EBS 2600User ManUal

2020/01/09#1.1EN

8 of 113

during installaon, operaon or maintenance of the EBS Ink Jet Systeme printers due to the fail-

ure to follow the safety instrucons and also the good manufacturing pracces and safety stan-

dards generally established in the industry.

Every user who modies or repairs the EBS Ink Jet Systeme printers using consumables, spare

parts or accessories other than those supplied by EBS Ink Jet Systeme or inconsistent with

the EBS Ink Jet Systeme specicaons shall bear exclusive responsibility for such behavior.

EBS Ink Jet Systeme shall not be responsible for any failures or damage caused by modicaons

to the printer or by the applicaon of the printer to other purposes than those the printer is

designed for. The user shall be responsible for ensuring that any required precauons are taken

each me the EBS Ink Jet Systeme printer is used.

The EBS Ink Jet Systeme consumables, spare parts and accessories are designed for use in the

EBS Ink Jet Systeme printers. The applicaon of consumables, spare parts and accessories not

manufactured or recommended by EBS Ink Jet Systeme for use with a parcular printer may

cause printer malfuncon or lead to printer damage, and it always results in loss of the right to

warranty claims.

The EBS Ink Jet Systeme printers are tested together with EBS Ink Jet Systeme consumables

and spare parts according to the relevant safety regulaons and standards, therefore any use of

consumables and spare parts other than those supplied by EBS Ink Jet Systeme may distort the

test condions and aect the conformity of the printer with certain standards. The user shall bear

all risks involved with the use of improper consumables and spare parts.

1.2. safety rules

Before using the EBS 2600 printer read carefully the consumable data sheets.

No eorts have been spared to design the printer diligently so that its operaon is safe and re-

liable. However, the knowledge and observance of a few safety rules and precauons are the pre-

requisite for safe use of the printer.

The printer should be operated by trained personnel. It is recommended that the printer be super-

vised during operaon.

Any service operaons, in parcular:

‑ installaon and removal of the printer,

‑ the operaons that involve opening or removing any of the printer’ protecve covers, must be

performed exclusively by the manufacturer’s authorized service point or by a user trained in such

operaons by the manufacturer’s authorized representaves.

– Do not print on objects whose temperature exceeds 100°C (212°F) at the me of labeling.

– Make any manipulaons in the electrical part of the printer only when the power is turned

o.

– Do not direct the printhead outlet towards persons or animals.

– Wear protecve clothing and goggles while performing any operaons in the ink system and

the printhead.

– Do not use plasc vessels for washing. Drip pans of metal are recommended.

– If you need to disconnect the printer from the electrical mains, take out power plug form the

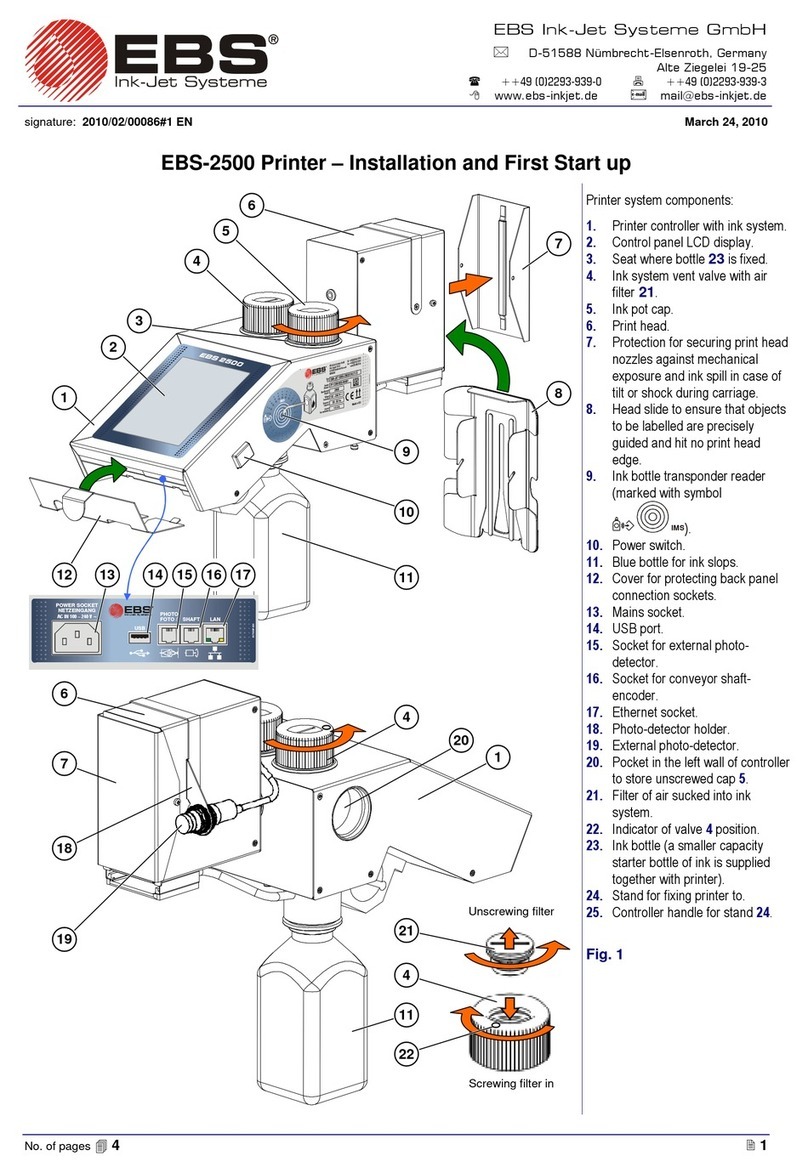

mains socket 13 (see Fig. 1 (p. 11)).