- 27 -

ENGLISH

INSTALLATION

If combining with a pre-fabricated Edilkamin covering, to deŎ-

ne the exact positioning of the thermo Ŏreplace, it is important

to take the chosen covering model into consideration.

The positioning is implemented according to the model chosen

(refer to the installation instructions found inside the packaging

of each thermo Ŏreplace covering).

Always ensure the thermo Ŏreplace is level during the installa-

tion process.

- Drill a hole into the wall or the ŏooring for the external air

intake and connect the air adjustment mechanism to the hole as

described in the chapter called “external air inlet”.

- Use a stainless steel ŏue to connect the thermo Ŏreplace to the

chimney ŏue, adhering with the diameters indicated in the spe-

ciŎcations table and the guidelines given in the chapter called

“chimney ŏues”.

- Verify that all moving parts function properly before setting

the thermo Ŏreplace covering in place.

- This system must be tested and ignited for the Ŏrst time

before the covering is set in place.

INSTALLATION COVERING, FIREPLACE MAN-

TEL AND VENTILATION OUTLETS

The base of the thermo Ŏreplace covering must allow the

internal air to be recycled. Therefore, suitable slots or apertures

must be made for the air to pass through. Parts of the thermo

Ŏreplace covering that are made of marble, stone and bricks

must be mounted with a small gap between them and the Ŏre-

place so as to prevent possible breakage due to expansion and

excessive overheating.

Wooden parts must be protected by Ŏre resistant panels and

Practical advice

It is recommended to keep the radiators closed in the room

where the thermo Ŏreplace is installed; The heat emitted from

the outlet may be sufŎcient to heat.

- An incomplete combustion process causes excessive fouling

on the heat exchanger pipe.

To prevent this you must:

- burn dry wood.

- ensure the hearth contains a bed of embers and burning car-

bon before adding more wood.

- place larger logs together with smaller ones.

- make sure the temperature of the return water is at least 50 °C

(use temperature control valve).

Igniting the Ŏreplace

- Ensure that at least one radiator is always open.

- Actuate the switches of the electronic regulator.

- Place a pile of medium-thin dry wood in the thermo Ŏreplace

and ignite the Ŏre.

- Wait a few minutes until it reaches sufŎcient combustion.

- Close the door

- Set the thermostat on the electronic regulator (*) at a tempera-

ture between 50 and 70° C.

NOTE: There may be a slight smell of paint the Ŏrst few times

it is ignited, however, this will disappear quickly.

no part must touch the thermo Ŏreplace, on the contrary, there

must be an appropriate distance of at least 1 cm to allow the

air to ŏow, preventing heat accumulation. The Ŏreplace mantel

can be made of Ŏreproof plasterboard panels or gypsum board

and, however, of completely Ŏreproof material. Air should be

allowed to ŏow inside the Ŏreplace mantel (through the gap

between the door and the beam). Through convective motion,

the air will ŏow out from the grille installed at the top, resulting

in heat recovery and preventing excessive overheating.

The Ŏreplace mantel must have appropriate openings to carry

out maintenance on the Ŏttings.

In addition to that mentioned above, please consider the in-

dications stipulated in the UNI 10683 standard, paragraphs

4.4 and 4.7: “insulation, Ŏnishing, Ŏreplace covering and

safety recommendations”.

Insulating mats must be applied when using an installation

KIT so as to protect it from the heat radiation emitted by

the thermo Ŏreplace.

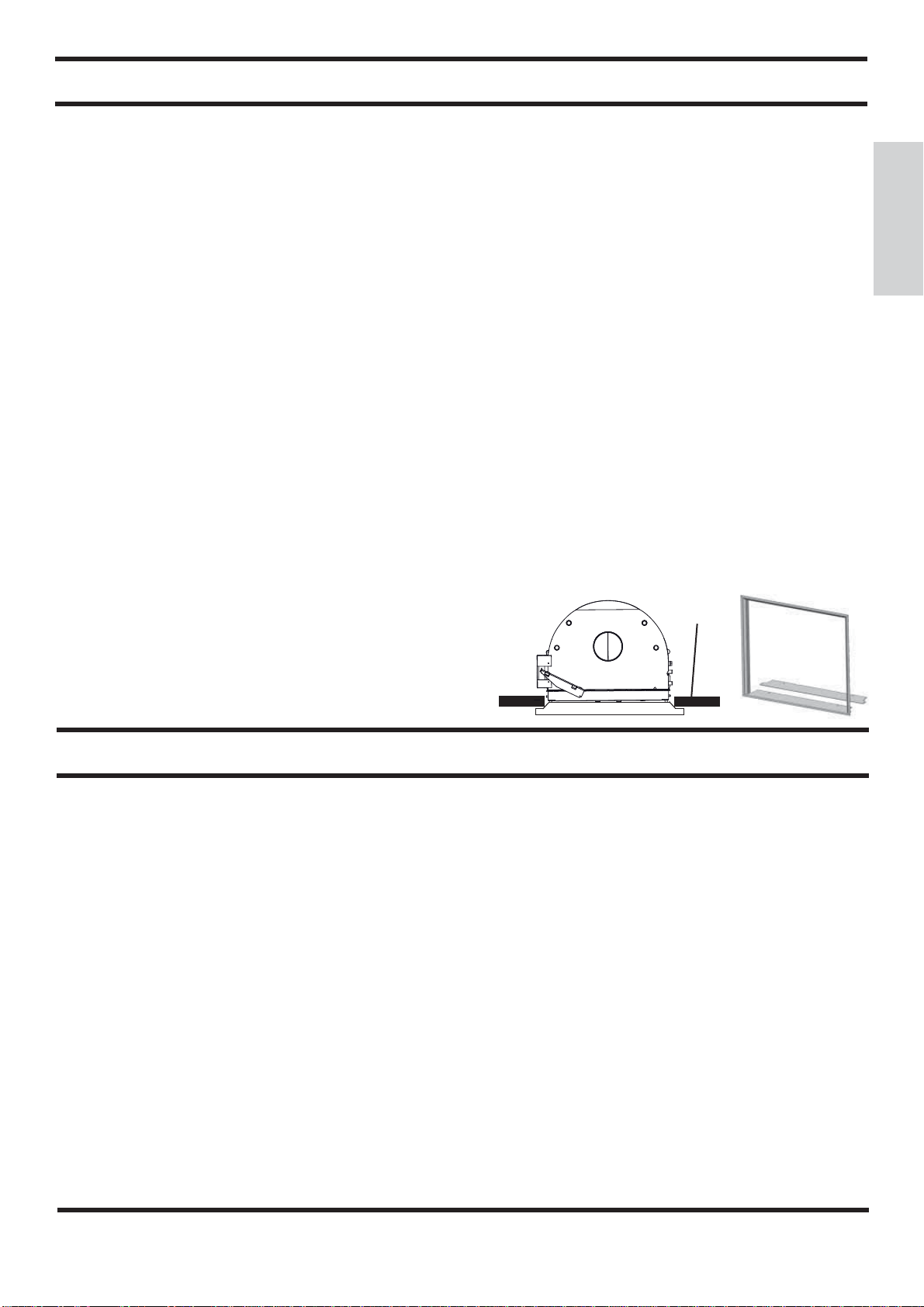

INLET FRAME (OPTIONAL)

To facilitate coupling with the covering’s components, the ther-

mo Ŏreplace can be Ŏtted with a frame (A) to be applied on the

front of the inlet.

INSTRUCTIONS FOR USE

3-way valve

- During ignition the 3-way valve (*) diverts the ŏow of water,

forcing it to return directly to the thermo Ŏreplace;

when the set temperature is reached, the 3- way valve (*)

diverts the ŏow to the system (does not depend on the kit

installed).

By-pass damper

- When the door is closed, the by-pass damper automatically

diverts smoke, thus improving efŎciency.

- When the door is opened, the damper bypass opens automa-

tically, allowing the smoke to reach the smoke ŏue directly,

preventing it from coming out of the inlet.

Thermal Relief Valve

If the water temperature exceeds 90° C (e.g. because of too

much wood being placed in the hearth) the thermal relief valve

will be activated and the acoustic signal triggered.

In this case you must proceed as follows:

Do not load additional fuel and wait for the temperature to fall

below 80°C checking the warning lights on the electronic regu-

lator. The hot water tap can be opened to speed up the cooling

process if the thermo Ŏreplace is equipped with a hot sanitary

water production KIT.

A

(*) these components of the system are to be provided by the installer.

Plasterboard

A