en

4

TABLE OF CONTENTS

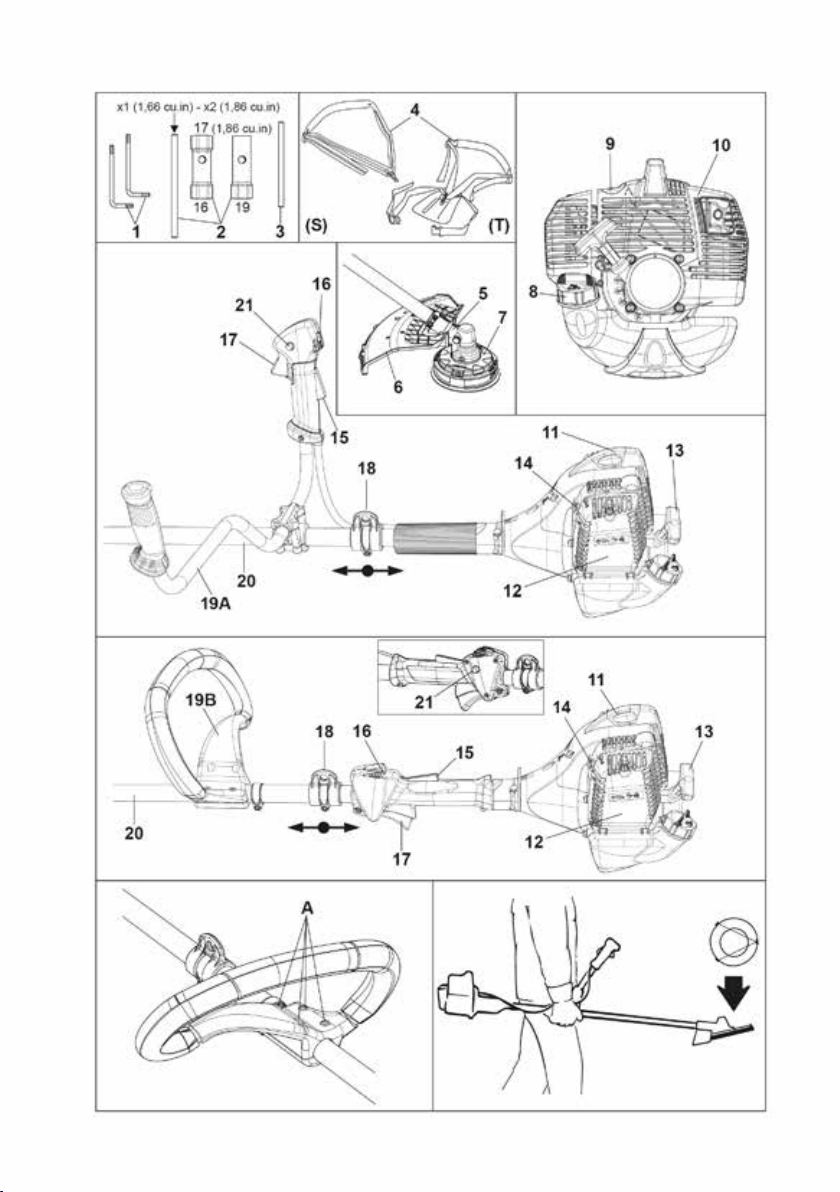

PRODUCT IDENTIFICATION

Brush Cutter Components ........................................... 5

SAFETY

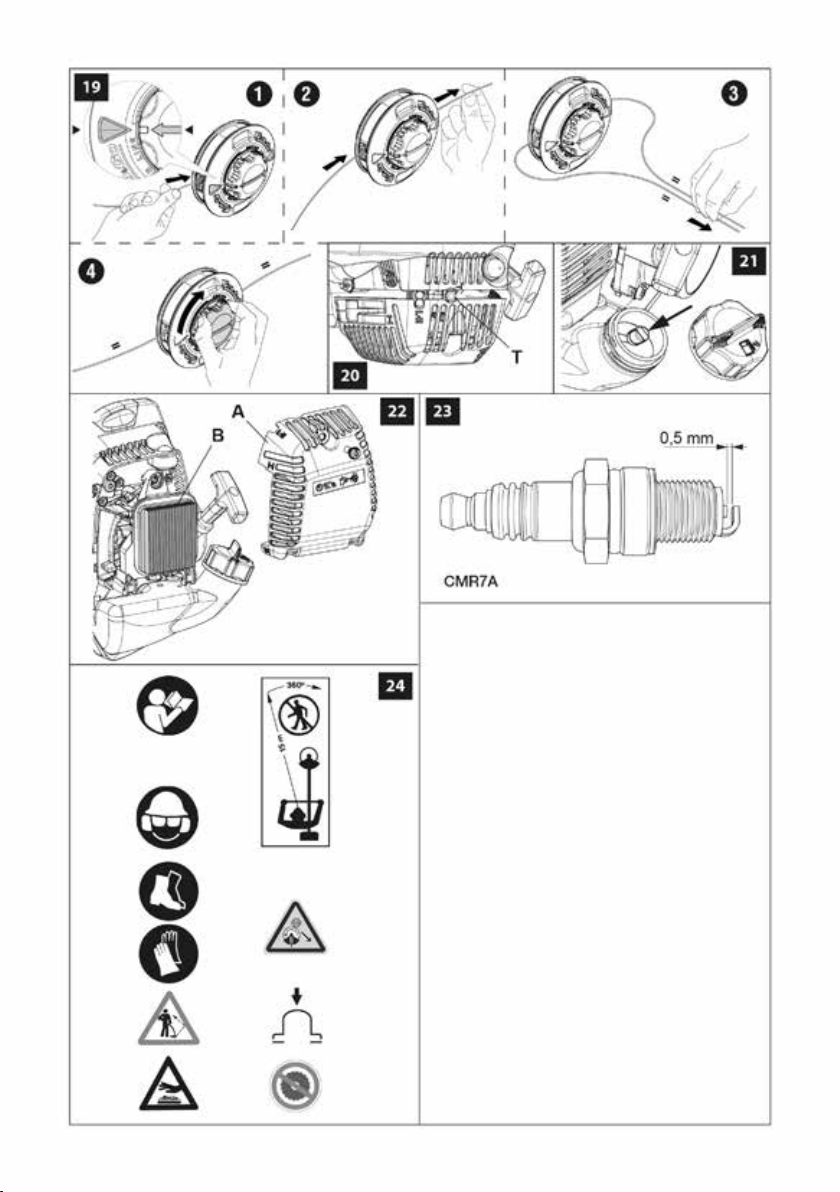

Understanding Safety Symbols ....................................... 5

State and Local Requirements ........................................ 6

SAFETY RULES

Basic Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fuel Handling ..................................................... 8

Operation and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Precautions Against Kickout.......................................... 9

Maintain Control ................................................... 9

Safety Features ................................................... 10

Recommended Cutting Attachments ................................... 10

Safety equipment checking .......................................... 11

Precautions to Reduce Vibration Risk .................................. 11

Maintenance Precautions............................................ 11

ASSEMBLY

Assembling the Safety Guard......................................... 13

Assembling the cutting attachment..................................... 13

Assembling the handle ............................................. 14

Assembling the bike handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Approved power tool attachment ...................................... 14

OPERATION

Fueling .......................................................... 15

Preparation for Cutting .............................................. 16

Starting the Engine................................................. 18

Breaking-in the Engine .............................................. 19

Stopping the Engine ................................................ 19

Working Techniques ................................................ 20

MAINTENANCE

Maintenance Chart ................................................. 24

Cutting Attachment Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Carburetor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fuel Filter ........................................................ 27

Air Filter ......................................................... 27

Starter Unit ....................................................... 27

Engine .......................................................... 27

Spark Plug ....................................................... 27

Mufer........................................................... 28

Bevel Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

TROUBLESHOOTING

Using Troubleshooting Chart ......................................... 30

STORAGE

Storing Brush cutter ................................................ 31

TECHNICAL DATA

DS 2700 - DS 3000 ................................................ 31