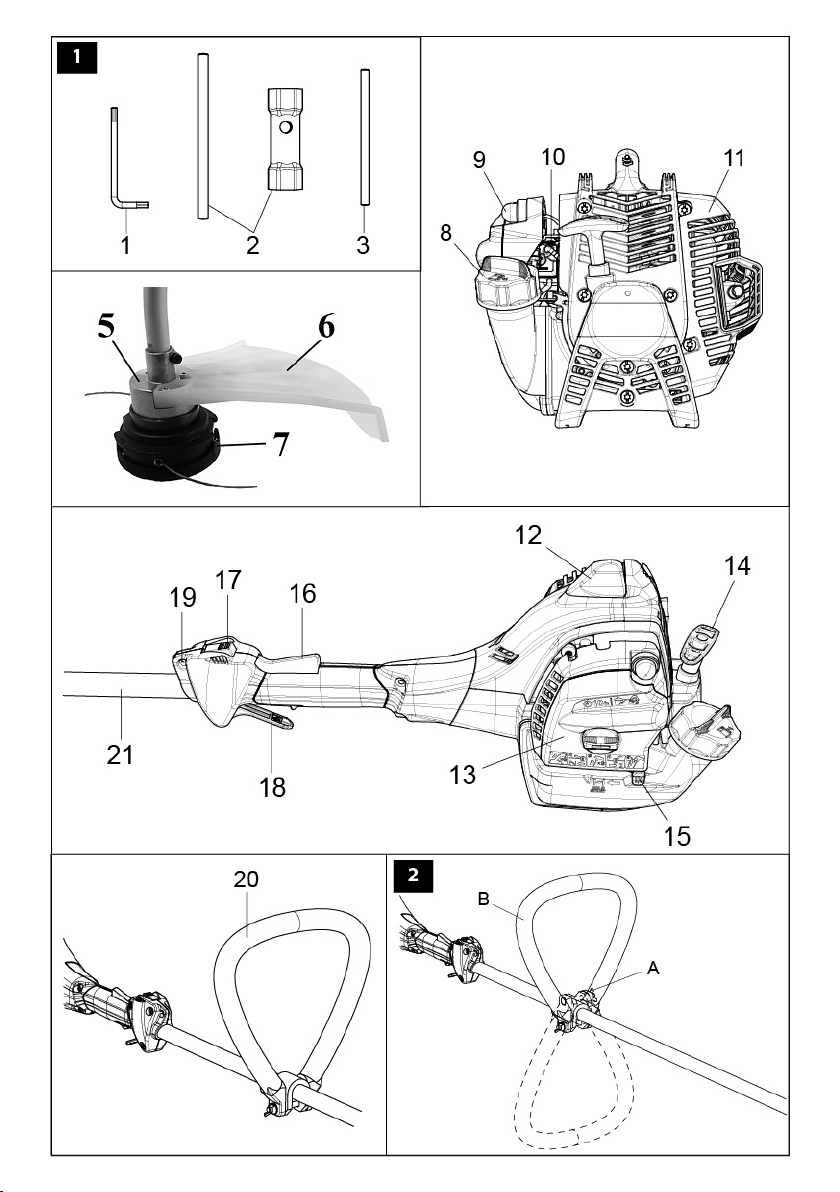

6

in good conditions. In case of damage or

deterioration, immediately substitute them

(Fig. 18).

15 - Do not utilize the machine for uses

different from the ones specified in the

manual (see pag. 8).

16 - Never leave the machine unattended with

the engine running.

17 - Do not start the engine with the arm not

mounted.

18 - Check the brush cutter daily to be sure that

components and safety devices are full

functioning properly.

19 - Do not attempt to carry out operations

or repairs that are not part of the normal

maintenance. See the authorised dealer.

20 - When disposing of the machine at the end

of its useful life, think of the environment.

Take your old unit to your dealer who will

be able to dispose of it in a proper manner.

21 - Only experienced persons who are familiar

with the operation and safe use of this

machine should use it. If you lend the

machine to someone, also give them the

instruction manual and ensure that they

read it before using the machine.

22 - All saw service, other than the operations

shown in the present manual, should be

performed by competent personnel.

23 - Keep this manual on hand and consult it

before each use of the tool.

WARNING

-Never use a machine with faulty safety

equipment. The machine’s safety

equipment must be checked and

maintained as described in this section. If

your machine fails any of these checks

contact an Authorised Service Centre to

get it repaired.

-Any use of the machine not expressly

envisaged in this manual is to be

considered improper and therefore a

source of risk to people and property.

WARNING: National regulations may limit

the use of the machine.

1 - Do not operate the machine unless you

have received specic instruction on its use.

First time users must familiarise themselves

thoroughlywiththeoperationofthemachine

before working in the eld.

2 - The machine must only be used by adults

in good physical condition who are familiar

with the operating instructions.

3 - Never use the brush cutter when you are

tired or fatigued or if you have taken alcohol,

drugs or medication.

4 - Wear appropriateclothingandsafetyarticles

such as: boots, heavy-duty trousers, gloves,

protective eyewear, ear protection and

protective helmet. Use clothing which is

close-tting but comfortable.

5 - Do notallowchildren touse thebrush cutter.

6 - Do not allow other people to remain within

15 metres during brush cutter use .

7 - The brush cutter must be equipped with the

cutting accessories recommended by the

manufacturer (look pag. 14).

8 - Never use the brush cutter without the head

guard.

9 - Before starting the engine, make sure that

theblade is free tomove and is notin contact

with any foreign objects.

10 - Only use the machine in well-ventilated

places, do not use in explosive or ammable

atmospheres or in closed environments.

11 - Never attempt any maintenance work while

the engine is running.

12 - It is prohibited to t any device other than

that supplied by the manufacturer.

13 - Donotuseamachinethathasbeendamaged,

badly repaired, improperly assembled or

modied. Do not attempt to remove or

bypass any of the safety devices. Only use

cutting attachments indicated in the table.

14 - All labels with health hazards must be kept