EBS Ink Jet Systeme GmbH D-51588 Nümbrecht, Germany, Alte Ziegelei 19-25 ++49 (0)2293/939-0 ++49 (0)2293/939-3 e-mail: mail@ebs-inkjet.de

20 20140417#2.2 edited on 2014.04.17 2

TABLE OF CONTENTS

1. General Information......................................................................................................................3

2. Printer Elements ...........................................................................................................................4

3. Safety Requirements....................................................................................................................4

4. Operating the Printer....................................................................................................................5

4.1. Switching the Printer On ............................................................................................................. 5

4.2. Operation Panel .......................................................................................................................... 6

4.3. Control MENU............................................................................................................................. 6

4.3.1. Choosing the Type of Menu....................................................................................................................6

4.3.2. Graphic Menu..........................................................................................................................................6

4.3.3. Text Menu ...............................................................................................................................................8

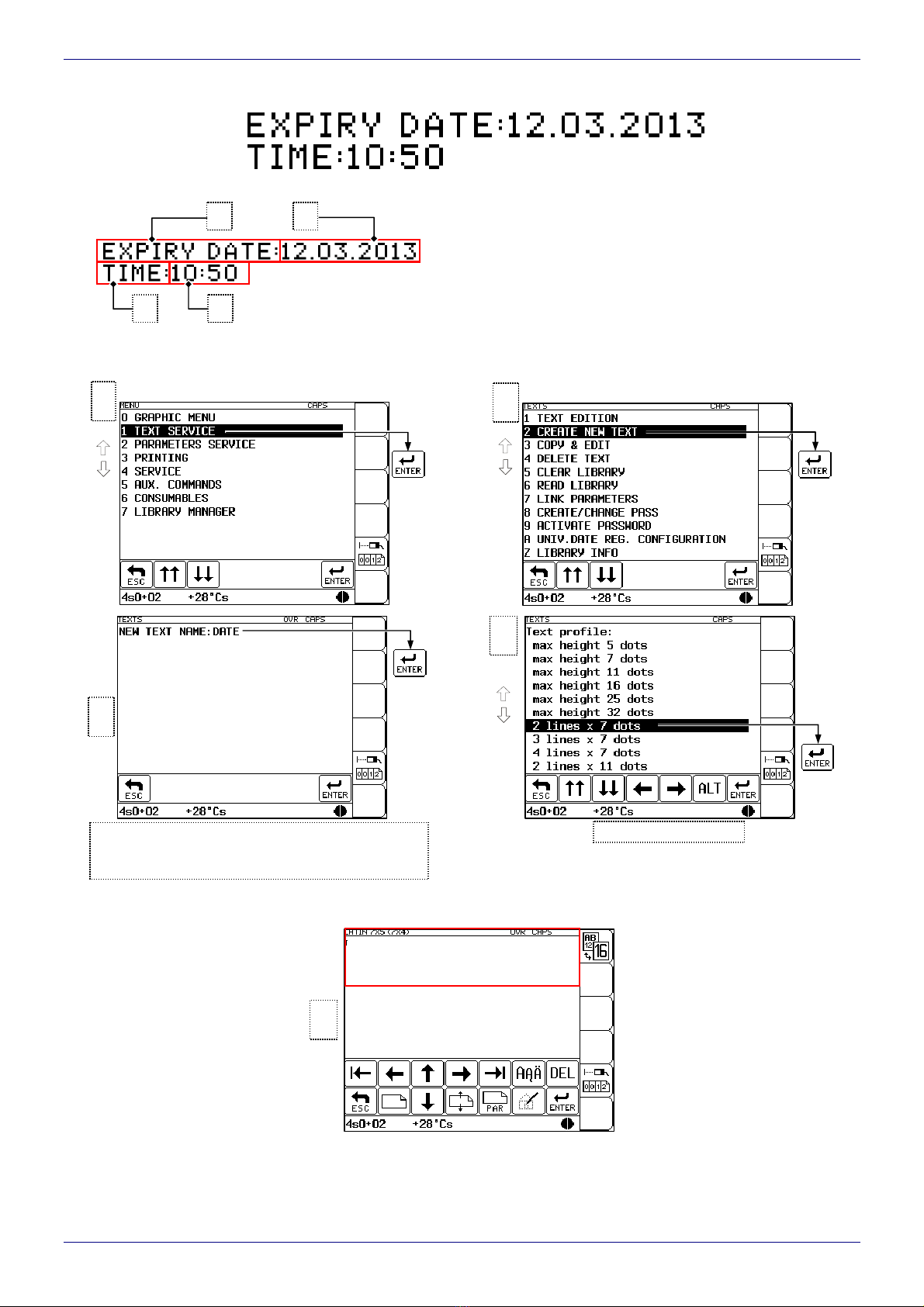

4.4. Opening and Editing a New File ................................................................................................. 9

4.5. Setting Print Parameters........................................................................................................... 12

4.6. Printing...................................................................................................................................... 13

4.6.1. Starting Printing.....................................................................................................................................13

4.6.2. Viewing a File to be Printed on the Terminal Display ...........................................................................14

4.6.3. Stopping Printing...................................................................................................................................15

4.7. Switching the Printer Off ........................................................................................................... 15

5. Routine Maintenance..................................................................................................................16

5.1. Replacing Ink/Solvent Bottle ..................................................................................................... 16

5.2. Replacing iModule®................................................................................................................... 17

5.3. Head Maintenance.................................................................................................................... 19

5.3.1. Removing Head Cover..........................................................................................................................19

5.3.2. Removing Dirt from Print Head .............................................................................................................20

Dear User,

This edition of the document includes most of the changes introduced to the EBS printers

with software version up to 32_0A and the descriptions contained therein correspond to

the printers that are equipped with this software version.

The product delivered to you corresponds to your specific order, and it may happen that

the options and functionality of your printing system differ from some descriptions or illus-

trations. As we need to keep pace with new technological advancement and wish to meet

individual requirements of our clients, we reserve the right to introduce changes in

the design and construction as and when necessary. Therefore, claims cannot be made re-

garding differences to data, illustrations or descriptions contained in this manual. Should

your printer be equipped with options or software that are not illustrated or described in this

manual or should you have additional queries after having read the manual, please contact

any EBS Ink Jet Systeme representative office for more information.

The manufacturer shall not be liable for any damages to the printer resulting from failure to

follow the instructions or from consequences of editorial or publishing errors contained in

this manual.

The application and use of the products are beyond our control and are the full responsibil-

ity of the user.