9 of 184

EN EBS‑2600 User Manual

G2023/04/26_1EN2023.05.16

Dear User,

Before using the printer, please read carefully the documents

aached to the printer, especially the Safety Manual and the material safety data

sheets (MSDSs) of consumables in use.

This User Manual should be easily accessible and ready to use whenever the need to do so arises.

This version of the document includes most of the modicaons implemented to the EBS printers

(manufactured by EBS Ink Jet Systeme GmbH) up to version 1.03.21 of the system and the descripons

contained herein correspond to the printers on which the system in this version is installed.

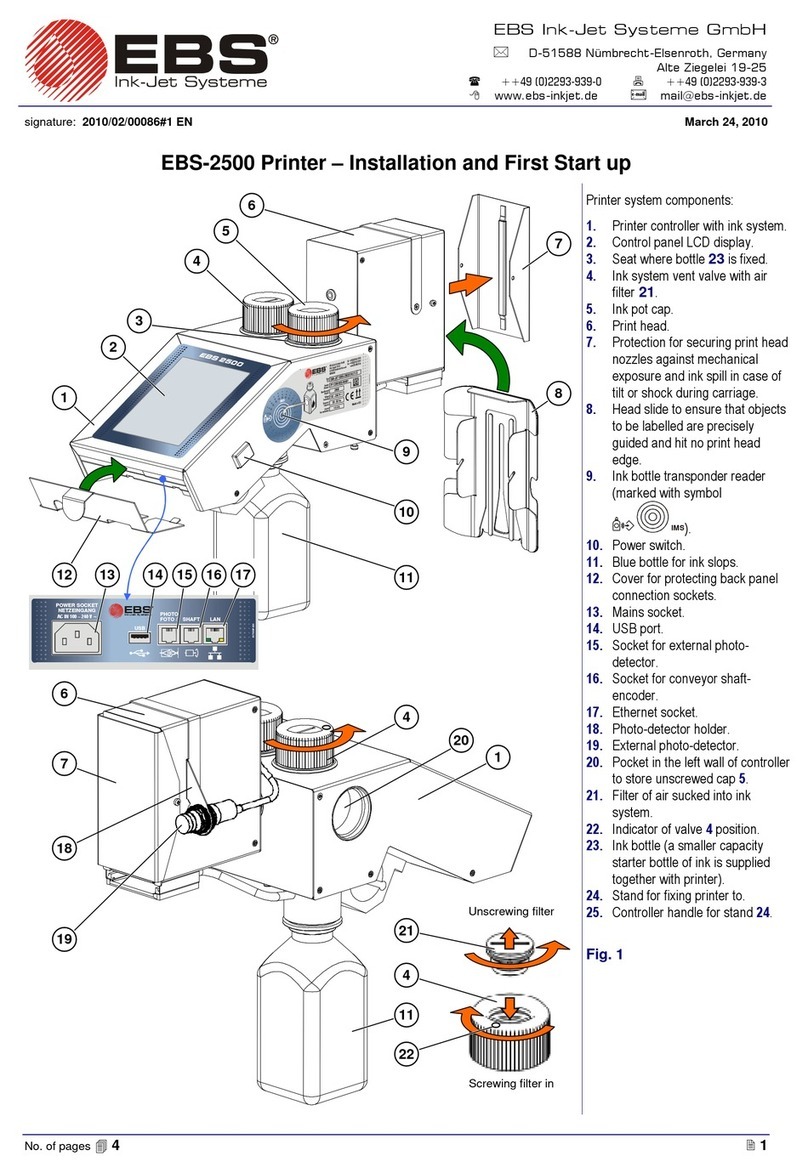

The scope of delivery depends on the order, therefore it may happen that the actual equipment

and funcons of your prinng system dier slightly from some descripons or illustraons. As we need

to keep pace with connual technical advancement and our customers’ individual requirements we

have to reserve the right to introduce changes in the design, system version and technical soluons.

Therefore, no data, illustraons and descripons contained in this User Manual shall make grounds for

any claims. Should your printer be provided with the details of the equipment or soware that are not

illustrated or described in this User Manual or should you have addional queries aer having read this

Manual, please contact an authorized representave of EBS Ink Jet Systeme GmbH for more informa-

on.

The manufacturer shall not be liable for any damage caused to the printer by improper handling or op-

eraon, that is the failure to follow this User Manual, and by the consequences of editorial or publishing

errors in the Manual.

The applicaon and use of products are beyond our control and thus you apply and use the products

exclusively on your own responsibility.

Original Instrucons.

The User Manual in the Polish and English languages are the original instrucons. In case of disputes,

these language versions shall prevail. The instrucons in other languages are translaon of the original

instrucons.