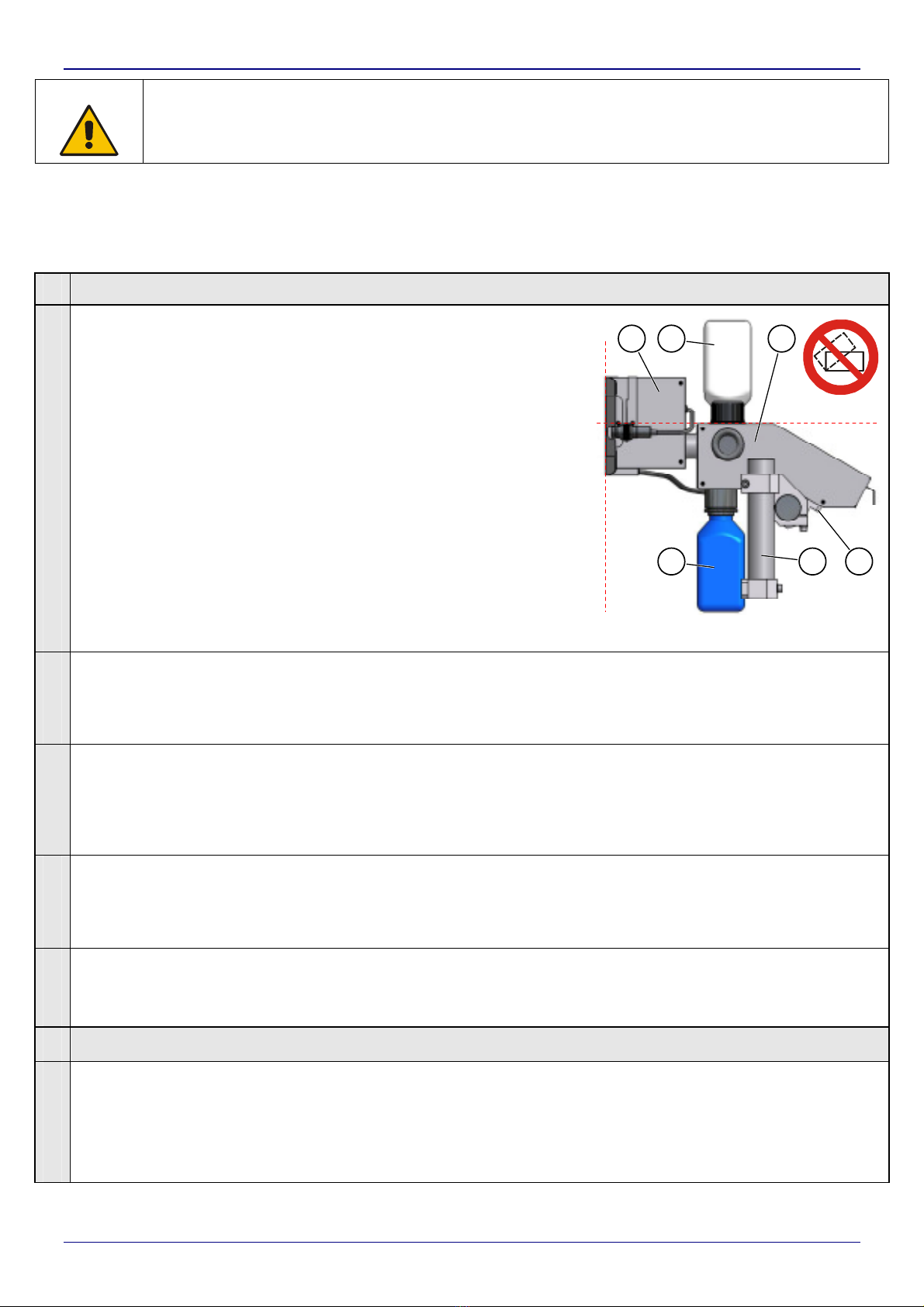

STEP 1

Install the printer on stand 24 in any convenient position in a

place that is free from vibration, shocks, excessive dust,

smoke and dirt as well as from aggressive or inflammable

vapours and gases.

If the printer is to be operated in a heavily dusty or

contaminated environment, please consider whether an

additional filter should be used in order to protect vent valve

4or whether a cover allowing free airflow should be installed

(ask your dealer for optional accessories).

Install and operate the printer in such a position that the line

determined by the top housing edge of controller 1shows the

HORIZONTAL DIRECTION, whereas the butting face of the

head shows the VERTICAL DIRECTION (see Fig. 2).

NOTE: The printer must not be tilted in any direction by

greater an angle than 30°while it is being installed

and operated.

DIRECTION

23

6

1

Fig. 2

STEP 2

Install internal photo-detector 19 in holder 18 on print head 6or in any other place that will allow

you to release printing conveniently within the reach of photo-detector cable (see STEP 3). The

holder can be put on the other side of the head, if need be, by unscrewing the holding down bolts

and reversing the holder 18.

You can fix an (external) photo-detector in a required place and attach it to connection socket 15

which is on the back panel.

You can also install a conveyor speed converter, a so called shaft-encoder, in a convenient place

on the conveyor on which objects to be labelled will move, so that the converter is driven by the

conveyor. Connect the shaft-encoder to socket 16 which is on the back panel.

STEP 4

Remove protection 7and screw in head slide 8in place of it. Install cover 12. Screw blue bottle

11 to the printer bottom to collect ink slops (make sure that the printer is not tilted by greater an

angle than 30°from the vertical direction). Remove protective film from panel LCD 2.

NOTE: The use of the slide is obligatory and vital for the proper operation of the printer!

STEP 5

Connect the controller feeder cable to socket 13 and to a mains socket and then start the printer

– by pressing switch 10 on the right wall of printer controller 1for a short time. Wait about 60

seconds for the printer system to start.

II MAKING READY FOR PRINTING

STEP 6

Check whether air filter 21 situated in vent valve 4is clean. The filter is unscrewed and screwed

in as it is shown in Fig. 1.

If the filter is dirty, clean it (see Basic Service Hints below). When the filter is clean, open valve 4

by turning the valve cap by about 15° counter clockwise - see Fig. 1 (the valve is open when

mark 22 on valve 4indicates the PRINTING position).