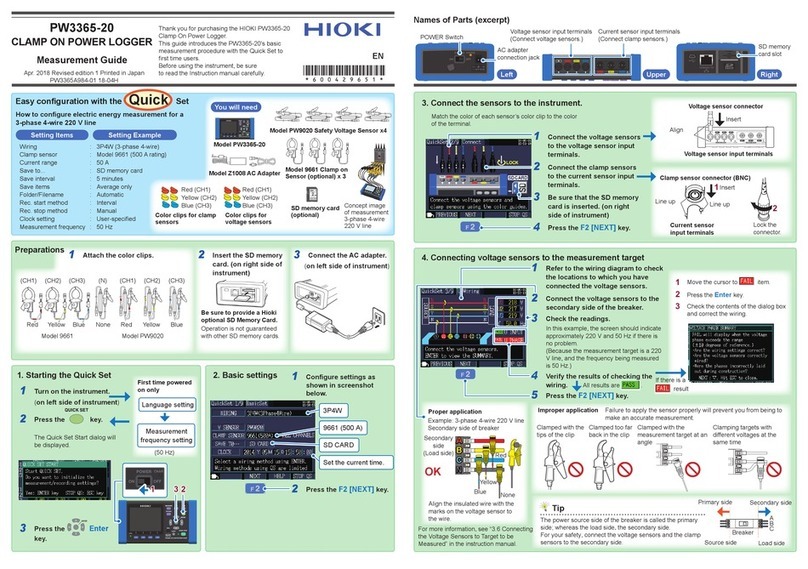

Standard Accessories and Options

2Quick Start Manual

Before using the 3196

• Before using the product the first time, verify that it operates nor-

mally to ensure that the no damage occurred during storage or

shipping. If you find any damage, contact your dealer or Hioki

representative.

• Before using the product, make sure that the insulation on the

9438-02 VOLTAGE CORD is undamaged and that no bare con-

ductors are improperly exposed. Using the product in such con-

ditions could cause an electric shock, so contact your dealer or

Hioki representative for repair.

Shipping precautions

Use the original packing materials when reshipping the product, if

possible.

Options

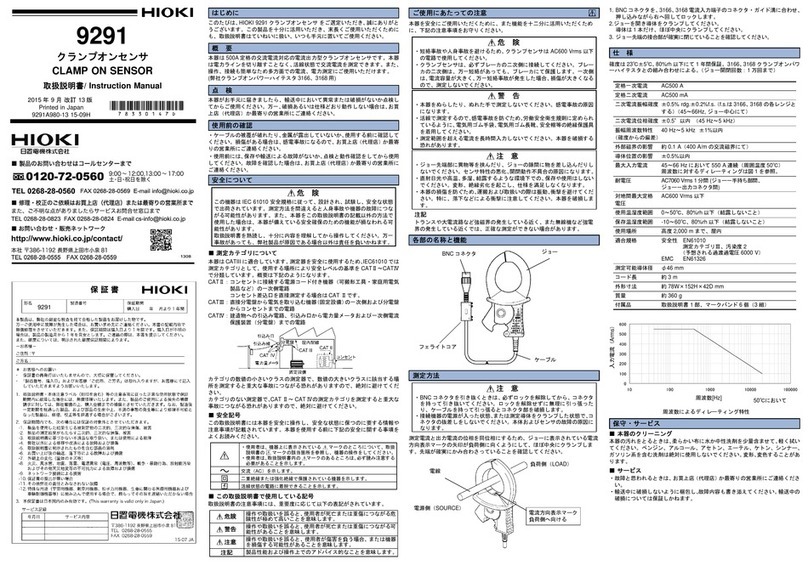

Clamps • 9660 CLAMP ON SENSOR (100 A rms rating)

• 9661 CLAMP ON SENSOR (500 A rms rating)

•

9667 FLEXIBLE CLAMP ON SENSOR

(500 A rms, 5000A rms rating)

• 9669 CLAMP ON SENSOR (1000 A rms rating)

• 9694 CLAMP ON SENSOR (5 A rms rating)

• 9695-02 CLAMP ON SENSOR (50 A rms rating)

• 9695-03 CLAMP ON SENSOR(100 A rms rating)

• 9657-10 CLAMP ON LEAK SENSOR

• 9675 CLAMP ON LEAK SENSOR

• 9290 CLAMP ON ADAPTER

(continuous 1000 A, up to 1500 A, CT ratio 10:1)

• 9219 CONNECTION CABLE (for Model 9695-02 and Model

9695-03)

Power supply • 9459 BATTERY PACK (7.2 V, 2700 mAh)

• 9458 AC ADAPTERx 1 (power cord included)

Printers • 9670 PRINTER

(with 1 roll of thermally sensitized paper supplied)

• 9671 AC ADAPTER (For the 9670 PRINTER)

• 9237 RECORDING PAPER (for printers, thermally sensitized

paper 80 mm x 25 m, 4 rolls)

• 9638 RS-232C CABLE

(for printers, cross cable, 9-pin to 25-pin/1.5 m)

Transport

case • 9339 CARRYING CASE (soft type)

• 9340 CARRYING CASE (hard type)

Adapters • 9264-01 WIRING ADAPTER

(For three-phase 3-wire (3P3W3M) systems)

• 9264-02 WIRING ADAPTER

(For three-phase 4-wire systems)