TH

- 10 -

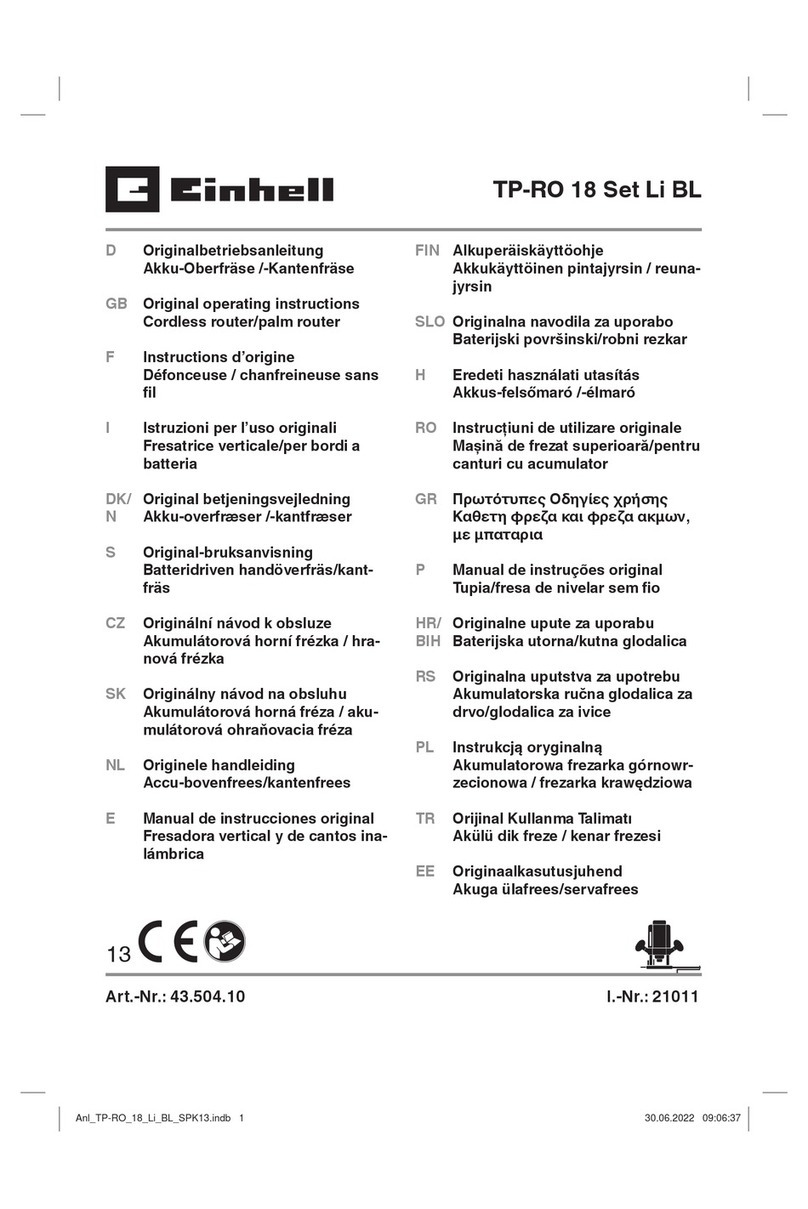

(18) ( 4)

• (18)

• (18)

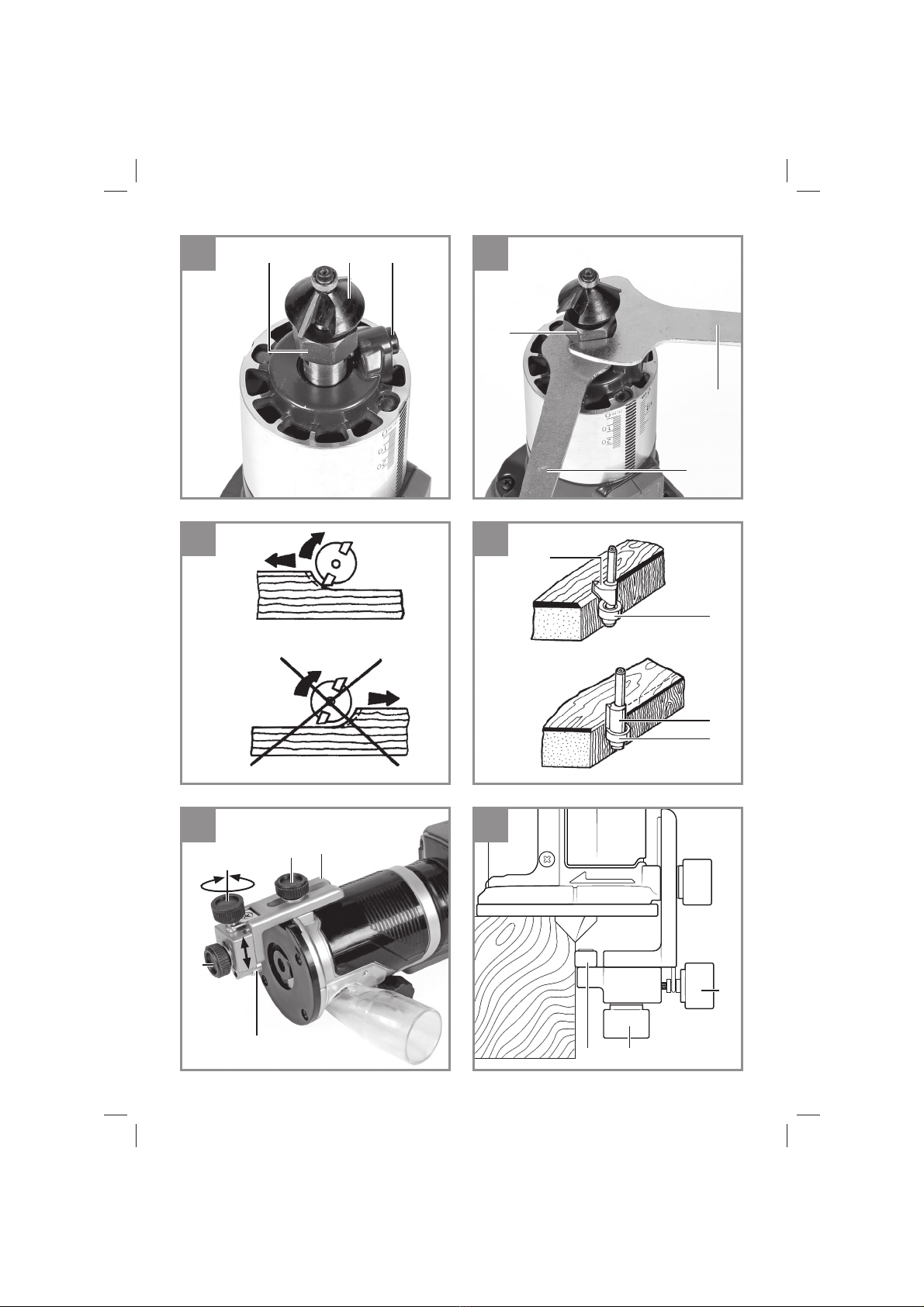

5.4 ( 5-8/ 14)

• 4 (d)

(e) ( 5)

• (14) 6

• (e) (d)

• (14) (g)

(f)

• (h)

“”

“” (i)

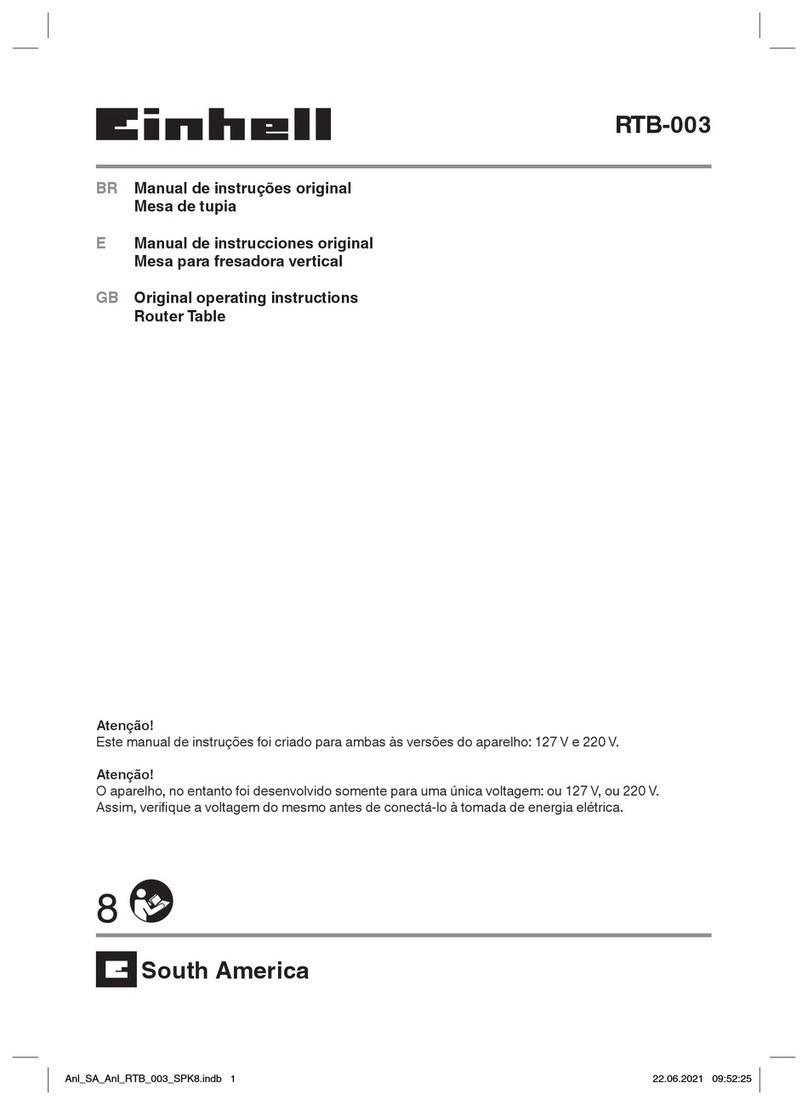

5.5 / ( 9)

!

• (1)

(20) (8)

(1)

• (9) (22)

• (8)

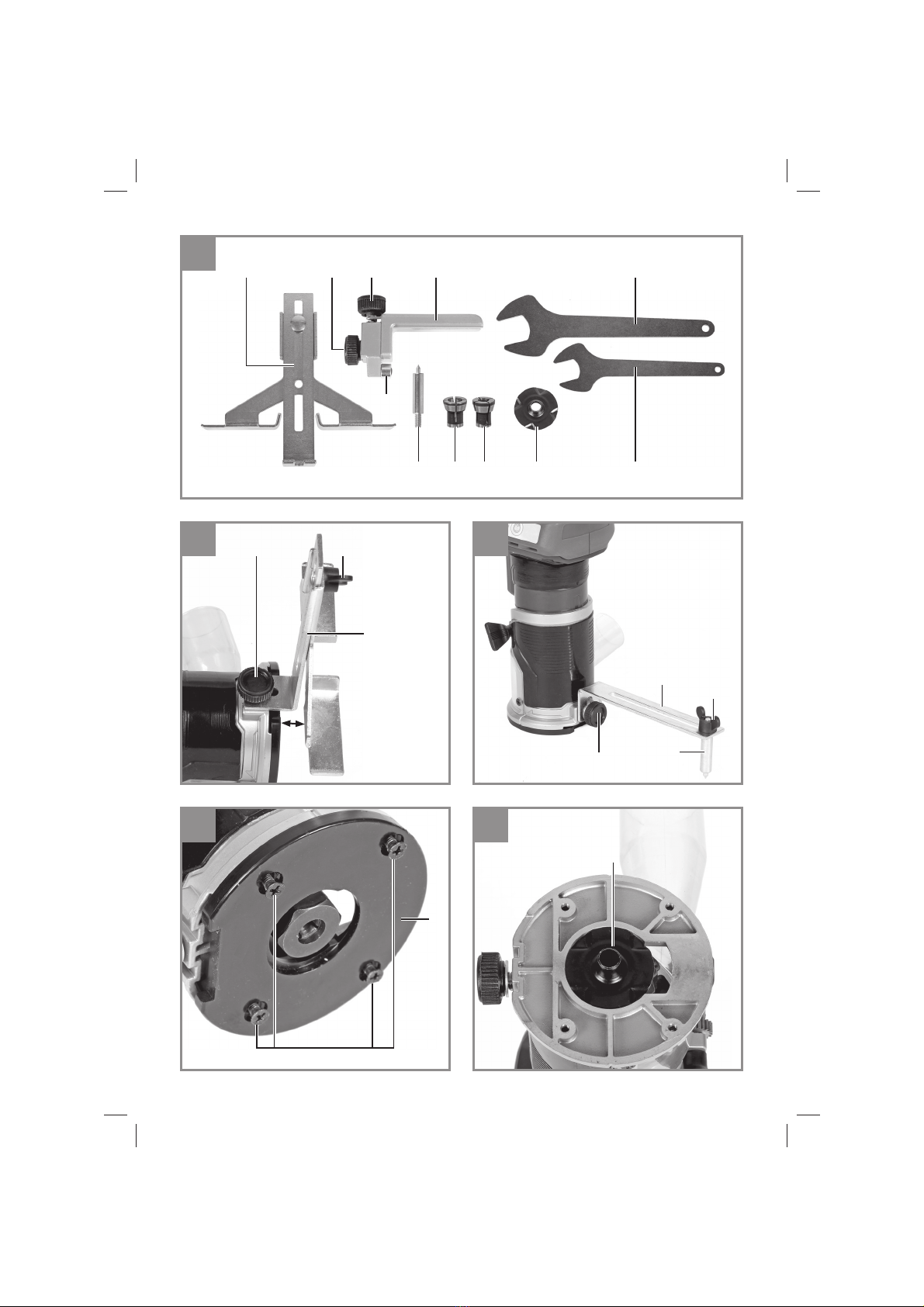

5.6 / ( 10-14)

!

!

!

!

•

(1)

5.5

• 6 . 8 .

• :

- HSS -

- TCT -

•

• :

•

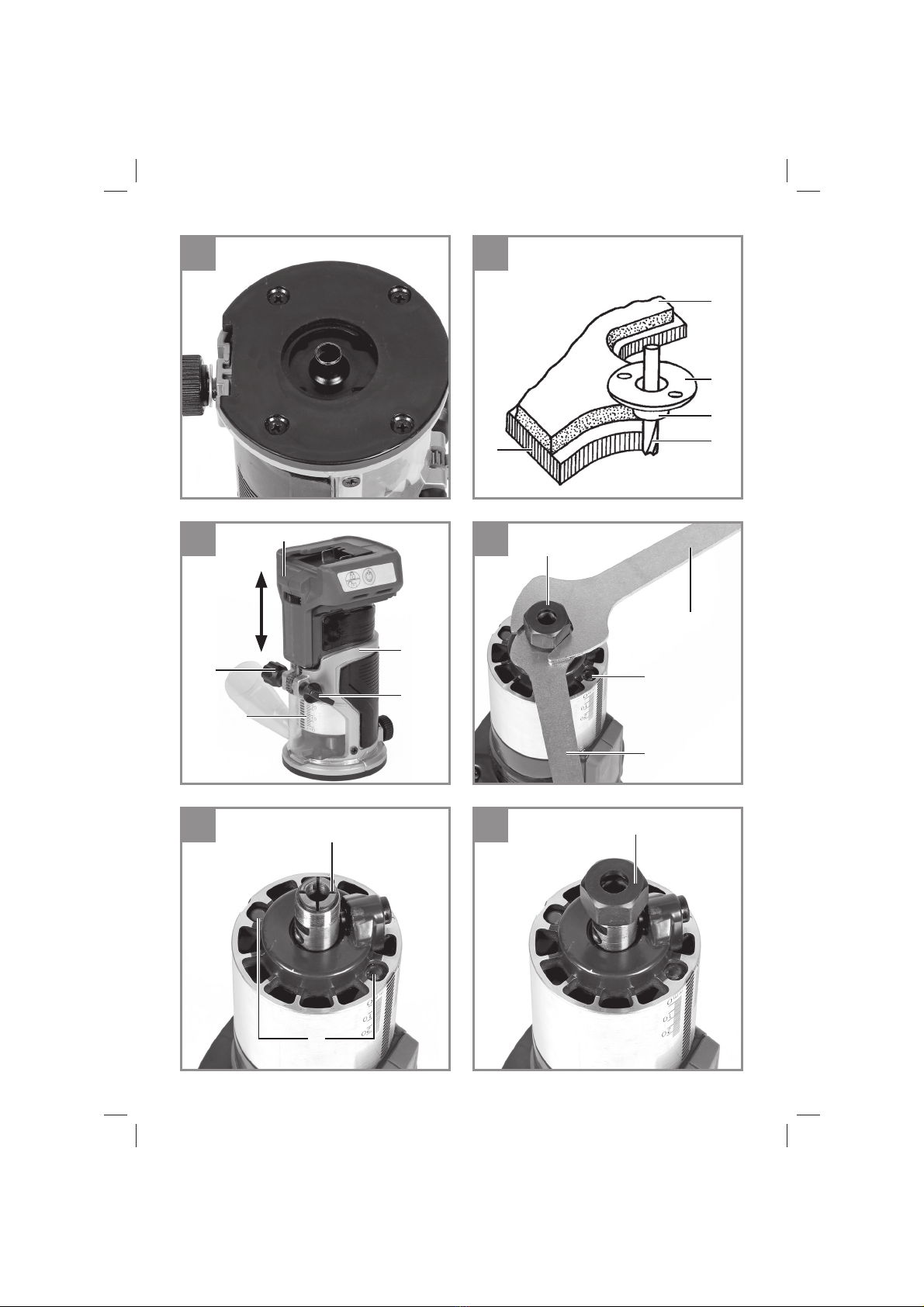

• (6) (13)

• (15/16)

•

• (15/16) (i)

• (15/16) ( 11)

• (6) ( 12)

• ( 13)

• (5) (6)

( 13)

• ! (13)

!

• (6) (13)

• (15/16) 20 .

•

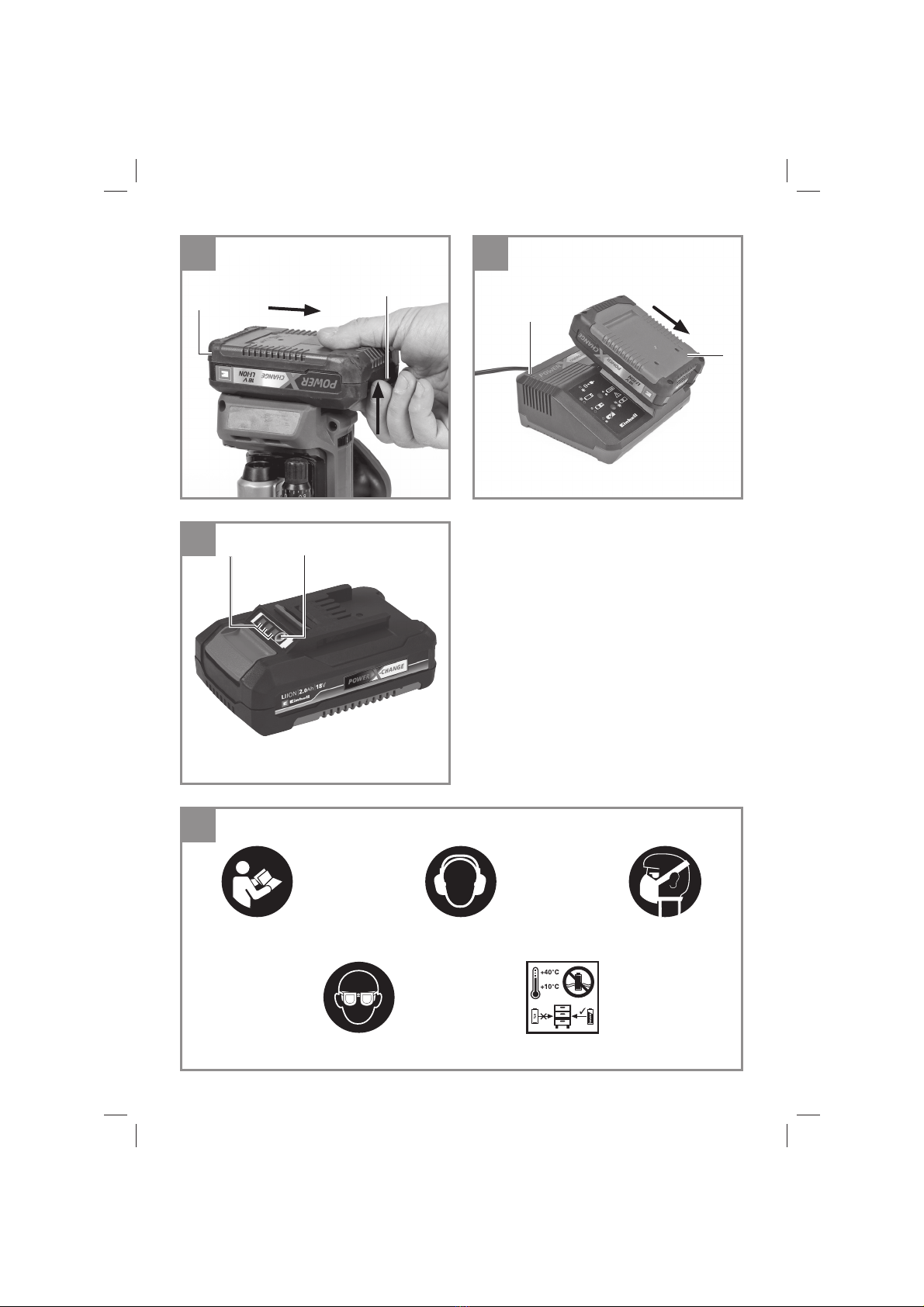

5.7 / ( 17 / 17)

• (10)

(17) 17

• (10)

• (c)

(b)

6.

•

6 . 8 .

•

•

Anl_TP_ET_18_Li_BL_SPK7_THA.indb 10Anl_TP_ET_18_Li_BL_SPK7_THA.indb 10 27.07.2023 07:48:3527.07.2023 07:48:35