TABLE OF CONTENTS 99944200540

2 X7532279111

© 02/2020 ECHO Inc.

TABLE OF CONTENTS

Table of Contents........................................................................................ 2

Introduction ................................................................................................. 3

Servicing Information .................................................................................. 3

Parts/Serial Number............................................................................. 3

Service................................................................................................. 4

ECHO Consumer Product Support...................................................... 4

Product Registration ............................................................................ 4

Additional Literature............................................................................. 4

Safety.......................................................................................................... 4

Manual Safety Symbols and Important Information............................. 4

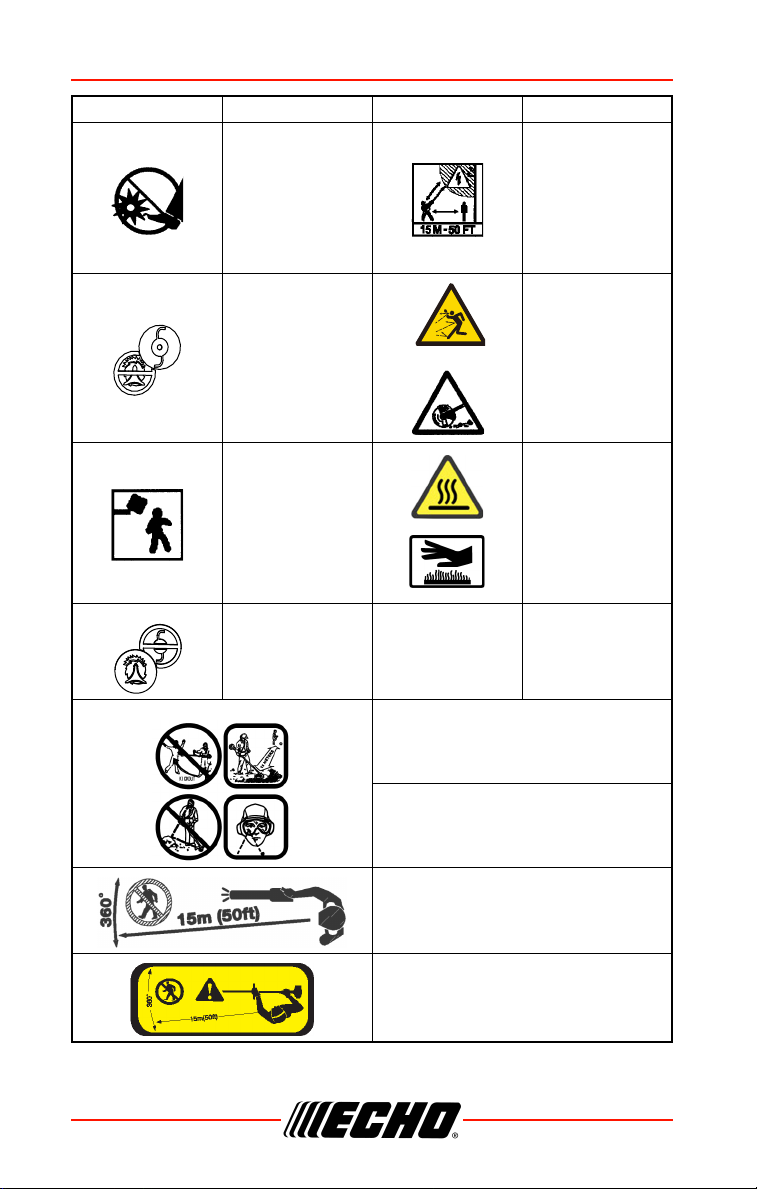

International Symbols .......................................................................... 5

Personal Condition and Safety Equipment .......................................... 7

Equipment.......................................................................................... 12

Description ................................................................................................ 13

Contents.................................................................................................... 14

Assembly................................................................................................... 14

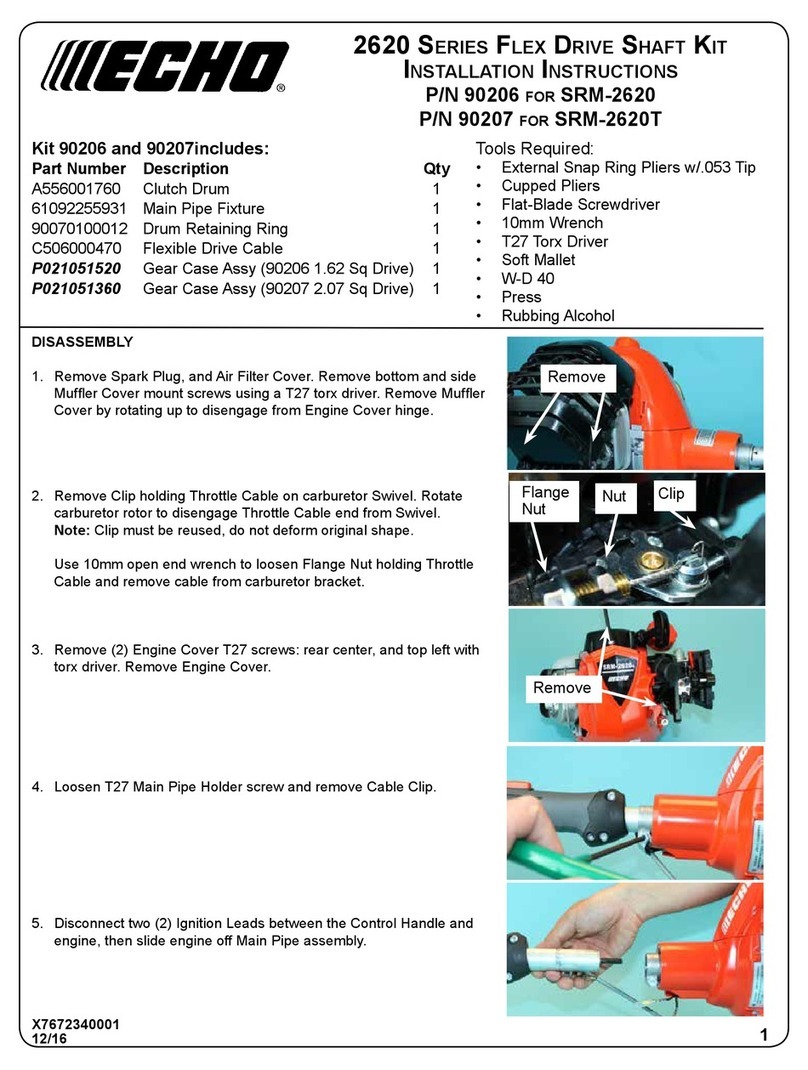

Power Head Shaft to Lower Shaft Assembly..................................... 14

Operation .................................................................................................. 15

Operation With Blades ....................................................................... 15

Blade Selection.................................................................................. 17

Applications ....................................................................................... 18

Operating Techniques - Nylon Line Head:......................................... 18

Operating Techniques - metal or plastic blade .................................. 19

Reaction Forces................................................................................. 20

Blade Cutting Problems ..................................................................... 22

Maintenance ............................................................................................. 22

Skill Levels ......................................................................................... 23

Maintenance Intervals........................................................................ 23

Lubrication ......................................................................................... 24

Nylon Line Replacement.................................................................... 25

Storage ..................................................................................................... 27

Storage Hook Installation................................................................... 27

Specifications............................................................................................ 27

Product Registration.................................................................................. 28

Notes .........................................................................................................30